Views: 222 Author: Amanda Publish Time: 2025-11-09 Origin: Site

Content Menu

● Understanding Turning Lathe Fundamentals

● Core Specifications and How They Drive Choice

● Manual vs CNC vs Hybrid: How to Decide

● Materials, Workpiece Types, and Cutting Considerations

● Shop Layout, Footprint, and Throughput

● Downtime, Maintenance, and Total Cost of Ownership

● Quality Assurance and Process Control

● Practical Evaluation and Selection Checklist

● Materials Handling, Fixturing, and Process Automation

● Case Studies and Real-World Scenarios

● Best Practices for OEMs and International Partners

● Why Shangchen Excels in OEM Turning Lathe Solutions

● FAQ

>> 1) What is the most important factor when choosing a turning lathe for a small shop?

>> 2) How does CNC control impact production efficiency on a turning lathe?

>> 3) What are common indicators of a turning lathe suffering from spindle misalignment?

>> 4) How can I estimate the total cost of ownership for a turning lathe?

>> 5) Which accessories most improve throughput on a turning lathe in a production environment?

Choosing the right turning lathe is a strategic decision that shapes product quality, production efficiency, and long-term profitability. For foreign brands, wholesalers, and manufacturers seeking reliable OEM capabilities, selecting a machine that balances capacity, rigidity, control, and total cost of ownership is essential. This guide synthesizes practical considerations—ranging from core specifications to shop-floor planning and supplier collaboration—so that workshop managers, engineers, and machinists can make informed, repeatable decisions. Although the focus is on turning lathe performance in prototype environments and scalable production contexts, the guidance applies across industries, from automotive components to precision fasteners. The aim is to help readers identify a turning lathe that integrates smoothly with existing workflow, tooling ecosystems, and quality assurance practices, delivering consistent parts and predictable throughput.

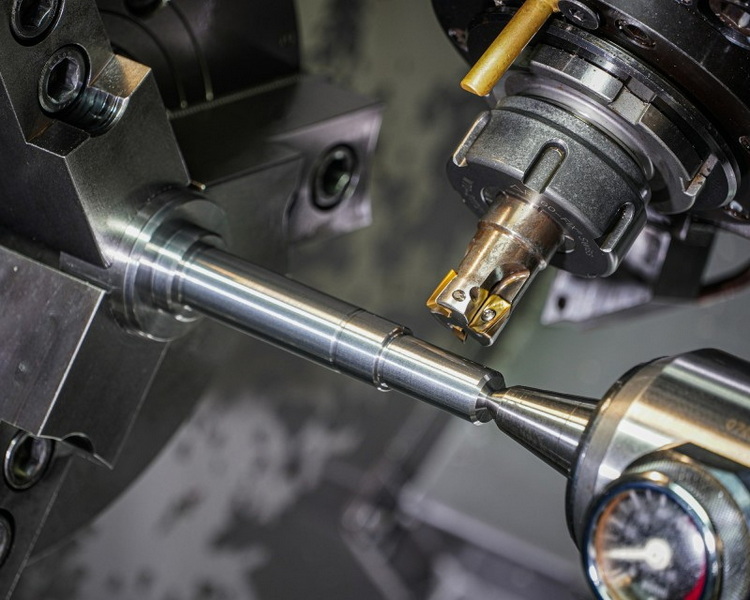

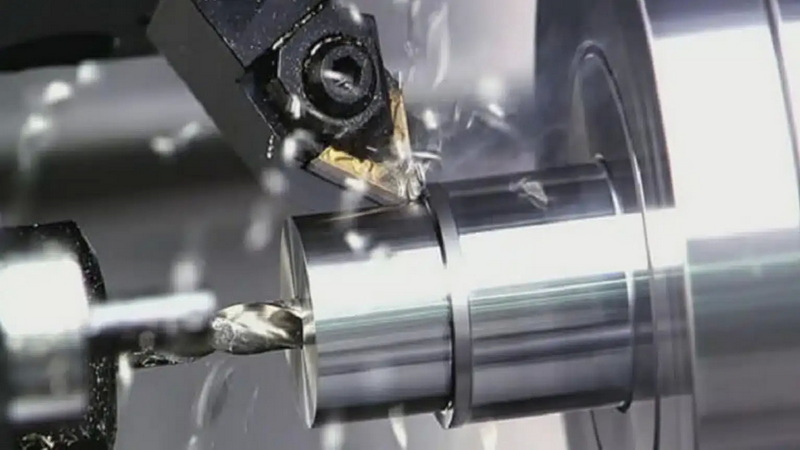

A turning lathe is a machine tool that rotates a workpiece while stationary cutting tools remove material to shape it. The headstock and spindle drive the rotation, while the tailstock supports longer or flexible workpieces. The carriage, cross-slide, and tool post provide precise tool positioning, enabling operations such as facing, turning, threading, and bore finishing. In a commercial setting, the key to successful turning lathe selection lies in balancing rigidity, thermal stability, and control with the anticipated mix of parts, production volume, and required tolerances. Factors such as bed stiffness, way design, spindle accuracy, and drive system quality determine how well the machine resists chatter and maintains dimensional integrity under load. A well-chosen turning lathe reduces scrap, shortens cycle times, and improves repeatability across batches, which is especially important for OEM supply chains and long-term supplier partnerships.

When evaluating turning lathes, several specifications directly influence capability and economics:

- Swing over bed and over carriage: These determine the largest diameter of a workpiece that can be turned without overhang issues. A larger swing expands part size capacity but often increases footprint and price.

- Distance between centers: This specifies the maximum part length that can be machined between the headstock and tailstock. Longer centers enable handling of extended shafts or prototypes with intricate end features.

- Spindle bore and speed range: A larger through-spindle bore allows through-spindle tooling or bar stock passage, while a wide speed range accommodates diverse materials and operations, from soft aluminum to hard alloys.

- Bed rigidity and ways: Rigid beds and precisely machined ways minimize deflection and chatter, supporting tight tolerances and smooth surface finishes.

- Power, torque, and cutting performance: Higher horsepower and torque at low speeds improve heavy-cut capability and prevent stalling with tough materials.

- Feed rates, threading capabilities, and automation: Programmable feeds and threading eliminate manual adjustments for recurring operations, boosting throughput and consistency.

- Control system (manual, CNC, or hybrid): CNC turning lathes enable automation, repeatability, and multi-program workflows; manual machines offer flexibility for quick setup and bespoke parts; hybrids provide a transitional path toward automation.

- Tooling ecosystem and accessory support: Availability of chucks, collets, live centers, steady rests, bar feeders, and tooling options affects setup speed and versatility.

- Thermal management and accuracy features: Elements such as thermal compensation, spindle pre-load, and temperature-stable components help maintain precision over long production runs.

- Manual turning lathes: Best for education, small-batch prototyping, and highly customized jobs requiring flexible setups. Throughput is limited by operator speed and precision, but the equipment cost is often lower and maintenance straightforward.

- CNC turning lathes: Ideal for consistent production runs, tight tolerances, and complex geometries. Automation enables repeatable quality, shorter cycle times, and easier scaling. These machines are well-suited for OEM pipelines, where volume, uniformity, and traceability matter.

- Hybrid turning lathes: Combine CNC features with manual overrides, offering a bridge for shops transitioning to automation or handling highly varied workloads. They can reduce changeover times while preserving some hands-on control for specialized parts.

Materials influence cutting strategies and tooling requirements. Softer materials like aluminum and many plastics respond to higher feed rates and lighter cuts, while stainless steel and hard alloys demand robust rigidity, effective cooling, and careful tool selection. The choice of toolholding, spindle accuracy, and geometric tolerances directly affects surface finish and dimensional control. A properly specified turning lathe should preserve stable cutting conditions across the intended material mix, supporting prototypes through production without compromising quality.

The physical footprint matters as much as capability. Larger bed lengths and swings demand more floor space, crane or cart access, and effective chip and coolant management. A well-planned layout minimizes travel time between operations, streamlines part transfer, and reduces handling. Consider future needs such as longer parts, larger diameters, or expanded automation when selecting a turning lathe. A modular approach, with compatible fixtures and job routing, helps establish a scalable workflow from prototype through mass production.

Total cost of ownership extends beyond the sticker price. Maintenance frequency, parts availability, tooling costs, and energy consumption all affect long-term value. Machines with proven reliability and a robust regional service network reduce downtime and facilitate timely repairs. Regular preventive maintenance—spindle alignment, ways lubrication, coolant system upkeep, and calibration checks—preserves accuracy and performance across the machine's lifecycle.

A turning lathe should integrate with a shop's quality system. In-process metrology, such as roundness checks, concentricity measurements, and surface finish assessments, ensures every batch meets spec. Data capture and traceability enable continuous improvement and compliance with industry standards. For high-mix, low-volume production, a flexible measurement plan and compact gauging fixtures support rapid validation without sacrificing accuracy.

- Define product mix and forecast demand for the next 12–24 months to understand throughput requirements.

- Determine the largest part geometry, required swing, center distance, and through-spindle needs.

- Decide on manual, CNC, or hybrid control based on production tempo, staffing, and future automation goals.

- Assess shop floor space, including machining area, fixturing, material handling, and maintenance access.

- Evaluate total cost of ownership: purchase price, tooling, maintenance contracts, energy usage, and downtime risks.

- Ensure reliable service and spare parts availability in the region to minimize downtime.

- Review the tooling ecosystem (collets, chucks, threading dies, bar feeders) and compatibility with current fixtures and measurement protocols.

- Plan for integration with existing software, databases, and data analytics tools used for quality and production planning.

A turning lathe thrives when paired with efficient fixtures, quick-change tooling, and an appropriate automation layer. Quick-change chucks, stable fixtures, and compatible probing or gauging devices reduce setup time and improve repeatability. For OEM operations with high-volume production, options such as automatic tool changers, robotic part loading, and off-line programming can yield meaningful gains in cycle time and part consistency.

- Prototyping with compact components: A small CNC turning lathe enables rapid iteration of part programs, reducing lead times while preserving tight tolerances essential for early-stage design validation.

- Moderate-volume production with high mix: A hybrid lathe supports a broad range of geometries and materials, enabling efficient changeovers and maintaining quality across diverse parts.

- High-volume, standardized parts: A dedicated CNC turning lathe with automation delivers consistent throughput and repeatability, supporting long production runs with minimal operator intervention.

- Align equipment choice with production volumes, lead times, and quality requirements of international brands and wholesale partners.

- Focus on customization: tooling compatibility, quick-change capabilities, and fixtures that align with existing designs and measurement protocols.

- Ensure robust traceability: integrate measurement data capture and batch-level documentation.

- Plan for after-sales support: a dependable service network, parts availability, and remote diagnostics can significantly reduce downtime.

Shangchen offers a comprehensive suite of rapid prototyping, CNC machining, precision mass production, turning, sheet metal fabrication, 3D printing, and mold production services for foreign brands, wholesalers, and manufacturers. The company emphasizes fast turnarounds, consistent quality, and scalable production, guiding clients from design through production to ensure parts meet exacting tolerances and regulatory requirements. An integrated approach supports smooth transitions from prototype to mass production, delivering reliable OEM solutions aligned with product specifications and market timelines.

Choosing the right turning lathe is a strategic decision that affects product quality, production efficiency, and long-term profitability. By evaluating capacity, rigidity, control systems, and the ecosystem of tooling, manufacturers can select equipment that scales with demand and integrates with existing processes. For international OEM partnerships and domestic workshops alike, a well-chosen turning lathe supports rapid prototyping, precise machining, and reliable production, enabling faster time-to-market and higher-quality parts.

- The most important factor is balancing capacity and rigidity with your production needs and budget to ensure consistent part quality and minimal downtime.

- CNC control improves repeatability, reduces cycle times, and enables automation and off-line programming for higher throughput and lower labor costs.

- Common indicators include unusual vibration, tapering, poor surface finish, and inconsistent diameters across parts, especially at higher speeds.

- Estimate by summing purchase price, tooling and consumables, maintenance and service, energy usage, and expected downtime or loss of productivity over the machine's life.

- Key accessories include quick-change chucks, bar feeders, automatic tool changers, probing/ gauging devices, and robotic or automated part loading systems.

[1](https://www.bhel.com/sites/default/files/VTL4000-COMBINED-NIT_6918.pdf)

[2](https://www.sahilcnc.com/guides/conventional-vertical-turning-lathe-machine-1/)

[3](https://www.kdkce.edu.in/upload/Lathe%20Machine.pdf)

[4](https://www.scribd.com/document/618645110/Schedule-of-Requirement)

[5](https://www.bintso.org.tr/Portals/304/Haber_Foto/CNC-Lathe-Machine-Specification.pdf)

[6](https://cncwmt.com/qa/how-do-you-read-a-lathe-specification-sheet-with-confidence/)

[7](https://www.goldenmachinery.com/blogs/specification-of-lathe-machine)

[8](https://headland.au/static/e5242825ceb226b61081f683c436db4a/BOST-Catalogue.pdf)

[9](https://www.dinosawmachine.com/blog/how-does-a-stone-lathe-work-a-technical-guide/)

[10](http://www.primero.com.tw/pdf/vertical_lathe_machine.pdf)

content is empty!

What Are The Benefits of Rapid Prototyping to The Manufacturer?

What Are The Advantages of Using Pytorch for Rapid Prototyping?

What Are The Advantages and Disadvantages of Rapid Prototyping?

Top On Demand 3D Printing Manufacturers and Suppliers in Netherlands

Top On Demand 3D Printing Manufacturers and Suppliers in Norway

Top On Demand 3D Printing Manufacturers and Suppliers in Turkey

Top On Demand 3D Printing Manufacturers and Suppliers in Poland

Top On Demand 3D Printing Manufacturers and Suppliers in Vietnam

Top On Demand 3D Printing Manufacturers and Suppliers in Japan