Views: 222 Author: Amanda Publish Time: 2025-09-04 Origin: Site

Content Menu

● Understanding CNC Lathe Turning

● What is a Coordinate Measuring Machine (CMM)?

● The Role of CMM in CNC Lathe Turning

>> Precision Verification Throughout Production

>> Ensuring Geometric Dimensioning and Tolerancing (GD&T) Compliance

>> Streamlining Quality Control with Automation

>> Handling Complex Geometries and Features

>> Real-Time Process Feedback and Adjustment

● How CMMs Enhance Manufacturing Productivity

● Integrating CMM Technology in CNC Lathe Turning Environments

● Key Considerations for Choosing a CMM for CNC Lathe Turning

● FAQ

>> 1. What is the primary advantage of using a CMM in CNC Lathe Turning?

>> 2. How does CMM help with the inspection of intricate parts produced by CNC lathes?

>> 3. Can CMM integration reduce production costs in CNC Lathe Turning?

>> 4. What types of probes are commonly used in CMMs for turning inspection?

>> 5. How does CMM measurement data improve manufacturing processes?

Coordinate Measuring Machines (CMM) have become an indispensable asset in precision manufacturing, especially in processes like CNC Lathe Turning. The accurate inspection and measurement capabilities of CMMs ensure that parts produced meet strict quality standards and complex dimensional requirements. As CNC lathe turning continues to be a mainstay in industries ranging from automotive to aerospace, the role of CMMs in maintaining quality and efficiency cannot be overstated.

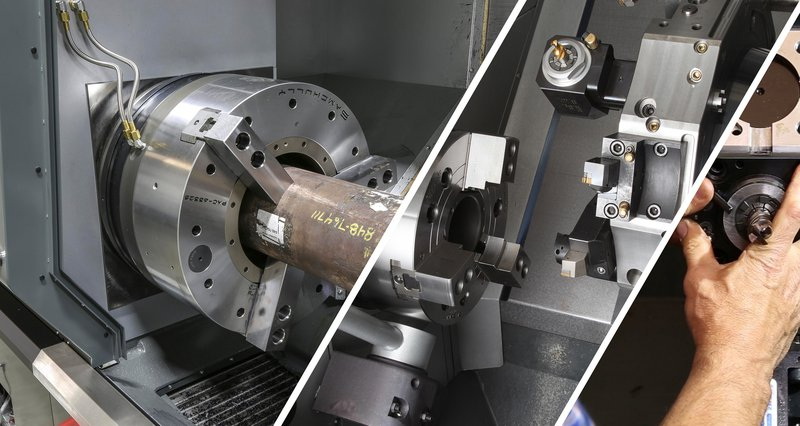

CNC Lathe Turning is a sophisticated machining process that involves the removal of material from a rotating workpiece using computer-controlled cutting tools. This process allows for the production of highly precise cylindrical parts with complex geometries and tight tolerances.

During CNC Lathe Turning, the raw material, usually metal or plastic, is securely fixed onto the lathe's spindle and rotated at high speeds. The cutting tool moves linearly to shape the outer or inner surface of the workpiece. The process includes several operations such as:

- Facing: Flattening the end of the workpiece.

- Straight Turning: Producing a consistent diameter along the length.

- Taper Turning: Shaping the workpiece surface into a conical form.

- Threading: Cutting helical threads onto the workpiece's surface.

- Grooving and Parting: Creating precise grooves or cutting through the part.

- Knurling: Producing textured surfaces for improved grip.

Each of these operations requires exact control to meet strict dimensional requirements. Even minor deviations can cause assembly problems or failure in the field, highlighting the necessity for stringent quality control.[1][2][3]

A Coordinate Measuring Machine is a precision instrument designed to measure the physical geometrical characteristics of an object. CMMs use probes that touch or scan the surface of a workpiece, collecting point coordinates along various axes. These points allow the machine to build a precise 3D digital map of the object.

There are several types of probes, including:

- Mechanical Touch Probes: Physically contact the surface to gather data.

- Laser Scanning Probes: Use laser light for non-contact measurement.

- Optical and White Light Probes: Capture surface details without touch, perfect for delicate or soft materials.

CMMs are available as manual systems or fully automated versions that integrate with software capable of comparing measured data with CAD models. The objective is to validate that the manufactured part aligns perfectly with design specifications.[4][5][6]

In CNC Lathe Turning, the margin for error is minimal. CMMs provide unmatched accuracy, often measuring within microns, ensuring that each feature on the turned part adheres strictly to its nominal dimensions. This precision reduces the likelihood of producing defective parts that require scrapping or costly rework.

GD&T is a language of symbols that precisely defines acceptable variations in part geometry, including straightness, flatness, circularity, and positional tolerances. CMMs can measure and verify these attributes, guaranteeing that parts meet engineering design criteria. By doing so, CMMs help maintain interchangeability and assembly fit in complex manufacturing environments.[7][8]

The integration of automated CMM inspections into CNC Lathe Turning workflows minimizes human error. Pre-programmed measurement strategies allow rapid data collection and analysis, accelerating inspection processes without compromising reliability. Automated CMMs can inspect multiple features and parts at once, significantly reducing cycle times compared to traditional methods.

Parts manufactured on CNC lathes often feature intricate grooves, threads, and tapered surfaces that are difficult to measure with calipers or gauges. CMMs, equipped with multi-axis probing systems, can freely navigate around these complex shapes, capturing data that would otherwise be impossible to obtain accurately.

By incorporating inline or near-line CMM inspections, manufacturers receive immediate feedback on machining accuracy. This enables quick process adjustments, minimizing off-spec production and limiting scrap rates. Real-time quality control is vital in high-volume operations and supports continuous improvement initiatives.[9][10][7]

The benefits of CMMs in CNC Lathe Turning are far-reaching:

- Improved First-Pass Yield: Accurate inspection reduces the occurrence of defects, increasing the percentage of parts that pass quality checks on their first attempt.

- Cost Savings: Early detection of dimensional issues prevents downstream production losses and decreases rework and material wastage.

- Efficient Use of Labor: Automated measurements reduce reliance on manual inspection, allowing skilled personnel to focus on optimizing manufacturing processes.

- Data-Driven Quality Management: Digital measurement data enables detailed statistical process control (SPC) analyses and traceability for customer audits.

- Scalability: CMMs support both prototype evaluations and high-volume production inspections, offering flexibility in evolving manufacturing demands.[8][11][9]

Effective integration of CMM technology into CNC lathe turning involves:

1. Design Phase Coordination: CAD files inform both CNC programming and CMM inspection routines to ensure design intent is fully accounted for during production and validation.

2. Programming Inspection Routines: CMM software is programmed with tailored measurement paths to optimize inspection efficiency for each part type.

3. Setup Consistency: Positioning parts consistently in fixtures for both CNC turning and CMM inspection ensures reliable comparisons between production and inspection data.

4. Feedback Loop: Measurement results are communicated to machine operators or connected to CNC controllers for adaptive process control, facilitating on-the-fly corrections.

5. Quality Documentation: CMM results are archived as digital records for certification and process validation, reinforcing quality management systems.

This cohesive approach minimizes errors, reduces production cycle times, and delivers high confidence in part compliance for OEM customers.[3][12][13]

- Measurement Volume and Speed: Ensure the CMM's measuring capacity accommodates the sizes and production volumes of lathe-turned parts efficiently.

- Accuracy Requirements: Select a CMM with accuracy specifications that surpass the tightest tolerances of produced parts.

- Type of Probe: Match the probing technology (touch, laser, optical) to the material and feature complexity of the parts.

- Software Compatibility: Choose inspection software compatible with existing CAD/CAM systems and capable of advanced GD&T analysis.

- Automation and Connectivity: Consider options for automation, robotic part loading, and integration with manufacturing execution systems (MES) for streamlined operations.

By carefully evaluating these factors, manufacturers and OEMs like Shangchen can maximize the return on investment in CMM technology.[6][14][4]

Coordinate Measuring Machines are essential for modern CNC Lathe Turning processes, guaranteeing exceptional accuracy, quality, and efficiency. Their advanced measurement capabilities enable manufacturers to verify complex geometries, maintain stringent tolerances, and optimize production workflows. Integration of CMM into CNC turning operations not only enhances product quality but also drives manufacturing productivity and cost savings.

For companies like Shangchen, which provide OEM services internationally, leveraging CMM technology is crucial to meet the demanding specifications of global brands and maintain a competitive edge in rapid prototyping, precision batch production, and advanced machining services.

The primary advantage is the highly accurate and automated measurement of turned parts, ensuring they meet precise design tolerances, which improves product quality and reduces errors.

CMM probes can access and measure complex features such as threads, grooves, and tapers with multi-axis movement, capturing detailed spatial data that traditional tools cannot.

Yes, by minimizing scrap, reducing rework, speeding inspection cycles, and enabling real-time process control, CMM integration significantly lowers operational costs.

Common probes include mechanical touch probes for direct contact, laser scanners for non-contact measurement, and optical sensors suited for delicate parts.

CMM data allows manufacturers to perform statistical analysis, monitor trends, identify errors early, and implement corrective actions, thereby continuously improving process capability and consistency.

[1](https://www.madearia.com/blog/cnc-turning-explained-process-operations-and-advantages/)

[2](https://www.rapiddirect.com/blog/what-is-cnc-turning/)

[3](https://fractory.com/cnc-turning/)

[4](https://en.wikipedia.org/wiki/Coordinate-measuring_machine)

[5](https://blog.3dcs.com/5-reasons-to-use-a-cmm-in-modern-manufacturing-and-the-value-of-5-axis-vs-3-axis)

[6](https://3d-engineering.net/what-is-cmm-machine/)

[7](https://www.pentaprecision.co.uk/role-of-cmm-in-cnc-quality-control)

[8](https://etherealmachines.com/blog/exploring-the-world-of-cmm-in-cnc-machining/)

[9](https://www.nolteprecise.com/nolte-notables/six-benefits-of-using-a-coordinate-measuring-machine-cmm/)

[10](https://coastalmachinesupply.com/coordinate-measuring-machines-used-in-precision-machining/)

[11](https://www.flextrades.com/blog/understanding-cmm-machines-in-manufacturing/)

[12](https://winndeavor.com/what-is-a-coordinate-measuring-machine-and-its-benefits-for-you/)

[13](https://www.rainhouse.com/manufacturing-blog/coordinate-measuring-machines/)

[14](https://www2.mitutoyo.co.jp/eng/technology/product/introduction_06/index.html)

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal