Views: 222 Author: Amanda Publish Time: 2025-11-07 Origin: Site

Content Menu

● The Current Landscape of Moulding Production

● The Rise of Data Analytics in Manufacturing

● Areas Where Data Analytics Improves Moulding Production

>> Real-Time Monitoring and Process Optimization

>> Predictive Maintenance and Equipment Reliability

>> Quality Assurance and Defect Reduction

>> Process Simulation and Digital Twins

>> Resource Allocation and Scheduling

● Case Study: Implementing Data Analytics in Moulding Production

● Integrating Data Analytics Into Existing Moulding Production

● Future Trends: Artificial Intelligence and Advanced Analytics

● FAQs

>> 1. How does data analytics increase moulding production efficiency?

>> 2. Can existing equipment be upgraded for data analytics integration?

>> 3. What role does predictive maintenance play in moulding production?

>> 4. How does data analytics help reduce defects in moulded parts?

>> 5. Is data analytics suitable for both high-volume and precision moulding production?

In the modern manufacturing sector, data analytics has become a critical driver for efficiency, especially in moulding production. As global competition intensifies, manufacturers are turning to advanced analytics to optimize every stage of their operations, from raw material intake to final product delivery. This article explores how data analytics is transforming moulding production, enabling companies to achieve higher throughput, reduce waste, and maintain consistent product quality.

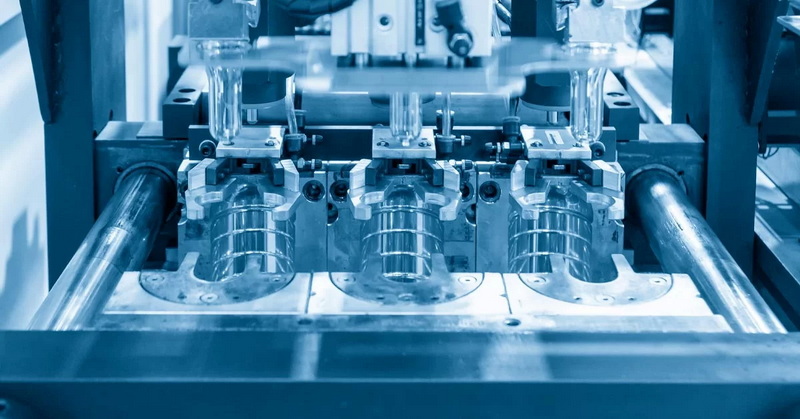

Moulding production encompasses a wide range of techniques, including injection moulding, blow moulding, compression moulding, and rotational moulding. These processes are used to create parts with high precision and repeatability, making them essential in industries such as automotive, electronics, and consumer goods. Traditionally, moulding production relied heavily on manual controls and operator expertise, which often led to inconsistencies in output quality and efficiency.

Challenges commonly faced in moulding production include:

- Material waste due to process variability.

- Unplanned downtime caused by equipment failures or maintenance issues.

- Fluctuations in part quality and dimensional accuracy.

- Slow cycle times and low throughput.

The adoption of smart factory concepts has led to the integration of data analytics into manufacturing processes. Data analytics involves the systematic assessment of large-scale data sets using statistical techniques and algorithms to uncover trends, forecast problems, and inform process improvements. Modern moulding production facilities are increasingly equipped with sensors, real-time monitoring systems, and digital controls that enable:

- Automatic data collection from machines, tools, and operators.

- Integration of Internet of Things (IoT) devices for enhanced connectivity.

- Cloud storage for centralized data management.

- Advanced analytical platforms for process optimization.

Real-time monitoring is one of the most significant advantages of data analytics in moulding production. By collecting and analyzing data on process variables such as temperature, pressure, fill time, and cycle duration, manufacturers can:

- Detect deviations from preset parameters immediately.

- Identify root causes of defects and intervene promptly.

- Reduce material waste by ensuring optimal machine settings.

- Minimize scrap rates and rework costs.

Advanced data dashboards display key performance indicators (KPIs) in real-time, providing operators and engineers with up-to-date information to make informed decisions quickly.

Downtime in moulding production can be extremely costly, often resulting from unexpected equipment failures. Data analytics enables predictive maintenance by:

- Monitoring usage patterns, vibrations, and thermal data from machines.

- Using machine learning algorithms to predict component wear or failure.

- Scheduling maintenance only when needed, avoiding unnecessary stoppages.

This approach not only increases equipment uptime but also extends the lifespan of moulds and machines, reducing capital expenditure in the long run.

Maintaining part quality and consistency is a cornerstone of successful moulding production. Data analytics supports quality assurance by:

- Enabling statistical process control (SPC) to track trends and variances.

- Pinpointing out-of-spec conditions in real-time.

- Providing traceability for all process steps, allowing root-cause analysis of recurring defects.

Operators and engineers can quickly identify which variables are linked to defects and use this knowledge to refine process settings, dramatically increasing yield and customer satisfaction.

Many forward-thinking manufacturers use data-driven process simulation and digital twins—virtual representations of moulding equipment—to model various production scenarios. With input from historical and real-time data, these tools can:

- Optimize cycle parameters for new parts without lengthy trial-and-error testing.

- Forecast the impact of equipment upgrades or material changes.

- Validate process modifications before applying them on the physical shop floor.

By simulating the entire production line, companies can plan improvements and scale operations more confidently.

Data analytics facilitates leaner resource allocation by identifying bottlenecks, tracking material inventory, and optimizing scheduling. With access to accurate, timely production data, managers can:

- Allocate machines and personnel based on demand forecasting.

- Prevent raw material shortages and excess inventories.

- Adjust schedules dynamically to meet urgent orders without disrupting existing plans.

These improvements result in higher throughput and cost-effective production.

A leading automotive supplier implemented a comprehensive data analytics platform across their injection moulding lines. By integrating machine sensors, centralized data servers, and analytics dashboards, the company achieved the following within the first year:

- 15% reduction in cycle times, increasing part output.

- 22% drop in scrap rates due to more accurate process controls.

- 30% less unplanned downtime after commencing predictive maintenance schedules.

- Improved first-pass yield and on-time delivery metrics.

The use of data analytics enabled the supplier to meet tighter tolerances, comply with regulatory demands, and reduce energy usage, boosting profitability and reputation in a highly competitive market.

While the benefits are substantial, successful integration of data analytics into moulding production does require careful planning.

- Sensor Installation: Upgrading legacy equipment with modern sensors and data loggers is often the first step.

- Staff Training: Operators, engineers, and managers must be trained to interpret data outputs and make data-driven decisions.

- Data Security: As more sensitive production data is collected, robust cybersecurity measures become essential to prevent intellectual property theft.

- Scalable Software Solutions: The analytics platform must be scalable and compatible with diverse manufacturing environments.

The future of moulding production lies in artificial intelligence (AI) and machine learning (ML) algorithms that go beyond traditional data analytics. These systems can:

- Automatically tune process variables for optimal efficiency in real-time.

- Analyze massive data sets for deep learning insights into process behavior.

- Coordinate multiple machines and production cells seamlessly.

As these trends mature, moulding production will become increasingly autonomous, adaptive, and resilient to fluctuations in demand and supply chains.

The integration of data analytics into moulding production is transformative, positioning manufacturers at the forefront of efficiency, quality, and innovation. Through precise, data-informed decision-making, companies achieve increased output, reduced waste, fewer defects, and lower operating costs while supporting the move toward more adaptive and intelligent production systems. As technology continues to develop, data analytics will remain a cornerstone of competitive moulding production, ensuring long-term growth and sustainability.

Data analytics streamlines moulding production by monitoring process parameters, detecting inefficiencies, and enabling rapid corrective actions, which reduces waste, shortens cycle times, and boosts throughput.

Yes, most legacy moulding production equipment can be retrofitted with modern sensors and communication modules, enabling data collection and analysis without extensive capital investment.

Predictive maintenance uses machine data to forecast potential failures, allowing maintenance teams to intervene before breakdowns occur, thus minimizing downtime and maintenance costs.

By continuously monitoring quality-related variables and alerting operators to deviations, data analytics supports faster defect detection, root cause analysis, and corrective actions, significantly reducing non-conformance rates.

Absolutely, data analytics provides benefits for both high-volume, repetitive production runs and small-batch, high-precision component manufacturing by improving consistency, predictability, and overall process control.

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal