Views: 222 Author: Amanda Publish Time: 2025-12-11 Origin: Site

Content Menu

● Market Research for CNC Machining Business

● Choosing Your CNC Machining Niche

● Business Model and Pricing Strategy

● Legal Setup, Certifications, and Compliance

● Planning the CNC Machining Workshop

● Equipment Needed for CNC Machining Business

● Estimating CNC Machining Startup Costs

● Skills and Team for CNC Machining

● Workflow: From RFQ to Delivery

● Quality Control in CNC Machining

● Attracting Customers to Your CNC Machining Services

● Content and Technical Demonstrations

● Working with Overseas OEM Clients

● Risk Management and Financial Planning

● Scaling and Automating CNC Machining Operations

● Building Long‑Term Customer Relationships

● FAQs

>> 1. What minimum equipment do I need to start CNC Machining?

>> 2. How much money do I need to start a CNC Machining business?

>> 3. How do I find customers for my CNC Machining services?

>> 4. Do I need certifications for my CNC Machining shop?

>> 5. How can I grow my CNC Machining business after the first year?

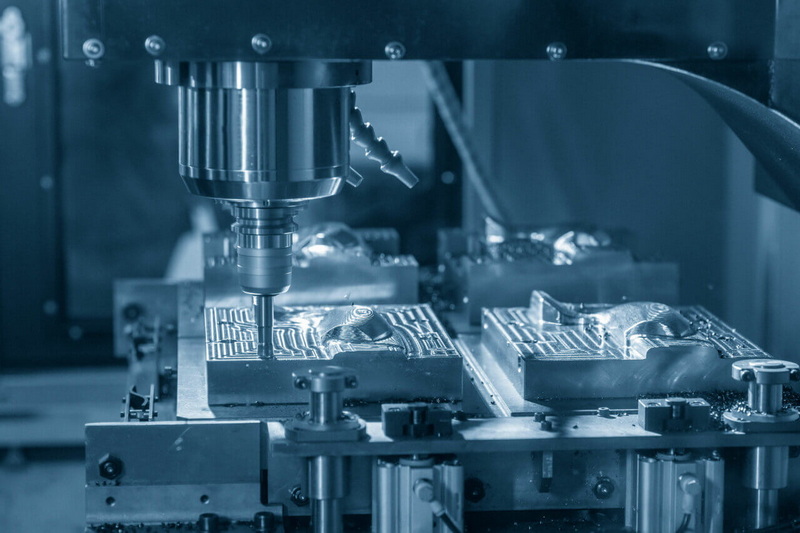

CNC Machining (Computer Numerical Control Machining) is a subtractive manufacturing process in which computer programs control machine tools such as mills, lathes, and routers to cut and shape materials into precise parts. By automating tool movements according to a digital design, CNC Machining achieves high accuracy, repeatability, and efficiency for both prototypes and production runs.[4][3]

In a CNC Machining business, customers usually provide 2D drawings or 3D CAD models along with tolerances, material specifications, and quantities. The shop then programs CNC equipment to convert raw material into finished components that meet strict dimensional and surface‑finish requirements, making CNC Machining ideal for demanding OEM applications.[5][3]

Thorough market research is essential before investing in CNC Machining equipment or renting a facility. Start by identifying which industries you can realistically serve, such as automotive, aerospace, medical devices, consumer electronics, robotics, industrial machinery, or energy.[2][6]

Each industry has different expectations for tolerances, materials, documentation, and certifications, so defining your targets early helps shape your CNC Machining capabilities and investments. Study existing suppliers in your region and abroad to see what CNC Machining services they offer, their lead times, and which gaps you can fill, such as faster prototypes or better communication.[7][2]

Focusing on a clear niche makes your CNC Machining brand easier to market and more efficient to operate. Examples of niche strategies include:[8]

- High‑precision CNC Machining for aerospace and defense parts with strict traceability.

- CNC Machining for medical components requiring consistent quality and documentation.

- Rapid prototyping and low‑volume CNC Machining for product design companies and hardware startups.

- Cost‑effective OEM CNC Machining services for overseas brands seeking long‑term manufacturing partners.

You can also specialize by process category, such as CNC Machining for milling complex prismatic parts, CNC turning of shafts and bushings, or combined CNC Machining plus sheet metal fabrication. Over time, extending into related services such as 3D printing, tooling, and mold fabrication makes your CNC Machining shop more attractive as a one‑stop solution.[9][3]

A CNC Machining business typically operates either as a job shop handling diverse custom orders or as a production‑oriented supplier focusing on repeat parts and long‑term contracts. Job shops benefit from flexibility and can often charge higher per‑part prices, while production shops rely on volume, efficiency, and strong OEM relationships.[6][2]

Pricing CNC Machining work involves several factors: machine hourly rate, setup time, programming time, material cost, tooling wear, inspection effort, and overhead. Many shops estimate CNC Machining cycle time for each operation, then add margins for profit and risk, with quantity‑based discounts for large batch orders or multi‑year OEM agreements.[10][11]

When starting a CNC Machining company, choose an appropriate legal structure such as sole proprietorship, partnership, limited liability company, or corporation, depending on local tax and liability rules. Register the company name, obtain any required industrial licenses, and ensure your premises meet safety and environmental regulations applied to machining operations.[1][2]

To attract high‑value CNC Machining clients, especially in aerospace, automotive, or defense, quality certifications like ISO 9001 and AS9100 are important. Even before attaining formal certification, implement documented processes for inspection, calibration, non‑conformance handling, and continuous improvement to show that your CNC Machining workflows are controlled and reliable.[12][7]

Workshop layout has a major impact on CNC Machining efficiency, safety, and part flow. Start with reliable infrastructure for power, compressed air, coolant, chip management, and ventilation, then arrange machines and support areas to minimize unnecessary movement.[2][1]

A typical CNC Machining layout might include dedicated zones for raw material storage, cutting and preparation, machining centers, turning centers, inspection, secondary operations, and packing. Maintaining logical, linear movement from material receipt to finished parts reduces handling time, lowers risk of damage, and supports standardized CNC Machining processes.[3][12]

The core investment in a CNC Machining business lies in machinery, tooling, and measurement equipment. Essential items for most new shops include:[1]

- Vertical CNC machining centers for general milling and drilling work.

- CNC lathes for turning cylindrical components and threaded parts.

- Workholding systems such as vises, chucks, fixtures, and modular fixturing solutions.

- Cutting tools, holders, and tool presetting solutions for efficient CNC Machining.

- Metrology tools such as micrometers, calipers, height gauges, and, for higher demands, coordinate measuring machines.

Entry‑level industrial CNC Machining centers can range from tens of thousands to well over one hundred thousand dollars, depending on size, accuracy, and features. In addition to machines, budget for CAM software, inspection equipment, coolant and lubrication systems, chip conveyors, and spare parts, which significantly contribute to total CNC Machining startup costs.[13][14]

Startup costs for CNC Machining operations vary with scale, country, and niche, but they always include machinery, facility, and working capital. A single new CNC machining center plus tooling, software, and setup can represent a large investment, while additional machines and inspection systems quickly multiply the budget.[14][13]

Beyond equipment, factor in deposits or renovations for the workshop, monthly rent, utilities, insurance, and the salaries of any CNC Machining staff you hire. Adequate working capital for raw materials, marketing, travel to client sites, and several months of operating expenses will help your CNC Machining business survive the ramp‑up phase before cash flow stabilizes.[11][10]

Technical capability is a key differentiator for any CNC Machining shop. Core roles include CNC programmers capable of creating safe and efficient toolpaths, setup technicians to configure machines and fixtures, operators to monitor production, and inspectors to verify parts meet specification.[12][1]

In the early stages, the founder may handle multiple tasks such as quoting, programming, and customer communication, but as the CNC Machining business grows, specialization becomes necessary to maintain quality and throughput. Ongoing training on new tooling strategies, CAM features, and process optimization keeps your CNC Machining team competitive and reduces scrap and rework costs.[6][8]

A standardized workflow helps you handle CNC Machining orders consistently and professionally. Typical stages include:[3]

1. Request for Quote (RFQ): The customer sends drawings or CAD models with quantity, material, and tolerance requirements, plus any standards or certifications required.

2. Feasibility and DFM Review: Your CNC Machining engineers evaluate manufacturability, identify risk areas, and suggest design changes that could reduce cost or improve reliability.[5]

3. Quotation: You estimate CNC Machining cycle time, setup time, material usage, and inspection needs, then issue a detailed quote with price, lead time, and payment terms.[10]

4. Order Confirmation: The customer confirms the order and, if needed, sends purchase orders, forecasts, or framework agreements for ongoing CNC Machining work.

5. Programming and Setup: CAM programmers generate toolpaths, and technicians prepare fixtures, tools, and offsets for trial runs.

6. Trial Run and First Article Inspection: A first batch is produced, inspected thoroughly, and approved by the customer if required.

7. Production and In‑Process Control: Full CNC Machining production follows controlled plans with scheduled in‑process inspections.

8. Final Inspection, Packing, and Shipping: Final measurements are recorded, documentation prepared, and parts are packed securely and dispatched using agreed logistics.

By defining and documenting each phase, your CNC Machining business can respond quickly to RFQs, control quality, and build trust with repeat OEM customers.[5]

Consistent quality is often the main reason customers choose and stay with a CNC Machining supplier. Implement clear work instructions, inspection plans, and sampling methods for each part, along with calibration schedules for measuring tools and gauges.[7][12]

Use first‑article inspection, in‑process checks, and final inspections to catch issues early in the CNC Machining process. Track non‑conformances, corrective actions, and process improvements so that complex parts become more stable and predictable over time, which is particularly important for sectors such as aerospace, automotive, and medical.[2][12]

Modern buyers usually research CNC Machining suppliers online before reaching out, so your digital presence must be professional and informative. A well‑structured English‑language website should clearly list your CNC Machining capabilities, typical tolerances, supported materials, lead times, and industries served, along with contact details and easy RFQ submission.[9][5]

Joining manufacturing platforms, attending trade shows, and networking with design firms and OEMs can also generate CNC Machining leads. Fast, clear communication—especially when responding to questions, design changes, or quality concerns—plays a big role in winning and retaining customers in competitive CNC Machining markets.[6][7]

Educational and technical content can significantly increase trust in your CNC Machining brand. Demonstrations of machining setups, tooling choices, or process optimization—shared through articles or short technical clips—help engineers and buyers understand your expertise without revealing confidential details.[15][8]

Explaining topics like how to reduce machining cost through design changes, how CNC Machining tolerances affect pricing, or how to combine CNC Machining with sheet metal manufacturing positions your company as a helpful technical partner. Buyers are more likely to work with a CNC Machining supplier that offers clear engineering support instead of simply quoting prices.[4][5]

Many OEMs from Europe, North America, and other regions outsource CNC Machining to specialized factories in China and similar manufacturing hubs. To win this business, your CNC Machining team must communicate professionally in English, respond quickly to RFQs and engineering questions, and be flexible with shipping solutions and trade terms.[9][5]

Providing design‑for‑manufacturing advice, early‑stage prototypes, and pilot runs gives OEMs confidence before committing to mass production CNC Machining orders. Stable quality, transparent communication, on‑time delivery, and long‑term pricing strategies are decisive factors when OEMs choose a CNC Machining partner for multi‑year projects.[7][5]

Financial discipline is crucial in the capital‑intensive world of CNC Machining. Many new shops fail because of underestimation of overhead, poor cash‑flow management, or accepting low‑margin jobs that consume valuable machine time.[8][1]

Build clear costing models that reflect realistic CNC Machining cycle times, scrap rates, and overhead, and monitor the profitability of different customers and part families. Consider financing options, such as equipment loans or leasing, but avoid taking on more CNC Machining capacity than your confirmed and forecasted orders require.[11][10]

Once your CNC Machining business has a stable customer base, focus on scaling intelligently instead of simply adding machines. Analyze utilization data, setup times, and scrap rates to identify bottlenecks and opportunities for automation, such as pallet systems, bar feeders, or standardized fixtures that reduce manual handling.[4][6]

Investing in production planning software, digital job tracking, and tool management systems can further streamline CNC Machining operations. By combining targeted automation with process standardization, you can increase throughput, improve quality, and handle more orders with the same or only slightly larger team.[2][7]

Many CNC Machining startups encounter similar pitfalls, especially during their first years. Common mistakes include buying more or larger CNC machines than necessary, ignoring marketing and relying solely on one or two customers, and underpricing complex jobs that require heavy programming and setup.[8][1]

Another frequent problem is accepting projects outside your technical capability or equipment range, leading to delayed deliveries and quality issues. Staying focused on your chosen CNC Machining niche, improving processes step by step, and building a diversified customer portfolio will greatly increase long‑term stability.[6][7]

Sustainable success in CNC Machining comes from long‑term customer relationships rather than one‑time jobs. Provide consistent quality, reliable lead times, and proactive communication about any risks or delays, which helps OEM clients plan their own production and strengthens trust.[12][5]

Offer engineering suggestions that reduce their costs or improve performance, such as optimizing designs for CNC Machining, adjusting tolerances, or consolidating parts when feasible. By positioning your shop as a technical partner rather than a transactional supplier, you can secure recurring CNC Machining orders and more stable revenue.[4][7]

Starting a CNC Machining business requires a combination of technical capability, careful planning, and strong communication with customers. By researching your market, selecting a profitable niche, investing wisely in equipment and quality systems, and building a reliable workflow from RFQ to delivery, you can create a CNC Machining operation that stands out in a competitive global landscape.[1][2]

Focusing on long‑term OEM partnerships, continuous improvement, and smart scaling strategies allows your CNC Machining shop to grow from a small startup into a trusted manufacturing partner for brands, wholesalers, and producers around the world. With disciplined financial management, robust quality control, and a clear value proposition, CNC Machining can become a highly sustainable and rewarding business model.[5][7]

At a basic level, many entrepreneurs start CNC Machining operations with a single vertical machining center, essential workholding, cutting tools, and measurement instruments such as calipers and micrometers. As demand grows, adding a CNC lathe, better fixturing, and more advanced metrology equipment increases flexibility and capability for more complex CNC Machining projects.[1][4]

The required investment depends on scale and location, but even a modest industrial CNC Machining setup with one machine, tooling, software, and setup can require tens of thousands of dollars. Costs can be reduced by purchasing used equipment, starting with a smaller workshop, and outsourcing some specialized CNC Machining processes while building your customer base.[13][14]

New CNC Machining businesses typically find customers through an informative website, online manufacturing platforms, trade shows, and direct outreach to local manufacturers or overseas OEMs. Quick responses to RFQs, transparent communication about capabilities and lead times, and sharing relevant technical content all help convert initial inquiries into long‑term CNC Machining clients.[9][5]

Not all CNC Machining shops need formal certifications, but industries such as aerospace, automotive, and medical devices often require or strongly prefer standards like ISO 9001 or AS9100. Even without certification initially, having documented quality procedures, inspection records, and traceability improves credibility and makes it easier to win CNC Machining contracts from demanding customers.[7][12]

After establishing a stable customer base, growth usually comes from expanding capabilities, improving efficiency, and deepening relationships with key clients. Adding complementary services, investing in targeted automation, and refining your focus on profitable CNC Machining niches will help your shop scale while maintaining high quality and reliable delivery.[8][6]

[1](https://www.mscdirect.com/knowledge-center/articles/how-start-cnc-shop-everything-you-need-know)

[2](https://www.elephant-cnc.com/blog/how-to-start-a-cnc-machine-shop/)

[3](https://www.cadrex.com/cnc-machining-starter-guide)

[4](https://uptivemfg.com/the-ultimate-guide-to-cnc-machining/)

[5](https://www.sunfastusa.com/offshore-industry-precision-machining)

[6](https://blog.thomasnet.com/tips-growing-cnc-machining-business)

[7](https://www.aerostarmfg.com/industry-news-blog/11-tips-for-growing-your-cnc-machining-business/)

[8](https://www.cnccookbook.com/profitable-cnc-business-ideas-to-make-money/)

[9](https://www.partmfg.com/cnc-machining-services/)

[10](https://xometry.pro/en/articles/cnc-machining-cost/)

[11](https://www.rotec-ltd.com/cnc-machining-costs)

[12](https://www.advancecnc.com)

[13](https://www.cnccookbook.com/how-much-does-a-cnc-machine-cost-comprehensive-guide/)

[14](https://rosnokmachine.com/cnc-machine-price/)

[15](https://www.youtube.com/watch?v=oWStIjcmMNs)

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal