Views: 222 Author: Amanda Publish Time: 2025-09-11 Origin: Site

Content Menu

● What Is Sheet Metal Fabrication?

>> Core Processes in Sheet Metal Fabrication

● Why Is Quality Control Crucial in Sheet Metal Fabrication?

● Key Elements of Sheet Metal Fabrication Quality Control

>> 2. Process Control and Monitoring

>> 3. Dimensional Accuracy Verification

>> 6. Documentation and Traceability

● Technologies Enhancing Sheet Metal Fabrication Quality Control

>> Advanced Measurement Systems

>> Real-Time Monitoring Software

>> Automated Optical Inspection (AOI)

● What Customers Should Expect From Their Sheet Metal Fabrication Partner

>> Certification and Compliance

>> Prototype to Production Consistency

● Challenges in Sheet Metal Fabrication Quality Control

● Case Study: Ensuring Quality in OEM Sheet Metal Production

● FAQ

>> 1. What materials are commonly used in sheet metal fabrication quality control?

>> 2. How do fabricators check dimensional accuracy in sheet metal parts?

>> 3. What certifications should customers look for in a sheet metal fabrication partner?

>> 4. How is surface finish quality controlled in sheet metal fabrication?

>> 5. What are the consequences of inadequate quality control in sheet metal fabrication?

Sheet metal fabrication is a cornerstone of modern manufacturing, powering industries from automotive to electronics, aerospace to consumer goods. For customers—whether brand owners, wholesalers, or manufacturers—understanding the intricacies of Sheet Metal Fabrication quality control is essential to ensure product reliability, precision, and longevity. Quality control in this sector is not merely a checkpoint but an ongoing process that guarantees final products meet or exceed expectations.

In this comprehensive article, we will explore every aspect of quality control in sheet metal fabrication, guiding customers through what standards should be upheld, what processes should be implemented, and how to evaluate a fabrication partner's commitment to quality. We will also address common concerns customers have alongside practical tips on what to expect during the entire production cycle.

Sheet metal fabrication is the process of shaping flat sheets of metal into specific designs and components using cutting, bending, and assembling techniques. The metals involved commonly include steel, aluminum, copper, and alloys, chosen based on application requirements such as strength, corrosion resistance, or electrical conductivity.

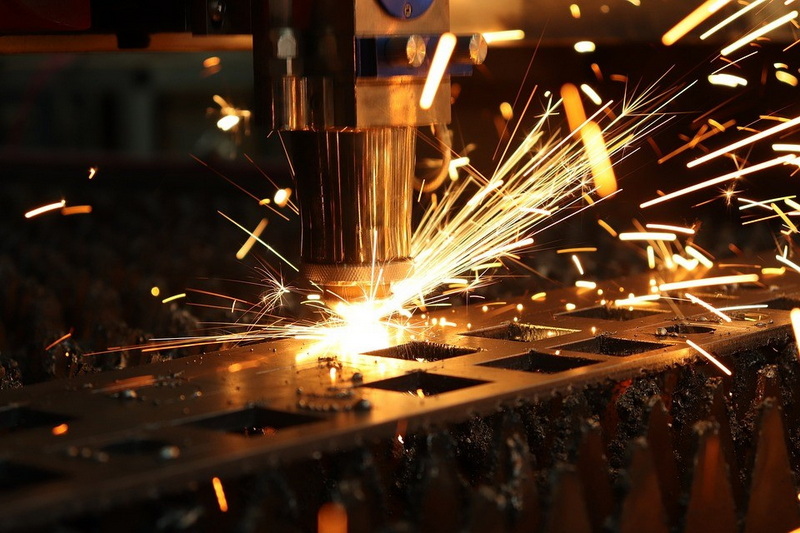

- Cutting: Laser cutting, plasma cutting, or shearing to achieve precise shapes.

- Bending: Using press brakes or rollers to form angles or curves.

- Punching: Creating holes or cutouts for assembly or functional design.

- Welding and Assembly: Joining components via welding or fastening methods.

- Finishing: Surface treatments like powder coating, anodizing, or painting.

Each step demands strict adherence to specifications and tolerances to maintain product integrity and aesthetics.

Quality control in sheet metal fabrication ensures that raw materials and finished parts conform to customer standards and industry benchmarks. Without stringent quality control, products risk failure due to structural weakness, dimensional inaccuracy, or surface defects, which can result in costly recalls, damaged brand reputation, or safety hazards.

Moreover, effective quality control reduces waste and improves production efficiency by catching defects early in the manufacturing process. It also fosters stronger relationships between manufacturers and customers by building trust in delivered products.

The foundation of quality begins with validating the raw materials. Inspected materials should come with certificates of conformity verifying their chemical composition, mechanical properties, and precise dimensions. This step prevents defects caused by subpar or counterfeit inputs, which can compromise product durability and safety.

This includes checking for inconsistencies in sheet thickness and surface conditions before the fabrication starts. Ensuring material compliance with customer specifications and industry standards such as ASTM (American Society for Testing and Materials) is a fundamental aspect.

Maintaining control over manufacturing processes is essential to uphold quality throughout the entire production cycle. This includes:

- Machine Calibration: Cutting, bending, and punching equipment must be frequently calibrated according to manufacturer specifications and industry norms to ensure repeatability.

- Operator Training: Skilled technicians must operate machinery and perform manual tasks. Their expertise impacts the precision and finish quality of each fabricated piece.

- Process Automation: Integrating CNC (Computer Numerical Control) machines and robotic systems helps increase consistency, reduce human error, and speed up production without sacrificing quality.

Real-time monitoring systems can track machine performance, detect anomalies early, and provide actionable data to operators and quality managers instantly.

Ensuring parts meet exact dimensional requirements is one of the most critical steps. Deviations from specified tolerances can cause assembly issues or operational failures.

Dimensional checks are performed at multiple stages:

- After initial cutting to verify outline conformity.

- After bending or shaping to confirm angles and radii.

- After final assembly for fit and alignment.

Precision instruments such as Vernier calipers and micrometers provide hands-on measurement, while Coordinate Measuring Machines (CMM) and 3D laser scanners allow for highly accurate, non-contact inspections. These devices generate digital models for comparison against CAD designs, highlighting discrepancies and enabling rapid corrective actions.

Advanced optical comparators magnify and project the part silhouette, speeding up visual dimension verification, especially for complex profiles.

Surface quality is a vital part of overall product quality, particularly for parts that are visible or exposed to harsh environments. Visual inspection helps identify:

- Scratches, dents, or gouges caused during handling or processing.

- Surface oxidation or corrosion from improper storage or processing conditions.

- Color inconsistencies and defective coatings on painted or anodized parts.

- Warping or surface deformation.

Trained inspectors often use magnification tools and controlled lighting environments for this purpose. In addition, automated optical inspection (AOI) systems equipped with cameras can detect surface flaws with high accuracy and report defects in real time.

Beyond visual and dimensional checks, functionality is key. Depending on the part's role, testing may include:

- Load Testing: Applying mechanical stress to simulate real-world conditions.

- Fit and Assembly Validation: Ensuring parts click, bolt, or weld together without gaps or interference.

- Electric Continuity Tests: For metal parts used in electrical applications.

- Corrosion Resistance Tests: For parts intended for challenging environments.

These tests confirm the fabricated parts perform reliably under specified conditions and customer use scenarios.

Maintaining detailed records for raw materials, inspection results, machine calibration, operator details, and process parameters supports quality assurance and traceability accountability.

Traceability is crucial for identifying causes in the event of failures or recalls. It also facilitates continuous improvement by providing data for statistical process control and performance benchmarking.

Technological advancements have revolutionized sheet metal fabrication quality protocols, giving fabricators the tools to meet rising customer demands for precision, speed, and customization.

3D laser scanners and high-precision Coordinate Measuring Machines allow fabricators to create accurate digital replicas of physical parts instantly. This non-contact measurement technology speeds up inspections and detects irregularities that might be missed by manual checks.

Modern factories implement Manufacturing Execution Systems (MES) that link CNC machinery, inspection devices, and operator terminals to central databases. These systems monitor equipment health, process deviations, and quality trends live, enabling proactive interventions.

AOI uses sophisticated vision systems capable of rapid, repeatable, and objective assessment of surface and dimensional quality. Integration with machine learning algorithms allows detection of subtle defects such as tiny scratches or surface inconsistencies that human inspectors may overlook.

Choosing the right fabrication partner is vital to ensuring quality throughout the product lifecycle. Customers should expect their provider to adhere to the following principles:

Customers deserve full visibility into the fabricator's quality control protocols, inspection reports, and corrective action records. Open communication fosters trust and allows timely response to production or quality issues.

Reputable sheet metal fabricators maintain certifications such as:

- ISO 9001: Quality management systems.

- AS9100: Aerospace industry quality standards.

- IATF 16949: Automotive industry requirements.

These certifications demonstrate a factory's ongoing commitment to meet stringent quality and compliance benchmarks.

Fabricators should ensure that the quality seen in prototypes is scalable to full production runs. This includes thorough validation of manufacturing processes, tooling, and assembly fixtures before large quantity orders begin.

Before mass manufacturing, customers should receive samples or first articles that conform to all technical specifications. This approval step prevents costly errors when transitioning to full production.

Quality issues can occasionally arise. A reliable fabricator offers rapid root cause analysis, transparent reporting, and effective corrective actions to minimize disruption and maintain quality standards.

While advances in technology and methodology have improved product quality, some challenges remain:

- Raw Material Variations: Even certified materials may differ slightly in properties due to batch variations affecting downstream processes.

- Operator Skill Variability: Despite automation, manual touchpoints like welding or assembly depend on skilled labor.

- Complex Geometries: Intricate designs complicate inspection, sometimes requiring custom fixtures and specialized measuring techniques.

- Environmental Influence: Temperature and humidity can affect metal properties and finishing processes, requiring controlled factory conditions.

Continuous collaboration between fabricator and customer can help identify and mitigate these challenges early.

At Shangchen, a leading Chinese sheet metal fabrication factory serving international clients, quality protocols are deeply integrated with production workflows:

1. Material Traceability: Each batch of steel and aluminum arrives accompanied by certificates and is retested on-site for compliance before acceptance.

2. CNC Machine Calibration: All machines are scheduled for daily calibration checks before production begins.

3. Multi-point Dimensional Checks: Coordinate Measuring Machines verify critical dimensions during key production stages.

4. Visual Inspection Teams: Dedicated quality staff conduct detailed surface inspections prior to packaging.

5. Customer Feedback Loop: Continuous improvements are driven by client input, ensuring all quality concerns are addressed promptly and efficiently.

This disciplined approach guarantees Shangchen's customers receive high-precision, durable, and consistent sheet metal components suitable for OEM applications worldwide.

Quality control in sheet metal fabrication is an indispensable part of delivering products that are dimensionally accurate, structurally sound, and visually flawless. A comprehensive and transparent quality assurance system encompassing raw material validation, precision process monitoring, thorough dimensional and visual inspections, functional testing, and meticulous documentation ensures customer expectations are consistently met.

Customers sourcing OEM sheet metal parts should partner with fabricators who uphold internationally recognized standards, leverage advanced technologies, and have proven quality management processes. Doing so protects product performance, enhances brand reputation, and reduces risk throughout the supply chain.

Common materials include stainless steel, carbon steel, aluminum, copper, and various alloys. Each requires specific tests to verify mechanical properties and ensure suitability for the intended application.

Dimensional accuracy is verified using precision instruments like Vernier calipers, coordinate measuring machines (CMM), and laser scanners to confirm parts meet specified tolerances.

Customers should look for ISO 9001 certification for quality management, plus industry-specific certifications like AS9100 (aerospace) or IATF 16949 (automotive) to ensure manufacturing standards.

Surface quality is inspected visually and sometimes with optical or laser-based measurement devices to detect scratches, dents, discoloration, or coating irregularities.

Poor quality control can lead to product failures, increased costs from rework, shipment delays, and damage to brand reputation due to unreliable or unsafe finished parts.

content is empty!

Top 5 Axis CNC Machining Manufacturers and Suppliers in Lithuania

Top 5 Axis CNC Machining Manufacturers and Suppliers in Norway

Top 5 Axis CNC Machining Manufacturers and Suppliers in Czech Republic

Top 5 Axis CNC Machining Manufacturers and Suppliers in Denmark

Top 5 Axis CNC Machining Manufacturers and Suppliers in Hungary

Top 5 Axis CNC Machining Manufacturers and Suppliers in Ireland

Top 5 Axis CNC Machining Manufacturers and Suppliers in Finland

Top 5 Axis CNC Machining Manufacturers and Suppliers in Greece

Top 5 Axis CNC Machining Manufacturers and Suppliers in Sweden

Top 5 Axis CNC Machining Manufacturers and Suppliers in Turkey