Views: 222 Author: Amanda Publish Time: 2025-11-01 Origin: Site

Content Menu

● Fundamentals of the two processes

>> What is Injection Moulding?

>> What is Compression Moulding?

● Materials and compatibility in moulding production

● Design implications for moulding production

● Process performance and throughput

● Design strategy: when to choose each

● Materials science and performance considerations

● Design for multi-process manufacturing

● Industry applications and case considerations

● Process optimization and quality assurance in moulding production

● Choosing the right path for your project: a practical framework

● FAQ

>> 2. How do cycle times compare between the two processes in practice?

>> 3. What materials are most compatible with each process?

>> 4. When is tooling cost a critical consideration in decision making?

>> 5. Can these processes be used together in a single product?

In the world of moulding production, making the right process choice directly influences design freedom, cost, lead times, and the ability to scale from prototyping to full-scale manufacturing. For international brand owners, distributors, and manufacturers seeking a reliable OEM partner, understanding the core differences between injection moulding and compression moulding—and knowing when to apply each—can unlock faster time to market, better part performance, and optimized total cost of ownership. Shangchen (SC-rapidmanufacturing.com) specializes in rapid prototyping and end-to-end production, including injection moulding and compression moulding, along with CNC machining, sheet metal fabrication, 3D printing, and mould production. This article provides a practical framework to decide which moulding route best fits your project, with design-for-manufacturability insights, process specifics, and real-world considerations across volume, materials, and quality requirements.

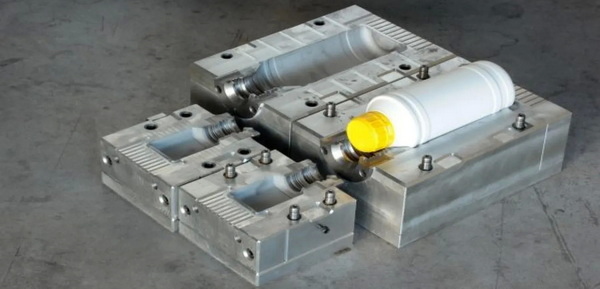

Injection moulding is a high-volume, automated process that melts thermoplastic or thermoset polymers and injects them under high pressure into a cooled mold cavity. The molten material rapidly fills intricate cavities, and after cooling and solidifying, the part is ejected. The process is renowned for repeatability, tight tolerances, excellent surface finishes, and the ability to produce complex geometries with thin walls. In moulding production, this makes injection moulding ideal for large quantities of parts with consistent quality, high surface integrity, and features such as fine ribs, undercuts, and detailed textures. The tooling investment is substantial, but the per-part cost declines with volume, making it the go-to choice for long-run production programs. Typical materials include rigid thermoplastics, reinforced polymers, and certain thermosets that cure in the mold. Careful design decisions—gate location, wall thickness, draft angles, and rib geometry—are crucial to optimize cycle time and mold life.

Compression moulding employs pre-formed material, often thermosets, elastomers, or composites, placed into a heated mold that is then closed under pressure to cure. The material undergoes curing and cross-linking within the mold, producing parts with strong adhesion between filler materials and matrices. This method excels for large, relatively simple geometries, elastomeric components (such as silicone and rubber parts), and composite panels (SMC/BMC) where long fiber or filler content is advantageous. Tooling costs are typically lower than for injection moulding, and the ramp-up to production can be faster for mid- to low-volume programs. However, compression moulding may present limits in achieving ultra-precise tolerances for complex features and may require secondary operations for surface finishes or post-curing in some cases.

- Cycle time: Injection moulding often achieves seconds-per-part cycles at scale; compression moulding cycles can be minutes due to curing.

- Tooling costs: Higher upfront tooling investments for injection moulding; lower tooling costs for compression moulding.

- Part complexity: Injection moulding supports highly complex geometries and fine features; compression moulding handles simpler geometries and larger panels well.

- Materials: Injection moulding covers a broad range of thermoplastics and thermosets; compression moulding is especially strong with thermosets, elastomers, silicones, and certain composites.

- Post-processing: Both may require finishing steps, but injection moulding frequently enables more immediate automation and reduced post-processing in high-volume runs.

- Injection moulding materials offer broad compatibility, including filled/rigid polymers and thermoplastic elastomers, with opportunities for color and finish customization.

- Compression moulding is well-suited for silicone, rubber, elastomeric compounds, and composite matrices; it supports SMC/BMC forms and is commonly used for larger, simpler panels or seals and gaskets.

- The material choice influences tool longevity, cycle stability, and final part properties (stiffness, heat resistance, chemical resistance), which must align with end-use requirements.

- For injection moulding, design-for-manufacturability emphasizes uniform wall thickness to minimize sink, appropriate draft angles to facilitate ejection, robust rib and boss geometries, optimized gate locations, and attention to parting lines to minimize flash and post-processing.

- For compression moulding, designs favor predictable cure behavior, appropriate venting to prevent trapped air, consistent wall features to avoid uneven shrinkage, and material-compatible fillers and reinforcement strategies. Simplified geometries often translate to lower tolerance demands and faster material flow into the mold.

- Injection moulding is highly automated, with robotic part handling, gas-assisted or hot runner options, and high-speed cycles tuned by process engineers in a moulding production environment.

- Compression moulding relies on controlled curing cycles and may involve manual loading/unloading in some setups, although modern presses also feature automation for material insertion and part extraction. The automation level affects throughput, labor costs, and consistency across batches.

- If part complexity, tight tolerances, and very high-volume production are primary, injection moulding typically delivers the best long-term cost efficiency and part quality.

- If parts are large, elastomeric or thermoset, or if tooling costs and ramp-up speed are prioritized for mid- to low-volume runs, compression moulding can be the more economical and practical option.

- For hybrid strategies, consider co-designs that allow insert molding, overmolding, or sequential processes to optimize performance and cost, leveraging the strengths of both approaches within a single product family.

- Thermoplastics used in injection moulding provide excellent toughness, impact resistance, and dimensional stability, with post-consumer recycling considerations often favorable for certain polymers.

- Thermosets and elastomers used in compression moulding offer superior chemical resistance, heat resistance, and elastomeric properties, with good dimensional stability in larger panel geometries.

- For some applications, multi-material assemblies or functional coatings integrated within the moulding production line can enhance performance while minimizing assembly steps.

- Hybrid approaches enable features that accommodate both processes; engineered inserts can be pre-attached, and overmolded components can join plastics with elastomeric seals or metal parts to meet complex performance targets.

- A well-planned design lifecycle includes early prototyping (3D-printed or machined models) to validate fit, form, and function before committing to full-scale tooling, reducing risk and accelerating the development timeline within moulding production.

- Consumer electronics and appliance housings demand intricate features, consistent color, and tight tolerances at scale—areas where injection moulding shines and where high-volume moulding production efficiencies can be realized.

- Automotive components benefit from strength-to-weight optimization, precise mating features, and durable finishes, where the choice between moulding processes depends on geometry, load paths, and environmental exposure.

- Medical devices require stringent cleanliness, biocompatibility, and regulatory considerations; both processes can be leveraged with appropriate materials and process controls to meet quality standards.

- Industrial machinery parts often require large, robust panels or seals where compression moulding offers efficient production for elastomeric or composite components.

- Process validation, SPC (statistical process control), and rigorous dimensional inspection underpin quality in both processes.

- Mould maintenance, tool life management, and energy efficiency strategies contribute to lower total cost of ownership and higher yield over time.

- Traceability, material certification, and robust testing regimes ensure compliance with customer specifications and regulatory requirements in global supply chains.

- Part geometry and tolerances: Complex, tight tolerances favor injection moulding; simple, large panels or elastomeric parts favor compression moulding.

- Volume forecast: High-volume programs justify the upfront tooling and automation of injection moulding; mid- to low-volume programs may prefer early compression moulding or hybrid strategies to minimize tooling investment.

- Material compatibility: Assess the material's performance, temperature resistance, and long-term stability within the chosen process.

- Lead times and supply chain: If rapid ramp-up is essential, compression moulding or hybrid prototyping pathways can reduce time to first production run.

- Total cost of ownership: Weigh tooling costs, cycle times, labor, scrap rates, and maintenance over the product's lifecycle.

Both injection moulding and compression moulding bring distinct strengths to moulding production. Injection moulding is typically the best fit for high-volume, feature-rich parts requiring tight tolerances and sophisticated surfaces, supported by strong automation and relatively low per-part costs at scale. Compression moulding, by contrast, shines for larger, simpler geometries, elastomeric or thermoset materials, and mid- to low-volume programs where tooling costs, lead times, and flexibility matter most. A disciplined design-for-manufacturing approach, combined with early prototyping and a clear material and cost strategy, enables the most efficient path from concept to high-volume production. For brands and manufacturers seeking a reliable, integrated OEM partner, Shangchen offers a cohesive suite of services—from rapid prototyping and mould production to full-scale moulding production and post-processing—delivering quality, consistency, and speed across diverse applications.

- Answer: Part geometry, required tolerances, material type, volume forecast, and post-processing needs drive the choice; injection moulding excels with complex features and high-volume runs, while compression moulding suits simpler geometries, elastomeric materials, and lower tooling costs. The decision should align with long-term production goals and total cost of ownership.

- Answer: Injection moulding cycles are typically measured in seconds per part at scale due to rapid filling and cooling, while compression moulding cycles are usually longer, often minutes, because cure time and warm-up contribute to overall throughput.

- Answer: Injection moulding supports a broad range of thermoplastics and certain thermosets, including reinforced variants; compression moulding is especially strong with thermosets, elastomers, silicone, and certain composites (SMC/BMC).

- Answer: Tooling costs dominate early in the product life cycle for injection moulding, particularly for high-volume programs; compression moulding offers lower tooling costs and faster ramp-up, benefiting smaller or mid-volume projects.

- Answer: Yes, hybrid approaches exist (inserts, overmolding, multi-material assemblies) to optimize performance and cost; early prototyping and design verification help validate integrated approaches within moulding production.

[1](https://www.xometry.com/resources/injection-molding/injection-molding-vs-compression-molding/)

[2](https://xometry.eu/en/injection-moulding-vs-compression-moulding/)

[3](https://xometry.pro/en/articles/injection-molding-vs-compression-molding/)

[4](https://www.fictiv.com/articles/compression-molding-versus-injection-molding)

[5](https://www.youtube.com/watch?v=w_ET0ykA8mg)

[6](https://www.rcoeng.com/blog/compression-molding-vs-injection-molding)

[7](https://www.husky.co/en/resources/blog/injectionvscompression/)

[8](https://reliantplastics.com/blog/injection-molding/compression-molding-vs-injection-molding/)

[9](https://sacmi.com/en-US/compression-molding-vs-injection-molding-for-caps-manufacturing)

[10](https://www.rapiddirect.com/blog/compression-molding-vs-injection-molding/)

content is empty!

Top On Demand 3D Printing Manufacturers and Suppliers in Japan

Top On Demand 3D Printing Manufacturers and Suppliers in Italy

Top On Demand 3D Printing Manufacturers and Suppliers in Germany

Top On Demand 3D Printing Manufacturers and Suppliers in Russia

Top On Demand 3D Printing Manufacturers and Suppliers in Portugal

Top On Demand 3D Printing Manufacturers and Suppliers in Spain

Top On Demand 3D Printing Manufacturers and Suppliers in France

Top CNC Turning Manufacturers and Suppliers in Czech Republic