Views: 222 Author: Amanda Publish Time: 2025-11-05 Origin: Site

Content Menu

● What Is Moulding Production?

● The Link Between Rapid Prototyping and Moulding Production

● Accelerating Product Development With Moulding Production

>> Fast Iteration and Low-Risk Investment

>> Streamlined Path From Design to Market

● Technologies in Moulding Production

>> Silicone Moulding and Urethane Casting

● Key Benefits for Modern Product Teams

● OEM Applications and Industry Case Studies

>> Automotive

● Step-By-Step: Workflow Overview

● Advanced Practices for Excellence

● Innovations in Moulding Production

● Real-World Application Highlights

● Frequently Asked Questions (FAQ)

>> 1. What materials are suitable for moulding production?

>> 2. How is rapid moulding production different from traditional mould production?

>> 3. What is the typical lead time for rapid moulding production?

>> 4. Can moulding production be combined with other manufacturing methods?

>> 5. Is moulding production appropriate for both prototypes and end-use parts?

Moulding production is a transformative force in rapid prototyping and product development, playing a pivotal role in accelerating innovation and reducing costs for OEMs, brands, and global manufacturers. By integrating moulding production with other advanced manufacturing services—such as CNC machining, lathe turning, sheet metal fabrication, and 3D printing—companies can advance from concept to market-ready products faster and more reliably than ever before.[1][6][9][10][11]

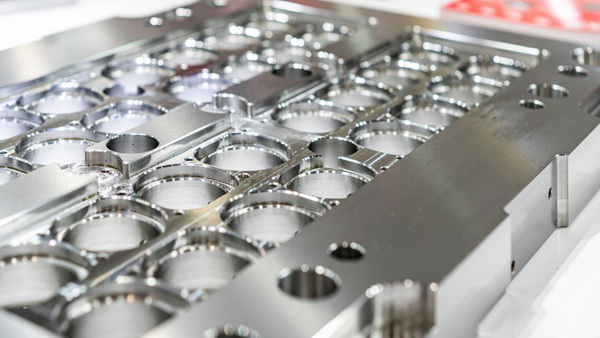

Moulding production consists of shaping raw materials such as plastics, metals, or composites into precision parts using specialized moulds or dies. The most common methods include injection moulding, compression moulding, and casting, with each delivering unique advantages for different product needs.[12][13][14][15]

The process typically involves:

- Creating a mould based on design specifications

- Injecting or applying material into the mould under heat and pressure

- Curing or cooling the material until it solidifies, taking the shape of the mould

- Releasing the finished part for post-processing or assembly

Rapid prototyping uses temporary, low-cost or flexible moulds to fabricate physical samples for evaluation and testing. This step allows engineering teams to:

- Validate designs quickly

- Refine geometry and function with real-world assessment

- Iterate with reduced risk and lead time

- Transition seamlessly to scaled mass production using refined, durable tooling.[3][4][6][1]

Traditional tooling is expensive and time-consuming, often creating barriers for innovation. Rapid moulding production mitigates these challenges by:

- Providing fast turnaround on prototype parts—sometimes in just days

- Reducing capital outlay until products are proven and market-ready

- Supporting short-run and custom batch production without high-volume tooling costs.[9][10]

Physical prototypes offer immediate feedback, empowering development teams to make necessary changes before committing to large production investments. This process shortens development cycles and lowers the risk of late-stage errors, ultimately improving product quality and speed to market.[6][11][1]

Modern manufacturers leverage versatile tooling systems for rapid moulding production, allowing swift transitions between designs and materials. This adaptability is crucial for addressing market demand, regulatory requirements, and competing effectively in global supply chains.[4][15]

The go-to technology for OEMs and high-volume producers, injection moulding injects molten material into robust, precision-engineered moulds. It is the preferred choice for manufacturing complex parts with tight tolerances and repeatable quality.[14][15][12]

For smaller runs or parts with intricate detail, silicone and urethane moulding provide fine surface finishes and flexible options, ideal for transitioning from prototype to limited production units.[10]

Advances in additive manufacturing make it possible to create highly customized, low-cost moulds using 3D printing. SLA, SLS, FDM, and PolyJet technologies allow rapid changes and deeper design exploration without major expenditure or delay.[1][4][6]

Interchangeable mould inserts accelerate changeovers and enable cost-effective prototyping, especially for shops producing multiple product variations.[9]

- Speed: Rapid transition from CAD design to physical part within days.[11][3][10]

- Cost-Effectiveness: Moulding production postpones large tooling investment until designs are market-validated.[4][12]

- Precision: High accuracy and surface finish in both prototypes and production components.[16][14]

- Flexibility: Easy design changes and material swaps to meet user feedback or certification requirements.[6][1]

- Scalability: Smooth ramp-up from sample to full production, supporting launches and pilot programs for new products.[15][9]

Automotive manufacturers rely on rapid moulding production for concept cars, custom parts, and fast tooling. Low-volume moulding allows for the cost-effective production of niche components, repairs, and jigs for quality control.[5]

Medical teams utilize rapid moulding and 3D-printed moulds for precise device housings, ergonomic enclosures, and patient-specific devices. Moulding production supports safety, fast regulatory approval, and innovation in healthcare.[4]

Moulding production enables rapid iteration for handheld devices, enclosures, and innovative consumer accessories. OEMs use engineering prototypes to perfect ergonomics, material selection, and assembly before large-scale launch.[15][9]

Dimensional accuracy and repeatability offered by moulding production are essential for mission-critical components, lightweight structures, and complex assemblies in aerospace and defense manufacturing.[3][16]

1. Design and DFM Review: Engineers collaborate to optimize CAD models for manufacturability—ensuring cost-effective tooling and high-yield production.[17][14]

2. Tool Fabrication: Prototype or low-volume production tooling is produced via CNC machining, additive manufacturing, or specialized casting.[1][4]

3. Sample Production and Evaluation: First-off samples are manufactured, inspected for fit, finish, and mechanical properties.

4. Design Iteration: Feedback from samples drives further design revisions and validation rounds, often using rapid or soft tooling updated for each cycle.[6][4]

5. Production Tooling and Scale-Up: Once prototypes meet standards, durable production moulds are made for high-volume runs.[18][9]

6. Mass Manufacture and Quality Assurance: Full-scale production utilizes established moulding systems, regularly monitored for consistency and compliance.[12][15]

- Start DFM reviews early to optimize for cost and effectiveness.

- Use additive manufacturing to produce complex moulds efficiently.

- Iterate designs with frequent communication between engineering and manufacturing teams.

- Partner with experts in moulding production and OEM services to ensure confidentiality, quality, and seamless integration with global supply chains.[1][6]

Recent technological advances make moulding production more accessible and versatile than ever. Customizable 3D-printed polymeric moulds, hybrid rapid tooling approaches, and new thermoplastic and metal materials enhance parts quality and open new application areas in modern manufacturing. These innovations help reduce lead times, minimize costs, and enable even highly complex geometries for demanding industries.[3][4]

Across sectors, moulding production drives value through:

- Fast development of automotive prototypes and tooling[5]

- Lead time reduction and cost savings for medical devices and consumer electronics[4][6]

- Functional testing and engineering prototypes, with design improvements that happen in real time

- Reliable low-volume production for niche markets and pilot launches

Moulding production sits at the heart of rapid prototyping and next-generation product development. Its flexible, scalable nature allows manufacturers and product teams to create, test, refine, and launch market-ready solutions with unprecedented speed and efficiency. By leveraging new technologies and integrating moulding with complementary services, companies gain the ability to pivot quickly, iterate wisely, and enter global markets with confidence—delivering innovative products faster and at lower cost.

Moulding production supports a vast range of materials, from robust engineering polymers (ABS, PC, PA), advanced silicone and elastomers, to technical metal alloys and composites. Material selection depends on mechanical, chemical, and regulatory requirements of the final part.[12][4]

Rapid moulding uses soft tooling or 3D-printed moulds to create prototypes and short runs quickly and economically, whereas traditional moulding uses hardened steel or aluminum tools for long-term, high-volume production.[10][9][4]

Typical rapid moulding production lead times range from a few days to two weeks, determined by part complexity and volume. Conventional tooling can take several weeks to months to produce.[1][4]

Yes, moulding production is often integrated with CNC machining, 3D printing, and sheet metal working for hybrid prototyping and customized solutions, enhancing overall part performance and flexibility.[10][6]

Absolutely. Properly executed, rapid moulding production yields prototypes that replicate production-grade parts in appearance, function, and durability, and in many cases, these parts can transition directly to market or limited production launches.[16][9][15][4]

[1](https://xometry.pro/en/articles/rapid-prototyping-manufacturing/)

[2](https://www.sciencedirect.com/science/article/pii/S2590123025013428)

[3](https://www.nature.com/articles/s41598-024-68761-5)

[4](https://pmc.ncbi.nlm.nih.gov/articles/PMC11054453/)

[5](https://www.rcoeng.com/blog/rapid-prototyping-the-future-of-manufacturing)

[6](https://formlabs.com/blog/ultimate-guide-to-rapid-prototyping/)

[7](https://www.caplugs.com/rapid-prototyping)

[8](https://www.reddit.com/r/manufacturing/comments/1cme87x/prototype_finished_next_step_finding_injection/)

[9](https://advancedplastiform.com/rapid-prototyping-injection-molding/)

[10](https://www.newayprecision.com/blogs/revolutionizing-prototyping-and-production-with-rapid-molding-techniques)

[11](https://protoshopinc.com/blog/understanding-rapid-prototyping/)

[12](https://www.protolabs.com/resources/blog/the-advantages-and-disadvantages-of-injection-molding/)

[13](https://www.thy-precision.com/injection-moulding-a-step-by-step-process-breakdown/)

[14](https://www.crescentind.com/blog/how-are-injection-molds-made-for-plastic-manufacturing)

[15](https://www.3ds.com/make/solutions/blog/injection-molding-what-are-advantages)

[16](https://us.arrk.com/how-precision-mold-manufacturing-shapes-industry-excellence/)

[17](https://www.crescentind.com/oem-guide-to-design-for-manufacturability-in-plastic-injection-molding)

[18](https://www.protolabs.com/resources/guides-and-trend-reports/rapid-prototyping-processes/)

content is empty!

What Are The Benefits of Rapid Prototyping to The Manufacturer?

What Are The Advantages of Using Pytorch for Rapid Prototyping?

What Are The Advantages and Disadvantages of Rapid Prototyping?

Top On Demand 3D Printing Manufacturers and Suppliers in Netherlands

Top On Demand 3D Printing Manufacturers and Suppliers in Norway

Top On Demand 3D Printing Manufacturers and Suppliers in Turkey

Top On Demand 3D Printing Manufacturers and Suppliers in Poland

Top On Demand 3D Printing Manufacturers and Suppliers in Vietnam