Views: 222 Author: Amanda Publish Time: 2025-09-18 Origin: Site

Content Menu

● Understanding Sheet Metal Fabrication Prototypes

● Importance of Prototype Evaluation in Sheet Metal Fabrication

● Step-by-Step Process to Evaluate Sheet Metal Fabrication Prototypes

>> Design Review and CAD Model Comparison

>> Visual and Aesthetic Inspection

>> Functional Testing and Performance Evaluation

>> Material and Process Validation

● Common Sheet Metal Fabrication Prototyping Methods and Their Evaluation

>> Laser Cutting & Waterjet Cutting

>> Sheet Metal Bending & Forming

● Advanced Testing Methods for Sheet Metal Prototypes

>> Finite Element Analysis (FEA)

>> Mechanical and Thermal Testing Machines

>> 3D Scanning and Measurement Automation

● Best Practices for Evaluating Sheet Metal Fabrication Prototypes

● FAQs

>> 1. How long does the sheet metal fabrication prototype evaluation process typically take?

>> 2. What are the most common issues found during prototype evaluation?

>> 3. Which materials are most suitable for sheet metal fabrication prototypes?

>> 4. Can 3D printing be used in sheet metal fabrication prototyping?

>> 5. How many prototype iterations are usually required before mass production?

Sheet metal fabrication plays a pivotal role in modern manufacturing, involving the cutting, bending, and assembling of thin metal sheets into functional parts and products. For manufacturers and product developers, evaluatingSheet Metal Fabrication prototypes before committing to mass production is essential. This evaluation ensures that the prototype meets all design, functional, and quality standards while identifying potential problems that could escalate costs or delay production. This article provides a comprehensive guide on how to evaluate sheet metal fabrication prototypes, focusing on best practices, testing methods, and practical tips to guarantee a smooth transition from prototype to full-scale manufacturing.

A sheet metal fabrication prototype is an early-stage physical model created to test the viability of the design and manufacturing process. Unlike digital models or simulations, these prototypes offer tangible insight into the product's fit, form, and function. They are created through various sheet metal processes including laser cutting, CNC machining, bending, welding, and surface finishing.

Prototyping in sheet metal fabrication serves as a valuable checkpoint for designers and engineers to visualize and physically interact with their concepts. It reduces the risk of design flaws and manufacturing defects when the product moves to mass production.

Thoroughly evaluating sheet metal fabrication prototypes provides critical advantages:

- Fit Verification: Ensures the prototype accurately assembles with other parts without unwanted gaps or misalignments.

- Form Assessment: Checks the prototype's structural integrity, surface finish, weight, and overall aesthetic appeal.

- Functional Testing: Confirms the prototype functions under real-world mechanical, thermal, and environmental conditions.

- Manufacturability Review: Detects possible difficulties or inefficiencies in fabrication processes such as bending, welding, or finishing.

Early identification of issues at the prototype stage saves time, reduces costs, and improves product quality by enabling necessary corrections before full-scale production.

The evaluation begins by comparing the fabricated prototype against the original computer-aided design (CAD) model specifications. Dimensional accuracy is verified using high-precision measurement tools such as coordinate measuring machines (CMM), laser scanning, or 3D optical profilers. This helps confirm that the prototype conforms to geometric dimensioning and tolerancing (GD&T) standards specified in the design.

Engineers perform detailed dimensional inspections to detect deviations in critical features such as hole sizes, bends, and flatness. This step is vital for ensuring compliance with product and assembly requirements.

A visual inspection focuses on the prototype's surface quality and finish. Inspectors look for defects such as scratches, dents, discoloration, or warping which might affect both functionality and appearance.

Welds, joints, and edges are reviewed for uniformity and strength, particularly where structural integrity is essential. The prototype's look and feel must align with intended design aesthetics, especially for consumer-facing products.

Fit testing involves physically assembling the prototype with other parts to evaluate the interaction and alignment. This step often reveals issues such as tight clearances, interference, or misaligned assembly points. Proper fitment is crucial to guarantee the final product's proper function and ease of assembly during manufacturing.

Functional tests simulate operational conditions the final product will encounter:

- Mechanical Testing: Assess strength, load capacity, fatigue resistance, and impact tolerance using universal testing machines or similar equipment.

- Thermal Testing: Verify behavior under temperature variations to ensure dimensional stability and material integrity.

- Environmental Testing: Evaluate corrosion resistance, chemical exposure tolerance, and other conditions relevant to the product's application.

These tests validate that the prototype will perform reliably in its intended environment.

Material selection and fabrication techniques directly affect a prototype's performance. It is essential to confirm that the prototype uses the correct sheet metal grade, thickness, and finishing processes such as powder coating or anodizing.

Fabrication steps—including cutting, bending, welding, and fastening—are examined to ensure they do not induce defects like residual stresses or distortions. This validation helps optimize manufacturing for scalability and cost-efficiency.

Prototype evaluation is inherently iterative. Documenting all findings and collaborating with design and fabrication teams facilitates refinement of the design or process. Multiple prototype versions may be produced to incorporate adjustments and achieve optimal performance and manufacturability.

Several sheet metal prototyping techniques are widely used, each with unique advantages and evaluation considerations:

Laser cutting provides precise, clean edges and intricate shapes through a controlled beam of light, minimizing material waste. Waterjet cutting, using high-pressure abrasive water, offers heat-free trimming ideal for sensitive materials. Evaluating prototypes from these methods involves checking edge quality, dimensional accuracy, and material warping.

CNC turret punching efficiently creates holes, slots, and cutouts with high reproducibility. Prototype assessment focuses on punch accuracy, hole quality, and absence of deformation around punched areas.

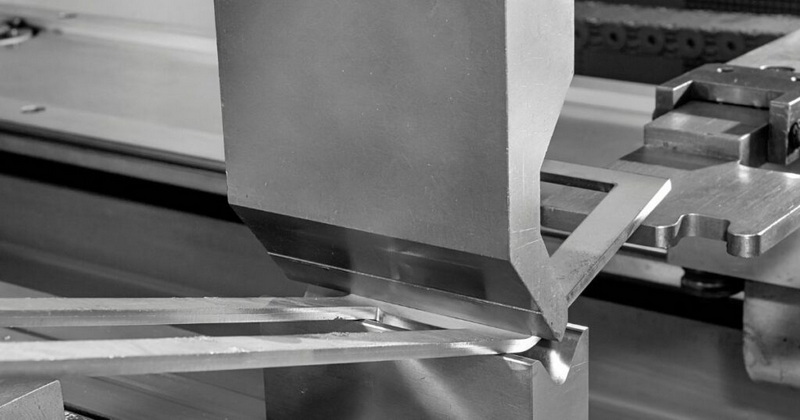

Press brakes and roll forming create bends and curves in sheet metal. Evaluating bent prototypes includes measuring bend angles, radii, and spring-back effects to verify alignment with design.

Welding (MIG, TIG, spot) and mechanical fastening (rivets, bolts) are assessed for joint strength, quality, and potential distortion. Visual and mechanical testing methods ensure durable, functional assembly.

Finished surfaces may undergo powder coating, anodizing, or plating to improve aesthetics and corrosion resistance. Prototypes are inspected for finish uniformity, adhesion, and color fidelity matching the final product standards.

FEA simulations complement physical testing by predicting stresses, deformation, and load-bearing capacity before making the physical prototype. Engineers validate FEA results with real-world testing to refine designs iteratively.

Universal testing machines apply tensile, compressive, and fatigue forces to quantify material and structural properties. Thermal analyzers measure expansion and conductivity for temperature-sensitive parts.

3D scanning technologies enable rapid, high-accuracy dimensional comparisons between physical prototypes and CAD models. Automation software accelerates inspection and reduces human error.

- Involve multidisciplinary teams (design, engineering, manufacturing) throughout evaluation to leverage diverse expertise.

- Employ precise, automated measurement and testing tools to increase reliability and repeatability.

- Use prototype evaluations to inform cost, time, and process efficiencies for mass production scaling.

- Maintain comprehensive documentation for quality control and traceability.

- Include client or end-user feedback during prototype reviews for market readiness assurance.

Evaluating sheet metal fabrication prototypes before mass production is a decisive step in product development that safeguards against design and manufacturing flaws. By systematically validating dimensional accuracy, visual appeal, fit, functionality, and material/process integrity, manufacturers ensure that the final products meet stringent quality and performance criteria. Integrating advanced testing techniques with iterative feedback loops optimizes prototype refinement, reduces time to market, and minimizes production costs. Companies embracing rigorous prototype evaluation establish a foundation for successful mass manufacturing, delivering superior products and enhanced customer satisfaction.

The evaluation timeline depends on prototype complexity but usually ranges from several days to a few weeks, allowing for detailed inspections, testing, and iterative refinements.

Typical issues include dimensional inaccuracies, assembly misfits, surface flaws, weak welds, and performance failures under load or environmental conditions.

Commonly used materials are aluminum, stainless steel, and mild steel due to their balance of machinability, strength, and corrosion resistance.

Yes, metal 3D printing methods like selective laser melting (SLM) complement traditional fabrication, especially for complex geometries or low-volume runs.

Generally, 2 to 3 iterations are needed to resolve design and manufacturing challenges, though this varies by product complexity.

[1](https://www.sofeast.com/resources/materials-processes/sheet-metal-prototype-fabrication/)

[2](https://www.fictiv.com/articles/sheet-metal-prototyping)

[3](https://firstmold.com/tips/making-a-metal-prototype/)

[4](https://cfmholdings.com/sheet-metal-prototyping-precision-engineering-for-rapid-development/)

[5](https://proleantech.com/sheet-metal-prototyping-guide/)

[6](https://ecoreprap.com/sheet-metal/metal-fabrication-prototyping/)

[7](https://kdmfab.com/sheet-metal-prototype-fabrication/)

[8](https://cumulusquality.com/mastering-sheet-metal-fabrication-a-step-by-step-guide-using-cumulus-pro/)

[9](https://www.protolabs.com/services/sheet-metal-fabrication/prototyping/)

[10](https://www.unionfab.com/blog/2024/11/sheet-metal-prototype)

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal