Views: 222 Author: Amanda Publish Time: 2025-12-11 Origin: Site

Content Menu

● What CNC Machining Clients Really Want

● Build a Strong CNC Machining Brand Online

● Website Content That Wins CNC Machining Work

● Use Visual Media and Process Demonstrations

● Leverage Directories and Marketplaces for CNC Machining

● Network and Partnerships in the CNC Machining Ecosystem

● Get More Work from Existing CNC Machining Customers

● Use Email and Cold Outreach for CNC Machining Projects

● Differentiate Your CNC Machining Services with Niche Focus

● Showcase CNC Machining Quality and Reliability

● Invest in Technology to Improve CNC Machining Efficiency

● Use Social Media and Content to Promote CNC Machining

● Develop a Clear CNC Machining RFQ and Quotation Process

● Offer Design for Manufacturing Support for CNC Machining

● Align CNC Machining with Other Manufacturing Services

● Build Trust Through Communication and After‑Sales Support

● Train and Retain Skilled CNC Machining Talent

● Implement Continuous Improvement in CNC Machining Processes

● Focus on Strategic Industries for CNC Machining Growth

● FAQs

>> 1. How can a new CNC Machining shop find its first customers?

>> 2. What digital channels work best for promoting CNC Machining services?

>> 3. How important is specialization in CNC Machining?

>> 4. How can existing customers give more CNC Machining work?

>> 5. What role do videos play in selling CNC Machining services?

Winning more CNC Machining work today requires a clear strategy that combines strong technical capability, smart positioning, and consistent marketing. For a CNC Machining factory like Shangchen that offers rapid prototyping, CNC Machining services, precision batch production, turning, sheet metal, 3D printing, and mold making, the key is to present these CNC Machining advantages in a way that foreign brands, wholesalers, and manufacturers can quickly understand and trust.[1]

Potential buyers of CNC Machining services are not just looking for low prices; they want reliability, speed, quality, and clear communication. Foreign OEM customers normally evaluate a CNC Machining supplier based on technical capability, lead time, quality system, communication, and logistics flexibility.[2]

For a CNC Machining factory, this means clearly showing real CNC Machining parts, tolerances, and materials that can be handled, so engineers can judge whether the supplier matches their technical level. It also means explaining rapid prototyping, small‑volume CNC Machining, and mass CNC Machining clearly for both engineers and purchasers who may not share the same technical language.[3]

Most CNC Machining work now starts online, with buyers using search engines and B2B platforms to find suppliers. If a CNC Machining factory does not appear when buyers search for terms like “CNC Machining service” or “rapid CNC Machining supplier in China”, it will miss many opportunities.[2]

To strengthen online presence, a CNC Machining supplier should actively optimize pages around high‑intent keywords such as “CNC Machining”, “CNC turning service”, “CNC milling service”, “rapid CNC Machining”, and “CNC Machining OEM”. Consistent branding across the website, directory profiles, and social channels builds recognition and helps potential buyers remember the CNC Machining factory when a new project appears.[4]

A CNC Machining website must do more than look modern; it must quickly answer buyer questions and reduce perceived risk. Purchasing managers usually check capability, quality certifications, and past CNC Machining projects before sending RFQs.[2]

Important website elements include a clearly structured services section that highlights CNC Machining, CNC turning, precision batch machining, sheet metal, 3D printing, and tooling in separate pages. Technical content such as material options, surface finishes, tolerances, design guidelines, and CNC Machining FAQs helps engineers confirm that the factory understands their challenges and can support DFM.[5]

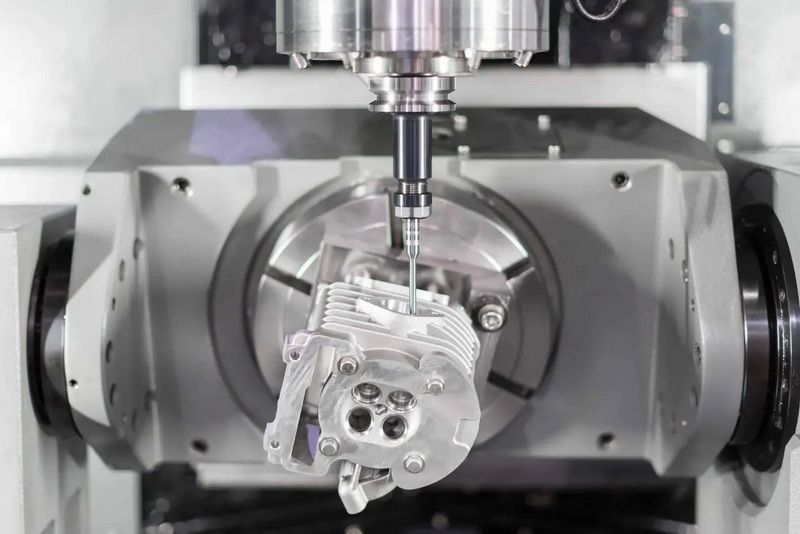

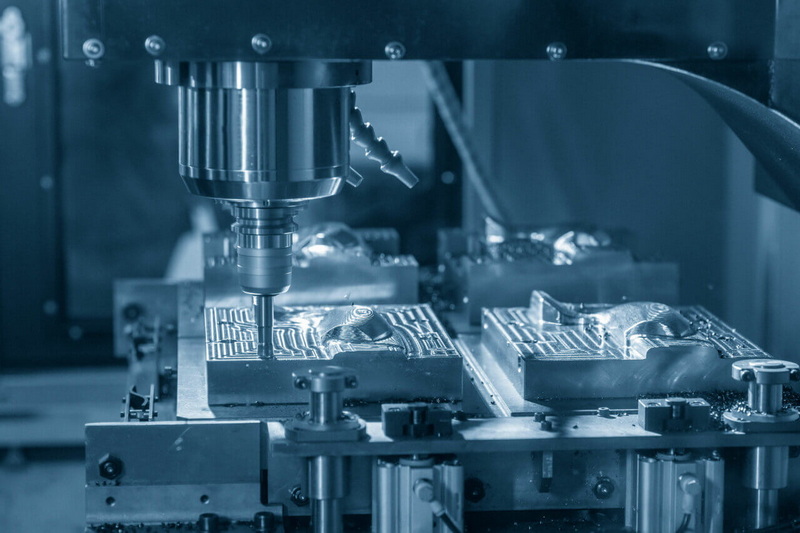

Although the text of the article should not contain any image phrases or links, visual media is still a powerful tool on the actual website or landing pages. Process demonstrations, factory tours, and inspection walkthroughs help overseas buyers understand CNC Machining capacity without visiting on site.[5]

Videos that show CNC Machining centers cutting complex parts, automated loading systems, tool presetting, or CMM inspection sequences reassure foreign customers about process stability. Short clips that follow a part through the CNC Machining workflow—from drawing, CAM programming, machining, deburring, inspection, to packaging—tell a compelling quality story that simple text cannot convey.[6]

Many industrial buyers now use B2B platforms and directories as the first step to finding CNC Machining suppliers. Being present on these sites increases the chances that a CNC Machining factory is discovered by foreign purchasers who may never search by company name.[2]

Practical steps include creating detailed company profiles on industrial directories that allow filtering by CNC Machining capability, location, certifications, and industries served. Joining online RFQ marketplaces specialized in CNC Machining lets suppliers quote on international jobs that match their processes and materials, often leading to repeat business if the first project goes well.[7]

Networking remains one of the most effective ways to get CNC Machining work, especially for complex or long‑term projects. Many machine shops grow by forming relationships with larger OEMs, other CNC Machining shops, and local or international industry groups.[6]

Useful networking approaches include building relationships with larger CNC Machining shops that may outsource small, complex, or urgent jobs that do not fit their own lines. Joining manufacturing associations and attending trade shows where buyers look for CNC Machining suppliers and contract manufacturers can generate face‑to‑face introductions that later become RFQs.[7]

One of the fastest ways to grow is to increase business from customers who already know the CNC Machining quality level. These customers trust the supplier's CNC Machining capabilities, so they are more likely to send repeat orders or new projects if the supplier communicates proactively.[1]

Actions to expand with existing clients include scheduling regular reviews with key customers to explore new CNC Machining parts, design revisions, or transfers from other suppliers. Offering value‑added suggestions such as design optimization for CNC Machining, material switching, or combining CNC Machining with sheet metal or molding can also position the factory as a strategic partner rather than just a job shop.[3]

Cold outreach remains a practical way to reach new CNC Machining buyers, especially in industrial markets where personal contact still matters. Well‑prepared emails and calls targeted at the right contacts can lead directly to RFQs for CNC Machining, tooling, or prototype batches.[1]

To be effective, outreach campaigns should start from a focused list of companies that routinely need CNC Machining parts in suitable industries such as automation, robotics, automotive, or consumer products. Messages should clearly explain how the supplier's CNC Machining capability, lead time, and cost structure can help the customer achieve faster launches or better margins, and they should invite the prospect to send trial drawings for quotation.[4]

Trying to serve all types of CNC Machining work can dilute a factory's value proposition, especially in competitive regions. Many successful CNC Machining shops focus on specific industries, materials, or part types so they can build deeper expertise and stronger references.[6]

Possible CNC Machining niches include high‑precision CNC Machining for aerospace, robotics, or instrumentation where tolerances, documentation, and cleanliness are critical. Another niche is rapid CNC Machining prototyping for product developers who need fast samples from aluminum or engineering plastics before committing to tooling, which fits perfectly with quick‑turn production models.[3]

Quality is often the deciding factor for foreign customers selecting a CNC Machining supplier, even more than unit price. Buyers want proof that the CNC Machining factory can consistently deliver exact specifications, stable surface finishes, and reliable lead times.[5]

Ways to demonstrate reliability include highlighting certifications, inspection equipment, process control, and traceability systems directly linked to CNC Machining operations. Real case studies that describe how CNC Machining projects were delivered on time, within tolerance, and under budget for foreign clients give buyers the confidence to shift more work to the supplier.[6]

Modern CNC Machining customers expect suppliers to use up‑to‑date technology and automation rather than relying only on manual processes. Adopting better equipment and software helps reduce costs, improve quality, and shorten lead times in CNC Machining.[3]

Useful investments include advanced CNC Machining centers, 5‑axis machines, multi‑tasking lathes, and automation such as pallet systems that handle larger volumes and complex flexible production. Software for CAD/CAM, nesting, and production monitoring also improves CNC Machining toolpaths, reduces setup time, and increases spindle utilization.[7]

Social media is increasingly important for CNC Machining marketing, especially for sharing technical content and visual proof of capability. Consistent posting helps position a CNC Machining factory as an expert partner rather than just a low‑cost supplier.[3]

Content ideas include short process clips, shop upgrades, and quality initiatives that indirectly promote CNC Machining professionalism and continuous improvement. Educational posts explaining design tips for CNC Machining, material selection, surface finishes, and tolerance trade‑offs attract engineers who may later send RFQs when new projects start.[5]

A transparent and efficient RFQ process can be a strong competitive advantage in CNC Machining. Buyers often complain about slow responses, incomplete quotations, or unclear assumptions in CNC Machining offers, which creates uncertainty and delays.[4]

A CNC Machining supplier should define a clear internal workflow for handling RFQs, including document checking, DFM review, cost estimation, and lead‑time calculation. Standardized quotation templates that clearly list CNC Machining operations, materials, finishes, tolerances, tooling costs, and shipping options reduce misunderstandings and make it easier for customers to compare suppliers.[5]

Design for Manufacturing (DFM) support is highly valued by engineers who rely on CNC Machining for prototypes and production. When a CNC Machining supplier helps optimize features, wall thicknesses, radii, and tolerances, projects are more likely to succeed and buyers are more likely to send repeat work.[3]

DFM for CNC Machining can include suggestions such as simplifying undercuts, adjusting fillet radii to match common tool sizes, or relaxing tolerances in non‑critical areas to lower cost. Documenting common CNC Machining design guidelines on the website and discussing them during early communication shows that the factory is a technical partner rather than just a part vendor.[6]

For a factory like Shangchen that offers CNC Machining, sheet metal, 3D printing, and mold making, integration is a major selling point. Many international customers prefer to work with one supplier that can support multiple manufacturing technologies instead of coordinating several separate factories.[4]

By structuring services around complete development cycles—such as rapid CNC Machining prototypes, low‑volume CNC Machining plus sheet metal assemblies, then molds and mass production—the factory can capture more value from each customer. This cross‑process capability simplifies project management for foreign clients and reduces the risk of miscommunication between different vendors.[8]

Communication quality strongly influences whether foreign buyers choose and stay with a CNC Machining supplier. Quick responses, clear technical explanations, and honest feedback when issues occur are just as important as CNC Machining accuracy.[2]

Regular updates during CNC Machining production, including progress reports, inspection summaries, and shipment tracking, reassure customers and reduce the need for constant follow‑up. When problems happen, fast root‑cause analysis, corrective actions, and transparent reporting demonstrate professionalism and often turn a negative event into a stronger relationship.[5]

Even with advanced machines, CNC Machining results depend heavily on programmers, operators, and inspectors. Shops that invest in systematic training, cross‑skill development, and long‑term career paths usually achieve more stable CNC Machining quality and shorter learning curves for new parts.[3]

Providing structured training in programming, tooling strategy, workholding, and in‑process inspection helps technicians handle more complex CNC Machining jobs and solve problems independently. When employees feel valued and see growth opportunities, turnover decreases, and knowledge about specialized CNC Machining processes remains inside the factory.[6]

Continuous improvement practices such as lean, 5S, and root‑cause problem solving help CNC Machining operations run more efficiently and predictably. Over time, these practices reduce scrap, rework, and downtime, which improves delivery performance and cost competitiveness.[7]

CNC Machining teams can regularly review bottlenecks such as long setup times, unplanned machine stops, or inspection delays, then test structured solutions. Documenting best practices—like optimized cutting parameters, standard tool libraries, or proven fixture concepts—makes future CNC Machining projects smoother and builds a sustainable competitive advantage.[3]

Not all industries offer the same long‑term potential for CNC Machining work. Some sectors, such as automation, robotics, medical devices, and new energy equipment, show strong demand for precision CNC Machining with complex geometries and high reliability.[6]

Targeting these sectors with dedicated content, case studies, and tailored capabilities helps a CNC Machining factory become recognized as a specialist supplier. Over time, this focused credibility can attract larger OEMs that prefer to work with CNC Machining partners who understand their regulatory, documentation, and performance requirements.[4]

Getting CNC Machining work in international markets depends on a combination of technical strength, strong branding, and consistent outreach. By building a clear online presence, leveraging directories and marketplaces, networking, maximizing existing customers, and focusing on niche CNC Machining capabilities, a factory like Shangchen can win more OEM projects from foreign brands, wholesalers, and manufacturers. Continuous improvement in CNC Machining technology, quality systems, communication, and integrated services with sheet metal, 3D printing, and molding will further increase trust and long‑term cooperation.[5]

New CNC Machining shops often start by targeting local manufacturers, maintenance departments, and smaller engineering companies that need quick, flexible machining support. Visiting potential customers in person, building relationships with maintenance managers, and offering responsive CNC Machining service on small jobs can quickly generate word‑of‑mouth referrals and initial references.[9]

Search‑optimized websites, industry directories, and B2B marketplaces are some of the most effective digital channels for CNC Machining promotion. When combined with a professional presence on platforms like LinkedIn and consistent content about CNC Machining projects, these channels bring highly qualified engineering and purchasing traffic that is actively looking for suppliers.[2]

Specializing in a particular industry, part type, or material can make a CNC Machining shop more attractive to buyers who value expertise over general capability. A focused CNC Machining offering also makes marketing easier because the factory can present deeper case studies, more relevant certifications, and targeted technical content that matches buyer expectations.[6]

Satisfied customers are often willing to send more CNC Machining jobs if the supplier communicates proactively and proves consistent reliability. Regular performance reviews, suggestions for machining cost reduction, and dedicated support for urgent orders encourage customers to centralize more CNC Machining work with the same supplier instead of spreading orders across many vendors.[1]

Videos help overseas buyers quickly understand a CNC Machining supplier's scale, equipment, and quality procedures without visiting the factory. Factory tours, process demonstrations, and customer testimonials in video form create confidence, answer common technical questions, and often lead to more RFQs for CNC Machining projects from cautious new customers.[5]

[1](https://facturmfg.com/blog/how-to-find-cnc-machine-work/)

[2](https://blog.thomasnet.com/how-to-find-customers-for-cnc-machine-shop)

[3](https://cncmachines.com/9-tips-for-growing-your-cnc-machining-business)

[4](https://www.wecreate.com/insights/how-to-find-customers-for-machine-shops-contract-manufacturers)

[5](https://blog.thomasnet.com/tips-growing-cnc-machining-business)

[6](https://www.aerostarmfg.com/industry-news-blog/11-tips-for-growing-your-cnc-machining-business/)

[7](https://datanomix.io/2024/07/15/five-marketing-strategies-to-grow-your-machine-shop/)

[8](https://www.hubs.com/cnc-machining/washington/seattle/)

[9](https://www.reddit.com/r/Machinists/comments/12gwa9x/where_would_a_new_machine_shop_find_first/)

content is empty!

Top Metal CNC Machining Manufacturers and Suppliers in Netherlands

Top Metal CNC Machining Manufacturers and Suppliers in Poland

Top Metal CNC Machining Manufacturers and Suppliers in Vietnam

Top Metal CNC Machining Manufacturers and Suppliers in Japan

Top Metal CNC Machining Manufacturers and Suppliers in Italy

Top Metal CNC Machining Manufacturers and Suppliers in Germany

Top Metal CNC Machining Manufacturers and Suppliers in Russia

Top Metal CNC Machining Manufacturers and Suppliers in Portugal

Top Metal CNC Machining Manufacturers and Suppliers in Spain

Top Metal CNC Machining Manufacturers and Suppliers in France