Content Menu

● How CNC Machining Pricing Works

● Machine Type and Hourly Rate

● Material Selection and Utilization

● Labor, Programming, and Setup Time

● Tooling, Fixtures, and Overhead

● When CNC Machining Seems Expensive

● Why CNC Machining Is Often Cost‑Effective

● CNC Machining vs. 3D Printing

● CNC Machining vs. Injection Molding

● Regional Cost Differences in CNC Machining

● Design for Manufacturability in CNC Machining

● Volume, Repeatability, and Long‑Term Cost

● Practical Ways to Reduce CNC Machining Cost

● FAQ

>> 1. Why do CNC Machining prices differ so much between suppliers?

>> 2. Is CNC Machining always more expensive than 3D printing?

>> 3. When does injection molding become cheaper than CNC Machining?

>> 4. How can I reduce the cost of an existing CNC Machining part?

>> 5. Is CNC Machining suitable for long‑term mass production?

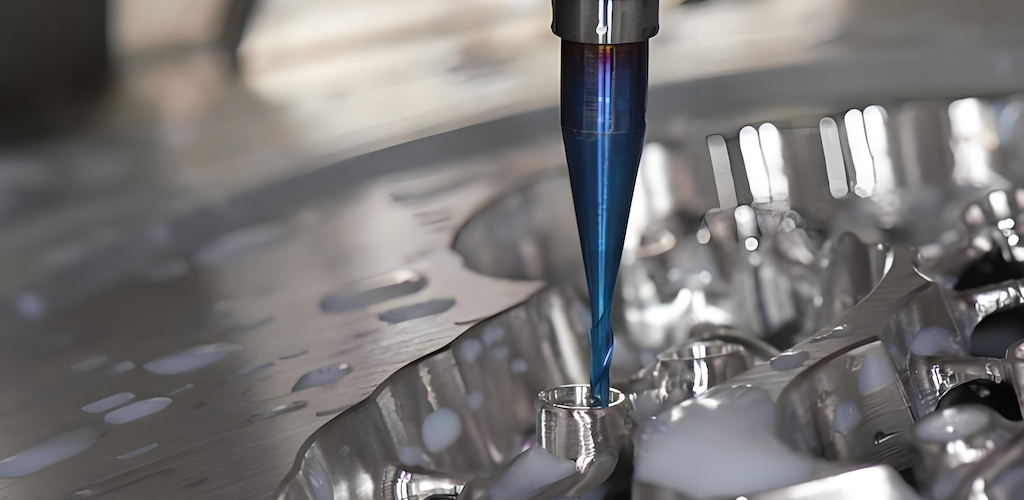

CNC Machining is a precise manufacturing method that uses computer‑controlled machines to remove material from a solid block and create accurate, repeatable parts. Instead of relying on manual machining, CNC Machining automates the cutting process with digital programs, enabling complex shapes, tight tolerances, and consistent quality from batch to batch. For OEM buyers, the real question is not simply whether CNC Machining is expensive, but whether it delivers the best cost‑to‑value ratio compared with alternative processes such as 3D printing or injection molding.

From a purchasing perspective, CNC Machining cost is the result of many technical and economic factors working together. Machine hour rate, labor, material, tooling, setup time, and overhead all contribute to the final price per part. When these elements are understood and optimized, CNC Machining can be one of the most economical ways to produce functional prototypes, small to medium production runs, and high‑precision components for demanding industries.

CNC Machining pricing generally starts with the machine hour rate multiplied by the total machining time required to complete each part. On top of that, suppliers add material cost, programming time, setup, tooling wear, inspection, and a portion of shop overhead. Each CNC Machining shop structures this calculation slightly differently, but the core logic is similar: the more time and resources a part consumes, the higher its price.

For simple parts, CNC Machining time is short, setup is easy, and standard tools can be used, so the unit price tends to be modest even at lower quantities. As parts become more complex—with deep pockets, thin walls, tight tolerances, or multi‑axis features—the CNC Machining cycle time increases, special fixtures or tools may be required, and more inspection is needed, which all raise the cost. Understanding how each of these elements behaves helps OEM buyers judge whether a CNC Machining quote is reasonable.

The machine type is one of the most visible cost drivers in CNC Machining. A basic 3‑axis vertical machining center used for milling simple prismatic parts has a relatively modest hourly rate compared with a high‑end 5‑axis machining center capable of reaching multiple faces in a single setup. Similarly, CNC turning centers used for shafts, bushings, and other rotational parts often have lower hourly costs than complex multi‑tasking machines.

These hourly rates reflect not only the purchase price of the CNC Machining equipment but also the cost of maintaining it, training operators, and keeping it productive. Shops that invest heavily in advanced CNC Machining centers will generally have higher rates but can sometimes offset this with fewer setups and faster cycle times. For some parts, paying more per hour but finishing the job in fewer hours actually reduces the total cost.

Material selection is another major consideration when evaluating whether CNC Machining is expensive. Different metals and plastics vary in raw material price and machinability. Aluminum alloys are often preferred for CNC Machining because they are relatively inexpensive, easy to cut, and yield good surface finishes with short cycle times. Stainless steels, titanium, and hardened tool steels are more difficult to machine, cause more tool wear, and therefore lead to higher CNC Machining costs for otherwise similar geometries.

In addition to material type, utilization matters. Because CNC Machining is subtractive, a part that starts from a large billet and ends with a small finished component generates a lot of scrap. If the material is costly, such as titanium or certain nickel alloys, this waste significantly increases the overall cost for CNC Machining. Good design practice aims to minimize unnecessary material removal while still meeting functional and strength requirements.

Labor is less visible than machine time but still critical in CNC Machining cost analysis. Before the first chip is cut, a programmer must create or validate toolpaths in CAM software, select tools, define cutting parameters, and simulate the process. This programming time is usually a one‑time investment per part number, then amortized over the batch size. For very small quantities, CNC Machining programming can feel disproportionately expensive because the cost is spread over only a few pieces.

Setup time includes mounting raw stock or fixtures on the machine, loading tools, measuring offsets, and running the first article for verification. Complex fixtures, multiple setups, and tight tolerance features extend this setup period. Since setup is largely independent of order quantity, unit cost for CNC Machining drops significantly as batch size increases and the same setup produces more parts.

CNC Machining requires cutting tools—end mills, drills, inserts, reamers—as well as holders, collets, and workholding fixtures. These items wear out or need periodic replacement, especially when cutting hard or abrasive materials. Tooling cost per part in CNC Machining reflects not only the purchase price but also how long each tool lasts and how many components can be produced before a tool change is necessary.

Fixtures range from simple vises and chucks to custom‑designed jigs that precisely locate irregular shapes. While CNC Machining does not require the high tooling investment of injection molding, complex fixtures still add engineering and manufacturing cost. Overhead, including rent, utilities, quality systems, management, and software licenses, is allocated across all CNC Machining jobs in the shop. This is one reason why hourly rates differ so much between regions and suppliers.

There are several common situations where CNC Machining is perceived as expensive:

- Very low quantity: If only a few pieces are needed, programming and setup cost dominate the CNC Machining price per part.

- Very complex geometry: Parts that need multiple setups, 5‑axis machining, or special tools will naturally cost more.

- Ultra‑tight tolerances: Demanding tolerances require slower feeds and speeds, additional passes, and more inspection steps, increasing CNC Machining time.

- Frequent design changes: Every design modification may require updated toolpaths, new first article inspections, and sometimes new fixtures.

In these cases, the buyer may see a high unit price and view CNC Machining as expensive, even though the underlying cost structure is logical. Understanding this helps set realistic expectations and encourages design changes that bring CNC Machining costs down.

On the other hand, CNC Machining becomes very cost‑effective when the design, volume, and process are aligned. For many metal parts, CNC Machining offers an excellent balance between accuracy, flexibility, and per‑part cost. It requires lower upfront investment compared with casting or molding and can adapt quickly to design updates without scrapping expensive tools.

CNC Machining is especially economical for:

- Functional prototypes that must closely match final production materials and tolerances.

- Bridge production before mass production tooling is ready.

- Small to medium production batches where high tooling investment cannot be justified.

- High‑precision parts where alternatives cannot hold the required tolerances.

In these scenarios, CNC Machining delivers a high level of value relative to its cost, making it a smart choice even if the unit price looks higher than rougher, less precise processes.

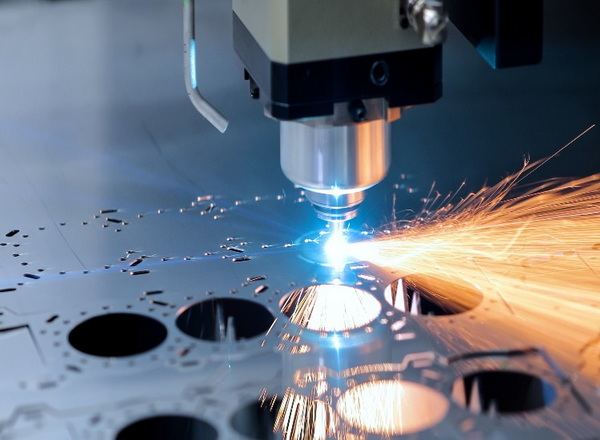

Comparing CNC Machining with 3D printing helps clarify cost perception. 3D printing usually has minimal setup cost and excels at one‑off or highly complex internal geometries. However, for simple shapes and moderate volumes, CNC Machining can be faster, with better surface finish and higher material performance.

When the geometry is straightforward and the batch is more than just a handful of parts, CNC Machining often wins on both cost and lead time. Conversely, when complexity is extreme and volume is tiny, additive manufacturing may be the cheaper option. Evaluating both technologies for each project ensures the best balance between cost and performance.

Injection molding is another key benchmark when discussing whether CNC Machining is expensive. Molding requires substantial upfront investment in steel or aluminum molds, which only makes sense at higher part volumes. The per‑piece price of injection‑molded parts becomes very low once the mold is paid off and millions of cycles are possible.

CNC Machining takes the opposite approach: low upfront cost but higher per‑piece machining cost. For low to medium volumes, this makes CNC Machining far more economical than building a mold. Even at higher volumes, when total tooling cost is considered and design changes are likely, CNC Machining remains attractive because it avoids the risk of freezing the design too early in a hard tool.

Regional labor and overhead differences strongly influence CNC Machining pricing. Shops in high‑wage countries often have higher hourly rates than those in lower‑cost regions. However, they may balance this with advanced automation, strict quality systems, and shorter domestic shipping times.

Chinese CNC Machining suppliers, for example, frequently combine competitive labor rates with modern equipment and integrated services such as turning, sheet metal, 3D printing, and mold building. For overseas OEM buyers, the resulting CNC Machining prices can be significantly lower than domestic alternatives, even after adding transport and customs costs. Evaluating suppliers globally rather than locally can therefore change the perception of how expensive CNC Machining really is.

Design for manufacturability (DFM) is one of the most powerful levers for reducing CNC Machining cost. Small changes in geometry can generate large savings:

- Increasing internal radii to match common tool sizes reduces tool stress and machining time.

- Avoiding extremely deep pockets or very thin walls makes CNC Machining more stable and predictable.

- Grouping features on fewer faces can cut down on setups and fixturing complexity.

- Relaxing tolerances on non‑critical surfaces allows faster cutting parameters and fewer inspections.

When engineers collaborate with CNC Machining suppliers early in the design phase, they can identify such opportunities before drawings are frozen. This partnership can convert a “too expensive” CNC Machining quote into a competitive one without losing essential functionality.

Volume has a strong impact on how CNC Machining costs behave over time. First prototypes may appear expensive, but once the program is proven and fixtures are validated, the same CNC Machining setup can produce stable, repeatable batches. As volumes grow, fixed costs such as programming and setup are spread over more parts, and the unit price falls.

From a long‑term perspective, consistent CNC Machining quality also reduces hidden costs such as assembly rework, field failures, and warranty claims. A slightly higher CNC Machining unit price that delivers reliable precision may be cheaper overall than a lower‑priced method that introduces variability and downstream issues.

OEM buyers and engineers can adopt several practical strategies to keep CNC Machining costs under control:

- Consolidate orders into larger batches to dilute setup and programming cost per part.

- Standardize materials and finishes across multiple part numbers to simplify CNC Machining processes.

- Use common hole sizes, threads, and radii to match standard tools and reduce tool changes.

- Clearly separate critical dimensions from non‑critical ones so the machining process can focus precision where it matters most.

- Engage with the CNC Machining supplier early for DFM feedback instead of presenting a locked design.

Applied consistently, these practices can transform CNC Machining from an apparently expensive option into a lean, competitive manufacturing solution.

Whether CNC Machining is expensive cannot be answered with a simple yes or no. The cost of CNC Machining is the sum of machine time, labor, material, tooling, setup, and overhead, all shaped by part design, tolerance, and production volume. In many cases, CNC Machining provides excellent value by combining precision, flexibility, and reasonable lead times without requiring heavy tooling investment.

When compared with 3D printing and injection molding, CNC Machining is often the most economical choice for functional prototypes, small to medium production runs, and high‑precision components. Smart design decisions, good volume planning, and collaboration with a capable CNC Machining supplier can dramatically lower costs and improve project outcomes. For OEM buyers, the key is not to ask only whether CNC Machining is expensive, but to evaluate how effectively CNC Machining transforms engineering ideas into reliable, repeatable products at a sustainable total cost.

CNC Machining prices vary because each supplier has a different mix of machine types, labor rates, overhead costs, and automation levels. Some shops also include engineering support, material sourcing, and inspection services in their quotes, while others charge separately, so unit prices are not always directly comparable.

No. For simple geometries and moderate quantities, CNC Machining is often less expensive than 3D printing because machining cycles are fast and materials like aluminum and steel are cost‑efficient. 3D printing tends to be more competitive only when parts are extremely complex, highly customized, and produced in very low volumes.

Injection molding becomes cheaper than CNC Machining once the total cost of the mold is spread over a large number of parts, typically hundreds or thousands depending on size and complexity. Before that volume is reached, CNC Machining usually offers lower total cost and greater flexibility because it avoids high upfront tooling.

To reduce cost, review the design with your CNC Machining supplier and look for ways to simplify geometry, relax tolerances where possible, and align features with standard tool sizes. Increasing batch size and choosing more machinable materials can also lower CNC Machining cycle time and tool wear, improving price per part.

CNC Machining can be suitable for long‑term mass production when parts require tight tolerances, flexible design updates, or materials that are difficult to process by other methods. For extremely high volumes with stable designs, processes like injection molding, die casting, or stamping may offer lower unit cost, but CNC Machining remains valuable for high‑precision cores, inserts, and variants.

content is empty!

Top Metal CNC Machining Manufacturers and Suppliers in Lithuania

Top Metal CNC Machining Manufacturers and Suppliers in Czech Republic

Top Metal CNC Machining Manufacturers and Suppliers in Hungary

Top Metal CNC Machining Manufacturers and Suppliers in Denmark

Top Metal CNC Machining Manufacturers and Suppliers in Ireland