Views: 222 Author: Amanda Publish Time: 2025-08-31 Origin: Site

Content Menu

● Understanding CNC Lathe Turning

● Key Factors in Choosing a CNC Lathe Turning Provider

>> Technical Expertise and Machinery

>> Quality Assurance and Certifications

>> Industry Experience and Application Knowledge

>> Communication and Customer Service

>> Production Capacity and Lead Time

● Additional Services to Look For

● Case Study: Applying CNC Lathe Turning in Different Industries

● How to Get the Best Quote and Samples

● Frequently Asked Questions (FAQ)

>> 1. What materials can CNC lathe turning work with?

>> 2. How can I optimize my design for CNC lathe turning?

>> 3. What are typical tolerances achievable with CNC lathe turning?

>> 4. Why are certifications important when selecting a CNC lathe turning supplier?

>> 5. Can CNC lathe turning providers support both prototyping and mass production?

In the modern manufacturing landscape, precision, efficiency, and reliability are paramount for success. Among the various machining processes available, CNC lathe turning stands out as one of the most versatile and essential methods used across numerous industries such as automotive, aerospace, medical devices, electronics, and consumer goods. Choosing the right CNC lathe turning provider can significantly elevate your product quality, shorten lead times, and optimize your production costs.

This article offers a thorough guide on how to identify the best CNC lathe turning provider tailored to the specific requirements of your industry. We will explore vital factors including technical expertise, machinery capabilities, quality assurance, production capacity, customer communication, and additional services. Practical insights and expert tips are also provided to help you successfully navigate the selection process for a reliable manufacturing partner.

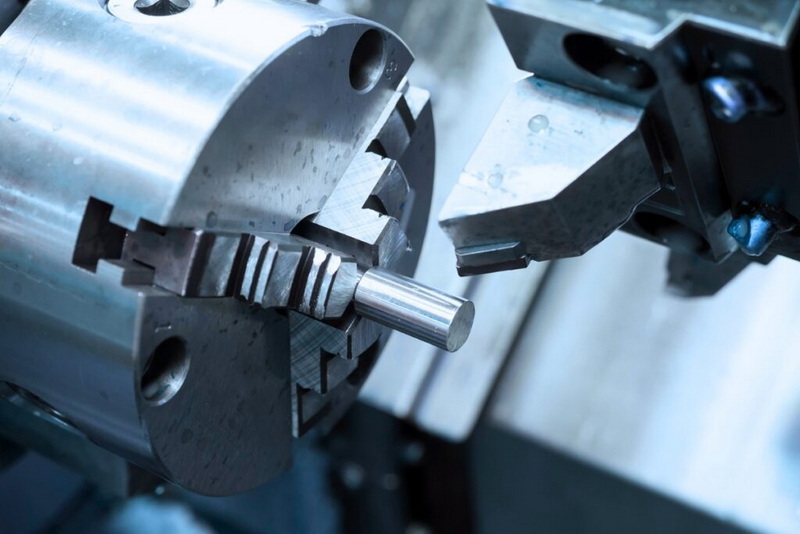

At its core, CNC lathe turning is a subtractive manufacturing technique where the workpiece is rotated on a spindle while a cutting tool shapes it by removing material. This process enables the creation of cylindrical parts such as shafts, bushings, pulleys, and threaded components with great accuracy and repeatability.

The use of computer numerical control dramatically enhances the precision and automation of this process, allowing complex geometries to be produced consistently with minimal human intervention. CNC lathe turning machines can handle a wide range of materials, including metals like aluminum, stainless steel, brass, titanium, and diverse plastics.

For industries that demand tight tolerances and smooth surface finishes — such as aerospace or medical — CNC lathe turning forms the backbone of quality parts production. Effective CNC turning not only affects product functionality but also reduces waste and production costs.

Choosing the right CNC lathe turning provider depends on a variety of factors that influence the success of your manufacturing projects. Here are the essential ones to consider:

The capability of a CNC lathe provider is fundamentally driven by its equipment and workforce skills:

- Machine Quality and Variety: Ensure that the provider uses advanced CNC lathes with multi-axis capabilities such as live tooling and milling options. Such machines can produce more intricate parts without transferring workpieces between multiple machines, improving accuracy and lead time.

- Modern Automation: Providers equipped with robotic loading systems, bar feeders, and automatic tool changers can maintain high throughput, reduce human error, and improve consistency.

- Engineer Experience: CNC programming and operator expertise matter just as much as the equipment. Providers with well-trained programmers can optimize tool paths and machining strategies, reducing cycle times and improving surface finishes.

Asking detailed questions about their machinery brands, ages, and maintenance schedules alongside operator training programs will give insight into their technical capabilities.

High-quality production requires rigorous quality management systems to be in place:

- Inspection Tools: Look for providers that utilize coordinate measuring machines (CMM), vision measurement systems, and other precision tools for in-process and final inspections.

- Standards Compliance: The presence of certifications such as ISO 9001 demonstrates adherence to internationally recognized quality standards. Specialized industries might require additional certifications, e.g., AS9100 for aerospace or ISO 13485 for medical devices.

- Documented Traceability: Reliable providers maintain documentation of material batches, inspection reports, and machine calibration records to ensure traceability and accountability.

- Continuous Improvement: Providers who pursue ongoing training, invest in new technology, and implement feedback loops typically maintain higher and more consistent quality standards.

Quality isn't just an internal process — it protects your investment and your brand reputation.

Different industries have unique manufacturing demands:

- Material Preferences: Aerospace parts may require titanium or high-strength aluminum alloys, whereas medical components often use biocompatible stainless steel or specialized plastics.

- Dimensional & Finish Requirements: Specific tolerances or surface textures might be mandatory to ensure part functionality or for regulatory compliance.

- Regulatory Compliance: Many sectors have strict certification mandates for raw materials and manufacturing conditions, such as FDA rules for medical devices.

A provider experienced in your industry will understand these nuances, reducing risk and accelerating product development. Request case studies or client references to validate their domain knowledge.

The best technical capabilities mean little without strong communication:

- Responsiveness: Timely responses to RFQs, questions, and concerns can prevent project delays.

- Technical Support: Providers who collaborate on design for manufacturability or suggest process improvements add value beyond machining.

- Transparent Status Updates: Regular updates on production, inspection, and delivery help you plan logistics and inventory.

- Flexible Scheduling: The ability to meet rush orders or adjust batch sizes to your changing needs can differentiate providers.

Strong project management smooths the entire manufacturing cycle.

Understanding a provider's production scale and delivery capabilities is essential:

- Capacity Options: Can they handle both small prototype runs and larger batch productions? Providers with flexible capacity help you scale production seamlessly.

- Lead Times: Typical lead times vary with complexity and volume, but you should confirm that timing aligns with your project schedule.

- Scalability: Ability to increase volume without sacrificing quality or pushing back delivery dates can support your growth.

- Expedited Service: Some providers offer rush manufacturing when deadlines are tight or for urgent part replacements.

Clear lead time commitments minimize disruptions to your supply chain.

Leading CNC lathe turning providers often offer add-on services that enhance efficiency and reduce your need for multiple vendors:

- Prototyping & Rapid Turnaround: Quick prototype runs for validation accelerate product development cycles.

- Secondary Operations: These include milling, drilling, tapping, grinding, heat treatment, anodizing, or plating, allowing finished parts ready for assembly.

- 3D Printing & Additive Manufacturing: Providers blending turning and additive technologies can offer hybrid manufacturing to optimize functionality or lower cost.

- Tooling and Mold Production: For industries needing specialized tooling, a vendor offering in-house mold production simplifies coordination.

- Supply Chain Management: Some providers assist with inventory management, JIT deliveries, or kitting services.

An integrated manufacturing partner reduces lead times and enhances quality control.

Examining applications across sectors clarifies why selecting the right partner is critical.

- Automotive: Crankshafts, camshafts, and complex engine components require tight dimensional tolerances to ensure engine efficiency and longevity. A CNC lathe provider familiar with automotive-grade materials and ISO/TS standards can ensure compliance and reliability.

- Medical Devices: Surgical instruments and implants demand high precision, biocompatible materials, and smooth finishes to meet regulatory and safety standards. A provider with FDA-related manufacturing experience and ISO 13485 certification is preferred.

- Electronics: Small connectors, heat sinks, and precision housings require exacting tolerances and often use exotic materials or composite plastics. Experience with miniaturization and complex geometries is essential.

- Aerospace: Lightweight, high-strength components such as bushings, shafts, and fittings require stringent process controls and AS9100 certification. Material traceability and rigorous inspection protocols are non-negotiable.

Matching your provider's expertise to your sector's nuances reduces development risks and boosts quality.

After narrowing down your list of potential CNC lathe turning providers, follow these steps:

1. Detailed Submission: Provide full CAD drawings with dimensions, tolerances, surface finish requirements, material specs, and quantity.

2. Request Comprehensive Quotes: Ask for details on tooling costs, setup fees, per-unit pricing, and any minimum order quantities.

3. Sample Evaluation: Obtain sample parts or prototypes to verify dimensional accuracy, surface finish, and material conformity.

4. Clarify Revision Policies: Understand the process for modifying tooling and designs if needed and associated costs.

5. Compare Suppliers: Assess not only cost but also communication, technical advice, and confidence in delivery.

A transparent quoting and sampling process lays the foundation for a strong partnership.

Selecting the best CNC lathe turning provider for your industry is a pivotal decision that impacts product quality, time to market, and overall manufacturing efficiency. Prioritize providers with advanced machinery, solid industry experience, rigorous quality systems, and excellent customer communication. Additionally, consider their flexibility in production capacity and the availability of value-added services like prototyping and secondary operations.

By doing thorough due diligence — including vetting certifications, reviewing references, and evaluating sample parts — you mitigate risks and ensure your OEM needs are met with precision and reliability. Partnering with a capable and responsive CNC lathe turning provider empowers your business to meet market demands and stay competitive in a complex manufacturing environment.

CNC lathe turning is compatible with a broad range of materials including metals such as aluminum, stainless steel, brass, copper, titanium, and various plastics like nylon, ABS, and polycarbonate. Selection depends on part function and industry standards.

Early collaboration with your CNC provider is key. Consider simplifying complex geometries, specifying achievable tolerances, and consulting on surface finishes to balance cost, manufacturability, and performance.

Depending on machine precision and material, tolerances typically range from ±0.01 mm to ±0.05 mm. Some high-precision applications may require specialized equipment to achieve even tighter tolerances.

Certifications such as ISO 9001 or AS9100 confirm that the provider follows consistent quality management processes. This reduces variability and provides assurance, especially critical in safety-sensitive industries like aerospace and medical.

Many qualified providers offer a range of services from rapid prototyping to high-volume batch runs. This flexibility allows seamless scaling from product development to full production without changing vendors.

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal