Views: 222 Author: Amanda Publish Time: 2025-11-05 Origin: Site

Content Menu

● Major Moulding Production Problems

>> Flow Lines

>> Sink Marks

>> Weld Lines

>> Short Shots

>> Flash

>> Splay Marks

>> Warping

>> Jetting

>> Burn Marks

● Systematic Troubleshooting Approach

>> Step 2: Machine and Process Review

>> Step 3: Material Quality Control

>> Step 5: Simulation and Digital Twin Analysis

>> Step 6: Real-Time Monitoring and Automated QC

● Innovations and Best Practices in Moulding Production

● Troubleshooting in Special Processes

>> Rotational Moulding Troubleshooting

>> Liquid Silicone Rubber (LSR) Moulding

● Quality Control and Continuous Improvement

● Troubleshooting Examples from Real Manufacturing

>> Example: Reducing Sink Marks in Large Automotive Parts

>> Example: Flash at Parting Line During Sporting Goods Production

>> Example: Burn Marks in Electronic Casings

● FAQ

>> 1. Why do weld lines occur in moulding production?

>> 2. How can sink marks be prevented in moulding production?

>> 3. What methods solve short-shot defects?

>> 4. How does simulation software benefit troubleshooting?

>> 5. What is the value of automated QC systems in moulding production?

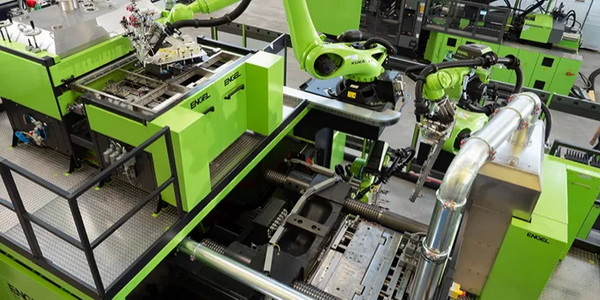

Moulding production is central to precision manufacturing across industries, enabling the creation of consistent, high-quality components for everything from automotive parts to sophisticated electronics. Rapid prototyping, CNC machining, 3D printing, and precision batch manufacturing all rely heavily on optimal moulding processes to realize creative designs and stringent tolerances. As such, troubleshooting common issues in moulding production is an essential part of ensuring efficient workflows, minimizing cost, and enhancing quality for OEM partners worldwide.[10]

Flow lines present as streaks or color variations, highlighting inconsistencies in how molten material fills the mould cavity. Common near mould gates or wall thickness transitions, their presence impacts both aesthetics and structural integrity.

- Main causes: Inadequate injection speed, low pressure, insufficient mould temperature.

- Key solutions: Increase injection speed/pressure, raise melt and mould temperature, redesign gates for smoother flow.[10]

Sink marks are depressions in thicker part sections due to uneven cooling or insufficient packing. This leads to cosmetic flaws and potential weak spots.

- Main causes: Unbalanced wall thickness, short packing phase, poor cooling system.

- Key solutions: Uniform wall thickness, extend packing time/pressure, improve cooling channel layout.[10]

Weld lines (knit lines) occur where two flow fronts meet but fail to bond, creating both cosmetic and strength concerns.

- Main causes: Low injection speeds, poor venting, inefficient gate locations.

- Key solutions: Increase injection speed/temperature, add proper venting, refine gate/part design.[4][10]

Short shots arise when the cavity is not fully filled, resulting in missing sections or incomplete parts.

- Main causes: Low shot size, insufficient injection pressure, thin or blocked gates.

- Key solutions: Adjust shot size, increase injection pressure, optimize gate design and ensure proper heating.[4][10]

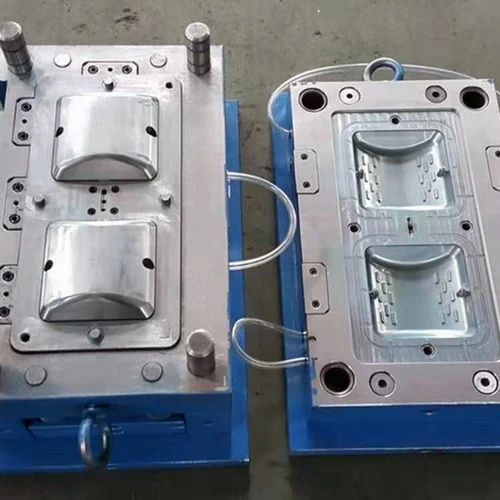

Flash is the excess material leaking at the mould parting line, caused by weak clamping, misalignment, or worn tooling.

- Main causes: Low clamp force, misaligned mould, damaged edges.

- Key solutions: Increase clamp force, align mould halves, regular maintenance of mould surfaces.[4][10]

Splay marks (“silver streaks”) are typically created by moisture, contamination in the resin, or overly rapid injection speeds.

- Main causes: Wet resin, high speed, foreign particles.

- Key solutions: Dry resin before use, improve material handling, adjust injection speed.[10]

Delamination is where surface layers separate or peel, from contamination or incompatible blends.

- Main causes: Incompatible materials, dirty resin, unsuitable blends.

- Key solutions: Clean and pre-dry resin, use compatible materials, ensure clean processing environment.[10]

Warping indicates parts that bend after cooling due to internal stresses or uneven heat management.

- Main causes: Uneven cooling, inconsistent wall thickness, temperature fluctuations.

- Key solutions: Uniform wall thickness, optimize cooling channels, control cooling cycle.[5][10]

Jetting (“snake-like streaks”) happens when material enters cavities at excessive speed, hitting surfaces too rapidly.

- Main causes: Excess injection speed, poor gate location/design.

- Key solutions: Reduce injection speed, reposition gates, refine temperature settings.[10]

These are pockets of trapped air inside a part, undermining appearance and strength.

- Main causes: Poor mould venting, improper injection speed, complex part design.

- Key solutions: Add/optimize vents, adjust injection speed, redesign to smooth fill path.[4][10]

Discoloration diminishes clarity or uniformity, often indicating material degradation or contamination.

- Main causes: Overheated resin, contaminants, colorant issues.

- Key solutions: Monitor resin temperature, filter and purify feedstock, use higher-grade colorants.[10]

Burn marks are dark areas due to trapped gases or overheating during fill.

- Main causes: High injection speed, inadequate venting, excessive melt temperature.

- Key solutions: Lower speed, enhance venting, reduce melt temperature.[4]

Begin with close visual checks for obvious issues such as flash, flow lines, packing depressions, or color variation.[10]

Verify process parameters—pressure settings, injection speed, material temperature, and shot size. Compare machine setup with resin and part design specifications.[10]

Monitor resin for moisture, degradation, or unwanted blends. Ensure proper storage, drying, and purification steps to improve part reliability.[10]

Inspect moulds for cleanliness, wear, or damage. Regularly clean vent channels and verify alignment to prevent defects.[10]

Leverage CAE simulation to predict fill patterns, heat distribution, and cooling profiles. This technology helps troubleshoot problems before a batch is run.[10]

Integrate vision systems and sensors for real-time defect detection and analytics. Rapid feedback enables immediate process corrections and consistent product quality.[10]

- 3D Printing for Prototyping: Use additive methods for rapid prototype moulds, enabling pre-commercial design verification and fast troubleshooting.[10]

- Digital Twins & Simulation: Apply simulation software to optimize process parameters and reduce errors prior to physical production.[10]

- Regular Training: Continuous education for technicians in defect identification, root cause analysis, and cutting-edge troubleshooting techniques.[10]

- Collaborative Quality Systems: Facilitate seamless feedback between design, production, QC, and customer teams to address real-world issues efficiently.[5][10]

- Automated Data Collection: Use high-frequency data logging to track, analyze, and mitigate process variation, supporting continuous process improvement.[10]

Rotational moulding requires careful control of material type, heating, and cooling. Common problems include incomplete filling, warping, bubbling, and burning:

- Incomplete filling: Use more resin, optimize heating, review mould design.

- Warping: Balance temperature and cooling rates; optimize design and materials.

- Bubbling: Improve venting, cooling, and material selection.

- Burning: Avoid overheating, use appropriate materials, and closely monitor process temperature.[5]

LSR-specific problems include under-filled parts, mold flashing, bubbles, and poor adhesion:

- Short shots: Increase injection speed/pressure, ensure proper meter-mix.

- Mold flashing: Check parting lines, increase clamp force, adjust injection speed.

- Bubbles: Improve venting, add vacuum, monitor material quality.[6]

Robust quality control (QC) systems are essential for reliably high production standards:

- Inspect raw material for moisture, contamination, and correct type/grade.[10]

- Maintain moulds and machinery at optimal conditions; clean regularly, calibrate clamp forces, and inspect vent channels.[10]

- Track process parameters, incorporate QC automation for defect detection, and maintain records for traceability and improvement initiatives.[5][10]

In a recent automotive batch, significant sink marks appeared. Through simulation analysis, cooling channel redesign, and extended packing pressure, QC teams eliminated sink defects and ensured batch consistency.[10]

Recurring flash was reported in sports equipment manufacturing. Process engineers realigned mould halves, raised clamp force, and polished edges, resulting in a defect-free production run.[4][10]

Burn marks marred electronic device shells due to high injection speed and poor venting. After lowering melt temperature and adding vent channels, part quality improved dramatically.[4][10]

Troubleshooting moulding production issues is vital in maintaining seamless workflows and quality batch manufacturing for OEM customers. From visual inspection to simulation, regular maintenance to automated QC, manufacturers must blend technology and expertise to proactively resolve defects. By applying systematic analysis and leveraging innovations like 3D printing and real-time monitoring, teams can sustain reliable, high-performing moulding production lines and exceed industry standards.[6][5][4][10]

Weld lines are formed when separate flow fronts meet without fully bonding, primarily due to low melt temperature, slow injection, poor venting, or suboptimal gate and product design. Solutions include raising melt temperature, improving mould venting, and adjusting gate placement and speed.[4][10]

Sink marks are avoided by maintaining uniform wall thickness, increasing packing phase pressure and time, and optimizing cooling channel placement to prevent uneven shrinkage or cooling.[10]

Short shots are addressed by raising injection pressure and speed, correcting material metering, clearing gates and runners, and verifying mould and resin temperature for full cavity filling.[6][4][10]

Simulation software predicts potential defects (such as sink marks, warping, flow lines) prior to batch runs, so designers and process engineers can optimize setups and minimize waste.[10]

Automated QC systems offer real-time defect detection using AI and vision tools, reducing manual workload, improving consistency, and guaranteeing quicker process correction.[5][10]

[1](https://www.idicomposites.com/pdfs/idi-molding-troubleshooting-guide.pdf)

[2](https://www.all-plastics.com/injection-molding-troubleshooting-guide/)

[3](https://www.rtpcompany.com/technical-info/molding-guidelines/troubleshooting-guide/)

[4](https://rjginc.com/how-to-troubleshoot-9-common-defects-in-injection-molded-parts/)

[5](https://in.chemtrend.com/news/troubleshooting-your-rotational-moulding-process-a-comprehensive-guide/)

[6](https://www.simtec-silicone.com/blogs/liquid-silicone-rubber-injection-molding-troubleshooting/)

[7](https://www.seaskymedical.com/injection-molding-troubleshooting-solutions-for-common-problems/)

[8](https://www.absolutehaitian.com/support-center/how-to-articles/injection-molding-processing-guidelines)

[9](https://www.moldmasters.com/support/troubleshooting)

[10](https://www.3erp.com/blog/injection-molding-defects/)

content is empty!

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes

Best Practices from Leading Vacuum Mold Casting Companies Worldwide

Top Vacuum Mold Casting Providers for Custom Batch Production

How to Choose the Right Vacuum Mold Casting Service for Your Product