Views: 222 Author: Amanda Publish Time: 2025-10-09 Origin: Site

Content Menu

● Understanding Moulding Production

● Injection Molding vs. Blow Molding

● Injection Molding vs. Compression Molding

● Injection Molding vs. Transfer Molding

● Materials Suitable for Injection Molding

● Mold Production and Tooling in Injection Molding

● Advantages of Injection Molding

● Disadvantages of Injection Molding

● Applications of Injection Molding

● Comparing Injection Molding with Other Molding Techniques

>> Injection Molding vs. Extrusion Molding

>> Injection Molding vs. Rotational Molding

>> Injection Molding vs. Thermoforming

● Frequently Asked Questions (FAQ)

>> 1. What is the main difference between injection molding and general molding production?

>> 2. Can injection molding produce hollow parts like blow molding?

>> 3. Is injection molding cost-effective for small batch production?

>> 4. What materials are commonly used in injection molding?

>> 5. How fast is injection molding compared to other molding processes?

In the manufacturing world, molding processes are central to producing plastic components with precision and efficiency. Among these,injection molding stands as a premier method known for producing complex plastic parts rapidly and with high accuracy. However, it is just one of many molding techniques encompassed in the broader category known as Moulding Production, which includes methods such as blow molding, compression molding, transfer molding, and more.

This article explores the nuances between Injection Molding and other molding production processes, highlighting their differences, advantages, limitations, and ideal applications. It is designed for manufacturers, product designers, brand owners, and OEM service providers seeking to understand how best to leverage each technique to meet specific production needs.

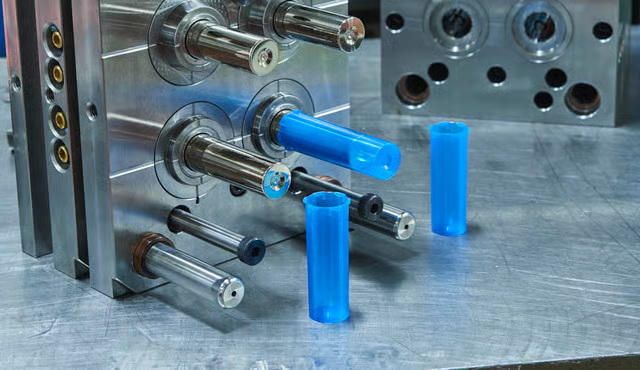

Injection Molding is a manufacturing process that involves injecting molten plastic into a mold cavity at very high pressure. The plastic cools and solidifies inside the mold, and the finished part is ejected once the mold opens. This method is widely used for mass production because it supports high precision, intricate designs, and rapid cycle times.

Materials typically used in injection molding include thermoplastics, thermosets, and thermoplastic elastomers. The molds themselves are engineered from durable materials like hardened steel or aluminum to withstand the stresses of high-pressure injection and repeated use. These molds often contain sophisticated cooling channels to hasten solidification and maintain part quality.

Injection Molding stands out for its ability to produce consistent, complex parts with great surface finish and minimal post-processing.

Moulding Production refers broadly to any manufacturing process that shapes raw materials—usually plastics or rubbers—inside a mold to create a desired form. It includes a variety of techniques:

- Injection Molding: High-pressure injection of molten plastic into molds.

- Blow Molding: Producing hollow, thin-walled items by inflating heated plastic.

- Compression Molding: Compressing a heated material charge inside a mold.

- Transfer Molding: Transferring material from a heated chamber into a mold.

- Vacuum Casting: Using vacuum to pull liquid resin into molds, usually for prototypes.

Each molding method varies in tooling complexity, material compatibility, production speed, volume suitability, and cost.

Blow molding specializes in creating hollow plastic parts such as bottles and containers by inflating a soft plastic parison inside a mold cavity.

Key distinctions include:

- Injection Molding produces solid, intricate parts with high precision.

- Blow Molding specializes in hollow, thin-walled items.

- Injection molds are generally more expensive and complex due to the need for tight tolerances and intricate cooling.

- Blow molding molds are simpler but geared toward hollow shapes.

- Injection Molding supports a more extensive variety of materials, including some thermosets and composite-filled plastics.

Injection Molding is preferred for engineering-grade components requiring strength and fine detail, whereas blow molding excels in packaging and container production.[5]

Compression Molding involves placing a measured amount of pliable material in an open mold, which is then closed and heated to form the part. It's commonly used for rubber, silicone, and composite materials.

Differences include:

- Injection Molding is highly automated, ideal for high-volume production, with fast cycle times (seconds).

- Compression Molding suits medium-volume production and larger or thicker parts but has slower cycles (minutes).

- Injection Molding molds are costly and complex; compression molding tooling is generally cheaper.

- Injection molding works well with thermoplastics, thermosets, and thermoplastic elastomers; compression molding is better for elastomers and composites.

- Compression molding frequently requires manual intervention for loading and unloading, whereas injection molding is automated.

Injection Molding produces complex, small to medium parts with speed and consistency. Compression molding handles thicker, more flexible parts that do not need tight dimensional control.[1][2]

In Transfer Molding, material is heated in a chamber and pushed into a closed mold, often used with thermoset plastics and rubbers.

Compared to injection molding:

- Injection Molding injects molten plastic directly into mold cavities at high pressure.

- Transfer Molding involves moving the preheated material from a pot, which adds time.

- Injection Molding is faster and better for large-scale, precise production.

- Transfer Molding offers lower setup costs and suits intricate rubber parts in smaller volumes.

- Waste (flash) is typically higher in transfer molding due to channels and overflow grooves.

Thus, while injection molding is preferred for complex, high-precision parts, transfer molding remains relevant for specific thermosetting applications or small batch runs.[4]

Injection Molding accommodates a wide variety of materials, including:

- Thermoplastics: Polypropylene, ABS, Polycarbonate, Polyethylene, among others.

- Thermosets: Epoxy, phenolic resins.

- Thermoplastic Elastomers: Flexible, rubber-like plastics.

- Specialty composites: Metal-filled or fiber-filled plastics for enhanced mechanical properties.

This vast material flexibility makes Injection Molding suitable for automotive parts, consumer electronics, medical devices, packaging, and many other industries.[2][11]

Tooling is a critical component of Injection Molding. Molds are precision-engineered tools typically made using CNC machining and electrical discharge machining (EDM) to achieve very tight tolerances.

Molds consist of multiple parts such as cores and cavities, designed to form the shape of the final product. Cooling channels inside the mold regulate the temperature to ensure rapid and even solidification, reducing cycle times and improving part quality.

Due to the high injection pressures, molds must be made from durable materials—often hardened steel—to withstand repeated usage without wear. Although mold production can be expensive and time-intensive, the ability to produce millions of consistent parts justifies this upfront investment.

Injection Molding offers numerous advantages:

- High-Speed Production: Cycle times range from a few seconds to under a minute, ideal for mass production.

- Complex Part Geometries: Multi-cavity molds with intricate designs are possible.

- Material Variety: Supports many plastics, including composites.

- Surface Finish: Excellent finishes, often eliminating post-processing.

- Automation: Low labor costs and high repeatability.

- Dimensional Accuracy: Extremely tight tolerances ensure consistency.

While powerful, Injection Molding has limitations:

- High Initial Cost: Tooling and mold fabrication are costly.

- Design Constraints: Large or very thin parts may not be economically feasible.

- Material Restrictions: Some flexible materials perform better in other molding types.

- Setup Complexity: Requires skilled designers and engineers for mold and process optimization.

- Post-Processing: Some parts need trimming or secondary operations.

Injection Molding is used across diverse industries, including:

- Automotive: Dashboard components, bumpers, engine covers.

- Medical: Syringes, labware, surgical instruments.

- Electronics: Housings for phones, remote controls.

- Consumer Goods: Toys, containers, household appliances.

- Packaging: Caps, closures, specialized containers.

Its ability to produce precise, functional parts consistently makes it indispensable for OEM manufacturing globally.

While Injection Molding shapes discrete parts by molding them in cavities, extrusion molding forms continuous profiles by pushing material through a die, producing long lengths of uniform cross-section such as pipes and sheets. Injection molding provides better part complexity, while extrusion excels at continuous shapes.

Rotational molding is ideal for large, hollow parts but requires long cycle times (hours) and is suited for low-volume production. Injection molding is much faster and more suited for high-volume, detailed parts.

Thermoforming heats plastic sheets which are then shaped over molds. This process is simpler and cheaper but less precise than injection molding. Thermoforming suits low- to medium-volume production while injection molding caters to high volumes with complex designs.

Injection Molding is a versatile, high-precision manufacturing process optimized for high-volume production of complex plastic parts. It differs fundamentally from other molding methods within the broader category of Moulding Production in terms of tooling, materials, speed, cost, and part geometry capabilities.

While Injection Molding demands significant upfront tooling investment, its advantages in cycle time, automation, and product consistency make it ideal for large-scale manufacturing and OEM applications. Understanding its nuances compared to blow molding, compression molding, transfer molding, and other methods enables manufacturers and product developers to choose the optimal process suited to product requirements, volume, and budget.

Injection Molding refers specifically to forcing molten plastic into mold cavities under high pressure to create precise, intricate parts. Moulding Production is a broader term encompassing various molding techniques that shape material inside molds using different principles and processes.[12]

Injection Molding typically produces solid parts and is unsuitable for hollow thin-walled products like bottles, which are better manufactured using blow molding due to their design and production method.[5]

Due to high tooling costs and setup time, injection molding is more cost-effective for medium to large production volumes. For small runs, alternative methods like compression molding or vacuum casting may be more economical.[11][2]

A diverse range of thermoplastics, thermosets, thermoplastic elastomers, and composite materials can be used, making injection molding adaptable across many applications.[2]

Injection Molding features rapid cycle times often just a few seconds to under a minute, much faster than compression or transfer molding, which may take minutes or longer per cycle.[1][4]

[1](https://xometry.pro/en/articles/injection-molding-vs-compression-molding/)

[2](https://www.xometry.com/resources/injection-molding/injection-molding-vs-compression-molding/)

[3](https://firstmold.com/tips/injection-molding-vs-extrusion-molding/)

[4](https://www.rapiddirect.com/blog/injection-molding-vs-transfer-molding/)

[5](https://www.xometry.com/resources/injection-molding/blow-molding-vs-injection-molding/)

[6](https://richfieldsplastics.com/blog/injection-molding-vs-rotational-molding/)

[7](https://ims-tex.com/comparing-plastic-manufacturing-techniques/)

[8](https://prototool.com/die-casting-vs-injection-molding/)

[9](https://rimnetics.com/blog/reaction-injection-molding-vs-sheet-metal-production/)

[10](https://www.productiveplastics.com/injection-molding-vs-thermoforming/)

[11](https://xometry.pro/en/articles/vacuum-casting-vs-injection-molding/)

[12](https://www.reddit.com/r/engineering/comments/j09gux/whats_the_difference_between_injection_moulding/)

content is empty!

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes

Best Practices from Leading Vacuum Mold Casting Companies Worldwide

Top Vacuum Mold Casting Providers for Custom Batch Production

How to Choose the Right Vacuum Mold Casting Service for Your Product