Views: 222 Author: Amanda Publish Time: 2025-12-16 Origin: Site

Content Menu

● From Concept to Clinical Trial-Ready Prototype

● Why Clinical Trials Need Rapid Prototyping

● Main Types of Rapid Prototyping Tools in Clinical Trial Design

● 3D Printing as a Rapid Prototyping Engine for Trials

● CNC Machining and Precision Rapid Prototyping

● Sheet Metal, Fabrication, and Supporting Structures

● Rapid Tooling and Small-Batch Clinical Supplies

● Digital Rapid Prototyping of Clinical Software and Workflows

● Improving Trial Design Quality with Rapid Prototyping

● Time, Cost, and Risk Benefits

● Regulatory and Documentation Advantages

● Supporting Patient-Centric and Personalized Trials

● Using Rapid Prototyping Data to Refine Protocols

● Role of Integrated OEM Partners Like Shangchen

● Practical Tips for Using Rapid Prototyping in Clinical Trials

● FAQ

>> 1. How does rapid prototyping specifically support early-phase clinical trials?

>> 2. Which rapid prototyping technologies are most useful for clinical trial devices?

>> 3. Can rapid prototyping parts be used directly with patients in a trial?

>> 4. How does rapid prototyping influence regulatory submissions?

>> 5. Why should sponsors work with an integrated OEM rapid prototyping partner?

Rapid prototyping has become a critical bridge between conceptual clinical trial designs and the real-world tools used by investigators and patients. By using rapid prototyping across hardware, software, and workflow elements, sponsors can expose weaknesses early and arrive at a more robust, patient-centric trial design. In this integrated context, an OEM partner capable of CNC machining, 3D printing, sheet metal fabrication, and mold production makes rapid prototyping far more powerful for global trial programs.

Rapid prototyping is a set of methods that quickly transform three-dimensional or digital designs into workable prototypes for evaluation and testing. In clinical trial design, this means moving from PowerPoint concepts, protocol drafts, or CAD sketches to tangible devices, instruments, and interfaces that doctors and patients can touch, use, and critique. When that loop becomes fast and inexpensive, trial teams can test more ideas before committing to a single design.

For physical tools such as delivery systems, diagnostic housings, and monitoring accessories, rapid prototyping allows multiple form factors and mechanisms to be built and compared side-by-side. For digital tools such as eCRFs, dashboards, and patient apps, rapid prototyping of wireframes and interactive mock-ups enables realistic usability sessions with clinicians and patients. In both domains, feedback flows directly into design improvements before regulatory filings or large-scale manufacturing.

Clinical trials are expensive and tightly regulated, so design errors discovered late can lead to delays, protocol amendments, or even failed studies. Rapid prototyping brings those risks forward into a safe sandbox where devices and tools can fail fast, be redesigned, and tested again without harming timelines or patients. This is especially important when new modes of action, new routes of administration, or novel digital endpoints are involved.

Rapid prototyping also supports a shift from paper-driven, assumption-based trial design towards evidence-informed design. Rather than guessing whether investigators will use a device correctly or whether patients will adhere to a digital diary, teams can prototype the actual tools and observe behavior in simulations or pilot studies. That evidence feeds back into more realistic schedules, training plans, and endpoint definitions.

In practice, rapid prototyping in clinical trial design typically uses a combination of:

- Additive manufacturing (for complex, low-volume clinical prototypes)

- Subtractive machining (for high-precision or production-like materials)

- Sheet metal and fabricated structures (for brackets, frames, and enclosures)

- Rapid tooling and soft molds (for small-scale injection or casting)

- Digital rapid prototyping (for software and clinical informatics tools)

The exact mix of rapid prototyping approaches depends on the device class, clinical indication, regulatory path, and planned scale of use in the trial. For early feasibility or first-in-human studies, sponsors often favor flexible additive and CNC rapid prototyping; for later pivotal trials that require many identical units, rapid tooling or near-production methods become more important.

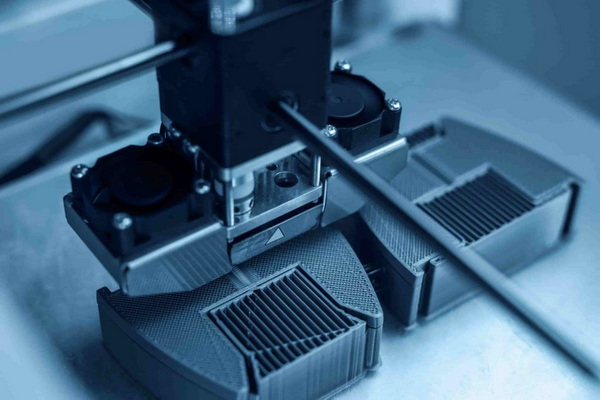

3D printing is one of the most versatile rapid prototyping tools for clinical programs because it can quickly produce complex shapes, internal channels, and patient-specific geometries. For example, surgical guides, anatomical models, and custom-fitting supports can be printed directly from medical imaging, then evaluated in simulations or preclinical work. This improves confidence that the device or tool will perform as expected when used in live trials.

Beyond purely anatomical models, rapid prototyping through 3D printing is used for housings of diagnostic devices, pump bodies, inhaler prototypes, wearable shells, and ergonomic grips. Because 3D printers can switch designs and material types quickly, sponsors can explore many variants—different button positions, indicator lights, surface textures, or strap geometries—without retooling. That flexibility reduces the chance that human-factor issues will surface unexpectedly in the middle of a pivotal trial.

When mechanical strength, tight tolerances, or metal components are required, CNC machining becomes a key rapid prototyping method in clinical development. CNC-machined prototypes can use materials similar or identical to those intended for the final product, allowing realistic evaluation of fatigue, sterilization response, and dimensional stability. This is vital for implants, orthopedic instruments, surgical robots, and devices that interface directly with other clinical systems.

In early-stage trials, CNC-based rapid prototyping is often used to create limited series of functional devices for bench testing and preclinical experiments. For later-phase trials and compassionate-use programs, CNC machining can bridge the gap between prototypes and full production by providing small to medium batches of production-grade parts. This continuity from prototype to clinical device simplifies validation and documentation because the same design and manufacturing assumptions can carry through.

Clinical trials often depend on more than the obvious “primary device.” They also require stands, brackets, frames, enclosures, carts, and installation fixtures used in operating rooms, wards, or outpatient clinics. Rapid prototyping using sheet metal fabrication and simple welded or assembled structures helps teams create these support elements quickly and refine them in real environments.

Using sheet metal rapid prototyping, sponsors and CROs can design equipment racks, mounting plates, and protective covers that integrate with hospital infrastructure. By testing these items early, they can identify conflicts with existing equipment, ensure compliance with infection-control practices, and optimize cable management or access panels. These details may seem minor, but they strongly influence ease of deployment and site satisfaction during large multicenter trials.

At some point, clinical trials require multiple identical devices or components, not just single prototypes. Rapid tooling—such as soft molds, bridge tooling, or modular inserts—allows sponsors to produce dozens or hundreds of units without waiting for final hardened steel molds. This intermediate rapid prototyping step reduces risk because designs can still be adjusted based on early trial experience before full-scale tooling is locked.

For example, a small batch of injection-molded housings or disposable parts can be produced via rapid tooling for a phase II study. If feedback reveals that a locking mechanism is confusing or a label recess is too small, adjustments can be made and a new rapid tool produced faster than a traditional mold modification. This approach keeps clinical development agile while moving closer to production realities.

Modern clinical trials depend heavily on digital ecosystems: eCRFs, decision-support algorithms, dashboards, and patient-facing apps. Applying rapid prototyping principles to these tools is just as important as rapid prototyping of physical devices. Low-fidelity wireframes and higher-fidelity clickable prototypes help teams explore user experience, data flows, and alert logic before building expensive, validated systems.

In co-design approaches, clinicians, nurses, coordinators, and sometimes patients interact with prototype clinical tools in simulated scenarios. Their feedback drives rapid prototyping changes to field labels, screen layouts, notification timing, and navigation structures. Once a design is proven to support the desired workflows and minimize cognitive load, developers can build the validated production system against a stable, tested specification.

Rapid prototyping improves clinical trial design quality by enabling user-centered development of both devices and workflows. Instead of imposing a design on investigators and patients, sponsors can invite them to participate in rapid prototyping sessions, review alternative configurations, and comment on real interactions. This collaborative process often reveals mismatches between protocol assumptions and actual practice.

For instance, rapid prototyping might show that a device requires too many steps during a busy clinical visit, leading to missed data or protocol deviations. Adjusting the interface, simplifying steps, or revising the protocol sequence based on rapid prototyping insights can significantly improve adherence. Over time, such refinements reduce the likelihood of under-enrollment, high dropout rates, or inconsistent execution across sites.

Although rapid prototyping sometimes has higher per-unit costs than traditional mass production, its value lies in avoiding rework, delays, and failed studies. Discovering design problems after investing in full tooling or after launching a pivotal trial can trigger costly redesigns and regulatory interactions. Rapid prototyping front-loads learning, making each subsequent stage more predictable.

Time savings also accumulate because detailed engineering decisions are validated earlier. When a design reaches later phases, both the clinical team and manufacturing partner already understand tolerances, material behaviors, assembly needs, and service procedures. This reduces surprises in scale-up and shortens the path from successful trial completion to market launch.

Regulators expect evidence that manufacturers have systematically addressed design risks, usability issues, and performance uncertainties. Rapid prototyping naturally generates such evidence in the form of test reports, design iteration records, and user-feedback notes. When organized correctly, this material strengthens design history files and technical documentation for submissions.

Furthermore, prototypes used in simulated or limited clinical settings can provide early insight into risk control measures, labeling strategies, and training requirements. Sponsors can use these lessons to develop more effective instructions for use and training packages for trial investigators. When regulators see that rapid prototyping has been used intelligently to reduce risk before broad exposure, it can support smoother review.

As medicine becomes more personalized, clinical trials increasingly involve patient-specific or subgroup-specific tools and pathways. Rapid prototyping is especially well suited to this environment because it can create bespoke or semi-custom components without prohibitive cost. Anatomical models for surgical planning, personalized braces, and tailored dosing adapters are prominent examples.

Rapid prototyping also enables trials to include patient-centric devices such as comfortable wearables, home-use sensors, and intuitive digital companions. Iterating these designs with real patients in a rapid prototyping loop helps refine comfort, aesthetics, and usability. Better experiences often translate into higher adherence, fewer missing data points, and stronger retention over time.

Data gathered during rapid prototyping cycles—whether from bench tests, usability studies, or simulations—can guide adjustments to clinical protocols. For example, if rapid prototyping reveals that a device requires twenty minutes to set up instead of ten, visit schedules might need adjustment to avoid clinic congestion. If usability tests show that elderly participants struggle with a particular step, sponsors might incorporate additional support or modify inclusion criteria.

By treating rapid prototyping as a structured learning phase, trial designers can fine-tune primary and secondary endpoints, visit windows, and training requirements. This not only improves operational feasibility but also strengthens the scientific integrity of the trial. When the final protocol reflects real-world insights gained through rapid prototyping, the probability of successful execution is higher.

An integrated OEM partner offers a single point of contact for multiple rapid prototyping technologies and the eventual transition to production. For overseas sponsors, this simplifies supply-chain management, technical communication, and quality oversight. With capabilities in rapid prototyping, CNC machining, precision batch production, turning, sheet metal, 3D printing, and mold production under one roof, Shangchen (sc-rapidmanufacturing.com) can support the entire path from first prototype to clinical and then commercial scale.

This integrated approach is particularly valuable for clinical trials because it keeps design intent, materials, and manufacturing parameters consistent through all phases. When early rapid prototyping parts prove successful, the same partner can efficiently ramp up to supply hundreds or thousands of trial devices with aligned quality systems. As trial results support commercialization, the same rapid prototyping foundation makes it easier to optimize cost and throughput without losing key performance attributes.

To maximize the benefits of rapid prototyping in clinical trial design:

- Involve cross-functional stakeholders (engineering, clinical operations, regulatory, quality, and manufacturing) early in rapid prototyping decisions.

- Define clear goals for each rapid prototyping cycle—what question is being answered, such as ergonomics, manufacturability, or software usability.

- Match rapid prototyping technologies to the stage of development, starting with flexible options and moving toward production-like methods as trials progress.

- Capture structured feedback from users and observers in every rapid prototyping round, then prioritize changes that directly impact safety, data quality, or operational feasibility.

- Choose an OEM rapid prototyping partner that understands both clinical and industrial requirements, including traceability, documentation, and validation needs.

Following these principles helps clinical teams use rapid prototyping as a strategic tool, not just a technical convenience.

Rapid prototyping tools now sit at the heart of modern clinical trial design because they turn abstract protocols into tangible, testable systems ahead of large-scale patient exposure. By combining 3D printing, CNC machining, sheet metal work, rapid tooling, and digital prototyping, sponsors can rapidly explore design space, capture real-world feedback, and refine both devices and workflows before committing to pivotal trials. This approach improves safety, usability, data quality, and overall trial success rates.

For international brands, wholesalers, and manufacturers, partnering with an integrated OEM factory like Shangchen (sc-rapidmanufacturing.com) ensures that rapid prototyping is fully aligned with scalable manufacturing. From first concept models to pilot-series devices and, ultimately, mass-produced products, the same partner can maintain consistent quality and support regulatory documentation. In a competitive, patient-centered healthcare landscape, using rapid prototyping intelligently has become one of the most effective ways to design clinical trials that are safer, faster, and more likely to lead to successful therapies.

In early-phase clinical trials, rapid prototyping delivers functional devices and tools that investigators can test in simulations and small pilot studies before exposing many patients. This helps confirm safety, usability, and workflow fit, reducing the likelihood of large design changes later. Early insights also guide targeted training for clinicians and coordinators.

For clinical trial devices, 3D printing is ideal for complex shapes and low volumes, while CNC machining is best for high-precision metal or production-like plastic components. Sheet metal fabrication, rapid tooling, and soft molds support mounts, enclosures, and small-batch disposables. Digital prototyping tools complement these by simulating software, dashboards, and eCRF interfaces.

Yes, in some cases rapid prototyping parts can be used directly with patients, as long as they meet material, safety, and quality requirements defined by regulators and internal procedures. Sponsors must control the rapid prototyping process, validate critical properties, and document the path from design to finished device. Limited initial use often starts in feasibility studies before broader deployment.

Rapid prototyping generates detailed evidence of how a design evolved, including test results, risk mitigations, and usability improvements, which strengthens design history and technical files. Physical and digital prototypes can support discussions with regulators by illustrating device features and workflows more clearly than drawings alone. When regulators see systematic learning through rapid prototyping, it can build confidence in the development process.

An integrated OEM partner can provide rapid prototyping and eventual production under one quality system, reducing handoff risks and communication gaps. This ensures that prototypes, clinical trial devices, and commercial products share consistent materials, tolerances, and documentation, simplifying validation and scaling. It also allows sponsors to move quickly from successful trial outcomes to market launch without re-qualifying new suppliers.

content is empty!

Top Metal CNC Machining Manufacturers and Suppliers in Lithuania

Top Metal CNC Machining Manufacturers and Suppliers in Czech Republic

Top Metal CNC Machining Manufacturers and Suppliers in Hungary

Top Metal CNC Machining Manufacturers and Suppliers in Denmark

Top Metal CNC Machining Manufacturers and Suppliers in Ireland