Views: 222 Author: Amanda Publish Time: 2025-10-21 Origin: Site

Content Menu

● Understanding Vacuum Mold Casting

● Why Vacuum Mold Casting Produces Superior Surface Finish

>> Exact Replication of Mold Details

>> Enhanced Mechanical Properties

● Materials Used in Vacuum Mold Casting

● Applications Across Industries

>> OEM Services

>> Consumer Products and Electronics

● Optimizing Vacuum Mold Casting for Best Results

>> Mold Quality

● Common Challenges and How to Overcome Them

● Innovations in Vacuum Mold Casting

● Frequently Asked Questions (FAQ)

>> 1. What types of materials can be used in vacuum mold casting?

>> 2. How does vacuum mold casting compare to 3D printing?

>> 3. Can vacuum mold casting be used for large parts?

>> 4. How long does the casting process take?

>> 5. Is vacuum mold casting environmentally friendly?

Vacuum mold casting is a cutting-edge technique widely used in rapid prototyping and small-scale manufacturing industries. It offers unparalleled surface finish and precision details that are often difficult to achieve with other casting methods. This article explores the principles behind Vacuum Mold Casting, its advantages in achieving superior finishes, and practical applications that make it a preferred choice for OEM service providers and manufacturers.

Vacuum mold casting is a process where liquid silicone molds are used to replicate prototypes or low-volume parts by employing a vacuum to eliminate air bubbles and imperfections. This technique involves placing the molding material into a vacuum chamber, where the air is evacuated to prevent bubbles and ensure the material flows into every fine detail of the mold.

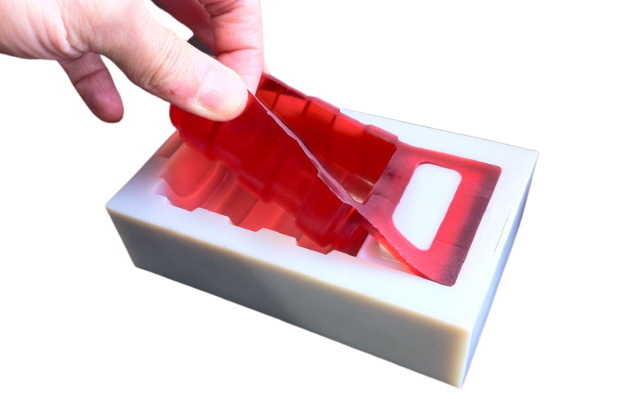

The process begins with creating a master model, which can be produced through 3D printing, CNC machining, or hand-crafted methods. This master model acts as the template for silicone mold production. The silicone mold is flexible and able to capture the finest surface features and crisp details due to its elastic nature.

During casting, polyurethane resin or other materials are mixed and poured into the mold. The mold is sealed inside a vacuum chamber where the air is sucked out, creating a vacuum that draws the resin deep into the mold's intricate features. This ensures minimal air entrapment, reducing defects, and producing a flawless finish.

One of the main causes of surface imperfections in casting is trapped air bubbles. Vacuum mold casting's vacuum environment pulls these air bubbles out before the resin cures, leading to a smooth, clean surface free from pits or voids.

The vacuum suction forces the liquid material to conform exactly to the mold, capturing every minute detail including surface textures, sharp edges, and fine geometries. This precision is especially important for parts that demand visual realism or functional surface features.

Since air bubbles and contaminants are minimized, the curing resin hardens uniformly. This reduces the need for sanding, polishing, or other post-processing operations to achieve a desirable finish, saving both time and costs.

Eliminating voids not only improves aesthetic quality but also enhances the mechanical strength and durability of the cast parts by preventing weak points formed by bubbles.

Vacuum mold casting commonly employs polyurethane resins, which are favored for their ease of use, fast curing times, and variety of available grades ranging from flexible to rigid. Other materials such as silicone rubber and epoxy can also be used depending on required properties like heat resistance or transparency.

Manufacturers often select materials based on desired color, hardness, flexibility, and purpose of the final part. Some cast parts require FDA or biocompatibility certifications for medical applications, which influences resin choice as well.

Vacuum mold casting is extensively used to develop prototypes with near-production quality appearance and function. Its ability to produce highly detailed parts with excellent surface finishes accelerates product design cycles and validation.

When production runs are limited, vacuum mold casting offers an economical alternative to injection molding, which requires expensive tooling. This makes it ideal for startups, custom orders, or specialty parts.

For brand owners and manufacturers, vacuum mold casting enables flexible scaling and customization of parts without heavy upfront costs. Its high accuracy ensures parts meet stringent specifications necessary for OEM suppliers.

The precision achievable enables creation of highly detailed anatomical models, surgical guides, and dental appliances that assist healthcare professionals.

The smooth surface finish and fine detail replication support production of cosmetic housings, wearable devices, and other consumer goods demanding aesthetic quality.

The quality of silicone molds fundamentally impacts the final cast parts. High-grade silicone with proper curing provides durable molds capable of producing dozens or hundreds of consistent parts while preserving fidelity to the master model.

Optimizing vacuum pressure and degassing time is critical. Insufficient vacuum can leave bubbles, while excessive vacuum can introduce problems such as mold damage or premature resin curing.

Maintaining appropriate temperatures during casting and curing affects resin flow and polymerization. Controlled environments help avoid warping or shrinking issues.

Proper mixing ratios and thorough blending of resin components ensure chemical consistency and improved mechanical performance. Automated dispensers or mixers are often used to standardize this step.

Although vacuum cast parts generally require minimal finishing, light sanding, polishing, or painting may be applied to enhance appearance or meet final use criteria.

Even with vacuum, improper mold design or pouring methods can cause microbubbles. Solutions include slow pouring, angled molds, and multiple vacuum cycles.

Repeated casting can degrade silicone molds, leading to loss of detail. Selecting durable materials and mold maintenance practices extend mold life.

Not all resins behave well in vacuum casting. Choosing compatible materials that do not emit gases during curing helps maintain quality.

Vacuum mold casting is better suited for smaller components due to mold handling and equipment size constraints. For large parts, other methods may be preferred.

Technological advancements are enhancing vacuum mold casting capabilities. New high-strength silicone formulations offer longer mold life. Automated casting systems improve consistency and throughput. Integration with digital workflows enables rapid iteration from CAD files to vacuum molded parts.

Researchers are exploring bio-based resins and recyclable materials to improve the environmental footprint of vacuum casting processes as sustainability becomes a priority.

Vacuum mold casting is a powerful and versatile manufacturing process that excels in producing parts with superior surface finish and intricate detail. By harnessing a vacuum environment, this method eliminates air bubbles, ensuring the liquid resin flows thoroughly into molds and faithfully replicates the master model's fine features.

Its advantages extend beyond aesthetics; vacuum mold casting enhances mechanical properties, reduces material waste, and shortens production cycles. These benefits make it an ideal choice for rapid prototyping, OEM manufacturing, medical applications, and low-volume production runs.

As innovations continue to refine materials and techniques, vacuum mold casting remains a cornerstone technology for companies seeking high-quality, cost-effective solutions that do not compromise on detail or finish.

Vacuum mold casting primarily uses polyurethane resins but can also include silicone rubber, epoxy, and other thermosetting materials depending on the desired flexibility, durability, and appearance of the final part.

Vacuum mold casting generally produces parts with smoother surfaces and better mechanical strength, especially when replicating molds with fine detail. In contrast, 3D printing offers rapid production of complex geometries without tooling but may require additional finishing.

Typically, vacuum mold casting is best suited for small to medium-sized parts because of mold size limitations and vacuum chamber capacity. Large parts may require alternative manufacturing methods.

From mold preparation to demolding, the casting and curing process usually takes several hours, allowing for fast turnaround in prototyping and small batch production.

Vacuum mold casting reduces waste by optimizing resin use and can utilize eco-friendly materials. However, its environmental impact depends on resin choices and disposal practices.

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal