Views: 222 Author: Amanda Publish Time: 2026-01-14 Origin: Site

Content Menu

● What Rapid Prototyping Really Means

● Why The Hyphen Disappeared In Everyday Usage

● Core Principles Of Rapid Prototyping

● Typical Rapid Prototyping Workflow

● Key Technologies Behind Rapid Prototyping

>> Additive Manufacturing / 3D Printing

>> Rapid Tooling And Small‑Batch Molding

● Benefits Of Rapid Prototyping For Global OEMs

● Rapid Prototyping From Prototype To Production

● Working With A Chinese Rapid Prototyping Partner

>> 1. Is “Rapid Prototyping” ever correctly written with a hyphen?

>> 2. What is the main purpose of Rapid Prototyping in product development?

>> 3. How does Rapid Prototyping differ from traditional prototyping?

>> 4. Which manufacturing processes are most commonly used in Rapid Prototyping?

>> 5. Why is Rapid Prototyping important for overseas OEM customers working with Chinese factories?

In professional usage across manufacturing, engineering, and product design, “Rapid Prototyping” is treated as an open compound noun. The first word “rapid” functions as an adjective modifying “prototyping,” and the two words appear together without a hyphen in most technical sources and glossaries. Over time, as the concept of rapid prototyping became standard in product development, the spelling stabilized in the simple, unhyphenated form.

When companies describe their services, they almost always write “rapid prototyping services,” “rapid prototyping supplier,” or “rapid prototyping process” instead of “rapid‑prototyping services.” This pattern reflects a broader trend in technical English where familiar multi‑word terms lose their hyphens once they become widely recognized. For brands, factories, and OEM suppliers, following this mainstream convention helps align language with customer expectations.

For your English website, marketing pages, and blogs, using the unhyphenated “Rapid Prototyping” consistently in titles, headings, and body text improves clarity, professionalism, and search visibility. It also ensures that potential customers searching online for rapid prototyping solutions find and understand your services quickly.

Rapid prototyping is not just a fancy phrase for basic samples; it describes a complete methodology for quickly turning ideas into testable products. In product development, rapid prototyping refers to the fast creation of physical or digital models directly from 3D CAD data so that designers and engineers can evaluate form, fit, and function early in the design cycle. These prototypes may range from simple visual models to fully functional assemblies that simulate final production parts.

Instead of waiting for traditional tooling or slow workshop methods, teams use rapid prototyping to obtain tangible parts in days or even hours. This allows multiple design variants to be produced, compared, and refined in quick succession. As a result, rapid prototyping becomes the backbone of an agile, iterative development workflow where feedback is fast, risk is reduced, and better designs are achieved before committing to mass production.

In practical terms, rapid prototyping covers multiple levels of detail. Early in a project, a company might need a rough shape to check ergonomic feel or overall dimensions. Later, they might require high‑precision, material‑correct prototypes to validate mechanical performance, reliability, and assembly. All of these fall under the broader umbrella of rapid prototyping.

From a pure grammar perspective, some style guides may suggest a hyphen when the phrase appears as a compound adjective before a noun, such as “rapid‑prototyping line.” However, in industry practice, most engineers, marketers, and technical writers have stopped inserting this hyphen in normal usage. When a term is widely understood, the visual simplicity and familiarity of the unhyphenated form usually win.

Another reason the hyphen disappeared is the influence of digital communication and search behavior. People search for “rapid prototyping service,” not “rapid‑prototyping service,” and technical websites, software vendors, and manufacturing platforms have adjusted their spelling accordingly. Over time, this created a natural standard that favors the open form without a hyphen in almost every context, including headings, user interfaces, documentation, and marketing copy.

Because of this evolution, using “Rapid Prototyping” without a hyphen signals that your content is up‑to‑date and aligned with global industry language. It prevents unnecessary confusion, keeps your message clean, and ensures consistency across your entire site, from blog content to quote request pages and service catalogs.

Rapid prototyping is built around a few key principles that make it fundamentally different from older, slower prototyping approaches:

- Speed over perfection in early stages

Teams intentionally prioritize faster iterations over fully polished models at the beginning, accepting that some prototypes will be rough but very informative.

- Iteration through real, physical feedback

Rather than debating designs only on screens, rapid prototyping uses real parts to test ergonomics, assembly, performance, and user experience.

- Digital‑to‑physical automation

The workflow depends on CAD models, CAM programming, and digital manufacturing technologies to shorten the path from design to prototype.

- Design for manufacturability awareness

Each prototype provides insight into how easily a part can be produced at scale, which helps engineers improve geometry, tolerances, and material selection.

These principles apply across sectors such as consumer products, industrial machinery, automotive, aerospace, robotics, and medical devices. Any organization that must innovate quickly and bring reliable products to market benefits from a solid rapid prototyping strategy.

Although each project is different, a common rapid prototyping workflow includes several recurring steps:

1. Concept and CAD modeling

Industrial designers and engineers collaborate to transform design requirements into 3D CAD models. At this stage, shapes, mechanisms, and interfaces are defined, but details can still change quickly.

2. Process selection and manufacturing planning

Based on geometry, material, and purpose, the team selects the most appropriate manufacturing method: 3D printing for complex shapes, CNC machining for precise functional parts, sheet metal for structural components, or soft tooling for small‑batch molded parts.

3. Prototype fabrication

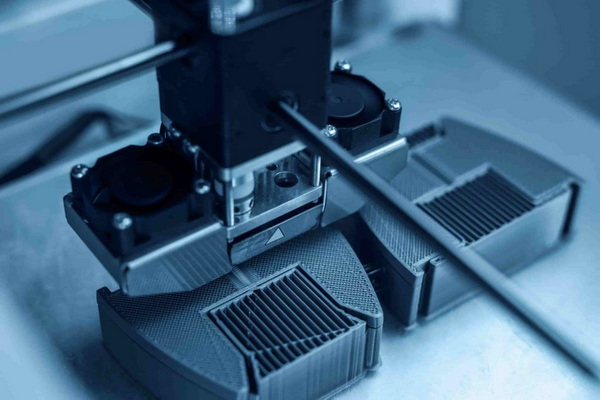

Machines such as CNC machining centers, lathes, 3D printers, and sheet metal lines produce the physical models. The goal is speed with sufficient accuracy for the intended tests.

4. Inspection and testing

The prototypes are measured, assembled, and tested. Engineers check dimensional accuracy, structural behavior, and usability, often using metrology tools and real‑world functional tests.

5. Design feedback and revision

Feedback is applied to update the CAD model. Sometimes there are only minor tweaks; sometimes the design is re‑thought completely based on what the prototype reveals.

6. Iteration and refinement

New prototypes are produced using updated designs. This iterative loop may run several times until the design is both functionally sound and ready for commercialization and mass production.

A mature rapid prototyping supplier supports all of these steps, offering engineering assistance, manufacturing know‑how, and flexible production capacity. This is especially valuable when the client is located overseas and depends on a dependable partner to handle both technical and logistical challenges.

A real rapid prototyping ecosystem relies on multiple complementary technologies rather than one single process. The most effective suppliers integrate several methods to handle a wide range of projects.

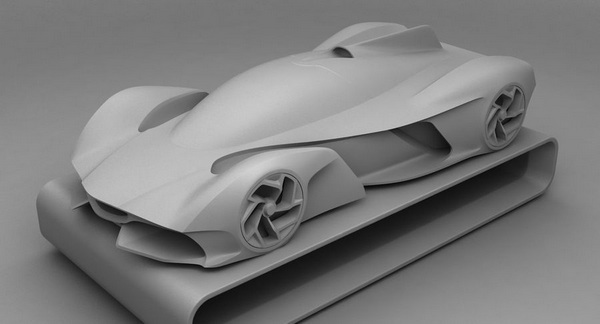

Additive manufacturing builds parts layer by layer from digital models. It is particularly useful in rapid prototyping because:

- Complex internal channels, lattice structures, and freeform surfaces are possible without expensive tooling.

- Fast design changes are easy to implement, since no molds or dedicated fixtures must be rebuilt.

- Different materials (plastics, resins, and metals) support visual models, functional prototypes, and even end‑use components.

In early design phases, polymer 3D printing is often used for visual models and ergonomic checks. In later stages, advanced systems can produce metal or high‑performance polymer parts for functional and environmental testing.

CNC machining and turning form the backbone of precision rapid prototyping. These processes are ideal when:

- Tight tolerances, flatness, concentricity, and surface finish are critical.

- The prototype must closely simulate a final metal or engineering‑plastic production part.

- Functional tests require realistic mechanical strength, heat resistance, or wear performance.

With multi‑axis mills and turning centers, complex housings, brackets, shafts, manifolds, and structural parts can be produced rapidly from aluminum, steel, stainless steel, brass, and engineering plastics. CNC turning is especially important for cylindrical components such as bushings, connectors, and threaded parts.

Sheet metal prototyping combines cutting, bending, punching, and welding to create enclosures, frames, racks, and structural components in a rapid prototyping environment. It is widely used for:

- Electrical and electronic device housings.

- Control cabinets, server racks, and machine covers.

- Brackets, mounting plates, and mechanical supports.

Because modern equipment can switch from one program to another quickly, single pieces and small batches can be produced with short lead times, making sheet metal a powerful part of the rapid prototyping toolkit.

In many projects, the goal of rapid prototyping is not just a single sample, but dozens or hundreds of parts that behave like final molded components. Rapid tooling strategies allow:

- Soft or semi‑permanent molds to be produced quickly to support short‑run injection molding.

- Early validation of gate positions, part deformation, shrinkage, and cosmetic quality.

- Bridge production to cover the gap between initial prototypes and full mass‑production tooling.

This approach is especially important for consumer products, automotive parts, and industrial components where final production will depend on injection molding or die‑casting.

Global OEMs, brand owners, and system integrators rely on rapid prototyping to reduce risk and speed up innovation. Key advantages include:

- Shorter development cycles

Rapid prototyping greatly compresses the path from idea to testable hardware. Instead of waiting months for traditional models, teams can evaluate parts within days and make earlier go/no‑go decisions.

- Lower total development cost

By discovering design flaws or manufacturing problems earlier, companies avoid expensive tooling changes and late-stage engineering modifications. Even if prototypes themselves require investment, the total lifecycle cost is reduced.

- Better design quality and innovation

Frequent iterations allow more exploration of design alternatives. Teams can test several concepts in parallel and learn from real‑world performance instead of relying only on theoretical analysis.

- Clearer communication between stakeholders

Physical prototypes provide a shared reference point for engineers, buyers, marketers, and end users. Discussions about shape, assembly, and usability become more concrete and less abstract.

For overseas customers working with a Chinese rapid prototyping supplier, these benefits come with additional advantages such as flexible order volumes, competitive pricing, and access to integrated machining, turning, sheet metal, and molding resources in one facility.

A strong rapid prototyping strategy also supports a smooth transition to mass production. This is where a factory that offers both rapid prototyping and precision batch manufacturing has a clear edge.

- Early design phases

The focus is on basic geometry, ergonomics, and visual appearance. 3D printing and simple CNC machining produce quick, informative prototypes.

- Engineering validation

As specifications firm up, CNC machining, turning, and higher grade materials are used to verify tolerances, strength, and functional performance.

- Pre‑production and pilot runs

Rapid tooling, sheet metal fabrication, and small‑batch CNC production generate realistic assemblies that can be used for certification tests, market trials, and initial customer deliveries.

- Mass production readiness

Lessons learned from rapid prototyping feed into final tooling design, process optimization, quality plans, and cost analysis. Because the same partner handled the earlier stages, knowledge transfer is faster and more reliable.

By viewing rapid prototyping and production as a continuous process rather than separate activities, OEMs can accelerate launches and improve overall product reliability.

For foreign brand owners, wholesalers, and manufacturers, partnering with an experienced Chinese rapid prototyping factory can be a strategic decision. Such a partner typically offers:

- A combination of CNC machining, turning, sheet metal fabrication, 3D printing, and mold manufacturing under one roof.

- Engineering support to optimize designs for manufacturability and cost without compromising functionality.

- Flexible order quantities that cover single prototype pieces, small pilot runs, and transition volumes before full mass production.

- Communication in English, rapid feedback, and project management focused on international OEM expectations.

In this model, rapid prototyping is more than just making samples; it becomes the central link connecting design teams in one country with manufacturing resources in another. When the same partner can also handle precision batch production and tooling, the entire lifecycle from prototype to final product is smoother and more predictable.

“Rapid Prototyping” is best written without a hyphen in contemporary manufacturing, engineering, and SEO contexts. The term has become a stable open compound that describes a family of fast, iterative methods for building physical models and functional parts from digital designs. More importantly, rapid prototyping is now a critical strategic capability that helps companies innovate faster, reduce risk, and bring better products to market.

By combining technologies such as 3D printing, CNC machining, turning, sheet metal fabrication, and rapid tooling, a modern rapid prototyping supplier can support every phase of product development—from early concept models through functional prototypes and pilot runs to final production. For international OEMs partnering with a Chinese manufacturing factory, a strong rapid prototyping workflow offers speed, flexibility, and technical confidence. Using the correct, unhyphenated form “Rapid Prototyping” in all English materials reinforces that capability and aligns your communication with global industry standards.

Technically, some style guides may allow a hyphen if the phrase is used directly as a compound adjective, but in real manufacturing and engineering practice, the unhyphenated “Rapid Prototyping” is overwhelmingly preferred. Most companies, software providers, and technical publishers use the open form in both headings and normal sentences because it is clearer and more recognizable for readers. For consistency and SEO, it is wise to follow this majority usage and avoid the hyphen.

The main purpose of rapid prototyping is to shorten the time between idea and physical validation so that teams can test and improve designs quickly. Instead of relying only on drawings or simulations, engineers and designers work with real parts early in the project, which reveals problems and opportunities that are easy to miss on a screen. This leads to better decisions, lower risk, and more successful final products.

Traditional prototyping often involves slow, manual, or tooling‑intensive methods, making each iteration expensive and time‑consuming. Rapid prototyping, by contrast, depends on digital models and automated processes like 3D printing, CNC machining, and flexible sheet metal fabrication to turn new designs into parts very quickly. This difference in speed and flexibility allows many more iterations and dramatically improves the efficiency of the development process.

The most common processes in rapid prototyping are 3D printing for complex shapes and early concept models, CNC machining and turning for precise functional parts, sheet metal fabrication for enclosures and structures, and rapid tooling for short‑run molded components. By combining these methods, a single rapid prototyping partner can handle plastic and metal parts, simple and complex geometries, and quantities ranging from one piece to pilot batches.

For overseas OEM customers, rapid prototyping is essential because it builds a bridge between remote design teams and manufacturing resources. Fast prototypes from a Chinese factory allow customers to evaluate quality, fit, and performance long before they commit to large orders or expensive tools. At the same time, the factory gains early insight into production challenges, which leads to more accurate quotations, smoother scale‑up, and fewer surprises when mass production begins.

content is empty!

Top On Demand 3D Printing Manufacturers and Suppliers in Russia

Top On Demand 3D Printing Manufacturers and Suppliers in Portugal

Top On Demand 3D Printing Manufacturers and Suppliers in Spain

Top On Demand 3D Printing Manufacturers and Suppliers in France

Top CNC Turning Manufacturers and Suppliers in Czech Republic