Views: 222 Author: Amanda Publish Time: 2025-09-15 Origin: Site

Content Menu

● Understanding Sheet Metal Fabrication

● Why Consistent Quality Matters

● Key Factors Influencing Quality in Batch Production

>> Material Selection and Control

>> Precision Cutting and Forming Techniques

>> Tooling and Equipment Maintenance

>> Skilled Workforce and Training

>> Process Monitoring and Quality Control Systems

● Best Practices for Quality Consistency

>> Employ Reliable Material Sources

>> Routine Equipment Calibration and Maintenance

>> Utilize Automation and Digitization

>> Monitor and Adjust Process Parameters

>> Implement Comprehensive Inspection Regimes

>> Apply Statistical Process Control (SPC)

>> Foster a Culture of Continuous Improvement

● Challenges and Their Solutions

>> Material Variability Management

>> Handling Complex Part Designs

● FAQ

>> 1. How important is material quality for batch sheet metal fabrication?

>> 2. What role does tooling maintenance play in consistent quality?

>> 3. How can automation improve sheet metal batch production quality?

>> 4. What inspection methods are recommended for sheet metal parts?

>> 5. How does statistical process control (SPC) benefit batch fabrication?

Ensuring consistent quality in batch production of sheet metal parts is critical for meeting customer expectations, minimizing waste, and maintaining efficient manufacturing operations. By implementing strategic controls over every stage—from raw material selection through fabrication processes to final inspections—manufacturers can deliver reliable, uniform products that align with stringent OEM standards. This article delves into actionable best practices to guarantee quality consistency in Sheet Metal Fabrication.

Sheet metal fabrication is the process of shaping thin metal sheets into functional components, extensively used in industries such as automotive, aerospace, electronics, and construction. It encompasses various techniques including cutting, bending, stamping, welding, and finishing. Batch production, where parts are manufactured in defined quantities, demands exceptional process control to ensure every component meets preset specifications without variation.

Inconsistent quality in batch manufacturing can cause cascading problems: defective parts lead to assembly line halts, increased material waste, higher costs due to rework or scrap, and ultimately dissatisfaction among end customers. Alternatively, consistent quality ensures each part integrates smoothly into larger assemblies, minimizing downtime and boosting overall operational efficiency. Maintaining such uniformity builds trust with international OEM clients demanding exacting standards, strengthens supplier reputation, and delivers cost savings through reduced failures.

Realizing consistent quality in sheet metal parts depends on careful management of several critical aspects:

High-quality sheet metal raw materials are the foundation for repeatable output. Variability in metal thickness, tensile strength, alloy composition, and surface finish can produce inconsistencies. Establishing strong supplier partnerships with verified certifications and subjecting received sheets to rigorous incoming inspection—including thickness gauging and surface defect detection—help assure batch uniformity.

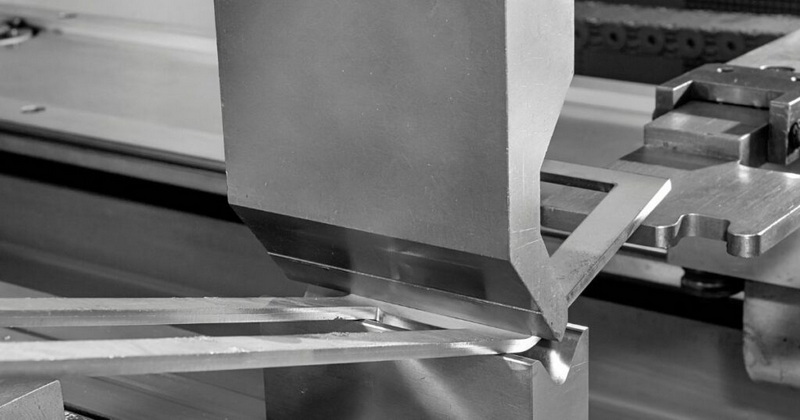

The selection and maintenance of cutting methods—laser, plasma, waterjet, or mechanical punching—significantly affect edge integrity and dimensional accuracy. Similarly, bending operations must be precisely controlled to achieve target angles and radii while mitigating springback effects common to metal forming. Advances in CNC press brakes with programmable back gauges provide enhanced repeatability essential for batch consistency.

Tool condition directly impacts part quality. Progressive wear on dies, punches, and bending tools causes measurement drifts and surface damage. Instituting a preventive maintenance schedule and using tool wear monitoring systems enables timely tool replacement, preventing quality degradation mid-production.

Even the best equipment requires seasoned operators and technicians. Well-trained personnel who understand machine parameters, quality standards, and troubleshooting protocols are fundamental to sustaining quality. Investing in continuous education fosters skill improvement and adherence to manufacturing guidelines.

Incorporating automated systems to monitor parameters such as cutting speed, laser power, bending force, and weld quality allows proactive detection of anomalies. Statistical process control (SPC) methods enable manufacturers to analyze variation trends and respond swiftly, minimizing defect propagation.

Achieving superior consistency in batch sheet metal fabrication depends on a multi-faceted approach encompassing the following practices:

Develop and enforce Standard Operating Procedures (SOPs) that detail every fabrication step—from machine settings and tool changes to inspection criteria. SOPs facilitate repeatability and reduce operator-dependent variability.

Select suppliers based on rigorous quality criteria, ensuring raw sheet metal complies with both dimensional and mechanical property requirements. Monitor incoming stock for deviations using thickness monitoring gauges and visual surface inspection to detect scratches, corrosion, or dents.

Regular calibration of cutting machines, press brakes, welding units, and inspection devices is essential for preserving accuracy. Schedule preventive maintenance to avoid unexpected failures that could disrupt production continuity.

Where feasible, integrate automated cutting, forming, and welding systems to minimize manual handling errors. Advanced CNC controls and robotic welders deliver precise, repeatable results. Digital record-keeping enhances traceability and supports continuous improvement initiatives.

Real-time sensing equipment measuring variables such as laser intensity, punch pressure, and bend angle enable immediate corrections if parameters drift outside tolerance ranges. Maintaining process stability reduces quality variation.

Adopt in-process and final quality checks using advanced measurement tools like coordinate measuring machines (CMM), optical comparators, surface roughness testers, and vision systems. Early detection of defects prevents defective parts from progressing further.

Use SPC charts to analyze quality data and monitor process capability indices. Detecting patterns or trends helps teams identify root causes before defects escalate, fostering data-driven decision making.

Gather feedback from operators, quality engineers, and customers to pinpoint inefficiencies. Employ Lean manufacturing and Six Sigma methodologies to refine processes continuously, eliminating non-value-added activities and enhancing uniformity.

While demands for high-quality, consistent sheet metal parts grow, manufacturers often face obstacles that must be addressed for successful batch production.

Fluctuations in sheet metal properties such as thickness and alloy composition affect bending springback and weld integrity. Close collaboration with suppliers, routine batch testing, and use of homogenized metal batches ensure raw material consistency.

Tools deteriorate over time, causing dimensional shifts and surface imperfections. Integrating tool condition monitoring and proactive replacement plans prevents impact on quality mid-run.

Temperature and humidity can influence metal behavior and machine accuracy. Maintaining climate-controlled production areas stabilizes material characteristics and dimensional results.

Multi-bend or tight-tolerance designs increase complexity. Investing in CNC press brakes programmed with precise bend sequences and incorporating bend compensation techniques achieves repeatability.

Consistent quality in batch production of sheet metal parts depends on meticulous management across materials, skilled labor, tooling, process control, and quality assurance. Standardized operations, automation, real-time monitoring, and rigorous inspection protocols combine to deliver uniform products that fulfill exacting OEM requirements. Tackling challenges such as material variability and tool wear through proactive strategies further supports reliability. Manufacturers who embed continuous improvement into their production systems enhance productivity, reduce waste, and strengthen competitive advantage in the demanding global market.

Material quality is foundational since variations in thickness and mechanical properties directly affect bending accuracy, weld strength, and final component uniformity. Ensuring certified, consistent raw material supply is critical.

Regular tooling maintenance prevents wear-induced dimensional shifts and surface defects. Timely inspection and replacement of worn dies and punches maintain machining precision and part integrity.

Automation minimizes human error, ensures exact repeatability of machine parameters, and facilitates real-time process control and data collection, thereby boosting overall product consistency.

Inspection techniques include coordinate measuring machines (CMM) for dimensional verification, optical comparators for profile checks, surface roughness testers for finish quality, and visual inspections to detect physical defects.

SPC enables continuous monitoring of manufacturing data to detect early deviations, facilitating timely corrective actions that prevent defective part production and maintain process stability.

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal