Views: 222 Author: Amanda Publish Time: 2025-12-11 Origin: Site

Content Menu

● Understanding Blue‑Collar Work Today

● What CNC Machining Actually Involves

● Why CNC Machining Is Still Blue Collar

● How CNC Machining Goes Beyond Traditional Labor

● The Role of CNC Operators, Machinists and Programmers

● CNC Machining in the Context of OEM Manufacturing

● CNC Machining and Industry 4.0

● Automation, Robotics and CNC Machining

● The Skills That Make CNC Machining a High‑Value Trade

● Education and Training Pathways

● Career Growth in CNC Machining

● CNC Machining vs. Office‑Based White‑Collar Work

● The Idea of “New Collar” for CNC Machining

● Why CNC Machining Matters for Global Supply Chains

● Is CNC Machining Right for Modern Workers?

● FAQ

>> 1. Is CNC machining really a blue‑collar job?

>> 2. Do CNC machinists need strong computer skills?

>> 3. Is CNC machining a good long‑term career?

>> 4. How is CNC machining changing with automation and robotics?

>> 5. Can a CNC machinist move into engineering or management roles?

CNC machining sits firmly within the world of industrial production and skilled trades, so in most labor statistics and industry discussions it is treated as a blue‑collar occupation. The people who run CNC machining centers work directly with materials, machines and measuring tools to deliver real parts that go into finished products.

At the same time, CNC Machining is not a simple, repetitive form of labor. It requires understanding G‑code, feeds and speeds, cutting conditions, workholding strategies, and quality control methods that demand serious training and ongoing learning. This makes CNC machining a modern, technology‑intensive form of blue‑collar work that is very different from many people's stereotypes.

Traditionally, blue‑collar jobs were linked with manual labor, physical tasks and industrial environments such as factories, construction sites and workshops. Workers in these roles often wore practical clothing and safety gear, which led to the “blue‑collar” name.

Today, the picture has changed. Many blue‑collar workers operate advanced machinery, interpret technical information and interact with digital systems every day. Skilled trades like CNC machining, welding, tool‑and‑die making and industrial maintenance are now recognized as critical to high‑value manufacturing, not just basic labor.

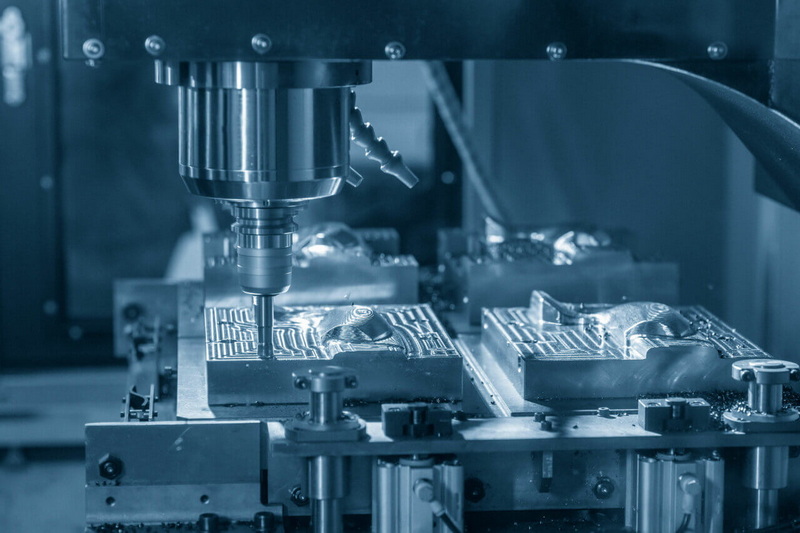

CNC machining, or Computer Numerical Control machining, is a process where pre‑programmed software controls the movement of tools and equipment to cut, drill, mill and turn raw material into precise components. Operators and machinists must read engineering drawings, set up workpieces, choose correct tools and verify results.

In a modern CNC machining environment, the work covers a spectrum of tasks: preparing fixtures, loading material, zeroing work coordinates, fine‑tuning offsets, checking surface finishes and dimensions, and reacting quickly if a tool chips or a dimension drifts. The combination of practical hands‑on work and digital control is what defines the job.

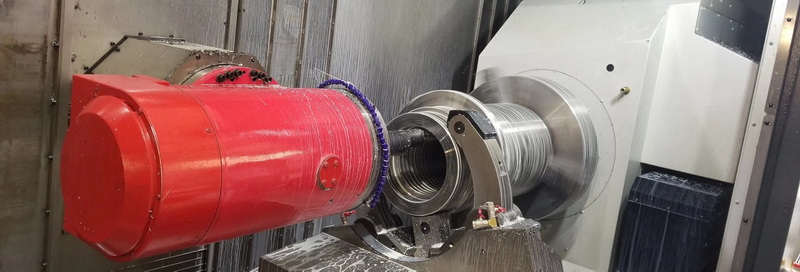

Even though CNC machining is high‑tech, it remains blue‑collar because the central mission is to produce parts in an industrial setting. The shop floor is full of machining centers, lathes, mills, grinders, inspection stations and support equipment, not desks and cubicles.

CNC machinists work in environments with machine noise, coolant mist, metal chips and strict safety rules. They wear protective shoes, safety glasses and often hearing protection. These conditions, along with the physical nature of setting up machines and handling material, keep CNC machining firmly in the blue‑collar category.

Where CNC machining clearly moves beyond the old idea of “manual labor” is in its technical depth. Machinists must understand:

- Cutting tool materials, coatings and geometries

- How different metals and plastics behave under cutting forces

- The relationship between spindle speed, feed rate, depth of cut and surface finish

- Tolerances, fits, geometric dimensioning and tolerancing concepts

A CNC machinist is constantly making judgments: whether to reduce feed to avoid chatter, how to adjust coolant for chip evacuation, or when to change a worn tool before it ruins a part. These decisions rely on knowledge and experience, not just physical effort.

In many factories, CNC machining work is divided into levels of responsibility:

- CNC operators may primarily run existing programs, load parts, press cycle start, and carry out basic checks.

- CNC machinists handle setups, dial in workholding, adjust tool offsets, troubleshoot problems and make minor program edits.

- CNC programmers or manufacturing engineers build toolpaths in CAD/CAM software, simulate operations, and optimize sequences for throughput and tool life.

While the entire chain is still anchored in production, the upper levels begin to look more like white‑collar technical roles because they involve computer‑based work, process planning and coordination with design teams.

For an OEM‑focused factory that offers CNC machining, rapid prototyping, precision batch production, lathe turning, sheet metal fabrication, 3D printing and mold manufacturing, CNC machining is the backbone of many projects. It converts 3D models and drawings from overseas brands, wholesalers and producers into accurate, repeatable physical parts.

This kind of environment demands consistent quality, fast turnaround and tight collaboration between CNC machining teams, quality engineers and project managers. Blue‑collar CNC machinists are directly responsible for whether a critical aerospace bracket meets tolerance or whether a medical housing has the correct surface finish for downstream coating.

Industry 4.0 links CNC machining centers with networks, sensors and software to create smart production systems. Machines can be connected to central monitoring dashboards, where spindle loads, tool wear indicators and cycle times are tracked in real time.

In such a system, CNC machining becomes part of a digital ecosystem. Programs are stored in centralized databases, updates are pushed wirelessly, and process data is logged for future optimization. Machinists and operators still work on the shop floor, but their work is informed by data, and they often collaborate with engineers or analysts to improve efficiency.

Automation is transforming CNC machining cells with pallet changers, bar feeders, gantry loaders and robotic arms for handling parts. These solutions reduce idle time, allow machines to run longer unattended, and can raise output without necessarily increasing headcount.

However, automation does not remove the need for skilled CNC machinists. Instead, it shifts their responsibilities toward tasks such as:

- Configuring automated loading systems

- Ensuring programs and probing routines are robust

- Diagnosing faults between the robot and the CNC machining center

- Planning how to combine multiple operations efficiently in one cell

So CNC machining stays blue collar, but becomes more about mastering systems, not just single machines.

Strong CNC machining professionals typically combine several types of skills:

- Technical: understanding of CNC controls, tool libraries, offsets, canned cycles and probing routines

- Analytical: ability to interpret inspection data, identify root causes of defects, and propose process improvements

- Practical: hands‑on competence with machine setup, workholding, tool changes and routine maintenance

- Communication: working with design, engineering and quality teams to clarify requirements and resolve issues

Because of this mix, CNC machining is often regarded as one of the more demanding and respected blue‑collar trades.

People enter CNC machining through different routes, including vocational schools, apprenticeships, company training programs and sometimes self‑study backed by hands‑on practice. Many training paths combine theory in classroom settings with long periods of supervised work on real machines.

Once in the trade, CNC machining professionals keep learning about new cutting tools, machine models, control systems and materials. As a factory adopts multi‑axis CNC machining, high‑speed machining strategies, or new probing technologies, workers need to update their skills to use the new capabilities effectively.

CNC machining offers multiple career ladders. A person might start as an operator, move up to machinist, then to lead machinist or team leader, and later into roles such as programmer, process engineer, production planner or shop supervisor.

With deep CNC machining experience and understanding of customer requirements, some professionals step into project management, sales engineering or technical support. Even in these roles, their credibility often comes from years spent on the shop floor solving real machining problems.

Compared with white‑collar office jobs, CNC machining usually involves more physical presence on the shop floor, more direct contact with physical materials, and tighter integration with production schedules and machine availability. The work is tied to shifts and machine runtime, not just meetings and emails.

On the other hand, CNC machining can offer a more immediate sense of accomplishment, because every day's work produces something concrete: parts that fit, assemblies that function, prototypes that help clients validate designs. For many people, this hands‑on impact is a major advantage over purely digital or paperwork‑driven roles.

Some observers use the term “new collar” to describe jobs like CNC machining that blend blue‑collar environments with white‑collar technology. The idea highlights how crucial technical literacy and problem‑solving have become, even in roles built around physical production.

CNC machining is a textbook example: it uses sophisticated machine tools, advanced control systems, high‑precision measuring equipment and often integrates with CAD/CAM, 3D printing and digital quality systems. Yet the job is still rooted in the daily reality of cutting metal and ensuring parts meet exact specifications.

In global OEM supply chains, CNC machining is often where design intent meets manufacturing reality. Engineers may specify a part with tight tolerances and complex geometry, but it is CNC machining that determines whether the part can be made repeatably at the required cost and lead time.

Factories that provide CNC machining, rapid prototyping, precision batch production, lathe machining, sheet metal work, 3D printing and mold manufacturing become strategic partners for their clients. The quality of their CNC machining directly affects the reliability of the end products and the reputation of the brands they serve.

For people who enjoy both technology and tangible results, CNC machining can be a strong fit. The role offers exposure to automation, digital controls and advanced tools, while still letting workers see and touch the components they create.

CNC machining also rewards curiosity and continuous improvement. Those who are willing to learn new techniques, investigate cutting problems, and propose better setups often progress quickly into more responsible positions. In a world where many jobs feel abstract, CNC machining provides clear feedback in the form of finished parts and satisfied customers.

CNC machining is, in formal terms, a blue‑collar profession: it takes place in workshops and factories, centers on operating and maintaining machines, and directly produces physical components. Yet it is simultaneously a high‑tech, high‑skill trade that demands deep technical understanding, digital literacy and strong problem‑solving abilities.

As automation, robotics and Industry 4.0 technologies spread, CNC machining is becoming even more central to advanced manufacturing. Rather than replacing machinists, these tools amplify their capabilities and shift their work toward higher‑value tasks like setup, optimization and integration across processes such as rapid prototyping, batch production, turning, sheet metal fabrication, 3D printing and mold making. In this sense, CNC machining represents the future of blue‑collar work: smart, skilled and essential to global OEM supply chains.

Yes, CNC machining is generally categorized as a blue‑collar job because it is performed in industrial environments and focuses on operating machinery to produce physical parts. At the same time, it is a skilled trade that requires significant technical knowledge, so it stands apart from low‑skill manual labor.

Modern CNC machinists benefit from solid computer skills because they interact with digital controls, may edit programs, and often work with data from measuring equipment or production monitoring systems. Familiarity with CAD/CAM software, file management and basic troubleshooting of control interfaces can significantly enhance their effectiveness.

CNC machining is a strong long‑term career choice because precise, repeatable machining remains essential in industries such as aerospace, automotive, medical devices, robotics and energy. As companies invest in more advanced equipment, they need experienced CNC machining professionals to set up, run and optimize those machines.

Automation and robotics are taking over repetitive tasks like loading and unloading parts, but they also create demand for machinists who can configure, monitor and maintain automated CNC machining cells. The work becomes more focused on setup, process planning, quality control and system‑level problem‑solving rather than simple button‑pushing.

Yes, many CNC machinists transition into roles such as CNC programmer, process engineer, production supervisor or even project manager and technical sales. Their practical CNC machining experience gives them valuable insight into what is feasible on the shop floor, which helps them make better decisions in planning, engineering and customer‑facing positions.

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal