Views: 222 Author: Amanda Publish Time: 2025-10-28 Origin: Site

Content Menu

● The Importance of a Strategic CNC Milling Partner

● Technical Capability: Not All Providers Are Created Equal

>> Experience and Proven Track Record

>> Advanced Machinery and Process Investment

● Quality Assurance: The Foundation of Reliable CNC Milling Services

>> Rigorous Quality Control Systems

>> Material Mastery and Specialized Standards

● Communication and Collaboration: The Human Factor

>> Responsiveness and Technical Support

>> Project Management and Transparency

>> Sample Orders and Trial Runs

● Scalability, Flexibility, and Value

>> Ability to Scale Production

● Intellectual Property, Data Security, and Compliance

>> Data Security and Confidentiality

>> Compliance and Documentation

● Reputation and Client Relationship

>> Client Reviews and Peer Recommendations

>> Long-Term Relationship Potential

● After-Sales Support and Ongoing Service

>> Responsive After-Sales Service

>> Warranties, Replacements, and Technical Documentation

● FAQs

>> 1. What certifications indicate a reliable CNC milling service?

>> 2. How do I check if a provider can handle my part's material and geometry?

>> 3. Is it risky to work with non-specialist CNC shops for complex parts?

>> 4. Why is after-sales support important in CNC milling services?

>> 5. How do I verify a provider's reputation?

In the world of precision manufacturing, choosing the right CNC Milling Services provider is a critical decision that determines project success and the long-term reliability of your supply chain. Partnering with a skilled provider helps you reduce lead times, minimize defects, lower costs, and remain agile in ever-evolving industries. This comprehensive guide walks you through the nuanced process of evaluation–from technical capability and quality control to communication, after-sales support, and the ability to scale.

For both startups and established enterprises, CNC milling is a foundational manufacturing process. Applications span everything from rapid prototyping to high-volume production in sectors like aerospace, automotive, medical devices, and consumer electronics. Securing a competent milling services partner ensures your products meet stringent safety, functional, and appearance standards, maintains compliance, and safeguards your brand reputation.[2][5][7]

When vetting providers for CNC milling services, prioritize those with deep industry experience and a broad project portfolio. History with complex geometries, tight tolerances, specialized materials (such as titanium alloys or engineering plastics), and sector-specific standards is a strong indicator of capability. Providers with expertise in your application area–be it medical, aerospace, automotive, or electronics–are more likely to deliver components that meet regulatory and functional requirements without costly trial and error.[5][7][8]

- Ask for case studies in your field.

- Request references from clients with similar parts or volumes.

- Review the provider's record handling different materials and part complexity.

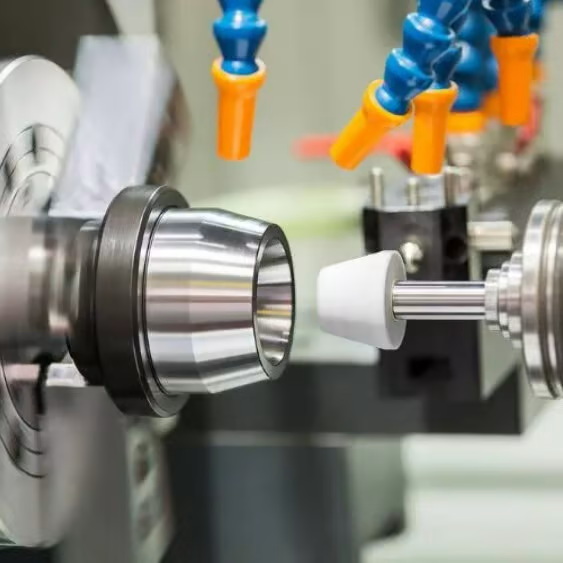

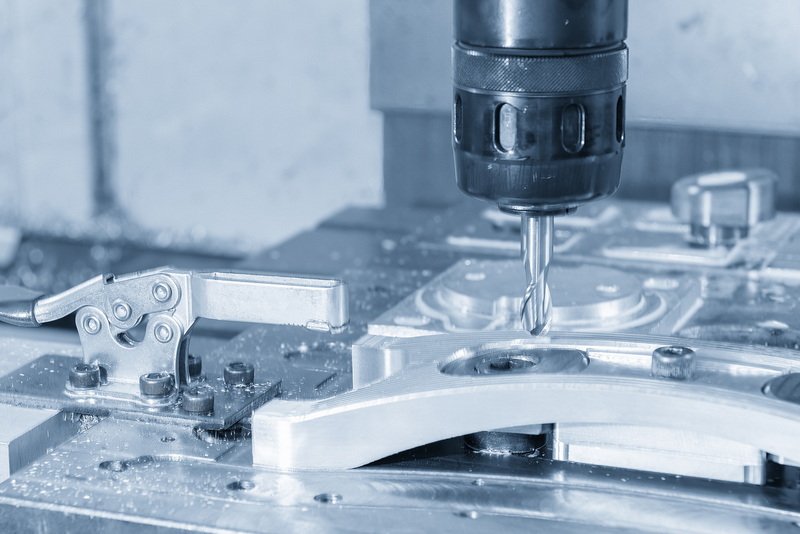

The caliber of a provider's machining equipment has a direct impact on production versatility and part precision. Top CNC milling services operate advanced multi-axis machining centers, use high-quality tool libraries, and adopt the latest in software-driven manufacturing. Modern equipment enables:[7][8][11]

- High accuracy and repeatability

- Efficient, automated large-batch or mixed-batch production

- Superior surface finishes and complex part geometries

- Better control over tight tolerances

Always inquire about the age, maintenance, and capabilities of the provider's machinery, including whether they perform 3-, 4-, or 5-axis milling and have automated inspection systems in place.

A strong quality management system is the backbone of any successful CNC machining operation. Your provider should follow comprehensive, standardized procedures for monitoring and verifying every stage of production. Indicators of robust QC include:[8][5][7]

- ISO 9001, AS9100, or industry-specific certifications

- Regular calibration of inspection equipment like CMMs, optical comparators, and micrometers

- In-process inspections, not just final checks

- Documented process controls and traceability measures

Quality CNC milling services are transparent about their process documentation, inspection workflows, and how they address non-conformities or rework.

Your parts may require special materials, from aerospace-grade metals to engineering plastics. Providers mastering multiple materials will know the best tooling, speeds, and cooling strategies, minimizing scrap and delivering ideal finishes. Industry-specific standards (ISO, ASTM, ITAR, etc.) also demand strict adherence and understanding from your partner; verify these competencies before moving forward.[5][7]

A collaborative CNC milling partner is essential for success. Responsive providers answer RFQs promptly, address engineering questions, and provide DFM (Design for Manufacturability) feedback so you can optimize product design for manufacturability and cost.[2][7][8]

Reliable communication also helps clarify surface finishes, tolerances, and logistics expectations, preventing expensive delays and surprises mid-project.

Look for providers who offer clear project timelines, status updates, and open communication at every project phase. Dedicated project managers or technical support staff signal a mature, customer-focused operation, and project transparency is a strong predictor of overall reliability.[9][5]

Evaluate potential CNC milling services by requesting a prototype or sample order. Assess results for:

- Dimensional accuracy

- Surface quality

- Packaging standards

- Delivery timeliness

A successful trial run builds trust and demonstrates a provider's true capability under real-world constraints.

In a dynamic business environment, your production needs may grow from prototypes to thousands of units. An ideal CNC milling partner will demonstrate:

- The capacity to scale up without compromising quality or speed

- Process automation and advanced scheduling tools for high-volume consistency

- Flexibility for design iterations, custom runs, and product variants

While pricing is important, total value–including reduction in rework, yield loss, scrap rates, and communication costs–should drive your decision. Seek transparent, all-inclusive quotations and request a breakdown of setup, tooling, production, and shipping fees.[8][5]

Build total cost of ownership (TCO) calculations into your sourcing process. A service with slightly higher rates but superior quality, on-time delivery, and fewer headaches can easily save more in the long run.

For sensitive designs, especially in defense, electronics, or high-value consumer products, data protection is paramount. Confirm that your CNC milling provider implements secure file transfer protocols, encrypted data storage, and regularly trains employees on intellectual property (IP) security. A robust NDA and clear confidentiality agreements are non-negotiable.[7]

Providers should supply all necessary certificates, test reports, or documentation needed for regulated markets (FDA, CE, automotive PPAP, etc.). Traceability, process audits, and end-to-end documentation are especially important when scaling to mass production.[8]

A provider's reputation speaks volumes about their reliability and results. Scan independent reviews, testimonials, and references from other manufacturers with similar needs.[6][9]

- Study both positive and negative feedback.

- Prioritize providers who are praised for long-term reliability, after-sales service, and technical knowledge.

- Consider their willingness to act as a strategic partner, not just a supplier.

True value accrues over time. Providers willing to invest in the partnership, adapt to your evolving needs, and actively share best practices become integral contributors to innovation and continual improvement.[6]

World-class CNC milling services extend their support well after delivery. This may include technical assistance, addressing issues, managing order changes, and even offering assembly, repair, or refurbishment support. Evaluate:[7][8]

- Responsiveness to questions post-shipment

- Efficiency in resolving complaints or claims

- Consistency in quality over repeat orders

Confirm what guarantees or warranties are offered for non-conforming parts. A supplier that provides replacements or repair, technical consultation, and thorough documentation demonstrates a true commitment to customer satisfaction.

Choosing the right CNC milling service provider is a multi-dimensional task that involves evaluating technical prowess, machinery, certifications, communication, and the ability to partner with you for growth. Assess each provider's industry expertise, portfolio, quality control frameworks, security protocols, and after-sales engagement. Building a strategic relationship with a top CNC milling company results not only in reliable, high-quality components but also in streamlined supply chains, reduced production headaches, and a significant competitive edge in your industry.

International standards such as ISO 9001 and sector-specific accreditations like AS9100 (for aerospace) show a commitment to consistent quality, process control, and traceability.[5][8]

Request examples of previously manufactured parts, inquire about their experience with similar materials, and review their machine lists for technical capability regarding your design's complexity.[5][7]

Yes, as specialized parts or regulated sectors (medical, aerospace) demand proven expertise and error-free execution. Generalist shops lacking domain experience may face steep learning curves.[12][8][5]

Reliable after-sales support ensures quick resolution of any part defects, technical consultation for future runs, and facilitates any change orders or spare part requests, building long-term trust.[6][7][8]

Check independent online reviews, request references, and examine case studies. Reputations built on technical skill, transparent communication, and customer support tend to last.[6][7]

[1](https://www.steckermachine.com/blog/selecting-cnc-machining-suppliers)

[2](https://www.americanmicroinc.com/resources/choosing-cnc-manufacturing-partner/)

[3](https://revpart.com/seven-essentials-to-identify-cnc-machining-partner/)

[4](https://www.modusadvanced.com/resources/blog/how-to-select-a-cnc-machining-services-partner)

[5](https://www.norck.com/blogs/news/choosing-the-right-cnc-machining-services-5-key-considerations)

[6](https://www.gemsons.com/importance-of-choosing-a-suitable-cnc-machining-service-provider/)

[7](https://www.3erp.com/blog/factors-to-consider-when-choosing-cnc-machining-service/)

[8](https://cncwmt.com/qa/how-to-choose-the-right-cnc-machining-center-supplier-a-complete-buyers-guide/)

[9](https://www.longshengmfg.com/cnc-machining-comparison-how-to-evaluate-services-through-reviews-head-to-head-analysis/)

[10](https://kesugroup.com/how-to-evaluate-the-machining-precision-and-quality-of-cnc-service-providers/)

[11](https://jlccnc.com/blog/10-key-factors-to-consider-when-choosing-a-cnc-machining-company)

[12](https://uptivemfg.com/best-cnc-machining-companies/)

content is empty!

What Are The Benefits of Rapid Prototyping to The Manufacturer?

What Are The Advantages of Using Pytorch for Rapid Prototyping?

What Are The Advantages and Disadvantages of Rapid Prototyping?

Top On Demand 3D Printing Manufacturers and Suppliers in Netherlands

Top On Demand 3D Printing Manufacturers and Suppliers in Norway

Top On Demand 3D Printing Manufacturers and Suppliers in Turkey

Top On Demand 3D Printing Manufacturers and Suppliers in Poland

Top On Demand 3D Printing Manufacturers and Suppliers in Vietnam