Content Menu

● Understanding CNC Machining Risks

● Typical Hazards in CNC Machining

● How Dangerous Are CNC Machining Accidents?

● Built-In Safety Features of Modern CNC Machines

● The Role of PPE in CNC Machining

● Safe Work Practices Around CNC Machining

● Automation and Risk Reduction in CNC Machining

● Safety Culture in CNC Machining Shops

● CNC Machining and Project Risk for Buyers

● Practical Tips for Safer CNC Machining Operations

● Is CNC Machining Dangerous for Everyday Production?

● FAQ

>> (1) Can CNC Machining be safely used for high-volume production?

>> (2) What is the biggest cause of CNC Machining accidents?

>> (3) How can a new operator learn to use CNC Machining safely?

>> (4) Is CNC Machining safer than traditional manual machining?

>> (5) What should buyers check to confirm that a CNC Machining supplier is safe?

CNC Machining is a powerful, precise, and highly repeatable manufacturing technology, but like all industrial equipment, it presents real risks if it is used without proper training or safety controls. When machines, people, and procedures are managed correctly, CNC Machining becomes a safe and reliable process for both rapid prototyping and mass production.

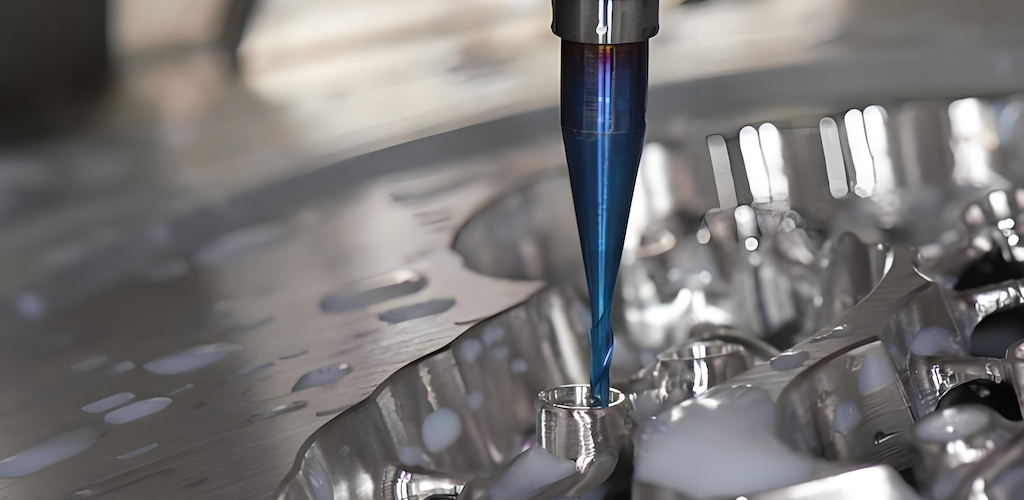

CNC Machining uses high-speed rotating tools, fast-moving axes, and strong clamping forces to remove material and create complex geometries. These elements mean that any direct contact between the operator and moving components can be dangerous. At the same time, modern CNC Machining centers are designed to keep operators separated from these hazard zones during normal operation.

Instead of manual control at the cutting interface, CNC Machining relies on programmed motion inside a fully or partially enclosed workspace. This enclosure, combined with interlocks, sensors, and automation, allows factories to produce precise CNC Machining parts while minimizing human exposure to rotating tools, hot chips, and high-pressure coolant.

CNC Machining risk can be grouped into several categories: mechanical hazards, projectiles, electrical hazards, and health-related exposure to coolants, fumes, dust, and noise. Mechanical hazards relate to the moving spindle, cutting tools, rotating bar stock, chucks, and fixtures. If guards are bypassed or doors are open during operation, there is a risk of entanglement, crushing, or impact.

Another major CNC Machining hazard is flying debris. Metal and plastic chips are ejected at high velocity, and in rare cases a poorly clamped part can be thrown from the workholding. Electrical hazards arise from the high-voltage systems that power CNC Machining drives and spindles. Health hazards include skin and respiratory irritation from coolant mists, fumes, and fine particulate, especially in enclosed CNC Machining environments without proper extraction.

The severity of CNC Machining accidents can be high, but the frequency is relatively low in professional, well-managed shops. Most serious incidents happen when safety procedures are ignored or when operators attempt to intervene too closely while a CNC Machining cycle is running or just finishing. Typical examples include reaching into the machine before it has fully stopped, defeating door interlocks, wearing loose clothing, or mishandling long bar stock and heavy fixtures.

Near-miss events often occur during setup and prove-out, when CNC Machining programs are still being adjusted and when offsets, tools, and workholding may not be fully validated. Crashes between tools and fixtures or the machine table are dangerous, expensive, and can send fragments flying. The best CNC Machining practice is to treat the setup and dry-run phase with the same discipline as full production, using reduced feed rates and additional verification.

Modern CNC Machining centers are engineered with layered safety features to eliminate or minimize exposure to hazards. The most visible element is the full enclosure: doors, windows, and panels that keep operators physically separated from chips, coolant, and spinning tools. These enclosures are usually fitted with door interlocks, so the CNC Machining spindle and axes cannot run at normal cutting speed when the doors are open.

Emergency stop circuits allow operators to quickly halt all motion and rotation if something unexpected occurs. Overload sensors and torque monitoring can detect abnormal loads and automatically stop CNC Machining before major mechanical damage or tool breakage happens. Many machines incorporate chip conveyors and coolant management systems, which keep most debris inside the enclosure and reduce manual handling.

In automated CNC Machining cells, additional guarding may include safety fences, light curtains, and safety-rated scanners around robots and pallet systems. These systems ensure that if a human enters the hazard zone unexpectedly, the CNC Machining cell will shut down safely.

Personal protective equipment (PPE) is the final barrier between people and the hazards that cannot be completely engineered out of CNC Machining. Eye protection is essential: safety glasses or goggles protect against stray chips and splashes whenever the operator is near the machine, even if the doors are closed most of the time. Face shields may be used for high-risk tasks like manual deburring or air-blowing parts.

Hearing protection is recommended in loud CNC Machining environments, where spindle noise, chip impact, and auxiliary equipment create sustained sound levels above safe limits. Cut-resistant gloves are commonly used for handling sharp stock and finished CNC Machining parts but must be removed before working near rotating tools to avoid entanglement. Safety footwear with reinforced toes protects against dropped parts, fixtures, and tools on the shop floor. Close-fitting clothing, tied hair, and removal of jewelry further reduce the chance of snagging on CNC Machining equipment.

Equipment design and PPE alone do not guarantee safety; disciplined work practices are just as important. Before running a CNC Machining job, operators should perform pre-start checks: confirming that guards and doors are intact, interlocks work, cutting tools are properly clamped, workholding is secure, and coolant and lubrication systems function normally.

During setup and prove-out, it is good practice to run CNC Machining programs at reduced feeds with the door closed, watching through the window to verify clearances and tool paths. A clean, organized work area reduces trip hazards and prevents accidental contact with sharp parts or exposed tools. Operators should never bypass interlocks, jam objects into door switches, or run CNC Machining with the door open simply to save a few seconds.

For maintenance, strict lockout/tagout procedures are critical. Power must be isolated and verified before any work is done on electrical components or moving mechanisms inside the CNC Machining envelope. Clear communication, written procedures, and regular safety training help standardize these practices across all shifts.

Automation has become a key enabler of both productivity and safety in CNC Machining. By adding robots, automatic pallet changers, gantry loaders, and part feeders, operators spend less time directly interacting with open machines. They can focus on setup, programming, inspection, and supervision outside the hazard zone while automation performs the repetitive loading and unloading.

This approach reduces ergonomic risks such as lifting heavy parts repeatedly, minimizes exposure to hot chips and coolant, and cuts down on the time operators spend near moving axes and spindles. In a well-designed automated CNC Machining cell, the danger area is tightly fenced or enclosed, and opening a gate or crossing a safety sensor immediately stops operation. This means one trained operator can safely supervise several CNC Machining centers rather than standing next to a single open machine.

Beyond physical technology, the safety level of CNC Machining depends heavily on the culture inside the factory. A strong safety culture is visible in small details: clean floors, labeled walkways, clear signage, organized tooling, and consistent PPE use. Operators are trained to recognize CNC Machining hazards, encouraged to report near-misses, and empowered to stop work if they see unsafe conditions.

Management support is crucial. Regular audits, toolbox talks, and continuous improvement programs keep CNC Machining risks in focus. Investing in updated guards, better extraction systems, and training shows that safety is treated as a long-term asset, not as a cost. New employees are onboarded through structured CNC Machining training programs rather than informal, ad hoc instruction.

For overseas buyers and brand owners, the core question is not whether the machines themselves are dangerous, but whether their suppliers manage CNC Machining risk effectively. A supplier with a strong safety record is more likely to have stable processes, lower downtime, better equipment condition, and higher-quality output.

Safe, well-controlled CNC Machining operations reduce the chance of late deliveries caused by machine damage or unplanned shutdowns. They also tend to correlate with better maintenance, calibration, and process discipline, which directly influence tolerances, surface finish, and long-term repeatability. When evaluating a CNC Machining partner, buyers can look for certifications, documented procedures, and evidence of continuous training and improvement.

Factories that want to strengthen their safety performance around CNC Machining can focus on a few practical steps:

- Standardize written setup and pre-start checklists so every CNC Machining job begins with the same checks.

- Implement mandatory dry runs and safe feeds for new or modified CNC Machining programs.

- Use visual management such as color-coded areas, warning labels, and clear instructions on each machine.

- Schedule regular preventive maintenance on CNC Machining equipment, focusing on guards, interlocks, coolant systems, and emergency stops.

- Track incidents and near-misses to identify recurring CNC Machining safety issues and address root causes.

These changes not only protect people but also stabilize quality and productivity, which directly benefits customers relying on CNC Machining services.

In a modern, well-managed workshop, CNC Machining operates more like a contained, automated process than a manually controlled cutting station. Operators spend most of their time programming, loading, unloading, and inspecting parts, rather than standing in front of exposed tools. This means that for everyday production, CNC Machining is not unreasonably dangerous as long as equipment, training, and procedures are up to date.

The real danger appears when shortcuts are taken: when people override interlocks, skip training, ignore PPE rules, or keep running CNC Machining equipment that is visibly damaged. When these behaviors are eliminated through leadership and culture, CNC Machining becomes an efficient, predictable, and acceptably safe technology for high-precision manufacturing.

CNC Machining is a high-energy industrial process that, by its nature, involves real mechanical, electrical, and health hazards. However, with modern enclosures, interlocks, emergency systems, PPE, automation, and disciplined procedures, these hazards can be effectively controlled. In professional OEM factories, CNC Machining is treated as a tightly managed process rather than an open, manually controlled operation.

For buyers and engineers, CNC Machining should be viewed not as an unmanageable danger, but as a stable, repeatable, and safe way to produce complex parts when the right supplier is chosen. By partnering with a factory that invests in safety culture, training, and modern equipment, companies can enjoy the advantages of CNC Machining—precision, speed, and scalability—while keeping physical risks at an acceptable minimum.

Yes. With proper guarding, automation, and standardized procedures, CNC Machining is very suitable for high-volume production. Automated loading and unloading keep operators outside hazard zones, while consistent programming and monitoring maintain both safety and quality during long runs.

The most common root cause is human error, often linked to bypassing safety systems, rushing setup, or not following procedures. When operators skip checks, override interlocks, or work close to moving tools, the built-in protections of CNC Machining cannot function as intended.

A new operator should start with structured training that covers machine controls, basic programming concepts, hazard recognition, PPE, and emergency actions. This is followed by supervised hands-on practice, where the operator gradually takes responsibility for setups and CNC Machining cycles under guidance from experienced staff.

In many cases, yes. Manual machines expose operators directly to rotating tools and workpieces, while CNC Machining typically runs inside enclosed, interlocked guards. As long as operators respect these barriers and avoid bypassing them, CNC Machining provides a safer environment for producing complex parts.

Buyers can look for clean, organized workshops, consistent PPE use, intact guards and doors, and clear safety signage on and around CNC Machining centers. They can also ask about training programs, maintenance schedules, and any certifications or documented safety procedures that demonstrate a systematic approach to risk management.

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal