Views: 222 Author: Amanda Publish Time: 2026-01-03 Origin: Site

Content Menu

● What Is an Instant CNC Machining Quote?

● Why Instant CNC Machining Quotes Matter

● How Online CNC Machining Quoting Works

>> Selecting CNC Machining Processes

>> Defining Materials and Surface Finishes

>> Setting Tolerances, Quantities, and Requirements

>> Receiving Price and Lead Time

>> Reviewing Design for Manufacturability (DFM)

● Key Factors That Influence CNC Machining Quotes

>> Geometry and Part Complexity

>> Tolerances and Quality Requirements

>> Batch Size and Production Strategy

>> Finishing, Assembly, and Logistics

● Preparing CAD for Better CNC Machining Quotes

>> Use Clean, Neutral CAD Files

>> Define Critical Features Clearly

>> Design for Stable Machining

>> Minimize Special Tooling Where Possible

● Instant CNC Machining Quotes for Rapid Prototyping

● Scaling from Prototype to Production with CNC Machining

● Why Many OEMs Choose China for CNC Machining

● How an Integrated OEM Partner Supports CNC Machining

● Best Practices for Comparing CNC Machining Quotes

● FAQ

>> 1. How do I get an instant CNC Machining quote?

>> 2. Which file formats work best for CNC Machining quotes?

>> 3. Can instant CNC Machining quotes handle very tight tolerances?

>> 4. Are online CNC Machining quotes suitable for production, not just prototypes?

>> 5. What are the main benefits of using a Chinese OEM supplier for CNC Machining?

Instant CNC machining quotes have reshaped how engineers, buyers, and OEM brands source precision parts, delivering prices and lead times within minutes instead of days. For global brands, wholesalers, and manufacturers, combining these digital quotation tools with an experienced OEM partner in China enables fast, cost‑effective CNC machining from prototype to production. By mastering how online quoting works and how to prepare designs correctly, you can consistently obtain accurate CNC machining quotes while keeping projects on schedule and within budget.

An instant CNC machining quote is an automatically generated price and lead time for machined parts based on your uploaded CAD model, chosen material, surface finish, tolerance, and order quantity. Rather than waiting for manual estimators to review drawings, online systems analyze part geometry and manufacturing parameters to calculate CNC machining cost and delivery almost immediately.

These systems are especially valuable for projects requiring frequent design changes, because every new iteration can be quoted quickly without starting a lengthy email chain. As a result, CNC machining becomes more agile, enabling rapid prototyping, bridge production, and long‑term OEM supply programs within a single digital workflow.

Fast quoting is more than a convenience; it directly affects time‑to‑market, engineering efficiency, and purchasing decisions. Development teams can make informed trade‑offs between CNC machining tolerances, materials, and quantities early, when changes are still inexpensive.

For purchasing and supply‑chain managers, instant CNC machining quotes provide up‑to‑date reference prices that support budgeting, supplier selection, and negotiations. In competitive industries, being able to confirm CNC machining feasibility and cost within the same day can be the difference between winning and losing new business.

Although platforms and suppliers differ in detail, most online CNC machining quotation workflows share a similar structure. Understanding each step helps you feed the system with the right information and obtain accurate, reliable quotes.

The process usually starts with creating an account on a manufacturing platform or OEM supplier portal, then uploading your 3D CAD model. Common formats include STEP and IGES, which preserve precise solid geometry for CNC machining, and some systems also accept STL or native CAD files.

Adding a 2D drawing can be helpful when you need to communicate specific tolerances, threads, surface roughness, or geometric dimensioning and tolerancing (GD&T). Clear drawings reduce the chance of misinterpretation and ensure the CNC machining quote reflects your real requirements.

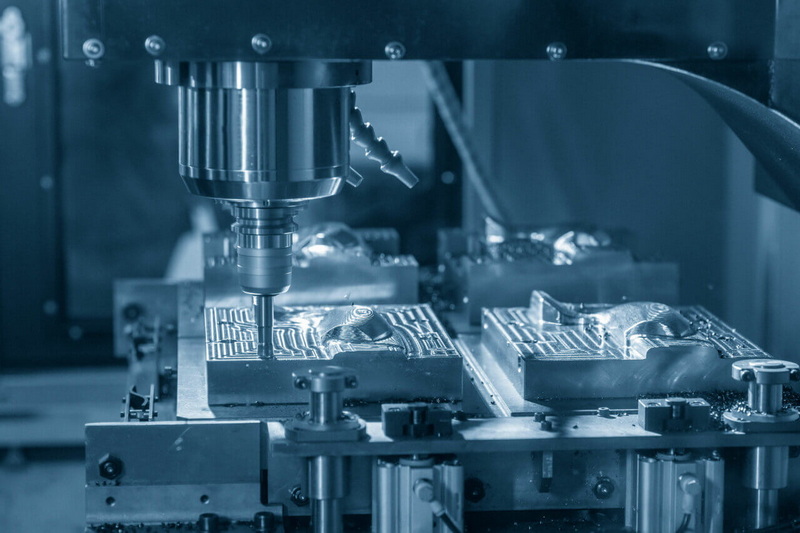

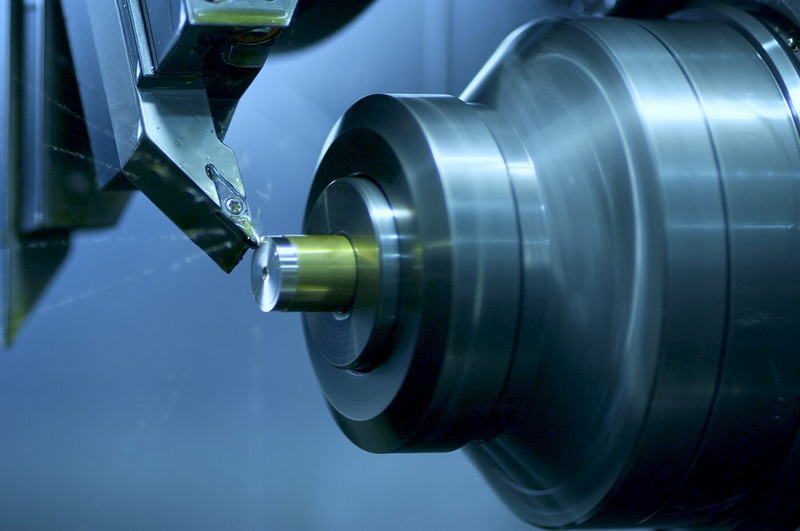

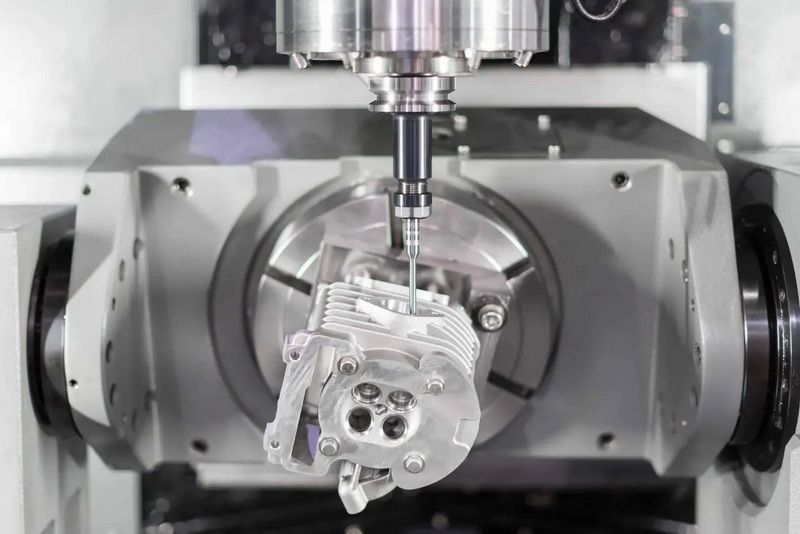

After upload, you choose the manufacturing process, typically one or more CNC machining operations such as milling, turning, drilling, or 5‑axis machining. For rotational parts like shafts or bushings, CNC turning (lathe machining) is often the primary process, while prismatic or complex parts may rely on multi‑axis CNC milling.

Many professional suppliers also offer complementary processes like sheet metal fabrication, injection molding, vacuum casting, and 3D printing alongside CNC machining. That makes it easier to handle full product assemblies in a single supply chain rather than splitting them across multiple vendors.

Material choice has a strong impact on CNC machining cost, speed, and achievable tolerances. For example, aluminum alloys are typically more economical and easier to machine than hardened steels or superalloys, while engineering plastics can be ideal for lightweight, corrosion‑resistant components.

Next, you select surface finishes such as anodizing, bead blasting, polishing, powder coating, or plating. Each finish adds extra steps beyond raw CNC machining, influencing both price and lead time, so it is important to include them in the quote rather than adding them later.

Most online quotation systems allow you to choose default tolerances or specify tighter limits on critical dimensions. It is often best to apply high precision only where it is functionally necessary, because extremely tight tolerances greatly increase CNC machining time and inspection effort.

You then define your quantity range, from single prototypes to small batches and larger production runs. Some platforms make it easy to compare several quantity scenarios in one view, showing how unit price for CNC machining decreases as volume increases.

Once these parameters are set, the platform's algorithm analyzes machining complexity, material, features, and quantity, then calculates an instant CNC machining quote. The result typically includes unit price, total cost, estimated production time, and expected shipping schedule.

For particularly complex parts or very tight tolerances, the system may switch from fully automatic quoting to a semi‑manual review. In those cases, you still receive your CNC machining quote rapidly—usually within a few working hours instead of days or weeks.

Many modern systems provide built‑in design‑for‑manufacturability feedback that flags thin walls, deep pockets, sharp internal corners, or other features that are challenging or expensive to machine. These DFM insights help you refine your CAD model before committing to CNC machining production.

Fine‑tuning your design at this stage often improves part quality and reduces cost simultaneously. It also avoids unpleasant surprises later, such as unexpected engineering change orders or delays caused by difficult CNC machining operations.

Accurate quotes depend on multiple technical and commercial factors, many of which you can control directly through design choices and sourcing strategy. Paying attention to these aspects leads to more predictable CNC machining pricing and delivery.

Simple prismatic components with accessible features are generally cheaper and faster to machine. Complex 3D surfaces, undercuts, deep cavities, and intricate pockets require specialized tooling, additional setups, and longer machining times, all of which increase CNC machining cost.

Where performance allows, simplifying fillets, radii, and transitions can significantly reduce the amount of CNC machining required. Organic shapes may still be feasible, but they often require multi‑axis machining and careful process planning.

Material price is only part of the equation; machinability also plays a major role. Aluminum alloys are usually cost‑effective for CNC machining, while tool steels, stainless steels, and exotic alloys tend to wear tools faster and demand lower cutting speeds.

The size and shape of the starting stock influence how much material must be removed during CNC machining. Choosing stock closer to the final geometry reduces both cycle time and raw material waste.

Every increment in precision requires additional time in CNC machining and inspection. Extremely tight dimensional tolerances, high surface flatness, or demanding roughness targets may need extra tool passes, fine finishing operations, or more sophisticated measurement.

By distinguishing between functional and non‑functional surfaces in your drawings, you allow the CNC machining supplier to focus effort only where needed, keeping overall cost competitive.

Setup and programming make up a significant share of CNC machining cost, especially for low‑volume runs. As quantities grow, those fixed costs are amortized across more parts, causing the per‑unit price to drop.

Splitting demand into staged batches can balance risk and cost: initial CNC machining runs validate design and process, while later larger batches deliver economies of scale. Instant quoting lets you test several volume options quickly before finalizing your purchasing plan.

Post‑processing operations—deburring, anodizing, painting, plating, heat treatment, and assembly—add both time and expense beyond CNC machining. If these are left unspecified in your request, a low quote might only cover basic machining, leading to higher real costs later.

Logistics choices such as express air shipping versus sea freight also affect total landed cost and delivery time. Comprehensive CNC machining quotes should capture both manufacturing and shipping options so you can evaluate the complete picture.

Good digital preparation makes CNC machining quoting smoother, more accurate, and easier to automate. A few best practices can significantly improve the quality of the instant quotes you receive.

Export solid models in widely supported formats and ensure they are free from redundant bodies, overlapping surfaces, or unresolved features. Clear, watertight geometry helps CNC machining software detect features correctly and estimate machining time accurately.

Check that units and coordinate systems are correct before uploading. Misaligned scales or axes can cause confusion and lead to incorrect CNC machining quotations.

On your 2D drawing, highlight only the dimensions that truly require tight tolerances or specific geometric controls. Over‑constraining an entire part increases the CNC machining burden and may trigger unnecessarily high quotes.

Where standard tolerances are acceptable, note this explicitly so the supplier knows that high‑precision CNC machining is not required everywhere.

Very thin walls, long slender features, and unsupported ribs tend to vibrate during cutting, which forces the CNC machining operator to reduce feed rates. Slightly thickening these features often improves part stability and allows faster, more economical machining.

Avoid sudden changes in wall thickness and extremely deep narrow pockets when possible. Gentle transitions and more moderate aspect ratios usually result in more efficient CNC machining and better quality.

Features requiring custom tools—such as unusual radii or proprietary profiles—can slow down CNC machining and increase setup costs. If these shapes are not functionally critical, consider standardizing them to use common cutters.

Similarly, internal sharp corners in pockets are impossible to machine with standard round cutters; generous fillets that match tool diameters simplify the CNC machining strategy.

Rapid prototyping is one of the main beneficiaries of instant CNC machining quotes. Engineers are free to experiment, test concepts, and validate assemblies because each design iteration can be priced quickly.

Compared with many other prototyping methods, CNC machining offers the advantage of using production‑grade materials. This means that mechanical properties, heat resistance, and dimensional stability in prototypes closely match those of final parts.

By combining fast digital quoting with short manufacturing lead times, teams can move from concept to functional CNC machining prototypes in days rather than weeks. That speed is crucial in markets where design windows and customer expectations evolve quickly.

Once a prototype proves successful, the same digital assets can support small‑batch and larger‑scale production. Online platforms and OEM suppliers reuse your validated CAD models, CAM strategies, and quality requirements to quote higher volumes efficiently.

As demand grows, the CNC machining process window is refined, tooling is optimized, and fixtures are improved. This gradual evolution builds a robust, repeatable manufacturing process that supports stable long‑term supply.

For OEM customers, this continuity from prototype through mass production reduces the risk associated with transferring CNC machining projects between different suppliers. A single, capable partner can maintain process knowledge and quality history over the full product lifecycle.

China has become a global center for CNC machining due to its large base of skilled machinists, broad equipment capacity, and competitive cost structure. Factories invest heavily in multi‑axis machining centers, CNC turning lathes, and automated inspection equipment to serve international markets.

For overseas brands and wholesalers, working with an experienced Chinese CNC machining supplier provides access to a wide range of metals, plastics, and finishing options. Combined with efficient logistics and flexible batch sizes, this makes it easier to support both small customized orders and large OEM programs.

Modern Chinese manufacturers increasingly use digital quoting tools and online communication to serve global customers. That allows buyers to receive instant CNC machining quotes, technical feedback, and project updates regardless of time zone.

An integrated OEM‑focused factory can provide more than basic CNC machining services. By combining rapid prototyping, CNC milling, CNC turning, sheet metal fabrication, 3D printing, vacuum casting, molding, and assembly, such a partner simplifies the entire manufacturing chain.

This integration reduces coordination costs because you no longer need to manage multiple vendors for different processes. It also supports better design decisions: engineers can choose the best process—CNC machining or otherwise—for each component while keeping quality and supply under one roof.

For overseas brands, wholesalers, and manufacturers, this kind of partnership enables faster response to new product ideas, engineering changes, and market feedback. Instant CNC machining quotes become part of a larger ecosystem that supports long‑term product development and continuous improvement.

When multiple platforms or suppliers provide instant CNC machining quotations, it is important to compare them using more than just price. Evaluating each offer across technical and commercial dimensions helps you build a resilient supply base.

Key elements to review include:

- Consistency of specifications: Confirm that all quotes use the same CAD version, material, finish, and tolerance requirements so comparisons are fair.

- Technical capability: Check that suppliers can achieve the necessary CNC machining tolerances, surface quality, and inspection standards for your industry.

- Quality systems: Look for evidence of robust quality control, measurement equipment, and traceability that match your application risk level.

- Communication quality: Assess responsiveness, clarity of engineering feedback, and willingness to support design optimization for CNC machining.

- Total landed cost: Include shipping, duties, packaging, and possible rework risk when deciding which CNC machining quote offers the best overall value.

By weighing these criteria together, you can select CNC machining partners that not only offer competitive pricing but also reliably support your schedules, quality targets, and long‑term growth.

Instant CNC machining quotes have transformed the way modern products are developed and manufactured, allowing engineers, buyers, and OEM brands to obtain fast, reliable pricing and lead times for complex parts. When combined with careful CAD preparation, thoughtful tolerance and material choices, and structured supplier comparison, these digital tools greatly accelerate development cycles while keeping machining costs under control.

By partnering with a capable OEM‑oriented factory that offers CNC machining alongside complementary processes such as sheet metal fabrication, molding, and 3D printing, overseas brands and wholesalers can manage entire product lines through a single, integrated supply chain. Instant online quoting then becomes the front door to a comprehensive manufacturing ecosystem that supports rapid prototyping, precision batch production, and scalable long‑term programs in a predictable, repeatable way.

You usually start by registering on a manufacturing platform or supplier portal and then uploading your 3D CAD file. After selecting CNC machining, choosing material, finish, and quantity, the system automatically generates pricing and lead‑time information for your parts.

Neutral solid‑model formats such as STEP and IGES are widely supported and preserve geometry accurately for CNC machining. Some portals also accept STL and native CAD files, but solid models typically give the most reliable quotes and machining outcomes.

Many online systems allow you to specify tight tolerances and will factor them into the CNC machining quote. However, extremely demanding requirements may trigger manual engineering review or result in higher prices due to slower machining and enhanced inspection.

Yes, instant CNC machining quotes are increasingly used for both prototypes and ongoing production runs. Once your design and process window are validated, suppliers can scale from small batches to larger volumes using the same digital setup.

Chinese OEM‑focused suppliers often combine competitive pricing with advanced CNC machining equipment, broad material options, and integrated services such as sheet metal fabrication and molding. For overseas brands and wholesalers, this means access to flexible batch sizes and a single partner capable of supporting the entire product lifecycle from prototype to mass production.

content is empty!

How Was Rapid Prototyping Implemented Into a Conditioning Program?

Top CNC Cutting Machine Manufacturers and Suppliers in Denmark

Top CNC Cutting Machine Manufacturers and Suppliers in Hungary

Top CNC Cutting Machine Manufacturers and Suppliers in Czech Republic

Top CNC Cutting Machine Manufacturers and Suppliers in Lithuania

Top CNC Cutting Machine Manufacturers and Suppliers in Ireland