Views: 222 Author: Amanda Publish Time: 2025-12-11 Origin: Site

Content Menu

● What “Dying Trade” Really Means

● Market Outlook: Growth, Not Decline

● Why CNC Machining Still Matters

● CNC Machining vs 3D Printing

● Hybrid Workflows: CNC Machining with Additive

● Automation, Cobots, and Smart CNC Shops

● Digitalization and Data‑Driven CNC Machining

● Trends Shaping the Future of CNC Machining

● CNC Machining and Supply Chain Resilience

● The Role of CNC Machining in High‑Value Industries

● Skills Evolution: From Machine Operator to CNC Technologist

● Education, Training, and Upskilling in CNC Machining

● When CNC Machining Is the Best Choice

● CNC Machining Across the Product Lifecycle

● Integrated Manufacturing: CNC Machining with Other Processes

● Quality Assurance in CNC Machining

● Sustainability and CNC Machining

● Opportunity for Global CNC Machining Service Providers

● FAQs

>> 1. Is CNC Machining really declining as a career?

>> 2. Will 3D printing completely replace CNC Machining?

>> 3. How is automation affecting CNC Machining jobs?

>> 4. Which industries still rely heavily on CNC Machining?

>> 5. Is it still worth investing in CNC Machining equipment?

CNC Machining is not a dying trade; it is evolving into a more automated, digital, and high‑value technology at the heart of modern manufacturing. Far from disappearing, the global CNC machine market is projected to keep growing strongly over the next decade, driven by demand from automotive, aerospace, medical, electronics, and other high‑precision industries.

When people ask whether CNC Machining is a dying trade, they usually mean one of three things: shrinking demand, declining wages, or disappearing career paths. In reality, CNC Machining is experiencing skill shortages rather than a lack of work, as many experienced machinists retire and too few young people enter the field.

At the same time, companies continue to invest in new CNC Machining centers, automation, and digital tools instead of abandoning the technology. For overseas OEM brands, wholesalers, and product manufacturers, this means CNC Machining remains a strategic capability, not an obsolete one.

Global and regional data show that CNC Machining is in a growth phase, not a collapse. The worldwide CNC machine and machine tool market is forecast to increase steadily in value, supported by investments in smarter, more energy‑efficient CNC Machining equipment.

In the United States and other major manufacturing regions, the CNC Machining market is expected to expand over the coming decade, confirming long‑term demand for capacity and expertise. Behind these numbers is sustained investment across industries that depend on CNC Machining for tight tolerances, repeatability, and certified quality.

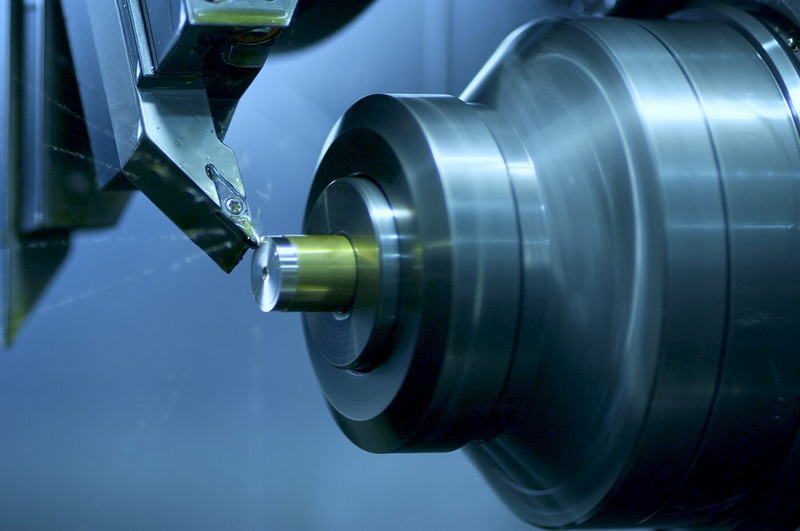

CNC Machining occupies a unique position among manufacturing technologies because it combines precision, versatility, and scalability. Compared with many other processes, CNC Machining routinely offers tighter tolerances and superior surface finishes, which are essential in high‑performance mechanical assemblies.

CNC Machining also supports a wide range of metals and engineering plastics, making it suitable for both prototypes and mass‑production parts. For applications like powertrain components, structural brackets, medical implants, valve bodies, and aerospace fittings, CNC Machining remains the preferred solution.

One key reason people worry about CNC Machining is the rapid rise of additive manufacturing. However, the relationship between 3D printing and CNC Machining is complementary rather than purely competitive in many real production workflows.

3D printing is ideal for rapid prototypes, complex internal channels, and small batch parts where design changes happen frequently. CNC Machining excels at final‑grade precision, durability, and surface quality, especially when parts must be made from strong metals or engineering plastics and held to demanding tolerances.

In practice, more factories now combine 3D printing and CNC Machining in hybrid workflows instead of choosing only one technology. Additive manufacturing can quickly build near‑net‑shape parts, and then CNC Machining brings them into tight tolerance and finishes critical surfaces.

This combined approach reduces waste and lead time compared with machining everything from solid stock, while still leveraging the accuracy and consistency of CNC Machining for the final dimensions. As a result, engineers and production teams who understand both 3D printing and CNC Machining are in a strong position to support modern product development.

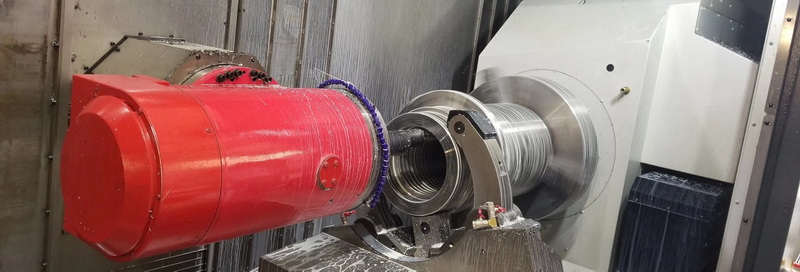

Modern CNC Machining is increasingly automated, which changes the skills required but does not eliminate the trade. Machine tending with collaborative robots allows CNC Machining centers to run longer hours with fewer interruptions, improving utilization and reducing labor‑intensive loading and unloading tasks.

These collaborative systems are becoming more intelligent and easier to program, making automation accessible even for small and mid‑sized CNC Machining shops. At the same time, probing systems, pallet changers, automatic tool changers, and in‑process measurement are transforming how CNC Machining cells operate on the shop floor.

Digital twins, machine connectivity, and data analytics are entering CNC Machining environments as part of the wider Industry 4.0 movement. Digital twins can simulate tool paths, tooling choices, and fixture strategies before implementation, helping optimize CNC Machining cycles and minimize downtime.

Connected CNC Machining cells use live data to track spindle hours, tool wear, scrap rates, and quality metrics. This information feeds into preventive maintenance, continuous improvement, and better quoting, making CNC Machining more predictable and competitive for both local and global customers.

Several technology and market trends are clearly shaping the future of CNC Machining rather than signaling its end. Multi‑axis and high‑speed CNC Machining systems are being adopted more widely because they reduce setups, improve flexibility, and allow more complex components to be machined in a single clamping.

Tooling technology is also advancing, with better coatings, carbide grades, and tool geometries enabling faster cutting and longer tool life in CNC Machining. Together with advanced CAM software, this allows programmers to use high‑efficiency strategies such as trochoidal milling and dynamic toolpaths to get more value from every CNC Machining center.

Recent years have shown how fragile global supply chains can be, which directly affects how companies use CNC Machining. Nearshoring and regionalized production are becoming more important, with many manufacturers seeking localized CNC Machining partners to shorten lead times and reduce logistics risk.

On‑demand capacity in CNC Machining helps absorb demand spikes and minimizes exposure to shipping delays and geopolitical uncertainty. Manufacturers increasingly value CNC Machining suppliers who can respond quickly with rapid prototyping, short‑run builds, and scalable batch production without sacrificing quality.

CNC Machining continues to be critical in sectors where failure is not an option. In aerospace and defense, CNC Machining produces structural components, mounts, brackets, and housings with rigorous material traceability and inspection documentation.

In medical and healthcare, CNC Machining is used for surgical instruments, implant components, and diagnostic equipment where biocompatibility, smooth surfaces, and tight tolerances are mandatory. In automotive and e‑mobility, CNC Machining supports powertrain parts, battery enclosures, cooling plates, and custom fixtures for assembly lines.

Although CNC Machining is not dying, the profile of a successful CNC professional is changing. Traditional manual programming and basic machine operation are gradually giving way to hybrid roles that combine CNC Machining knowledge with CAD/CAM skills, automation setup, and process optimization.

Employers now look for CNC Machining talent that can interpret 3D models, choose appropriate machining strategies, and collaborate with robotics or measuring systems. As automation handles more repetitive tasks, human specialists in CNC Machining focus on fixture design, multi‑axis path planning, process improvement, and advanced quality control.

To keep pace with technology, technical schools and training centers are updating their programs to include more advanced CNC Machining content. Students learn not only G‑code and basic setup but also CAM programming, simulation, and integration with digital quality systems.

For working machinists and programmers, continuous learning has become a core part of the profession. Online courses, in‑house training, and certification programs help CNC Machining personnel stay current on tooling innovations, new control features, and best practices for high‑speed, multi‑axis, and automated CNC Machining.

Even as other technologies advance, there are many situations where CNC Machining remains the best or only practical option. For high‑volume production of metal parts that must meet strict tolerances and withstand demanding environments, CNC Machining routinely provides the reliability and unit cost that manufacturers need.

CNC Machining is particularly strong in these areas:

- Precision housings and enclosures that must seal, align bearings, or interface with other precision assemblies.

- Shafts, gears, and mechanical components where concentricity, surface finish, and fatigue strength are critical.

- Tooling, fixtures, and molds that need hardened steel, complex surfaces, and long‑term durability under load.

In each of these cases, CNC Machining delivers predictable performance and traceability that many alternative processes still struggle to match.

For many OEMs and product developers, CNC Machining is a bridge between early prototypes and full‑scale production. During early design stages, CNC Machining allows engineers to validate parts in the actual production materials, which is essential for mechanical testing and functional verification.

As products move toward launch, CNC Machining supports pilot runs, engineering validation builds, and low‑volume production, often in parallel with tooling development. Once molds or casting tools are ready, CNC Machining remains important for secondary operations, precision finishing, and features that cannot be produced accurately by forming processes alone.

Modern factories increasingly combine CNC Machining with a range of other capabilities to serve global OEM customers. When CNC Machining is integrated with rapid prototyping, sheet metal fabrication, 3D printing, and mold production, a single facility can support the entire product journey from concept to mass production.

In this integrated model, CNC Machining plays several roles: creating functional prototypes, producing precision inserts and mold components, machining metal parts that complement sheet metal structures, and finishing printed or cast parts. This makes CNC Machining a central pillar in flexible, multi‑process manufacturing.

Quality expectations for CNC Machining have grown as parts become more complex and industries more regulated. Coordinate measuring machines, optical inspection, surface roughness testing, and in‑machine probing are now common tools connected to CNC Machining workflows.

By combining robust process control with detailed inspection plans, CNC Machining suppliers can maintain consistent quality across prototypes, small batches, and large production runs. Digital records of measurements and material certificates increase trust for overseas OEM customers sourcing CNC Machining parts from global partners.

Sustainability is increasingly important in manufacturing, and CNC Machining is adapting through better process planning and smart material use. Advanced CAM strategies and optimized fixturing can reduce cycle times, energy consumption, and scrap rates in CNC Machining.

Recycling programs for metal chips and coolant, combined with more efficient machines and careful process selection, help reduce the environmental footprint of CNC Machining operations. When CNC Machining is part of a well‑designed workflow, it can support both technical performance and sustainability goals for demanding products.

For international OEM customers seeking reliable manufacturing partners, modern CNC Machining service providers can offer a complete package. By combining CNC Machining with rapid prototyping, sheet metal fabrication, 3D printing, and mold production, a single factory can support everything from one‑off concept models to precision batch production and long‑term OEM supply.

Because the CNC Machining market is growing and becoming more sophisticated, buyers increasingly look for partners who can deliver stable quality, flexible order quantities, and strong engineering support. Factories that invest in multi‑axis CNC Machining, automation, digital inspection, and responsive communication are well positioned to serve overseas brand owners, wholesalers, and manufacturers who need dependable OEM solutions.

CNC Machining is not a dying trade; it is a core pillar of advanced manufacturing that is being reshaped by automation, digitalization, and integration with other technologies. Market forecasts, technology trends, and real‑world factory practices all indicate that CNC Machining will remain essential for high‑precision components, demanding materials, and mission‑critical applications across many industries.

Rather than disappearing, CNC Machining is evolving into a more strategic, skill‑intensive, and globally connected discipline. Companies and professionals who embrace multi‑axis CNC Machining, automated handling, digital quality systems, and hybrid workflows with additive manufacturing will continue to find strong demand, attractive projects, and long‑term opportunities in this important field.

CNC Machining is not broadly declining as a career; demand for skilled CNC professionals remains strong in many manufacturing regions. In fact, many shops report difficulty finding qualified CNC Machining operators and programmers, especially those familiar with automation, multi‑axis systems, and modern CAM software.

3D printing will not completely replace CNC Machining because the two technologies serve different but complementary roles. Additive manufacturing is excellent for complex, lightweight designs and rapid changes, while CNC Machining is usually the best choice for tight tolerances, critical surfaces, and mass‑produced metal components.

Automation is changing CNC Machining jobs by shifting human work away from manual loading and repetitive tasks toward programming, setup, optimization, and quality control. This creates new opportunities for CNC Machining professionals who are comfortable with robots, sensors, and data analysis, and who can design efficient automated processes.

Industries such as automotive, aerospace, defense, medical devices, electronics, industrial equipment, and energy still rely heavily on CNC Machining. These sectors need precise, certified, and durable parts, and CNC Machining offers the combination of accuracy, repeatability, and material flexibility they require for critical components.

It is still worth investing in CNC Machining equipment, especially when combined with automation, CAD/CAM integration, and complementary technologies like 3D printing. Modern CNC Machining centers with multi‑axis capability and high‑speed spindles can deliver excellent productivity, help win high‑value contracts, and support long‑term growth in global manufacturing markets.

content is empty!

Top Metal CNC Machining Manufacturers and Suppliers in Netherlands

Top Metal CNC Machining Manufacturers and Suppliers in Poland

Top Metal CNC Machining Manufacturers and Suppliers in Vietnam

Top Metal CNC Machining Manufacturers and Suppliers in Japan

Top Metal CNC Machining Manufacturers and Suppliers in Italy

Top Metal CNC Machining Manufacturers and Suppliers in Germany

Top Metal CNC Machining Manufacturers and Suppliers in Russia

Top Metal CNC Machining Manufacturers and Suppliers in Portugal

Top Metal CNC Machining Manufacturers and Suppliers in Spain

Top Metal CNC Machining Manufacturers and Suppliers in France