Views: 222 Author: Amanda Publish Time: 2025-11-04 Origin: Site

Content Menu

● Understanding Moulding Production

● Key Factors Influencing Your Moulding Production Selection

>> Product Specifications and Complexity

>> Volume and Production Scale

>> Tolerances and Surface Requirements

>> Lead Time and Speed to Market

● Overview of Major Moulding Production Methods

>>> How It Works

>>> Variations

>>> Process Features

>>> How It Works

>>> Limitations

>>> How It Works

>>> Limitations

>>> How It Works

>>> Limitations

>>> How It Works

>>> Limitations

>>> How It Works

>>> Limitations

● Specialization Trends in Modern Moulding Production

>> Multi-Material and Insert Moulding

>> Smart Manufacturing and Automation

>> Sustainable Moulding Production

>> Rapid Prototyping and Soft-Tooling

● Process Control, Testing, and Quality Assurance

>> Tooling Design and Validation

>> Injection Moulding Process Steps

>> Post-Processing and Quality

● How to Choose the Right Moulding Production Method

>> Step 1: Define Specifications

>> Step 2: Evaluate Process Alignment

>> Step 3: Prototyping & Iteration

>> Step 4: Refinement and Production Launch

>> Step 5: Continual Assessment

● FAQ

>> 1. What is the most efficient moulding production technique for complex, high-precision parts?

>> 2. Which moulding production process is ideal for large hollow products?

>> 3. How do I lower my upfront costs when launching a new product?

>> 4. What are key considerations for sustainable moulding production?

>> 5. How vital is prototyping before mass production?

Selecting the appropriate moulding production method is fundamental for ensuring product quality, manufacturing speed, and commercial competitiveness. As global business relationships deepen and demands for rapid prototyping and sophisticated parts increase, a strategic approach to moulding production yields clear commercial benefits. Modern factories, like Shangchen, provide comprehensive OEM services across prototyping, CNC machining, volume production, and mold manufacturing, earning trust among international brands, wholesalers, and manufacturers.[1][11]

Properly matching your product, market, and business objectives to the right moulding production process can save considerable costs, shorten delivery cycles, and guarantee that your products meet stringent industry standards. In this detailed guide, you'll learn everything necessary to make informed decisions regarding moulding production, so your product reaches the market swiftly, efficiently, and with uncompromising quality.

Moulding production is the process of shaping raw materials into usable parts or products by forcing them into custom-shaped molds. It encompasses a diverse set of processes, each with its own technical nuances, cost structures, and areas of optimal use.[11][12]

The core processes used in moulding production include:

- Injection Moulding: For high-precision, high-volume production.

- Rotational Moulding: For hollow products, such as tanks.

- Blow Moulding: For bottles and other uniform, hollow items.

- Compression Moulding: For thermoset plastics and large, simple parts.

- Extrusion Moulding: For long, uniform profiles like pipes.

- Thermoforming: For packaging, trays, and other simple thin-walled forms.

Understanding each method's strengths and limitations is essential for cost-efficient, quality-driven manufacturing.

The size, geometry, structural details, material, and finishing needs of the product will determine which moulding production method is suitable. Complex features, undercuts, threads, or multi-material parts often require different moulding strategies, such as overmoulding or insert moulding.[1][11]

Not all materials are compatible with every moulding production technique. Thermoplastics like ABS, PC, and PE are best processed via injection or blow moulding, whereas thermosets and certain composites might require compression moulding or specialized approaches.[6][11]

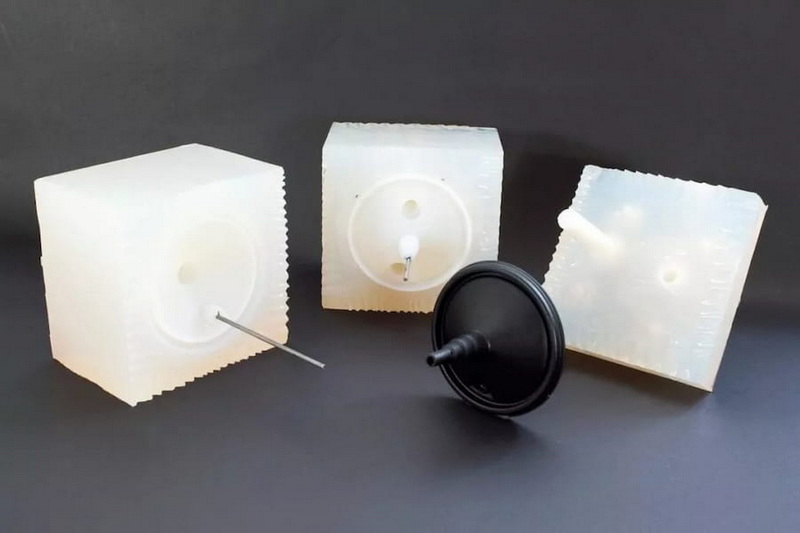

- Prototyping/Low Volumes: Silicone casting, 3D printing, or rapid tooling.

- Limited to Medium Runs: Rotational, compression, or blow moulding.

- Mass Production: Typically injection or extrusion moulding, which are cost-effective at high volume due to lower per-unit costs after recouping tooling investments.[11][1]

Parts requiring precision tolerances and perfect surface finishes are best made through tightly controlled processes like injection moulding. When tolerance is less stringent, other methods may be more practical and budget-friendly.

Moulding production involves both up-front and per-unit costs. High production volumes often justify more significant investments in durable tooling, while short runs benefit from techniques with lower start-up costs.

When timelines are tight, rapid prototyping, soft tooling for injection moulding, or 3D printed moulds may be preferable. For ongoing, large-scale production requiring high repeatability, investing in hard tooling is more cost-efficient.[5][11]

- Tooling is fabricated using CNC machining or EDM (Electrical Discharge Machining), typically in hardened steel or aluminum.[3][5]

- Plastic pellets are melted then injected into a clamped mold at high pressure.[5][6]

- The material fills every detail of the cavity, cools, and solidifies, after which the part is ejected and trimmed.

- Extremely accurate, ideal for intricate plastic parts (automotive, medical, consumer goods).

- Supports virtually any thermoplastic and some thermosets.

- Highly efficient for mass production due to quick cycle times and low per-part cost at volume.[13][1]

- Overmoulding: Combines multiple materials, such as soft grips on tools.

- Insert Moulding: Embeds metal or other elements in plastics for integrated features.

- Liquid Silicone Rubber Moulding: Uses silicone for soft, flexible products.[1]

- High upfront tooling cost, offset by the low marginal cost in volume production.

- Ability to include design details such as text, logos, threads, or tight assembly features.[2][3]

- Powder or liquid resin is introduced into a hollow mold.

- The mold rotates in multiple axes as it is heated, causing the resin to stick evenly to all interior surfaces.

- The mold cools, and the hollow part is demolded.[11]

- Perfect for tanks, playground structures, and complex, seamless hollow shapes.

- Flexible production for large and medium volumes.

- Minimal material waste and relatively low tooling cost.

- Limited to hollow items, fewer suitable materials, longer cycle times.

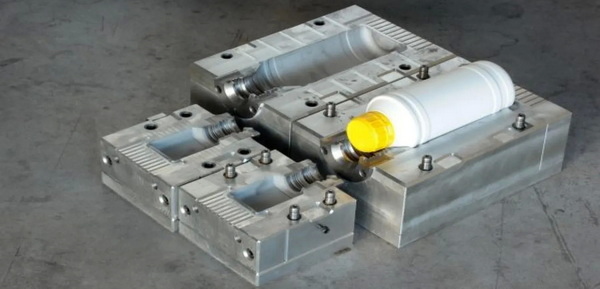

- A softened tube of plastic (parison) is placed in a mold and then inflated to conform to shape.[6]

- Cooling finalizes the form, which is then ejected for trimming.

- Most common method for manufacturing bottles, containers, and drums.

- Low cycle times and costs per part at high volume.

- Mostly limited to uniform, hollow forms.

- Pre-measured, often thermoset material is placed in an open mold cavity and compressed with another mold.

- Heat and pressure shape the part, then it cools and solidifies.[12][11]

- Well-suited for large items, automotive components, and electrical enclosures needing rigidity or high strength.

- Less suitable for intricate details, sometimes slower than injection processes.

- Material is forced through a die of the desired cross-sectional profile, cut to length as required.

- Ideal for pipes, profiles, films, and sheets.

- Fast, efficient, virtually no material waste.

- Only possible for shapes with uniform cross-sections.

- Plastic sheet is heated, then stretched over or into a mold and trimmed to shape.

- Cost-effective for large, thin-walled parts such as signs or packaging trays.

- Designs are restricted to simple, relatively shallow shapes.

The demand for products that combine properties, for example, rigid bodies with soft touch surfaces, is increasing. Overmoulding and insert moulding allow engineers to combine multiple materials or embed electronics and fastenings directly into products. These advanced moulding production capabilities expand design potential and unlock new market opportunities.[1]

Advancements in automation, robotics, and real-time monitoring have resulted in highly precise, repeatable, and automated moulding production lines. This ensures consistent product quality and cost savings, essential for industries such as automotive, aerospace, and consumer electronics.[5]

Sustainability is a growing concern for global OEMs. Many manufacturers are shifting towards recyclable materials, closed-loop processes, and energy-efficient machinery. Deflashing and recycling of scrap plastic from trimming is increasingly standard.

3D printing and other additive approaches support quick, affordable iteration in design, allowing for pre-production validation before expensive hard tools are committed. Soft tooling can bridge the gap between initial prototypes and full-scale moulding production.[3]

Modern CAD/CAM software and virtual simulation allow engineers to test flow, cooling rates, stress concentrations, and manufacturability before the first tool is cut. Rapid prototyping offers an additional check, so flaws are identified early.[3]

1. Clamping: Secures mold halves together under pressure.[2]

2. Injection: Hot, liquefied material injected to fill the cavity.

3. Dwelling: Material is held under pressure to eliminate air pockets.[2]

4. Cooling: Mold is cooled until the product solidifies.

5. Mold Opening: Clamps release, mold parts are separated.[2]

6. Ejection: Mechanical systems eject the finished part for trimming.[2]

Each stage is tightly monitored using sophisticated controls to maintain high part consistency and prevent defects.

Typical post-processing steps for moulded products include deflashing, trimming, surface calendaring, or applying textured finishes. Quality programs (such as ISO, PPAP, or sector-specific certifications) are standard for high-value applications.[5]

Document volume, geometry, material needs, tolerances, budget, technical complexity, and lead time targets in detail.

Match your project's attributes to candidate moulding production techniques, using the detailed overviews above. Consult with suppliers for input on manufacturability and cost.

Develop prototypes via 3D printing or soft tooling to validate part fit, function, and market acceptance before moving to hard tooling and mass moulding production.

After pilot and prototype validation, commence full-scale production with robust quality control, in-process monitoring, and clear supply chain communication.

As your production volumes or product mix evolves, periodically reassess if your current moulding production method remains the most competitive and reliable choice.

Making the best choice for your moulding production method is the foundation of successful, cost-effective, and high-quality manufacturing. By taking a systematic approach—analyzing product requirements, material compatibility, expected volumes, cost structure, and production timelines—companies can maximize value, minimize waste, and ensure their products are ready for global competition. Leveraging the expertise of specialized OEM partners supports successful launches and long-term operational excellence.[6][11][1][5]

Injection moulding is the preferred method for high-volume, intricate plastics, offering low unit costs at scale and tight tolerances.[1][5]

Rotational moulding is unmatched for producing tanks, playground equipment, and other seamless hollow components, balancing low tooling cost with flexible design.[11]

Utilize 3D printing for pre-series prototypes or soft tooling for limited runs, before committing to high-investment hard tooling for mass moulding production.[3]

Prioritize material recyclability, use efficient machinery, recycle scrap, and choose processes that minimize waste, such as extrusion and rotational moulding.[5]

Prototyping is critical for verifying fit, finish, functionality, and user satisfaction before investing in production moulds and full-volume manufacturing, reducing costly errors and market risk.[3]

[1](https://www.protolabs.com/resources/guides-and-trend-reports/designing-for-moldability-fundamental-elements/)

[2](https://sybridge.com/injection-molding-guide/)

[3](https://advancedplastiform.com/a-guide-to-injection-molding-tooling/)

[4](https://www.extrememolding.com/blog/guide-to-mold-manufacturing-its-processes)

[5](https://geomiq.com/injection-moulding-guide/)

[6](https://formlabs.com/blog/guide-to-manufacturing-processes-for-plastics/)

[7](https://www.ksplastic.com/blog/comprehensive-guide-to-plastic-injection-molding/)

[8](https://toolbox.igus.com/10143/what-is-injection-molding)

[9](https://www.cadrex.com/a-starter-guide-to-injection-molding)

[10](https://iranettekal.com/moulding-and-molding/)

[11](https://fibertechplastics.com/custom-rotational-molding/a-simple-guide-to-plastic-molding/)

[12](https://formlabs.com/blog/how-to-make-a-mold/)

[13](https://uptivemfg.com/8-advantages-of-injection-molding/)

content is empty!

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes

Best Practices from Leading Vacuum Mold Casting Companies Worldwide

Top Vacuum Mold Casting Providers for Custom Batch Production

How to Choose the Right Vacuum Mold Casting Service for Your Product