Views: 222 Author: Amanda Publish Time: 2025-11-14 Origin: Site

Content Menu

● The Fundamentals of Turning Lathe Efficiency

● Laying the Foundation: Proper Turning Lathe Setup

>> Positioning, Leveling, and Installation

● Mastering Cutting Parameters for Peak Productivity

>> Spindle Speed, Feed Rate, Depth of Cut

● Tooling, Automation, and Workflow Optimization

>> High-Efficiency Tooling Selection

>> Minimizing Setup and Changeover Losses

>> CNC Programming—Fine-Tuning for Efficiency

● Quality Control: Ensuring Consistency Every Run

>> Precision Monitoring and Measurement

>> Coolant, Lubrication, and Chip Management

● Advanced Machine Types and Specialized Practices

>> Swiss Turning Lathes for High-Volume Precision

>> Plastic Turning and Exotic Materials

● Maintenance, Training, and Continuous Improvement

>> Preventive Care and Scheduled Upkeep

● Troubleshooting: Practical Solutions to Common Turning Lathe Problems

● Automating for Lights-Out Manufacturing

● Frequently Asked Questions (FAQ)

>> 1. What is the most critical factor for maximizing turning lathe efficiency?

>> 2. How can setup and tooling changeover times be minimized in turning lathe workflows?

>> 3. What value does automation bring to turning lathe efficiency?

>> 4. How does consistent maintenance impact overall turning lathe performance?

Efficiency is the lifeblood of competitive manufacturing, especially when using a turning lathe for precision prototyping, batch runs, or high-volume production. A finely-tuned turning lathe setup delivers not just consistent quality and reduced cycle times, but also longer tool life, fewer reworks, and improved profitability for your shop. This complete guide takes you from foundation basics to advanced optimization—revealing expert techniques, modern workflow strategies, and actionable troubleshooting insights designed for global OEMs and manufacturers. Explore the latest best practices to extract maximum value and reliability from your turning lathe, no matter the project scale.[1][2][3]

A turning lathe performs material removal by rotating a workpiece against a stationary or moving cutting tool. The heart of efficiency lies in producing each part to exact specifications, in the shortest possible time, with minimum waste and cost. The turning lathe represents the cornerstone of precision engineering—chosen for its ability to deliver superior surface finishes, tight tolerances, and exceptional repeatability in components ranging from simple pins to complex shafts.

- Reliable setups minimize human error and speed throughput.[3]

- Smart tooling and programming extend equipment longevity.[1]

- Robust workflow strategies ensure consistent productivity and predictable output.[2]

Every efficient turning lathe operation starts with a properly installed machine. Begin by selecting a vibration-free, stable floor position, away from heavy traffic and temperature swings. Precision leveling is crucial—use dial indicators and spirit levels along at least two axes. A misaligned lathe bed causes built-in taper, irregular finishes, and premature tool wear; correcting these issues upfront saves hours of troubleshooting later.[4]

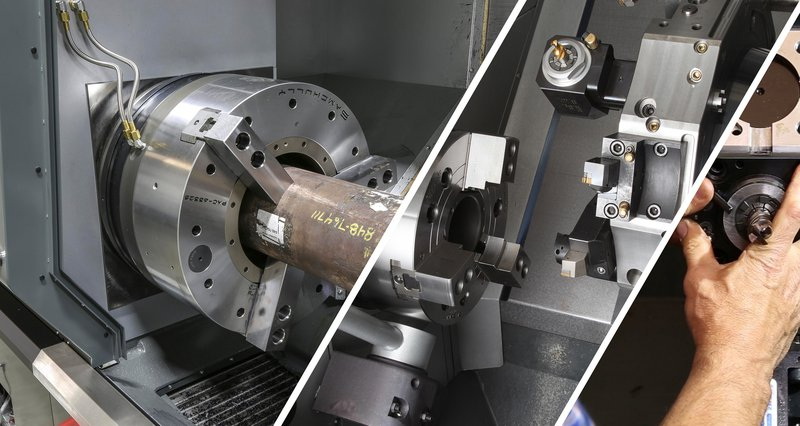

Solid workholding is central to repeatability and part accuracy. Match your approach to the job:

- Three-jaw chucks: Best for round stock and general work.

- Four-jaw chucks: Offer independent adjustment for irregular shapes.

- Collet chucks: Deliver high concentricity for delicate or high-volume jobs.

- Steady rest and tailstock: Essential for long or slender parts, preventing deflection and vibration.

Careful clamping avoids workpiece deformation and poor cuts, and modular quick-change systems drastically reduce setup times during batch production.[1]

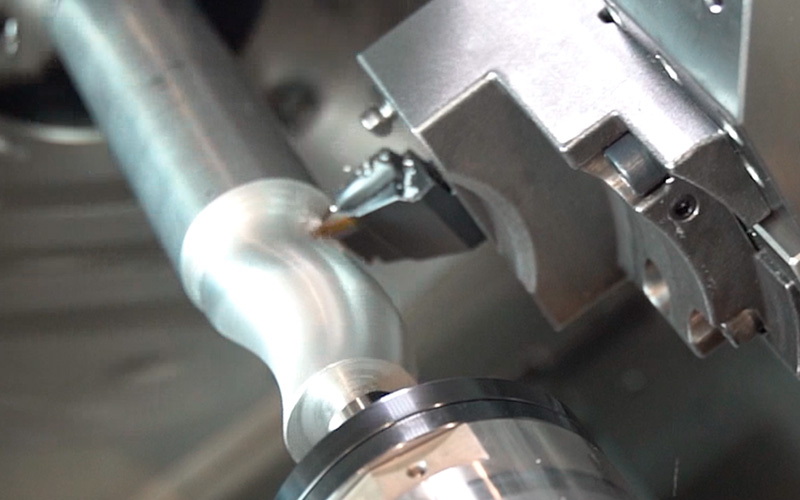

Choose the correct cutting tool geometry, grade, and coating for your application. High-speed steel suits general turning; carbide inserts shine in high-volume CNC work. Set tool tips precisely at the workpiece centerline using either digital height gauges or traditional alignment methods—a small misalignment can induce vibration, chatter, and excessive tool wear.

Confirm the rigidity of your toolholder and minimize protrusion to boost stability during operations. When switching jobs, modular toolholders and presetters save vital minutes on each changeover.[10][11]

Achieving optimal cutting performance involves balancing several key variables:

- Spindle Speed: Impacts surface finish and chip formation. Adjust RPM precisely to workpiece diameter and material hardness—stainless steel typically requires lower SFM, while aluminum allows much higher speeds.

- Feed Rate: Determines metal removal rate and finishing quality. Match the feed to tool nose radius and part specifications, increasing feed for roughing and lowering for finishing.

- Depth of Cut: Larger cuts improve removal rates during roughing; for finishing passes, use narrower cuts to enhance accuracy and surface finish.

Advanced approaches, such as the Taguchi method, can statistically optimize these parameters for a given job, balancing rapid cycle times with extended tool life and superior finish.[1]

Modern turning lathe shops gain a competitive edge through high-performance carbide inserts with advanced coatings, backed by robust toolholder designs. Tool life monitoring—whether via scheduled checks or sensor-based systems—prevents unexpected breakage and downtime.

Presetting tools outside the machine and using modular tool systems streamline changeovers, supporting repeatable setups that eliminate operator error and maintain production tempo.[2][10]

Standardize your fixture layouts and tool kits so every new run begins quickly and predictably. Quick-change workholding jaws, collet systems, and modular fixtures can decrease swap times by as much as 70%, converting downtime into productive spindle hours.[3][1]

Automation further enhances workflow: bar feeders, robotic arms, and lights-out scheduling allow for seamless, error-free production during off-peak hours. Such enhancements not only boost efficiency, but also support higher ROI by reducing labor costs and manual intervention.[2][1]

Efficient toolpath programming saves hours over a production run. Use advanced CAM software to:

- Limit air cutting and non-productive motion.

- Maintain constant engagement with the workpiece.

- Utilize strategies such as Constant Surface Speed (CSS) to optimize spindle RPM across varying diameters.

Collaboration between programmers and operators refines toolpaths, minimizing trial-and-error and maximizing ramp-up speed on new jobs.[2]

Integrate in-process probing, laser measurement, and sensor-based systems to verify dimensions automatically. Real-time feedback and automatic compensation ensure that each turning lathe part matches specifications—reducing scrap and eliminating excessive manual inspection.

Begin with top-quality raw materials, but also inspect for warping and burrs prior to setup. Automated measurement at critical points ensures that process drift is caught before defects reach the next stage.[2]

Efficient coolant management prevents thermal buildup, facilitates chip evacuation, and prolongs tool life. Match coolant type and delivery system to both material and operation—emulsified coolants for steel; oil-based for tough alloys. Maintain coolant cleanliness and filtration to prevent corrosion and part defects.

Strategic chip control reduces downtime and prevents part misalignment and surface scratching during extended turning lathe operations.[12][1]

Swiss-style turning lathes are the tool of choice for lengthy, slender, or complex parts requiring zero deflection and high consistency. Employ guide bushings for long workpieces, or swap to bushingless for shorter runs. Opt for modular, overlapping tooling layouts and synchronize operations to maximize cycle efficiency.[5]

Swiss lathes are designed for automation—implement segmented turning approaches to minimize part deflection and boost output for tight tolerance batches.[6]

Special requirements exist for plastics and other advanced materials: use the finest carbide grades, sharp tool edges, and lower feeds/speeds to prevent melting or warping. Each material demands a unique setup and parameter optimization.[9]

Routine checklists—daily, weekly, monthly—should cover lubrication, spindle bearings, slide ways, coolant system, and toolholder alignment. Log maintenance actions and monitor for warning signals such as excessive vibration, abnormal noise, or thermal spikes. A healthy turning lathe outlasts and outperforms neglected machines, delivering reliable results over time.[3][1]

The best turning lathe setups are only as effective as their operators. Invest in thorough technical training, focusing on machine controls, drawing interpretation, troubleshooting, and safety practices. Skilled machinists quickly identify issues and adjust operations for peak performance, reinforcing a culture of responsibility and continuous learning.[3]

Mistakes occur even in the most organized shops, but a systematic troubleshooting protocol resolves defects fast:

- Vibration or Chatter: Check tool alignment, machine leveling, and workholding rigidity first.

- Inconsistent Tolerances: Inspect for worn bearings, improper tool setup, or incorrect spindle speed.

- Excessive Tool Wear: Review coolant application, feed rate, and material hardness.

- Surface Finish Defects: Switch insert geometry, adjust depth of cut, or optimize toolpath for smoother engagement.

Quick reference guides and video tutorials accelerate root cause diagnosis and maintain shop momentum under pressure.[11][1][2]

Modern manufacturing integrates automation with turning lathe setups—bar feeders, robotic arms, and advanced software allow for overnight production without human presence. This not only increases uptime but also permits error-free high-volume batches and data-driven quality assurance. Machines equipped for IoT communication further boost efficiency by offering predictive maintenance and real-time process optimization.[1][2]

Efficiency in turning lathe operations results from more than state-of-the-art machines—it's forged through smart technical choices, precise machine setup, rigorous maintenance, advanced programming, and knowledgeable operators. By investing in high-performance tooling, standardizing changeover routines, leveraging automation, and implementing thorough training and upkeep, any manufacturer can reliably deliver consistent, high-quality results for demanding global clients.

Continuous improvement is the guiding principle: reassess workflows regularly, engage with new technologies, and never underestimate the power of operator expertise. The right turning lathe setup transforms your business from reactive to predictive, unlocking new levels of productivity for prototypes and mass production alike.[13][4][5][9][10][3][1][2]

Optimal cutting parameters, especially the careful coordination of spindle speed, feed rate, and depth of cut according to material and tooling, directly affect part quality, tool life, and throughput in every turning lathe operation.[3][1]

Quick-change workholding systems and standardized tool kits significantly reduce downtime. Modular fixtures and preset tools allow operators to switch jobs with minimal loss of productive spindle time—it's the easiest way for any shop to maximize throughput.[10][1]

Automation systems (bar feeders, robotic loaders, in-process measurement) free up labor and enable "lights-out" manufacturing, drastically increasing operational uptime and enabling error-free, high-volume production—essential for scaling modern OEM businesses.[1][2]

Regular preventive maintenance (lubrication, alignment checks, coolant system care) ensures that the turning lathe remains reliable and accurate, reducing the frequency and severity of breakdowns that can jeopardize deadlines.[3][1]

Adopt automated probing and measurement systems for real-time quality assurance. Combined with in-process adjustments and routine raw material inspections, these systems ensure each turned part matches specifications—improving customer satisfaction and profitability.[2]

[1](https://machinetoolspecialties.com/blog/1554-maximize-cnc-lathe-performance-optimization-with-smart-tips)

[2](https://thorrez.com/maximizing-efficiency-with-cnc-turning-a-comprehensive-guide/)

[3](https://www.stdmt.com/blogs/news/heavy-duty-lathes-best-practices-for-maximizing-efficiency)

[4](https://cncwmt.com/qa/how-to-level-a-manual-lathe-a-complete-guide-to-accuracy-stability-long-term-performance/)

[5](https://nomura-ds.com/blog/high-volume-tight-tolerance-things-to-consider-for-your-swiss-lathe)

[6](https://www.improprecision.com/tips-optimizing-swiss-screw-machining-efficiency/)

[7](https://www.makerverse.com/resources/cnc-machining-guides/best-practices-designing-for-cnc-turning/)

[8](https://www.dajinprecision.com/news/113--guide-to-internal-turning-on-lathe-factors-and-optimization-tips-of-internal-turning--dajin-precision)

[9](https://www.curbellplastics.com/services-capabilities/fabrication-machined-parts/plastic-machining-guidelines/plastic-turning-machining-guidelines/)

[10](https://www.pioneergroup-cn.com/maximizing-efficiency-how-a-lathe-tool-setter-can-help.html)

[11](https://www.instructables.com/Correct-Lathe-Cutter-Setup/)

[12](https://www.sureliaindustries.com/perfect-turning-techniques-on-the-lathe-machine/)

[13](https://machinetoolspecialties.com/blog/1519-comparing-lathe-machine-features-for-optimal-performance)

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal