Views: 222 Author: Amanda Publish Time: 2025-10-17 Origin: Site

Content Menu

● From Idea to Concept Development

● Digital Precision: CAD Modeling and Design Optimization

● Rapid Realization through 3D Print Prototype Production

● Transitioning to CNC Machining and Precision Batch Production

● Sheet Metal Fabrication and Mold Production Services

● Rigorous Quality Assurance at All Stages

● Delivery, Support, and OEM Partnership

● Frequently Asked Questions (FAQ)

>> 1. What exactly is a 3D print prototype, and why should I use it?

>> 2. How does Shangchen maintain high quality for 3D print prototypes?

>> 3. Can Shangchen support both prototyping and full production volumes?

>> 4. What materials are available for my 3D print prototype at Shangchen?

>> 5. How fast can I expect delivery of my 3D print prototype?

In today's fast-paced manufacturing world, bringing an idea to physical reality efficiently and accurately is key to business success. Shangchen, a leading Chinese factory specializing in rapid prototyping, CNC machining, precision batch production, lathe turning, sheet metal fabrication, 3D printing services, and mold production, serves as a trusted OEM partner for global brands, wholesalers, and manufacturers. This article explores the comprehensive customer journey from concept to 3D print prototype with Shangchen, highlighting each step and the seamless integration of advanced manufacturing technologies.

Every remarkable product begins with an idea. Prospective customers reach out to Shangchen with their concepts—ranging from entirely new product innovations to enhancements of existing components. The initial phase is a collaborative process where Shangchen's expert team partners closely with clients to grasp their vision, functional needs, and project goals. This stage encompasses feasibility discussions, material considerations, and production timeline projections to build a strong foundation.

During concept development, rough sketches, reference samples, or basic drawings help crystallize the product vision. Clients benefit from Shangchen's expertise in design for manufacturability, which helps preempt potential challenges and streamlines the development path. Establishing clear communication early guarantees that subsequent prototyping phases accurately embody the customer's creative goals.[1][2]

Turning ideas into reality requires precise digital representation. Shangchen's team utilizes cutting-edge CAD software to create detailed 3D models that serve as the blueprint for prototyping and manufacturing. This phase is crucial for refining product geometry, optimizing design for both 3D printing and CNC machining, and ensuring all details meet functional and aesthetic specifications.

In-depth CAD modeling enables the detection of potential design flaws before physical production begins, saving time and cost. Files are prepared in standardized formats such as STL or STEP, ensuring compatibility with various manufacturing technologies. Customers receive realistic digital previews, enabling them to provide feedback early and iterate designs promptly.[3][4]

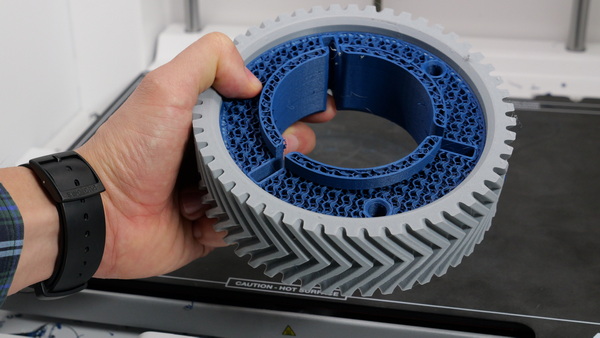

Leveraging the 3D Print Prototype step is a hallmark of Shangchen's manufacturing process. Once CAD models are finalized, Shangchen employs state-of-the-art 3D printing technologies, producing tangible prototypes rapidly and with high precision. This additive manufacturing process builds models layer-by-layer, allowing for complex geometries that traditional manufacturing methods cannot easily achieve.

The advantages of 3D print prototypes include:

- Quick turnaround times, typically within days

- Cost-efficiency by reducing tooling requirements

- Early functional and visual validation of designs

- Flexibility for rapid iterative improvements

Shangchen's multi-technology 3D printing capabilities cater to diverse project needs, including plastic and resin parts for aesthetic prototypes and durable materials for functional tests. This stage significantly accelerates the product development timeline, enabling problem-solving and refinement before committing to mass production.[5][1][3]

While 3D printing provides speed and flexibility, certain project stages demand the material properties and precision attainable via CNC machining. Shangchen's integrated manufacturing services combine rapid prototyping with advanced CNC machining to deliver higher fidelity prototypes and small-volume production parts that closely mimic final product performance.

CNC machining offers several benefits complementary to 3D printed prototypes:

- Use of industrial-grade metals and engineering plastics

- Tight tolerances down to micrometers for functional testing

- Superior surface finishes and mechanical strength

- Scalability from prototype to pilot batch runs

This synergy between additive and subtractive manufacturing ensures that Shangchen clients receive prototypes and components that meet rigorous OEM quality standards, fostering confidence as the project advances to production-ready phases.[2][6]

Expanding beyond prototyping and machining, Shangchen also provides specialized sheet metal fabrication and mold producing capabilities. Sheet metal processing is crucial for industries requiring metal housings, brackets, or enclosures, realized with techniques such as:

- Laser cutting and precision punching

- Bending and welding assemblage

- Surface treatments including anodizing or powder coating

Mold production for injection molding or die casting supports mass manufacturing after prototype validation. Shangchen engineers optimize molds to ensure durability and efficient production cycles, supporting clients' transition from prototype to full-scale manufacturing with minimized risk and cost.[7][2]

A pivotal element of Shangchen's customer journey is its commitment to quality control. Every prototype and batch undergoes comprehensive inspection using both automated systems and manual measurement tools. Critical checks include dimensional accuracy, material consistency, mechanical testing, and aesthetic appearance.

Quality assurance protocols reduce design flaws, catch manufacturing errors early, and verify that prototypes and production parts align perfectly with client specifications. This rigorous testing adds value by safeguarding product integrity and accelerating time-to-market for international brands and wholesalers relying on Shangchen's OEM expertise.[1][2]

Shangchen completes the customer journey by offering efficient logistics and ongoing support. Prototypes and small batch parts are delivered on time with reliable tracking and packaging solutions ensuring safe transit worldwide.

As a committed OEM partner, Shangchen supports clients across the entire product lifecycle—from iterative 3D print prototype enhancements to scaled batch production and final manufacturing. They provide competitive pricing, flexibility to adjust volumes, and post-production assistance such as assembly, packaging, and product customization, facilitating smooth market entry and expansion.[2][7]

The customer journey with Shangchen—from the first idea through 3D print prototype creation and beyond—is a testament to innovation, precision, and customer-focused manufacturing. Shangchen's expertise across rapid prototyping, CNC machining, sheet metal fabrication, and mold production offers a one-stop OEM solution for global brands aiming to transform concepts into high-quality, ready-for-market products.

Through seamless integration of design, additive manufacturing, and precision machining, Shangchen empowers clients to save time, reduce costs, and confidently bring their product visions to life. The emphasis on the 3D print prototype stage accelerates innovation cycles and fosters effective design validation, making Shangchen a preferred partner for progressive manufacturing worldwide.

A 3D print prototype is a physical model created directly from digital designs using additive manufacturing processes. It allows fast visual and functional testing of a concept before expensive tooling or mass manufacturing, reducing development time and cost.

Shangchen applies stringent quality controls that include dimensional accuracy checks, material verification, and functional evaluation using both automated inspection tools and manual methods, ensuring prototypes meet client and OEM standards.

Yes, Shangchen offers a full spectrum of services from rapid 3D print prototyping to CNC machining and precision batch production, enabling smooth transitions from design validation to scalable manufacturing.

Shangchen provides a wide range of materials, including PLA, ABS, resin, nylon, and various industrial-grade metals, allowing prototypes to be tailored for cosmetic, functional, or pre-production testing purposes.

Delivery times depend on the complexity and size of the project but typically range from a few days to one week, thanks to Shangchen's advanced rapid manufacturing capabilities and streamlined workflow.

[1](https://www.design2market.co.uk/academy/3d-printing-prototype-the-essential-guide-to-rapid-product-development-success/)

[2](https://www.sc-rapidmanufacturing.com)

[3](https://bigrep.com/posts/rapid-prototyping-3d-printing/)

[4](https://etedge-insights.com/technology/innovation/prototyping-in-the-age-of-3d-printing-innovation-at-the-speed-of-thought/)

[5](https://formlabs.com/applications/rapid-prototyping/)

[6](https://www.newayprecision.com/zh/services/cnc-machining-prototyping/faq-cnc-machining-prototyping-vs-3d-printing-prototyping)

[7](https://www.apt-mold.com/oem-3d-printing-prototype-service/)

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal