Views: 222 Author: Amanda Publish Time: 2025-10-14 Origin: Site

Content Menu

● Introduction to 3D Print Prototyping and Automation

● AI-Driven Design Optimization for Precision

● Increased Speed and Repeatability Through Automation

● Hybrid Manufacturing: Combining 3D Printing and CNC Machining

● Automation in Post-Processing and Quality Assurance

● Expanding Material Capabilities with Automation

● Real-World Applications of Automation in 3D Print Prototyping

● Benefits of Automation in 3D Print Prototype Manufacturing

● Frequently Asked Questions (FAQs)

>> 1. How does automation improve 3D print prototype accuracy?

>> 2. Is automation necessary for achieving high-precision prototypes with 3D printing?

>> 3. What role does AI play in enhancing 3D print prototypes?

>> 4. How does hybrid manufacturing benefit 3D print prototyping?

>> 5. Which materials are supported in automated 3D print prototype production?

In today's fast-paced manufacturing landscape, 3D print prototypes are integral to accelerating product development cycles. With rapid advancements in automation, the accuracy and efficiency of these prototypes have significantly improved. Automation technologies—ranging from artificial intelligence (AI) and robotics to computer numerical control (CNC) machining and advanced quality control systems—play a pivotal role in refining 3D print prototypes. This article explores how automation enhances the precision, speed, and versatility of 3D print prototype production, benefiting industries from aerospace to healthcare.

3D printing has revolutionized the prototyping process by allowing designers and engineers to create physical models directly from digital files. This has substantially shortened lead times and cut prototyping costs. However, the intrinsic challenges of manual intervention, variability in material properties, and design complexities demand sophisticated solutions. Automation emerges as the answer, offering streamlined workflows, reduced errors, and enhanced prototype quality.

By integrating AI-driven design optimization, robotic printing systems, and automated post-processing, manufacturers ensure that 3D print prototypes meet stringent specifications while accelerating innovation. These advancements not only increase accuracy but also reduce human error and operational downtime.

One of the most transformative impacts of automation in 3D printing is the incorporation of AI to optimize prototype designs. AI algorithms can rapidly analyze countless design iterations and simulate various performance scenarios, resulting in lightweight, robust structures tailored to functional requirements. This replaces the traditional trial-and-error approach, saving valuable engineering time.

AI also facilitates predictive modeling of material behavior during the printing process, accounting for thermal stresses, warping, and shrinkage, all of which can influence accuracy. Automated generation of technical documentation speeds up the handoff process between design and production teams, ensuring designs are manufacturable and precise from the outset. The result is a streamlined workflow that maximizes both design integrity and printing fidelity.

Automation significantly accelerates prototype production by reducing the time taken for iterative testing and refinement. Automated 3D print setups enable continuous, unattended printing, allowing multiple prototypes to be produced rapidly without sacrificing quality. Robotics systems can handle delicate 3D printed parts or perform tasks such as part removal and replacement, reducing human handling errors.

Moreover, automated monitoring systems continually check printer status and part quality in real-time, identifying defects or deviations early. This capability helps maintain uniformity between batches, increasing repeatability and ensuring each 3D print prototype meets rigorous standards.

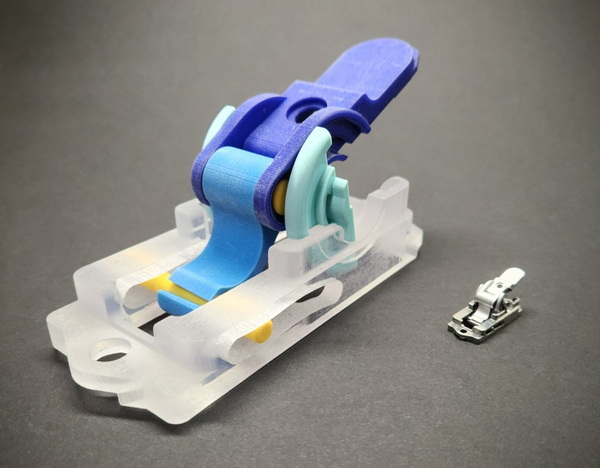

The integration of CNC machining with 3D printing represents a frontier in precision prototyping. While 3D printing excels at producing complex geometries and internal structures, CNC machining provides superior surface finishes, tighter dimensional tolerances, and stronger mechanical properties through controlled material removal.

Hybrid manufacturing workflows leverage robotic automation to seamlessly transfer parts between additive and subtractive processes. For example, a 3D printed prototype can be precisely machined to refine critical features or to prepare surfaces for assembly and testing. This complementary relationship enhances the overall quality and functionality of prototypes, particularly in high-performance sectors such as aerospace and medical device manufacturing.

Post-processing is essential for achieving the final dimensional and aesthetic standards of 3D print prototypes. Automation has transformed traditionally manual post-printing steps—such as support removal, cleaning, curing, surface smoothing, and painting—through robotic systems that ensure consistency and speed.

Integrated inspection technologies, including laser scanners and optical systems, enable automated quality assurance by capturing precise measurements and detecting surface defects immediately after printing and post-processing. This minimizes inspection bottlenecks and provides quick feedback loops for design or process adjustments.

Automated workflows maintain tight tolerances and ensure prototypes are ready for functional testing or end-use applications without delays caused by manual rework.

Material selection critically impacts prototype performance. Automation facilitates the seamless use of multiple material types within a single production run, including engineering-grade plastics, carbon-fiber composites, and even metals.

With automated material handling systems, printers can switch between feedstocks or mix materials dynamically to achieve desired mechanical properties. This capability opens doors for prototyping multifunctional components with gradients of strength, flexibility, or heat resistance, all while maintaining high precision.

Such advanced material versatility is vital for industries requiring prototypes that mimic final production parts in both form and function.

Aerospace firms deploy AI to optimize structural components, reducing weight while preserving strength. Robotic 3D printing cells fabricate complex aerodynamic parts, and automated inspections ensure every prototype meets strict regulatory requirements.

Car manufacturers integrate automated 3D printing with CNC machining for rapidly producing precise jigs, fixtures, and prototype parts. Robotics handle part transfers and post-processing, enabling faster iteration and higher quality.

Medical innovators rely on automated workflows to produce accurate surgical models, implants, and custom devices. Hybrid manufacturing ensures prototypes possess the precise fit and finish necessary for clinical testing.

Companies designing robotic systems benefit from automated prototyping processes to test components under real-world conditions quickly. Automated quality control reduces iteration cycles.

Automation delivers numerous advantages for 3D print prototyping including:

- Higher Precision: Automated design optimization and quality control reduce dimensional errors.

- Speed: Continuous and unattended production accelerates prototype delivery.

- Consistency: Automated monitoring and robotic handling ensure repeatable results.

- Material Innovation: Enables complex multi-material prototypes with tailored properties.

- Cost Efficiency: Decreases manual labor, reduces waste, and shortens time to market.

These benefits collectively empower OEMs and manufacturers to provide premium prototype services efficiently.

Automation is reshaping the landscape of 3D print prototyping by fundamentally improving accuracy, speed, and versatility. The strategic blend of AI, robotics, CNC machining, and automated quality assurance unlocks unparalleled potential to create reliable, high-fidelity prototypes that meet the demands of modern industries.

For manufacturers like Shangchen, embracing automation technologies means delivering superior OEM 3D print prototype services that accelerate innovation and reduce costs. As industries continue to push boundaries, automation will remain essential in realizing the full promise of 3D printing technology.

Automation boosts accuracy through AI-driven design refinement, robotic print and handling processes, and automated inspection systems that detect and correct deviations in real time.

While 3D printing can produce complex shapes, achieving tight tolerances and surface quality typically requires automation in monitoring, post-processing, and hybrid CNC machining.

AI accelerates design iterations, optimizes structural integrity, predicts material behavior, and automates documentation, streamlining the entire prototyping workflow.

Combining 3D printing with CNC machining creates prototypes with complex geometries and precise surface finishes, improving durability and functional testing accuracy.

Automated systems handle a variety of materials including advanced plastics, carbon-fiber composites, and metals, enabling multifunctional and high-performance prototypes.

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal