Views: 222 Author: Amanda Publish Time: 2025-12-18 Origin: Site

Content Menu

● How Hard Is CNC Machining Compared to Other Skills?

● Key Skills Involved in CNC Machining

● Typical Learning Timeline for CNC Machining

● Factors That Make CNC Machining Feel Difficult

● What Makes CNC Machining Easier to Learn Today?

● Different Learning Paths into CNC Machining

● How CAD/CAM Changes the Learning Focus

● Physical and Mental Demands of CNC Machining

● Design Perspective: How Much CNC Machining Do Engineers Need to Learn?

● Role of Professional CNC Machining Partners

● Practical Tips to Learn CNC Machining Faster

● When Does It Make Sense to Outsource Instead of Learning Everything?

● How CNC Machining Fits Into a Complete Manufacturing Strategy

● FAQ

>> Q1: How long does it usually take to learn basic CNC machining?

>> Q2: Is CNC programming harder than operating a CNC machine?

>> Q3: Can someone without a technical background learn CNC machining?

>> Q4: Do engineers need to know CNC machining in detail?

>> Q5: When is it better to outsource CNC machining to a specialist factory?

CNC machining looks intimidating from the outside: large machines, complex code, and high‑precision metal parts all suggest that only experts can do it. In reality, CNC machining is a learnable skill that becomes much less mysterious once you break it into clear steps and focus on what you actually need for your role. For machinists, that means deep hands‑on skills; for engineers and purchasing teams, it means understanding what CNC Machining can deliver and how to design parts that are easy to manufacture.

For global OEM brands working with Chinese factories like Shangchen (sc‑rapidmanufacturing.com), CNC machining is not just a technology—it is a strategic capability that connects rapid prototyping, small‑batch production, and precision mass manufacturing. When you understand how CNC machining works and how hard it is to learn, you can decide when to train internal staff and when to rely on a professional CNC machining partner.

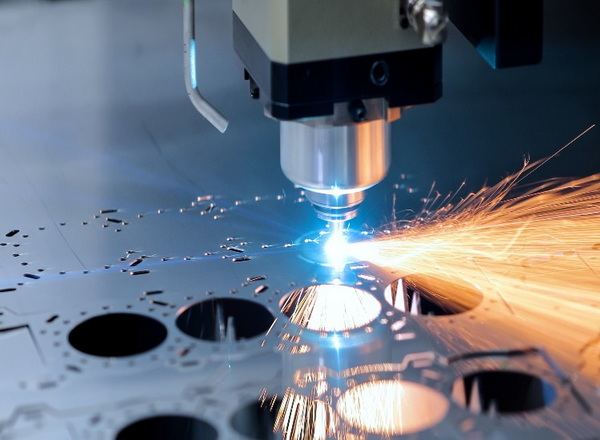

CNC machining (Computer Numerical Control machining) is a subtractive manufacturing process that removes material from a solid block using rotating cutting tools controlled by a computer program. The machine follows coordinates and commands to cut, drill, bore, and finish the workpiece into a precise 3D shape. Typical CNC machining centers include 3‑axis mills, lathes, 4‑axis and 5‑axis machines, and mill‑turn equipment for complex parts.

The CNC machining workflow usually starts with a 3D CAD model and a 2D drawing that define geometry, tolerances, and critical features. CAM software converts the model into toolpaths, generates G‑code, and then the CNC machining center executes that code to produce real parts. Because CNC machining is highly repeatable, it is ideal for rapid prototyping, functional samples, jigs and fixtures, and production‑grade components in metals and engineering plastics.

To understand whether CNC machining is hard to learn, it helps to compare it with other technical skills. Learning CNC machining has a similar difficulty level to learning welding, automotive repair, or industrial maintenance: the basics are accessible, but true mastery takes years. At the entry level, CNC machining is no harder than learning to operate complex software or to program a simple robot.

What makes CNC machining feel different is the combination of physical machines and digital programming. Beginners must learn how the machine behaves, how tools cut material, and how code translates into movement. Mistakes can break tools or scrap parts, so CNC machining demands more focus and responsibility than purely digital skills. However, with good instruction and supervision, most people can become comfortable with basic CNC machining in a reasonable time.

CNC machining is not one single skill but a cluster of related abilities. Understanding these areas makes the learning path clearer and less intimidating.

- Technical drawing and GD&T: You need to read mechanical drawings, dimensions, tolerances, and surface finish requirements so you know what the part must achieve.

- Basic math and geometry: CNC machining uses addition, subtraction, decimals, angles, and trigonometry to position features and calculate toolpaths.

- Machine operation: You must understand machine axes, home position, work coordinates, tool length and diameter offsets, plus how to safely start, stop, and reset the machine.

- Programming and CAM: CNC machining uses G‑code and M‑code, often generated from CAM software, to define motions, feed rates, and machining strategies.

- Tooling and materials: Knowing which cutting tools to use for aluminum, steel, stainless steel, titanium, or plastics—plus how speed, feed, and depth of cut affect tool life and surface quality—is essential.

- Measurement and quality: Calipers, micrometers, height gauges, and CMMs are used to verify that CNC machining meets tolerance and functional requirements.

Each of these elements can be learned step by step. You do not need to understand everything perfectly before you can start making simple parts with CNC machining.

The time required to learn CNC machining depends on your starting point, learning environment, and goals. For many beginners:

- 0–1 month: You learn terminology, safety, basic machine components, and how to run pre‑written programs under supervision. By the end of this period, you may be loading parts, pressing cycle start, and doing simple measurements.

- 1–3 months: You become more comfortable setting work offsets, loading tools, and making simple edits to CNC machining programs. You may start using CAM software to generate basic 2.5D operations like facing, pocketing, and drilling.

- 3–6 months: You can set up simple jobs independently, choose tools for straightforward materials, and adjust feeds and speeds when problems appear. At this stage, you are an entry‑level CNC machining operator or junior programmer.

- 6–24 months: You gain experience with more complex parts, multi‑axis CNC machining, fixturing strategies, and tolerance control. You become capable of planning processes, programming from scratch, and improving cycle times.

Beyond two years, CNC machining skills continue to grow as you work with more problematic materials, tighter tolerances, and multi‑step processes that integrate turning, milling, and secondary operations.

Several factors can make CNC machining feel harder than it really is:

1. Information overload

Beginners often see many unfamiliar concepts at once: G‑code, CAM software, offsets, tool libraries, coolant types, and measurement tools. Without a structured learning plan, CNC machining can feel confusing and overwhelming.

2. Fear of making mistakes

Because CNC machining involves expensive machines and tools, learners sometimes hesitate to experiment or ask questions. This fear slows learning, even though controlled mistakes and supervision are part of the normal learning process.

3. Poor training environment

If the shop has no clear procedures, no mentors, or no time for questions, newcomers can struggle. A supportive environment where experienced machinists explain decisions makes CNC machining much easier to learn.

4. Jumping ahead too fast

Trying to start directly with advanced 5‑axis CNC machining or complicated programming can be frustrating. Better results come from mastering 3‑axis basics, then gradually moving to more complex CNC machining tasks.

The good news is that CNC machining is easier to learn now than it was in the past, mainly because of better tools and resources:

- Modern CAM software

CAM packages generate toolpaths automatically from CAD models, providing visual simulations and collision checks before any real cutting. This reduces the need to write every line of G‑code by hand and shortens the CNC machining learning curve.

- Rich online learning content

There are thousands of training videos, interactive courses, and forums where CNC machining experts share tips and problem‑solving methods. Beginners can replay tricky steps as often as needed and learn at their own pace.

- Machine control improvements

Newer CNC controls include conversational programming, graphical verification, and user‑friendly screens, which help operators understand what the CNC machining program will do before pressing cycle start.

- Integrated training programs

Many schools and factories use structured curricula that combine classroom theory, simulation, and hands‑on practice. This blended approach helps learners connect abstract concepts with real CNC machining results.

There is no single “correct” route into CNC machining. Common paths include:

- Vocational school or technical college

These programs mix theory with shop time on real machines, covering blueprint reading, basic machining, CNC programming, and inspection. Graduates are ready for entry‑level CNC machining jobs with a broad foundation.

- Apprenticeship

Some learners start as shop assistants, then gradually take on more responsibility: measuring parts, setting tools, editing programs, and eventually programming complete jobs. This route offers deep practical experience in real production.

- On‑the‑job cross‑training

Manual machinists, toolmakers, or maintenance technicians may add CNC machining to their skill set. Their background in materials and hand tools helps them learn CNC with less difficulty.

- Engineer or designer route

Mechanical engineers and product designers often learn CNC machining to improve design‑for‑manufacturing and communicate better with suppliers. They may focus more on CAD/CAM and CNC machining capabilities than on day‑to‑day machine operation.

In modern manufacturing, CAD and CAM sit at the heart of CNC machining. This changes what learners must focus on:

- Instead of memorizing every G‑code, beginners learn how toolpaths work conceptually—entry, engagement, step‑over, step‑down, lead‑in, and retract.

- Much of the detailed code is generated automatically, so the main challenge is choosing the right strategy for efficient and safe CNC machining.

- Learners must pay attention to work coordinate systems, tool libraries, and post‑processors, which translate CAM operations into the specific dialect of G‑code for each machine.

For OEM customers, this means sending accurate CAD data and clearly defined tolerances is more important than understanding the internal details of every CNC machining program. The supplier's engineers handle CAM programming and optimization.

CNC machining combines mental concentration with physical work:

- Mental demands

Machinists must monitor dimensions, listen for changes in cutting sound, notice vibration or chatter, and respond quickly to alarms. They need to think ahead about tool wear, next steps, and potential problems in the CNC machining process.

- Physical demands

Work often involves standing for long periods, loading and unloading parts, and moving fixtures or raw material. Good ergonomics, proper lifting practices, and clean layouts reduce fatigue and risk.

For many people, this blend of physical activity and problem‑solving makes CNC machining satisfying. Every day brings new challenges and opportunities to improve processes.

If you are a mechanical engineer, product manager, or sourcing specialist, you usually do not need to be a full‑time machinist. Instead, you need “design‑aware” CNC machining knowledge:

- Which geometries are easy to machine and which ones raise cost.

- Typical tolerance ranges for CNC machining and how they affect pricing.

- How material selection (aluminum, steel, brass, plastics) interacts with CNC machining time and tool wear.

- When it is better to use CNC machining versus 3D printing, sheet metal, or die casting.

This level of understanding helps you design parts that are economical and realistic to produce, and it makes communication with factories like Shangchen smoother and more efficient.

For many overseas brands, the practical question is not “Can we learn CNC machining?” but “Should we build this capacity in‑house or work with an external partner?” Professional suppliers like Shangchen specialize in:

- CNC machining of complex prototypes and production parts.

- CNC turning for shafts, bushings, and rotational components.

- Sheet metal fabrication for enclosures, brackets, and frames.

- 3D printing for rapid concept models and complex internal geometries.

- Mold production and low‑volume injection molding.

By working with such partners, your internal team can focus on design, testing, marketing, and sales while still leveraging advanced CNC machining and related processes. You do not have to learn how to run every machine; you only need enough knowledge to define requirements and evaluate quotes.

Anyone serious about learning CNC machining can speed up progress by following a few simple principles:

- Start simple and repeat

Pick one machine type (for example, a 3‑axis milling center) and practice simple parts repeatedly: faces, pockets, bosses, holes, and chamfers. Repetition builds confidence and intuition about how CNC machining responds to changes in setup and cutting parameters.

- Learn the “why,” not just the “how”

Whenever a mentor tells you to use a certain feed rate or tool, ask why. Understanding the reason behind decisions lets you adapt CNC machining strategies when materials, machines, or part geometries change.

- Use simulations and dry runs

Always simulate toolpaths in CAM and run programs in single‑block mode or with the feed override turned down when trying something new. This habit protects machines and tools while you learn.

- Keep a CNC machining notebook

Record successful cutting parameters, tool combinations, problem cases, and solutions. Over time, your notes become a personal CNC machining handbook tailored to your environment.

- Learn to measure well

Take measurement training seriously. If you can measure accurately and understand tolerance stacks, you will design better setups and catch CNC machining issues early.

There are many situations where it is more efficient to outsource CNC machining rather than building internal capability:

- Your volumes are intermittent or low, making machine investment and staff hiring hard to justify.

- Your core competency is product design, branding, or system integration, not running factories.

- You need access to multiple processes—CNC machining, sheet metal, 3D printing, and molding—without purchasing all that equipment.

- You need to ramp up quickly, using an existing CNC machining team that already has experience with similar parts and materials.

In these cases, partnering with an integrated supplier like Shangchen gives you flexibility while maintaining quality and lead time. You can still learn enough CNC machining knowledge to design good parts and evaluate suppliers, without having to master every shop‑floor detail.

In modern product development, CNC machining is rarely used alone. Instead, it forms part of a comprehensive manufacturing strategy:

- Early concept stages may use 3D printing for quick design validation.

- CNC machining then produces functional prototypes in real materials, with accurate tolerances and surface finishes.

- For bridge production or high‑value components, CNC machining continues to be the main process.

- For large volumes, injection molding, die casting, or stamping may be introduced, while CNC machining handles precision inserts, critical features, and fixtures.

Factories like Shangchen can coordinate these steps so that lessons learned in prototyping feed directly into tooling design and production process control.

CNC machining is not easy in the sense of being instantly mastered, but it is very learnable for anyone willing to follow a structured path, practice regularly, and learn from mistakes. The basic skills of CNC machining—reading drawings, operating machines, using CAM, and measuring parts—can be acquired in months, while deeper expertise grows naturally with real projects and experience.

For engineers, buyers, and brand owners, the key is to understand what CNC machining can achieve, how to design CNC‑friendly parts, and when to partner with specialized suppliers. With an experienced factory such as Shangchen handling CNC machining, turning, sheet metal, 3D printing, and mold production, you can focus on product design and market success while still benefiting from world‑class manufacturing capability.

Most motivated beginners can learn basic CNC machining operation and simple programming in about 3–6 months, especially if they have access to structured training and hands‑on practice. This level typically covers loading parts, running existing programs, and editing simple parameters under supervision.

CNC programming is more intellectually demanding than basic operation because it requires understanding geometry, toolpaths, and cutting strategies. However, modern CAM software reduces the difficulty by automating many steps, so beginners can gradually move from operating machines to programming straightforward parts.

Yes, many successful CNC machinists started without a formal technical background. As long as you are willing to learn basic math, follow safety rules, and practice regularly, you can build CNC machining skills. Technical courses and patient mentorship make the process significantly easier.

Engineers do not need to know every machine detail, but they benefit greatly from understanding CNC machining capabilities, typical tolerances, and design‑for‑manufacturing principles. This knowledge leads to parts that are easier to machine, cheaper to produce, and more consistent in quality.

It is usually better to outsource CNC machining when your volumes are variable, your team lacks machining experience, or you want to avoid large capital investments in equipment and staff. Working with a specialist OEM partner such as Shangchen lets you access advanced CNC machining and related processes while keeping your internal team focused on design, testing, and sales.

content is empty!

Top Metal CNC Machining Manufacturers and Suppliers in Lithuania

Top Metal CNC Machining Manufacturers and Suppliers in Czech Republic

Top Metal CNC Machining Manufacturers and Suppliers in Hungary

Top Metal CNC Machining Manufacturers and Suppliers in Denmark

Top Metal CNC Machining Manufacturers and Suppliers in Ireland