Views: 222 Author: Amanda Publish Time: 2026-01-14 Origin: Site

Content Menu

● Rapid Prototyping vs Testing: Core Differences

● How Rapid Prototyping Supports Testing

● Key Rapid Prototyping Methods in Manufacturing

● Where Testing Fits in the Product Lifecycle

● Why People Confuse Rapid Prototyping with Testing

● Benefits of Combining Rapid Prototyping and Testing

● How Shangchen Uses Rapid Prototyping for Overseas OEM Projects

● When to Prioritize Rapid Prototyping, When to Prioritize Testing

● How Many Rapid Prototyping Iterations Are Enough?

● How Rapid Prototyping Influences Final Production

● FAQ About Rapid Prototyping and Testing

>> 1. Is Rapid Prototyping considered a type of testing?

>> 2. Can Rapid Prototyping replace formal product testing?

>> 3. How many Rapid Prototyping cycles are typical before testing?

>> 4. What kinds of tests are best suited for Rapid Prototyping parts?

>> 5. Why should overseas OEM buyers choose Shangchen for Rapid Prototyping?

Rapid Prototyping is not the same as testing, even though the two activities are tightly connected in every serious product development program. In a professional OEM workflow, Rapid Prototyping is focused on quickly creating physical or digital models, while testing is focused on gathering evidence that these models and final products actually meet performance, safety, and user requirements. Rapid Prototyping builds what will be tested; testing decides what must change before a design is ready for mass production.

Rapid Prototyping is a method used in design and development to quickly create models of a product or part so that teams can test and refine the design early in the lifecycle. It is highly valued because it dramatically shortens the time between an idea and a tangible sample that engineers, designers, and customers can evaluate. In manufacturing environments, Rapid Prototyping is linked directly to CAD data and uses flexible processes that can adapt to frequent design changes.

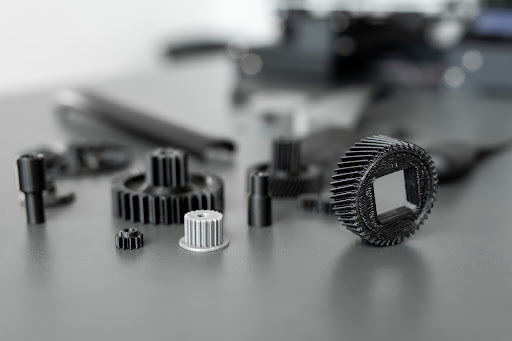

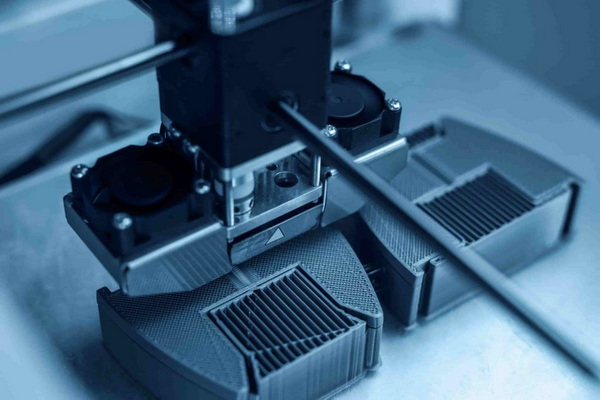

Rapid Prototyping in manufacturing normally relies on technologies such as CNC machining, 3D printing, and sheet metal fabrication to turn digital models into physical components in days rather than weeks. These Rapid Prototyping workflows allow teams to explore different shapes, materials, tolerances, and assembly methods without committing to expensive, long-lead production tooling. By making Rapid Prototyping a routine step, product teams reduce overall project risk and gain more confidence before ramping up production.

Product testing is a structured process that evaluates whether a prototype or final product meets defined requirements, such as technical performance, durability, safety, and user satisfaction. Testing can take many forms, from basic dimensional inspection and functional checks all the way up to rigorous environmental, regulatory, and life-cycle evaluations. The key point is that testing generates objective evidence to show whether the design is truly ready for its intended use.

Within formal design control systems, testing usually includes both verification and validation activities. Verification focuses on confirming that the design outputs match the documented design inputs, such as dimensions, electrical characteristics, or software functions. Validation focuses on proving that the overall device or product actually satisfies user needs and works correctly in realistic conditions. Both stages may use prototypes, but their objectives are different from Rapid Prototyping itself.

Although Rapid Prototyping and testing often happen close together in time, they solve different problems inside a project. Rapid Prototyping answers the question “What if we build this version of the design?” while testing answers “Does this version meet our requirements and our users' expectations?”. Confusing these two concepts often leads to weak documentation and unclear decision-making in OEM programs.

Rapid Prototyping emphasizes speed, flexibility, and low barrier to iteration. The success of Rapid Prototyping is measured by how quickly the team can explore alternatives and learn from physical samples. By contrast, testing emphasizes reproducibility, rigor, and evidence. The success of a test program is measured by how clearly it shows whether requirements have been met, how well it reveals hidden weaknesses, and how effectively it supports decisions about design changes or production release.

Rapid Prototyping is powerful because it feeds testing with realistic parts at very early stages. Instead of relying only on simulations or rough mock-ups, teams can use Rapid Prototyping to create components that are close enough to the final design to undergo meaningful tests. These tests generate data about performance, usability, and manufacturability that would be difficult to obtain from purely digital models.

Each Rapid Prototyping iteration becomes a vehicle for multiple types of testing. Engineers may perform dimensional checks to confirm that Rapid Prototyping parts match CAD tolerances. Designers may conduct ergonomic evaluations and user interviews using Rapid Prototyping samples to see how people interact with the product. In parallel, quality and reliability teams may perform preliminary stress or fatigue tests on Rapid Prototyping parts to identify design weaknesses before committing to full tooling or large validation builds. In all cases, Rapid Prototyping and testing work as a loop: build, test, learn, then build again.

In real OEM supply chains, Rapid Prototyping is not a single process but a family of complementary methods. Each method offers different strengths in terms of speed, accuracy, material properties, and cost. Selecting the appropriate Rapid Prototyping process is part of good engineering practice and can have a big impact on the quality and relevance of test results.

- CNC machining Rapid Prototyping: Ideal for parts that must closely match the mechanical performance of final production components, such as metal housings, structural brackets, and precision plastic parts. CNC-based Rapid Prototyping provides tight tolerances and good surface finishes, which is valuable when testing assembly behavior and functional performance.

- 3D printing Rapid Prototyping: Often used for complex geometries, lightweight designs, internal channels, and rapid appearance models. 3D-print-based Rapid Prototyping makes it easy to revise shapes overnight and is perfect for early-stage concept testing, ergonomic trials, and quick integration checks.

- Sheet metal Rapid Prototyping: Used for enclosures, brackets, frames, and functional structures that will eventually move into stamping or fabrication. Sheet metal Rapid Prototyping allows engineers to test bending, assembly methods, and mounting options before locking in large tooling investments.

- Mold-related Rapid Prototyping: Includes soft tooling, bridge tooling, and prototype molds for low-volume plastic parts. This Rapid Prototyping approach is critical when the production process will rely on molding; it allows realistic material and process tests at manageable cost.

In a structured hardware development framework, Rapid Prototyping and testing appear at multiple stages, but testing becomes more formal and demanding as the product moves closer to launch. Early on, Rapid Prototyping parts might be tested informally by engineers themselves, while later stages involve dedicated labs, documented protocols, and cross-functional review.

Many organizations divide hardware testing into high-level phases such as Engineering Validation Testing (EVT), Design Validation Testing (DVT), and Production Validation Testing (PVT). During EVT, Rapid Prototyping and early pre-production parts are used to prove that the core architecture and critical functions work as intended. During DVT, more refined assemblies are tested against full performance and regulatory requirements, often using parts that are much closer to final materials and processes. During PVT, the focus shifts to verifying that production lines, tooling, and quality systems can consistently deliver parts that pass the same tests.

In practice, engineers and product managers often talk about “testing a prototype” as if prototyping and testing are a single step. That everyday language makes sense in busy project environments, but it hides the fundamental distinction between creating a prototype and evaluating it. Over time, this casual mixing of terms can make teams underestimate how much structured testing is still needed after Rapid Prototyping.

Another reason for confusion is that fast, iterative development processes blur the boundaries between design, Rapid Prototyping, and testing. In agile or sprint-based hardware programs, a team might design for a few days, use Rapid Prototyping to produce a new version, immediately test it with users, update the design, and repeat. Because all of this can happen in a tight loop, it is tempting to view Rapid Prototyping and testing as the same thing. Yet from a quality, regulatory, and risk perspective, they remain distinct activities that should be tracked and documented separately.

Even though Rapid Prototyping and testing are different, the combination of both is what makes modern product development fast and reliable. When an organization has strong Rapid Prototyping capability and a disciplined test strategy, each project milestone becomes better informed and less risky. Instead of guessing how a design will behave, teams can rely on real test data gathered from successive Rapid Prototyping iterations.

The benefits of connecting Rapid Prototyping and testing in a structured way include:

- Faster time-to-market, because potential failures and design weaknesses are discovered and fixed earlier, before major commitments are made.

- Lower development cost, because Rapid Prototyping allows targeted testing on critical features without building full production tooling too soon.

- Higher product quality, because multiple Rapid Prototyping and testing cycles refine not only technical performance but also user experience and perceived value.

- Better communication, because physical Rapid Prototyping samples and clear test results create a common language for engineers, marketers, and customers.

For international brands, wholesalers, and manufacturers, choosing a partner like Shangchen that understands both Rapid Prototyping and testing requirements is essential. Shangchen offers Rapid Prototyping using CNC machining, precision turning, sheet metal fabrication, 3D printing, and mold manufacturing, all aimed at supporting fast, testable iterations for global OEM customers.

By leveraging an integrated Rapid Prototyping and production environment, Shangchen can help buyers move efficiently from one stage of development to the next. Early in a project, Rapid Prototyping parts from 3D printing or machined plastics may be used to check ergonomics and assembly. In later stages, metal Rapid Prototyping parts from CNC and turning can be supplied for functional, strength, and thermal tests. When the design stabilizes, prototype molds and small pilot runs allow customers to perform broader validation and market tests before committing to large-volume tooling and long-term supply contracts.

A practical way to think about Rapid Prototyping and testing is to decide which activity should dominate at each moment in a project. Early on, the emphasis should be on exploration, and therefore on Rapid Prototyping. As a project matures, the emphasis naturally shifts toward demonstrating reliability, compliance, and manufacturability, which means more formal testing.

Use Rapid Prototyping when a design is still flexible, requirements may change, and the goal is to learn quickly with minimal cost. At this stage, it is normal to build several Rapid Prototyping variants to explore different geometries, materials, and mechanisms. Use structured testing when requirements are fixed and the goal is to prove that the chosen design actually meets them. At that point, Rapid Prototyping is still useful to fine-tune details, but tests become the primary driver of decisions.

There is no single correct number of Rapid Prototyping cycles for every project, but there are common patterns. Simple components may only require one or two Rapid Prototyping iterations before they are tested and locked for production. Complex assemblies, or systems that must pass demanding safety regulations, may go through many Rapid Prototyping versions as each round of testing reveals new requirements or edge cases.

The right strategy is to keep Rapid Prototyping cycles short and purposeful. Each new prototype should be built with a clear test plan in mind: which questions must be answered, what measurements will be taken, and what decisions will follow. When teams notice that new Rapid Prototyping iterations are no longer revealing meaningful new information in tests, they are usually close to a stable design that is ready for final validation and ramp-up.

Decisions made during Rapid Prototyping have lasting effects on mass production. Choosing certain materials or geometries during Rapid Prototyping may simplify or complicate later manufacturing steps. For example, a design that is easy to produce through 3D printing during Rapid Prototyping may be difficult to mold at high volume without additional changes. In contrast, Rapid Prototyping using CNC machining or sheet metal that mimics production constraints can make the transition to full-scale manufacturing more predictable.

A well-planned Rapid Prototyping strategy works backwards from production realities. By involving manufacturing engineers early and designing Rapid Prototyping parts with production methods in mind, teams can test not only the performance of a design but also its manufacturability. When Shangchen supports a project, Rapid Prototyping results feed directly into process planning, fixture design, tolerancing strategies, and quality control methods for future batches and OEM supply.

Rapid Prototyping and testing are closely linked but fundamentally different steps in product development. Rapid Prototyping focuses on quickly turning digital designs into physical or digital models to support exploration, iteration, and communication. Testing focuses on generating reliable evidence that those models and the final products meet technical, regulatory, and user requirements. When Rapid Prototyping is treated as the engine of iteration and testing is treated as the engine of verification and validation, OEM projects gain speed without sacrificing quality. By working with an experienced manufacturing partner like Shangchen that offers strong Rapid Prototyping capabilities and a deep understanding of test-driven development, overseas buyers can reduce risk, compress schedules, and move from concept to mass production with far greater confidence.

Rapid Prototyping is not itself a type of testing; it is a method for quickly creating prototypes from CAD data so that they can be examined and evaluated. However, Rapid Prototyping is usually followed immediately by engineering checks, user studies, and other tests, which is why people often talk about “testing prototypes” as if Rapid Prototyping and testing were a single step.

Rapid Prototyping cannot replace formal testing, especially in industries where safety, regulatory compliance, or warranty risk must be managed carefully. Rapid Prototyping helps teams find and fix problems before they reach formal test stages, but products still need structured verification and validation to show that all requirements are met and that the design is ready for market release.

Most projects run several Rapid Prototyping cycles before committing parts to formal test programs. Simple parts might need only one or two iterations, while sophisticated systems may require many Rapid Prototyping loops as each round of testing reveals new insights. The key is to design each Rapid Prototyping cycle around clear questions and to stop iterating once additional prototypes stop changing test outcomes.

Rapid Prototyping parts are ideal for early form and fit checks, ergonomic assessments, initial functional evaluations, and preliminary strength or durability trials. These tests help teams decide whether the design direction is correct and what must be changed before investing in final materials and production processes. For ultimate certification or life-cycle testing, teams usually rely on pre-production units made with the same methods planned for mass production.

Overseas OEM buyers benefit from working with Shangchen because the same team that delivers Rapid Prototyping also supports precision batch production, turning, sheet metal fabrication, 3D printing, and mold manufacturing. This integrated approach allows Rapid Prototyping results to flow directly into tooling design, process optimization, and long-term supply planning, giving international customers a smoother, faster, and more reliable path from initial sample to ongoing OEM production.

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal