Views: 222 Author: Amanda Publish Time: 2025-09-07 Origin: Site

Content Menu

● Introduction to Smart Manufacturing

>> Key Features of Smart Manufacturing:

● Understanding CNC Lathe Turning

>> What Makes CNC Lathe Turning Stand Out?

● Benefits of Combining Smart Manufacturing with CNC Lathe Turning

>> 1. Real-Time Process Monitoring and Optimization

>> 3. Enhanced Quality Control

>> 4. Increased Flexibility and Reduced Setup Times

>> 5. Cost Efficiency and Resource Optimization

● Applications Across Industries

>> Aerospace

>> Electronics

● Challenges and How to Overcome Them

>> Skill Gap

● The Future of CNC Lathe Turning in Smart Manufacturing

● FAQ

>> 1. What is CNC lathe turning, and why is it important?

>> 2. How does smart manufacturing improve CNC lathe turning?

>> 3. What industries benefit most from the combination of smart manufacturing and CNC lathe turning?

>> 4. What challenges are associated with implementing smart manufacturing in CNC lathe turning?

>> 5. What is the future outlook for CNC lathe turning in smart manufacturing?

In the evolving landscape of modern manufacturing, the integration of advanced technologies has become essential for companies striving to stay competitive. Two powerful technologies that have rapidly transformed manufacturing processes are smart manufacturing and CNC lathe turning. When combined, they offer unparalleled enhancements in precision, efficiency, and flexibility — crucial factors for industries seeking to meet the demands of high-quality, cost-effective production.

This comprehensive article explores how smart manufacturing and CNC lathe turning form a perfect match, their synergistic benefits, and how industries can leverage these technologies to revolutionize their production lines. We will also delve into practical applications, case studies, and future prospects that highlight why this combination is indispensable in today's manufacturing arena.

Smart manufacturing represents the next evolution in industrial production. It integrates digital technologies such as the Internet of Things (IoT), big data analytics, artificial intelligence (AI), and automation to create highly flexible and efficient manufacturing systems.

Smart manufacturing aims to create a connected and intelligent factory environment where machines, systems, and humans collaborate seamlessly to optimize every step of the production lifecycle—from design and prototyping to mass production and quality control.

- Real-time monitoring and control of equipment

- Predictive maintenance to reduce downtime

- Adaptive production lines with low changeover times

- Enhanced data collection and analysis for process optimization

- Integration with supply chain and enterprise resource planning (ERP) systems

These capabilities lead to improved product quality, faster response to market changes, and reduced operational costs.

Furthermore, smart manufacturing fosters a data-driven culture. This means decisions are made based on concrete, real-time information rather than intuition alone. By collecting data at every stage—from raw material sourcing, machining processes like CNC lathe turning, to final inspection—manufacturers obtain a comprehensive view of their operations. This enables continuous improvement through analytics and reduces waste at every level.

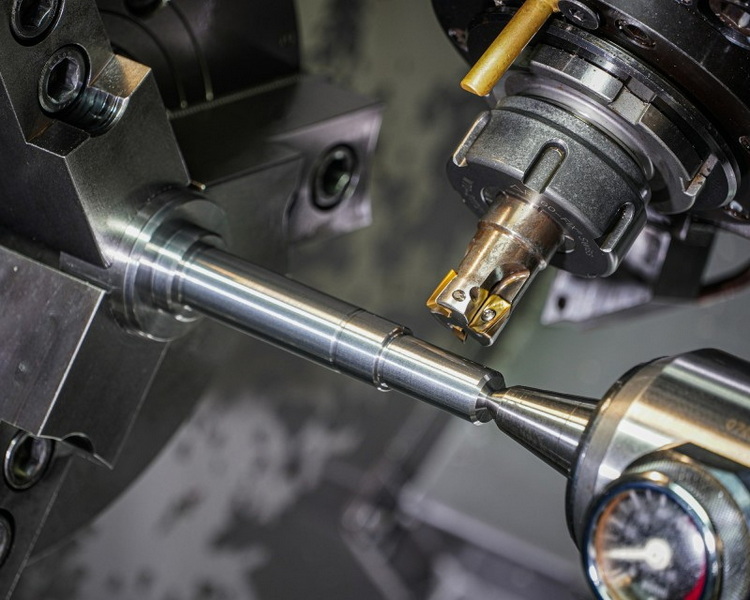

CNC lathe turning is a machining process that removes material from a rotating workpiece using cutting tools. This process is computer-controlled, allowing for precise manufacture of complex cylindrical parts, such as shafts, bolts, and components with threads or grooves.

- High precision and repeatability

- Ability to produce complex geometries

- Flexible programming for different part designs

- Fast throughput suitable for both prototypes and mass production

- Minimal human intervention, resulting in consistent quality

The CNC (Computer Numerical Control) system translates design files into precise movements of the lathe and cutting tool, ensuring accuracy and repeatability across batches.

In addition to traditional turning operations like facing, threading, and grooving, CNC lathe turning techniques have evolved to include multi-axis turning centers capable of integrated milling and drilling tasks. This expands their applicability and allows manufacturers to consolidate processes that once required multiple machines. The flexibility to perform such complex operations within a single setup greatly reduces cycle times and the risk of human error during part transfer.

Because CNC lathe turning machines heavily rely on digital control, they are excellent candidates for integration with smart manufacturing environments. The data they generate about every spindle rotation, tool engagement, and feed movement provide invaluable feedback for process optimization.

The fusion of smart manufacturing principles with CNC lathe turning produces a synergistic effect, enhancing overall manufacturing capability. Here are the key benefits:

Smart sensors integrated with CNC lathes collect data on tool wear, vibration, temperature, and cutting forces. This data is analyzed in real-time to optimize machining parameters, improving surface finish and enhancing tool life.

For instance, if a sensor detects excessive vibration, the system can automatically adjust feed rates or spindle speeds to prevent premature tool damage or workpiece defects. This proactive adaptation reduces scrap rates and boosts efficiency.

Machine learning algorithms analyze historical and real-time data to predict failures before they occur. Predictive maintenance reduces unexpected downtime, improves machine utilization, and lowers maintenance costs.

This approach contrasts sharply with traditional reactive maintenance, which relies on fixing machines only after breakdowns. With predictive maintenance, critical components such as bearings, spindles, and hydraulic systems can be serviced or replaced just in time, increasing overall equipment effectiveness (OEE).

Smart manufacturing architectures enable automated inspection methods integrated directly into CNC lathe systems, such as in-line measurement devices and AI-driven defect detection, ensuring near-zero defects and higher first-pass quality rates.

Automated quality control systems paired with CNC lathe turning not only catch defective parts early in the process but also provide feedback loops to adjust machining parameters on the fly, maintaining tolerance compliance batch after batch.

With smart manufacturing, CNC lathe turning machines can quickly switch between different part programs, aided by automated setup and calibration, which shortens lead times for small-batch or customized production.

Dynamic scheduling and job sequencing software, powered by smart manufacturing, auctions machine time in real time, balancing workload among multiple CNC lathes and minimizing idle times.

Data-driven insights enable better scheduling of machine use and raw material consumption, which limits waste and maximizes output from CNC lathe operations.

Smart manufacturing systems can optimize tool paths and cutting speeds based on real-time feedback, reducing energy consumption and extending tool life. Additionally, inventory management systems synced with CNC lathe turning operations ensure materials are available just in time, preventing overstock and tying up capital unnecessarily.

CNC lathe turning powered by smart manufacturing finds wide application across diverse sectors:

Used for manufacturing engine parts, drive shafts, and custom components with tight tolerance requirements. Smart manufacturing enhances production agility to accommodate evolving vehicle designs.

For example, CNC lathe turning machines in automotive plants equipped with smart sensors enable rapid adaptation to new model variants. They support flexible lot sizes ranging from single prototype parts to high-volume production, ensuring consistent quality despite design changes.

Precision and reliability are critical here. CNC lathe turning produces high-performance parts from exotic alloys like titanium and Inconel. Smart manufacturing ensures compliance with stringent certification and traceability protocols.

Traceability is critical in aerospace, and integrating CNC lathe turning with smart manufacturing facilitates comprehensive data logging for every part's manufacturing history. This digital passport supports quality audits and regulatory approvals.

Highly customized surgical instruments and implants are manufactured via CNC lathe turning. Real-time quality checks and error detection through smart manufacturing make this feasible.

Smart manufacturing enables manufacturers to meet the demanding quality and hygiene standards of medical components. Automated systems minimize human contact during production and inspection, lowering contamination risks.

Components like connectors and heat sinks benefit from the precision and speed of CNC lathe turning integrated with smart feedback loops.

Small yet complicated electronic parts demand rapid setups that smart CNC lathe turning setups readily provide. Data-driven tool condition monitoring ensures ultra-fine tolerances with minimal rework.

Customization trends and short product cycles are supported by flexible CNC lathe setups monitored and optimized through smart manufacturing.

From fitness equipment shafts to coffee machine parts, manufacturers harness smart CNC lathe turning systems to produce small lots tailored to consumer preferences without compromising efficiency.

The integration of smart technologies into CNC lathe turning requires upfront capital expenditure on equipment and software. However, long-term savings and productivity gains justify this investment.

To mitigate costs, companies can adopt phased implementation strategies—starting with retrofit sensor kits on existing CNC lathes and gradually expanding to fully networked systems.

As machines connect to networks, cybersecurity risks rise. Implementing strong encryption, firewalls, and secure access protocols is essential.

Manufacturers should partner with trusted cybersecurity firms to conduct regular vulnerability assessments and employee training on best practices.

Operators and engineers need training on smart systems and CNC programming. Ongoing education and collaboration with technology providers alleviate this hurdle.

Online courses, on-site workshops, and simulation-based training platforms help workers gain proficiency without disrupting production.

Ensuring various smart manufacturing components work harmoniously with existing CNC machinery can be complex. Standardization and modular design philosophies help ease integration.

Adopting open communication protocols like OPC UA for machine-to-machine connectivity simplifies cross-platform integration and future scalability.

Emerging trends promise to further elevate CNC lathe turning capabilities within smart manufacturing ecosystems:

- AI-Driven Machining: Greater autonomy where AI dynamically adjusts cutting paths and parameters optimizing performance without human input.

- Edge Computing: On-machine data processing to reduce latency and enable faster decision-making.

- Digital Twins: Creating virtual models of CNC lathes for simulation, performance forecasting, and training.

- Additive and Hybrid Manufacturing: Combining CNC lathe turning with 3D printing to produce complex parts with internal structures not feasible through subtractive machining alone.

- Sustainability: Smart manufacturing coupled with CNC lathe turning helps reduce energy consumption, raw material waste, and carbon footprint.

The combination of these advances will enable factories to become more adaptive, environmentally responsible, and efficient—keeping pace with increasing demands and complexity in manufacturing.

Smart manufacturing and CNC lathe turning, when combined, offer a formidable manufacturing synergy. This alliance enhances productivity, accuracy, flexibility, and cost efficiency, empowering manufacturers to meet the demands of a rapidly changing market. Companies like Shangchen (sc-rapidmanufacturing.com), specializing in precision prototyping and OEM services, utilize this integration to provide superior quality, faster turnaround, and scalable production for global brands across industries.

As technology advances, the smart manufacturing framework will further elevate the capabilities of CNC lathe turning, ushering in an era of truly intelligent, flexible, and sustainable manufacturing.

CNC lathe turning is a computer-controlled machining process that shapes parts by rotating the workpiece against cutting tools. It is essential for producing precise, complex cylindrical components efficiently and with consistent quality.

Smart manufacturing integrates real-time monitoring, predictive maintenance, and data analytics with CNC lathe turning, enhancing machine uptime, product quality, and process flexibility.

Automotive, aerospace, medical devices, electronics, and consumer goods industries benefit significantly due to their need for high precision, rapid turnaround, and complex components.

Primary challenges include initial investment costs, cybersecurity risks, skill gaps, and integration complexities between smart systems and existing machinery.

Future advancements include AI-driven machining, edge computing, digital twins, hybrid manufacturing, and sustainability-focused innovations, promising smarter and more efficient manufacturing processes.

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal