Views: 222 Author: Amanda Publish Time: 2025-08-11 Origin: Site

Content Menu

● Understanding Machining Tolerances in 5-Axis CNC

>> What Are Machining Tolerances?

>> Why Tolerances Matter in 5-Axis Machining

● Types of Machining Tolerances in 5-Axis CNC

>> Maximum Material Condition (MMC) and Least Material Condition (LMC)

● Typical 5-Axis Machining Tolerances and Capabilities

● Factors Affecting 5-Axis Machining Tolerances

>> Machine Accuracy and Calibration

>> Programming and Toolpath Strategy

>> Environmental and Thermal Conditions

● Advantages of Tight Tolerances in 5-Axis CNC Machining

● Best Practices to Achieve and Control 5-Axis Machining Tolerances

>> 1. What is the typical tolerance capability of 5-axis CNC machines?

>> 2. Why are tight tolerances important in 5-axis machining?

>> 3. How does the 5-Axis Auto Tuning System improve machining accuracy?

>> 4. Can all materials achieve the same tolerances with 5-axis machining?

>> 5. How can I reduce costs while maintaining tight tolerances?

In the advanced manufacturing landscape, 5-axis machining has become indispensable for producing complex, high-precision components across many industries such as aerospace, automotive, medical devices, and industrial equipment. This sophisticated machining process involves simultaneous movement of the cutting tool or the workpiece across five axes, enabling unparalleled access to intricate geometries and complex surfaces in fewer setups.

One of the most critical factors influencing the success of 5-axis machining is understanding and controlling tolerances—the allowable deviations from nominal dimensions on a machined part. Proper tolerance management ensures parts not only function as designed but also meet strict quality requirements while minimizing waste and reducing costs.

This article provides a thorough, detailed explanation of 5-axis machining tolerances, highlighting their types, importance, factors affecting them, best practices, and practical insights for manufacturers, OEMs, and technical professionals aiming to optimize their CNC machining projects.

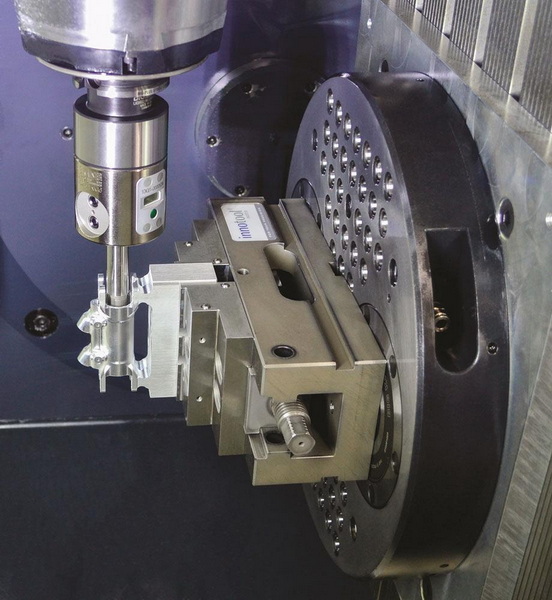

At its core, 5-axis machining refers to CNC machining where the cutting tool or the workpiece moves simultaneously along five different axes. The three linear axes — X, Y, and Z — cover traditional left-right, forward-back, and up-down movements. The additional two rotational axes (commonly called A and B or A and C) allow the tool or the part to tilt and rotate, enabling machining from multiple angles in a single setup.

This multi-axis capability dramatically reduces the need for repositioning parts multiple times, which is often required in 3-axis machining, thereby saving time, reducing risk of human error, and improving dimensional accuracy. The technology is essential for machining highly complex parts with compound curvatures, undercuts, and intricate details — such as turbine blades, mold inserts, medical implants, and aerospace components.

A machining tolerance defines the allowable variation in a physical dimension relative to its nominal or design size. It is the permitted range within which a manufactured part's dimension can fall while still being considered acceptable. Tolerances are vital because it is practically impossible to manufacture parts to exact nominal dimensions due to tool deflection, machine errors, material properties, and other factors.

Tolerances are often presented as plus-or-minus values (e.g., ±0.005 inches) or as specified upper and lower dimension limits. These limits define the maximum acceptable deviation to ensure the part functions properly within an assembly or system.

The complexity of the tool movements and multi-axis rotations in 5-axis machining presents unique challenges for maintaining dimensional accuracy. Properly defined tolerances ensure:

- Functional Fit: Components assemble seamlessly without excessive play or interference.

- Reduced Rework: Parts manufactured within tolerance minimize costly corrections and scrap.

- Machine Efficiency: Fewer setups and repositioning mean relying heavily on initial machine accuracy and consistent performance.

- Superior Surface Quality: Tight tolerance control improves surface finish, form, and location of critical features.

These tolerances apply to straight-line dimensions such as lengths, widths, diameters, hole sizes, and thicknesses. In 5-axis machining, typical linear tolerances for standard operations are around ±0.005 inches (±0.13 mm). For precision applications, tolerances can be tightened down to ±0.001 inches (±0.025 mm) or less.

Geometric tolerances specify acceptable deviations in form, orientation, location, and runout, which are especially important when machining complex 3D surfaces:

- Profile Tolerance: Controls surface contour deviations, crucial for curved and complex profiles typical in 5-axis machining.

- Orientation Tolerance: Ensures features maintain prescribed angular relationships such as perpendicularity, parallelism, or angularity relative to datum points.

- Location Tolerance: Ensures positional accuracy for holes, slots, and other features with respect to reference datums.

- Runout Tolerance: Controls variation when a feature rotates, important for shafts or circular features.

These concepts define tolerances based on the maximum or minimum material control — for example, the smallest hole diameter (MMC) or largest hole diameter (LMC) to ensure proper fit during assembly. MMC and LMC help leverage bonus tolerances, allowing more manufacturing flexibility while still guaranteeing functionality.

Modern 5-axis CNC machines equipped with advanced control systems and error compensation can achieve highly precise tolerances:

- Standard Linear Tolerances: Approximately ±0.005 inches (±0.13 mm), sufficient for many industrial applications.

- Tight Tolerances: Around ±0.001 inches (±0.025 mm) achievable for critical features and highly precise components.

- Surface Finish: Typical roughness values are around 125 RA (microinches), with finer finishes possible through advanced toolpaths and post-processing.

The use of 5-axis auto tuning systems can reduce geometric errors on rotary axes from typical values around 12 micrometers to as low as 3 micrometers, producing parts with superior dimensional integrity and repeatability.

Achieving and maintaining precise tolerances depends on multiple interrelated factors:

The mechanical design, rigidity, servo control, and calibration routines (including thermal compensation and dynamic error corrections) directly impact tolerances. Machines equipped with automatic tuning or compensation can detect and adjust for errors in real-time.

Different materials behave differently during machining. Harder materials, composites, or those with variable hardness can cause tool wear or deflection leading to tolerance deviations. Thermal expansion properties also affect dimensional stability during cutting.

Proper workholding is critical to minimize part movement, vibration, and misalignment. Accurate fixture setup aligned with machine datums reduces cumulative errors and improves repeatability across batches.

Advanced CAM software is essential for 5-axis toolpath generation. Smooth, continuous tool movements with proper compensation for tool length, diameter, and machine kinematics reduce surface errors and dimensional deviations.

Temperature fluctuations can cause thermal expansion of the machine structure, cutting tools, and workpieces, influencing machining tolerances. Controlled environments and machines with thermal compensation features help maintain consistent accuracy.

Maintaining tight tolerances offers significant benefits in competitive manufacturing environments:

- Precision Assemblies: Ensures complex assemblies function without adjustment or rework.

- Reduced Secondary Operations: Minimizes or eliminates the need for grinding, polishing, or manual finishing.

- Consistent Quality: Lowers scrap rates and improves customer satisfaction through repeatable part production.

- Optimized Performance: Critical in aerospace, medical, and automotive where safety and performance standards are stringent.

To optimize tolerance control during 5-axis machining, manufacturers should:

- Focus Tight Tolerances on Critical Features: Avoid excessive tight tolerances on non-critical dimensions to control costs.

- Collaborate Closely with OEMs and Machinists: Engage experts early to set realistic and achievable tolerance goals.

- Use Machines with Advanced Error Compensation: Employ CNC machines featuring calibration, tuning, and thermal compensation technologies.

- Select Appropriate Materials and Tools: Match the tooling and machining strategies to material properties to reduce tool wear and deformation.

- Implement Robust Inspection Regimes: Use coordinate measuring machines (CMMs), laser scanning, and in-process probing for quality control.

- Optimize CAM Programming: Leverage software to create smooth, continuous toolpaths minimizing machine stresses and dimensional errors.

Mastering tolerance management in 5-axis machining is essential to fabricating highly complex parts that meet tight specifications without sacrificing productivity or incurring excessive costs. The combination of advanced multi-axis CNC technology, precise machine calibration, material understanding, and optimized programming enables manufacturers to deliver parts with superior dimensional accuracy and surface quality.

As global markets demand increasingly intricate components with stringent quality requirements, OEMs and production shops must invest in knowledge and technologies for tolerance control. By doing so, they can maintain competitive advantages and ensure consistent customer satisfaction in fields ranging from aerospace to medical devices and automotive.

Typical 5-axis machines routinely achieve ±0.005 inches (±0.13 mm) tolerances. With advanced tuning and compensation systems, tolerances as tight as ±0.001 inches (±0.025 mm) or better are possible.

Tight tolerances ensure parts fit precisely in assemblies, minimize rework, and maintain superior surface finishes—critical factors for industries such as aerospace, medical, and precision engineering.

It identifies and compensates automatically for geometric errors like rotary axis misalignment and backlash, significantly reducing dimensional and surface errors over the machining cycle.

No. Material hardness, machinability, and thermal properties affect achievable tolerances. Softer materials typically allow tighter tolerances, while harder or abrasive materials may require looser tolerances due to tool wear and thermal effects.

Apply tight tolerances only to critical features, use CNC machines with error compensation, optimize CAM toolpaths, select proper fixturing, and consult with machining experts for realistic dimensioning strategies.

[1] https://www.3erp.com/blog/cnc-machining-tolerances/

[2] https://www.uti.edu/blog/cnc/what-are-machining-tolerances

[3] https://www.essaii.com/case/custom-oem-5-axis-cnc-turning-service/

[4] https://www.okuma.co.jp/english/onlyone/fivetuning/

[5] https://www.dmgmori.co.jp/en/theme/movie/id=4727

[6] https://bredo.com.au/blog/cnc-machining-tolerances/

[7] https://www.rapiddirect.com/docs/cnc-machining-tolerance.pdf

[8] https://www.aixihardware.com/oem-odm-customized-cheap-cnc-service-5-axis-cnc-peek-parts/

[9] https://www.3ds.com/make/solutions/blog/5-axis-cnc-machining-service

[10] https://www.youtube.com/watch?v=VpfLnxymnHk

[11] https://hwacheonasia.com/the-essential-guide-to-5-axis-cnc-machining/

[12] https://vocal.media/journal/5-axis-cnc-machining-for-aerospace-meeting-strict-tolerances-with-ease

[13] https://www.alibaba.com/product-detail/High-Quality-OEM-Service-DMG-5_60474771846.html

[14] https://www.snkc.co.jp/en/tax_products/tax02

[15] https://www.shutterstock.com/video/search/5-axis-cnc

[16] https://www.zintilon.com/blog/5-axis-cnc-machining-the-ultimate-guide/

[17] https://ecommercefastlane.com/what-is-cnc-machining-tolerance-types-and-standards/

[18] https://anebonmetal.com/top-5-axis-cnc-machining-services-manufacturers-and-suppliers-in-japan/

[19] https://www.aikoku.co.jp/en/ap/index.html

[20] https://www.youtube.com/watch?v=9FN6_4EM5kU

[21] https://www.youtube.com/watch?v=n7Un4cGmiH8

[22] https://www.youtube.com/watch?v=gn7oFVEhjHA

[23] https://www.hongsinn.com/video-237322-videos-5-axis-cnc-machining-parts-service.html

[24] https://geomiq.com/blog/what-is-5-axis-cnc-machining/

[25] https://www.gncorporations.com/the-ultimate-guide-to-5-axis-cnc-machining-precision-and-efficiency-for-modern-manufacturing

[26] https://www.youtube.com/watch?v=kAVtQhuUq00

[27] https://www.youtube.com/watch?v=Pwcez_OfEoo

[28] https://jlccnc.com/help/article/5-axis-cnc-machining

[29] https://www.istockphoto.com/photos/5-axis-machining

[30] https://www.fanucamerica.com/products/cnc/5-axis-cnc-machining/advanced-machining-tips-tricks

[31] https://www.youtube.com/watch?v=TRmvk6Mw03Y

[32] https://www.youtube.com/watch?v=qlWIarFHvzA

[33] https://www.shutterstock.com/search/5-axis-cnc-machining

[34] https://www.shutterstock.com/search/5-axis

[35] https://www.youtube.com/watch?v=ICjcNhjij0A

[36] https://www.youtube.com/watch?v=QZXy-oWMsBE

[37] https://absmachining.com/video-library.html

[38] https://stock.adobe.com/search/images?k=5+axis+cnc+machining

[39] https://www.pinterest.com/pin/5axis-precision-machining-for-home-decor--1002402829543617813/

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal