Views: 222 Author: Amanda Publish Time: 2025-08-19 Origin: Site

Content Menu

● Understanding CNC Machining and Its Material Requirements

>> Why Material Choice Matters in CNC Machining

● Key Factors to Consider When Selecting Materials for CNC Machining

>> 4. Thermal Conductivity and Expansion

>> 5. Corrosion Resistance and Environmental Factors

>> 7. Post-Machining Processing

● Overview of Common CNC Machinable Materials

>> Metals

>>> Aluminum

>>> Stainless Steel

>>> Brass

>>> Titanium

>> Plastics

>>> ABS (Acrylonitrile Butadiene Styrene)

>>> Nylon

>>> Delrin (Acetal)

>> Composites

● How Material Selection Affects CNC Machining Processes

● Advanced Considerations in Material Selection for CNC Machining

>> Surface Finish Requirements

>> Structural vs. Non-Structural Parts

>> Environmental Impact and Sustainability

>> Post-Machining Processing and Assembly

● Case Studies and Examples of Successful Material Selection

>> Case Study 1: Aerospace Bracket Prototyping with Aluminum

>> Case Study 2: Medical Device Components in Stainless Steel

>> Case Study 3: Custom Plastic Enclosures in ABS

>> Case Study 4: High-Performance Racing Parts in Titanium

● FAQ

>> 1. What is the easiest material to machine in CNC projects?

>> 2. Can CNC machines work with both metals and plastics?

>> 3. How does material hardness affect CNC machining?

>> 4. What factors influence machining cost related to material?

>> 5. Are composites suitable for CNC machining?

CNC machining has revolutionized the manufacturing world by providing high precision, repeatability, and efficiency. Yet, one of the most critical choices in any CNC machining project is selecting the right material. The material directly impacts the machining process, product durability, cost, and end-use functionality. Whether you are prototyping a new design or embarking on precision batch production, understanding the nuances of material selection can vastly enhance your results.

In this comprehensive guide, we delve into the best materials for CNC machining projects, their properties, benefits, and drawbacks, helping you make an informed choice for your manufacturing needs.

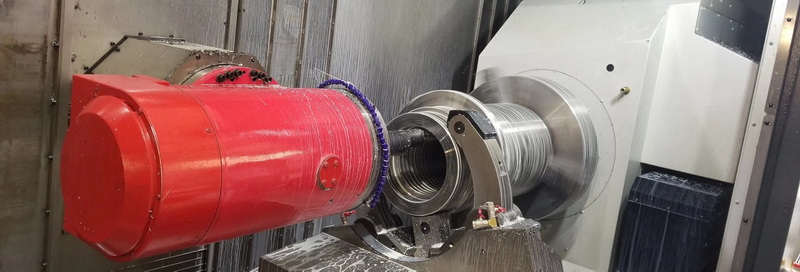

CNC (Computer Numerical Control) machining is a subtractive manufacturing process where machine tools such as mills, lathes, grinders, or routers are operated by programmed commands. It can produce intricate, high-precision components with consistent quality and is widely used in industries ranging from aerospace to consumer electronics.

The choice of material in CNC machining projects plays a pivotal role because the material's machinability, hardness, strength, and thermal properties affect tool wear, processing time, surface finish, and overall manufacturing costs.

- Tool Life and Maintenance: Harder or abrasive materials wear down cutting tools faster, increasing costs and machine downtime.

- Surface Finish: Softer materials might achieve a smoother finish, affecting product aesthetics and functional performance.

- Precision and Tolerances: Some materials machine with greater accuracy, which is crucial for parts needing tight tolerances.

- Thermal and Mechanical Properties: These influence how the material behaves under machining stresses, heat buildup, and the potential for distortion.

Proper material selection can directly influence CNC machining efficiency, scrap rates, and the longevity of your cutting tools.

Selecting a material involves balancing mechanical performance, cost, and manufacturability to match project requirements.

Key mechanical traits like tensile strength, hardness, ductility, and impact resistance inform how the part will behave during service. For instance, a high-strength alloy might be necessary for load-bearing components, while a more flexible plastic could work well in less structural roles.

Machinability defines how easily a material can be cut without causing excessive tool wear, chip clogging, or surface defects. High machinability materials improve throughput and reduce production costs.

The budget often dictates whether exotic or standard materials are used. Availability is also critical; ordering unusual alloys or plastics may cause delays.

Materials with high thermal conductivity disperse heat generated during machining, minimizing warping or dimensional changes. Coefficients of thermal expansion also matter to maintain tight tolerances after cooling.

Exposure to moisture, chemicals, or UV light requires materials that withstand such conditions without degrading, especially for outdoor or marine applications.

Weight limitations, aesthetic finishes, electrical insulation, or biocompatibility might drive material choices. For example, aerospace parts often mandate lightweight titanium or aluminum alloys.

Some materials are easier to anodize, paint, or polish after machining, which may be necessary for final product appearance or function.

Metal remains the backbone of CNC machining due to its strength and versatility.

Aluminum is the most widely used metal for CNC machining, thanks to its light weight, corrosion resistance, and excellent machinability. It allows high-speed machining and produces a good surface finish at relatively low cost, ideal for aerospace structural parts, automotive components, and electronics housings. Aluminum alloys such as 6061 and 7075 provide varying strength levels.

Additional Insights:

Aluminum's softness compared to steel minimizes cutting forces but can cause issues with chip formation—“stringy” chips that require proper chip evacuation. Using sharp tooling and optimal feeds can mitigate these challenges.

Known for its durability and corrosion resistance, stainless steel is favored in environments exposed to moisture or chemicals like medical instruments, food processing equipment, and marine hardware. However, stainless steel is harder and less machinable than aluminum, demanding slower spindle speeds, higher-quality tooling, and often more frequent tool replacement.

Additional Insights:

Grades like 304 and 316 stainless steel offer a good balance of machinability and corrosion resistance, but certain grades (e.g., 17-4 PH) are much harder and benefit from CNC practices such as peck drilling and coolant lubrication.

Brass machines easily and produces aesthetically pleasing, corrosion-resistant parts used in decorative hardware, plumbing, and electrical components. It has excellent machinability because of its low friction and ductility, allowing fine surface finishes with less tool wear.

Additional Insights:

Brass components are ideal where good conductivity and lower tensile strength are acceptable. However, it's not suitable for structural parts subjected to heavy stress.

Titanium is prized for aerospace and medical implants due to its high strength-to-weight ratio and excellent corrosion resistance. However, machining titanium requires experience because of its toughness, propensity to work harden, and heat retention.

Additional Insights:

Cutting titanium efficiently requires low cutting speeds, high feed rates, advanced carbide tooling, and ample coolant usage to prolong tool life and avoid part deformation.

Plastics are commonly machined for their light weight, corrosion resistance, and electrical insulating properties.

ABS is tough, impact-resistant, and relatively inexpensive. It is widely used for prototyping and end-use parts in the automotive and consumer electronics sectors. ABS machines easily with minimal burr formation, resulting in excellent surface finish.

Additional Insights:

ABS can release fumes when overheated; proper ventilation and coolant are recommended for health and surface integrity.

Nylon is known for wear resistance and self-lubricating qualities making it suitable for gears, bushings, and mechanical parts. It is tougher than many other plastics but absorbs moisture, which may cause dimensional instability if not properly dry-stored.

Additional Insights:

Machining nylon requires controlling heat buildup to prevent melting or warping; dry machining or mist coolant is often used.

Delrin is a highly crystalline plastic offering high stiffness, low friction, and excellent dimensional stability. Parts made from Delrin are common in precision engineering components like bearings and gears.

Additional Insights:

Delrin machines well with low tool wear. Its stability under varied temperatures makes it particularly suitable for tight tolerance assemblies.

Composites such as carbon fiber reinforced plastics (CFRP) combine light weight with high strength but present challenges for CNC machining.

Additional Insights:

The abrasive fibers wear cutting tools quickly, and improper feeds can cause fiber pullout or delamination, compromising structural integrity. Specialized diamond-coated tools and lower feed rates improve results. Additionally, dust extraction is essential due to airborne hazardous fibers.

The chosen material defines operational parameters and tooling selections:

- Cutting Speed: Materials like aluminum permit high spindle speeds, whereas hard metals require slower speeds to prevent tool damage.

- Feed Rate: Softer materials allow faster feeds; however, plastics often need slower feed to avoid melting.

- Tooling: Carbide tools are best for metals, while plastics may be machined effectively with high-speed steel or diamond-tipped tools.

- Coolants and Lubricants: Most metals benefit from coolants to reduce heat and flush away chips. Plastics often require careful coolant use to avoid thermal shock.

- Chip Management: Materials generate different chip types—from small segments to long ribbons—affecting chip evacuation and tool wear.

Setting appropriate machining parameters suited to material type optimizes productivity while maintaining part quality and tool life.

Parts with demanding aesthetic or functional surface finish needs may dictate the choice of material. For example, some aluminum alloys achieve excellent finishes after CNC machining and anodizing, while stainless steel may require additional polishing to reach the same level.

The intended load conditions influence material choice. Metals such as stainless steel or titanium are best for load-bearing or high-stress parts, while plastics suffice for housing components or weightsensitive applications.

Selecting recyclable or environmentally friendly materials aligns with green manufacturing trends. Aluminum and certain plastics can be recycled or sourced from recycled feedstock, reducing environmental footprint.

Consider if the material allows secondary operations such as welding, adhesive bonding, or plating. For example, some plastics do not adhere well to typical adhesives, influencing assembly processes.

Using aluminum alloys such as 7075 enabled rapid prototyping with good strength-to-weight balance. The material's machinability reduced production time and tool wear, facilitating quick design iterations.

Components requiring repeated sterilization and corrosion resistance were machined from 316L stainless steel. Cutting parameters were adjusted to minimize tool wear and maintain precision.

ABS permitted fast CNC machining and easy finishing for electronic enclosures, providing impact resistance and aesthetic appeal at a low cost.

Titanium was chosen for critical weight-sensitive engine components requiring high strength and corrosion resistance. Specialized tooling and machining strategies were implemented to address titanium's challenging properties.

Selecting the best material for your CNC machining project is a cornerstone of manufacturing success. Each material group offers unique advantages and challenges—from the machinability and cost-effectiveness of aluminum and plastics to the toughness and durability of stainless steel and titanium. By carefully considering mechanical properties, surface finish needs, environmental exposure, and machining parameters, you can optimize both the manufacturing process and the quality of the final product.

Whether you are working on rapid prototyping or precision batch production, being knowledgeable about material attributes ensures your CNC machining project is efficient, cost-effective, and delivers high performance.

Aluminum and plastics such as ABS and Delrin generally offer the easiest machinability due to their low hardness and favorable chip formation.

Yes, CNC machines are versatile and can be programmed to machine metals, plastics, and even composites with the appropriate tooling and parameters.

Harder materials increase tool wear and require reduced cutting speeds and feed rates, along with more durable tooling to ensure precision and tool longevity.

The raw material price, machinability, tool wear rates, cycle time, and requirements for post-processing all impact overall machining cost.

Composites such as carbon fiber reinforced plastics can be machined but require specialized tools, slower feed rates, and dust extraction due to their abrasive and hazardous nature.

content is empty!

Top 5 Axis CNC Machining Manufacturers and Suppliers in Norway

Top 5 Axis CNC Machining Manufacturers and Suppliers in Finland

Top 5 Axis CNC Machining Manufacturers and Suppliers in Greece

Top 5 Axis CNC Machining Manufacturers and Suppliers in Sweden

Top 5 Axis CNC Machining Manufacturers and Suppliers in Turkey

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes