Views: 222 Author: Amanda Publish Time: 2025-08-11 Origin: Site

Content Menu

● Importance of Design Optimization for 5-Axis Machining

● Key Design Considerations for 5-Axis Machining

>> 1. Maximize Tool Accessibility

>> 2. Design with Tool Geometry in Mind

>> 3. Minimize the Number of Setups

>> 4. Account for Fixturing and Workholding

>> 5. Tolerance and Surface Finish Specifications

● Advanced Design Strategies for Enhanced 5-Axis Machining

>> 6. Incorporate Feature Symmetry and Modular Design

>> 7. Optimize Material Removal and Chip Evacuation

>> 8. Mind Machine Kinematics and Axis Limits

>> 9. Minimize Lightweight or Thin-Walled Features Susceptible to Vibration

>> 10. Integrate Inspection and Measurement Features

● Best Practices in Designing for 5-Axis Machining

>> Use Simulation and CAM Software Early

>> Consult with Your Machine Shop Early

>> Consider Material Characteristics

>> Document Design Intent and Requirements Clearly

● Common Design Challenges and How to Overcome Them

>> Machining Undercuts and Complex Internal Features

>> Handling Large and Heavy Parts

>> Surface Finish Consistency Across Complex Surfaces

● Frequently Asked Questions (FAQ)

>> 1. What types of parts benefit the most from 5-axis machining?

>> 2. How does 5-axis machining reduce manufacturing costs?

>> 3. Are there specific design features to avoid in 5-axis machining?

>> 4. Can 5-axis machining work with all materials?

>> 5. How do I communicate 5-axis machining requirements to my manufacturer?

In the ever-evolving world of manufacturing, 5-axis machining has become a transformative technology, enabling the creation of complex, precise components with efficiency that was once unattainable. For manufacturers and designers alike, understanding how to optimize designs specifically for 5-axis machining processes is essential to maximize the benefits of this advanced capability. This article provides a comprehensive guide on optimizing your design for 5-axis machining, outlines best practices, and answers common questions to assist you in harnessing the full potential of this powerful technology.

5-axis machining refers to a CNC milling process where cutting tools move along five different axes simultaneously. This adds two additional axes of rotation beyond the traditional X, Y, and Z linear movements, allowing:

- Greater flexibility in cutting complex shapes.

- Enhanced precision by reducing setups and repositioning.

- Production of parts with intricate geometries otherwise impossible or inefficient on 3-axis machines.

The two additional axes usually represent rotation around the X and Y axes (A and B axes). The capability to orient the cutting tool into almost any position relative to the part surface is what sets 5-axis machining apart.

While 5-axis machining opens the doors to intricate designs, not every design is automatically suitable for this process. Optimizing your design for 5-axis machining can drastically reduce manufacturing costs, minimize lead times, improve surface finishes, and increase overall efficiency.

Optimizing means considering tool access, material removal strategies, fixture placement, and tolerances right from the design stage. This foresight avoids costly redesigns, tool collisions, and machining challenges.

In 5-axis machining, tool accessibility is much improved compared to 3-axis machining, but still needs smart design:

- Ensure unobstructed tool paths: Avoid internal undercuts or deep pockets that are inaccessible despite the rotating axes.

- Use fillets and chamfers: Sharp internal corners can be difficult to machine. Fillets and chamfers ease tool movement and reduce stress concentrations.

- Optimize tool engagement angles: Design features that allow the tool to maintain a favorable cutting angle reduce tool wear and improve surface finish.

Cutting tools have specific geometries, such as tool length, diameter, and flute design, which affect machining outcomes.

- Avoid sharp internal radii smaller than the tool radius.

- Keep features larger than the smallest available tool diameter to facilitate efficient cutting.

- Consider standard tool lengths and diameters to avoid custom tooling, which can add cost and lead time.

One of the biggest advantages of 5-axis machining is the ability to machine complex parts in a single setup.

- Design parts to avoid multiple repositioning: Combine features on various faces reachable by the rotating axes.

- Think in terms of machining orientation: Arrange your design features so the tool can reach them within the machine's rotational limits.

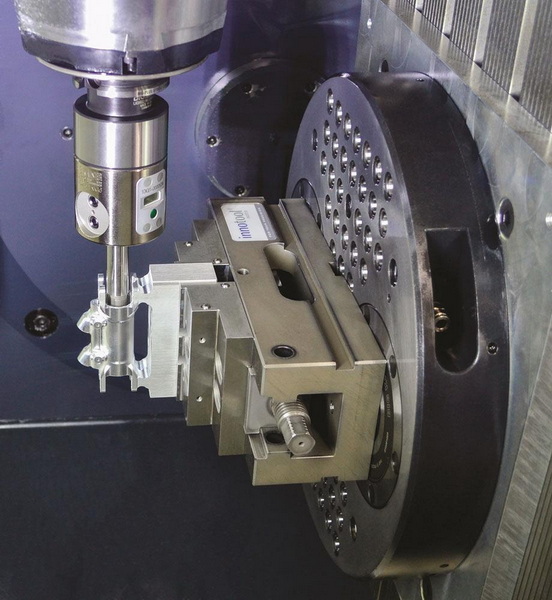

Proper fixturing is critical in 5-axis machining to maintain part stability.

- Include flat surfaces or datum faces for secure clamping.

- Avoid designs that require extensive custom fixtures unless necessary.

- Allow clearance for clamps and fixtures so that the tool is never obstructed.

Design tolerances should balance precision needs with manufacturing capabilities.

- Specify tighter tolerances only where functionally required.

- Leverage the smooth surface quality achievable with 5-axis machining to reduce post-processing.

- Communicate clear surface finish requirements in the design to avoid misunderstandings.

Designing components with symmetrical features or modular sections can simplify 5-axis machining by reducing complexity while maintaining functionality.

- Symmetry enables consistent tool paths and easier programming.

- Modular design allows separate machining of sections that can be assembled post-process, which sometimes reduces setup challenges.

Efficient chip removal during machining is critical to preserving tool life and achieving superior surface finish.

- Design channels or clearances facilitating chip evacuation, particularly in deep cavities.

- Avoid enclosed pockets without exits for chips to prevent clogging.

- Utilize through-holes or venting features to aid cutting fluid penetration and chip clearance.

Every 5-axis machine has mechanical constraints like rotation limits and axis travel distances.

- Understand your shop's specific machine capabilities and design within these limitations.

- Avoid steep rotational angles or large axis movements that force slow or inefficient machining.

- Considering axis limits early prevents revisions after CAM programming.

Thin walls or lightweight features are more prone to vibration or deflection, impacting precision.

- Increase wall thickness where possible without compromising design intent.

- Add ribs, gussets, or supports to stiffen delicate areas.

- Consider dynamic balancing if large slender components require 5-axis machining.

Incorporating accessible reference points and datums for in-process or post-process inspection helps maintain quality.

- Provide flat surfaces or grooves for probe contact in Coordinate Measuring Machines (CMM).

- Design features to allow non-destructive testing without disassembly.

- This foresight reduces quality assurance time and identifies issues swiftly.

Leverage CAM software simulations with 5-axis capabilities to verify tool paths and identify:

- Potential tool collisions.

- Areas difficult to machine.

- Opportunities to optimize tool orientation.

5-axis CAM programs often feature collision detection and dynamic visualization, allowing iterative design and machining process improvement.

5-axis machining involves advanced equipment, and each shop may have unique capabilities.

- Early collaboration ensures designs are tailored for actual machine capabilities.

- Manufacturers can advise on best tooling strategies and setup plans.

- A collaborative approach reduces surprises during manufacturing and improves delivery times.

Some materials, such as titanium or hardened steels, are more challenging to machine.

- Design to minimize heavy cutting loads.

- Use features that reduce long, slender tool engagement.

- Specify cutting strategy preferences, such as high-speed machining or adaptive clearing.

Communicating design intent includes specifying critical dimensions, surfaces, and functional requirements.

- Use clear technical drawings or 3D CAD annotations.

- Specify permissible tolerances, surface finish, material grade, and heat treatments.

- Clarify whether parts will undergo secondary operations like coating or welding.

While 5-axis provides superior access, some undercuts remain challenging.

- Minimize deep internal features or design them in segments.

- Use specialized tooling like lollipop cutters or custom-shaped tools.

- Apply multi-step machining with intermediate inspections.

Large, heavy parts often require special fixturing and stable setups.

- Design for sturdy clamping points.

- Consider machining allowances for roughing and finishing in stages.

- Avoid delicate features sensitive to vibrations caused by size.

Achieving uniform surface finish on freeform shapes depends on tool orientation and path strategy.

- Use CAM programs with surface finish optimization features.

- Include blending radii and curvature continuity in the design.

- Select suitable cutting tools and feed rates compatible with the surface texture desired.

Optimizing your design for 5-axis machining unlocks immense benefits in precision, efficiency, and manufacturability. By ensuring proper tool accessibility, aligning designs with tooling geometry, minimizing setups, accounting for fixturing, and specifying smart tolerances, you streamline production workflows and elevate the quality of your final parts. Advanced strategies such as modular design, chip evacuation, and consideration of machine kinematics further enhance machinability. Employing simulation tools and maintaining early collaboration with your machine shop are critical to successfully harness the power of 5-axis machining for complex manufacturing projects.

Parts with complex geometries such as aerospace components, medical implants, and molds benefit most due to the ability to machine undercuts and intricate features in one setup.

It reduces cost by minimizing multiple setups and repositioning, cutting down on labor, machine time, and risks of errors or inaccuracies.

Avoid features that cause tool collisions, are too small for standard tooling, or require custom fixtures that complicate workholding.

Yes, but materials like aluminum, titanium, and stainless steel are common. Highly abrasive or extremely hard materials may need specific tooling and adjustments.

Provide detailed 3D CAD models, specify tolerances and surface finish, and consult early to understand machine capabilities and tooling options.

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal