Views: 222 Author: Amanda Publish Time: 2025-09-02 Origin: Site

Content Menu

● Understanding CNC Lathe Turning

>> Benefits of CNC Lathe Turning

● Advanced Techniques in CNC Lathe Turning That Save Time

>> 1. High-Speed Machining (HSM)

>> 2. Multi-Axis CNC Lathe Turning

>> 3. Live Tooling and C-Axis Control

>> 4. Tool Path Optimization with CAM Software

>> 5. Use of Specialized Cutting Tools and Coatings

● Integration of Automation and Smart Technologies

>> Automation for Continuous Production

>> Predictive Maintenance and IoT

● Software Innovations Enhancing CNC Lathe Turning Efficiency

>> Artificial Intelligence (AI) in CNC Programming

>> Real-Time Monitoring and Adaptive Control

● Practical Applications and Industry Implications

● Case Study: Shangchen's Implementation and Impact

● Frequently Asked Questions (FAQ)

>> 1. What is CNC lathe turning, and how does it differ from manual lathe turning?

>> 2. How do multi-axis CNC lathes improve production efficiency?

>> 3. What role does live tooling play in CNC lathe turning?

>> 4. Can high-speed machining be used on all materials?

>> 5. How does CAM software optimize CNC lathe turning processes?

Manufacturing industries today constantly seek ways to improve efficiency and reduce production time without compromising quality. One crucial process that has witnessed remarkable advancements is CNC lathe turning. As an integral part of modern manufacturing, CNC lathe turning enables precise shaping and machining of metal parts through computer-controlled tools. At Shangchen, a leading Chinese factory specializing in fast prototyping, CNC machining, precision batch production, turning, sheet metal fabrication, 3D printing, and mold manufacturing, we continuously adopt the latest CNC lathe turning techniques to deliver OEM services to overseas brands, wholesalers, and manufacturers efficiently.

This article explores how advanced CNC lathe turning techniques significantly reduce production time while ensuring superior product quality. From optimizing tool paths to implementing multi-axis machining, we will delve into key strategies and technologies used today. We will also discuss practical benefits that help manufacturers meet demanding delivery schedules and maintain competitive advantages.

CNC lathe turning is a subtractive manufacturing process where raw material stock, typically metal rods or bars, is rotated at high speed while cutting tools remove unwanted material to create desired shapes. Unlike manual lathe operations, CNC lathe turning uses numerical control (NC) programming to automate precise, repeatable movements of tools, reducing human error and increasing production efficiency.

- High precision and repeatability

- Capability to produce complex geometries

- Reduced operator intervention, lowering labor costs

- Ability to run unattended through multiple machining cycles

- Faster turnaround times compared to manual machining

High-Speed Machining involves increasing spindle speeds and feed rates beyond conventional limits. Modern CNC machines and cutting tools are designed to handle higher speeds without sacrificing tool life or part quality.

- Effect on Production Time: HSM drastically cuts cycle times by enabling faster material removal rates. This technique allows multiple operations in one setup.

- Implementation: Optimizing cutting parameters such as depth of cut, spindle speed, and feed rate balances cutting forces and heat buildup to maximize efficiency.

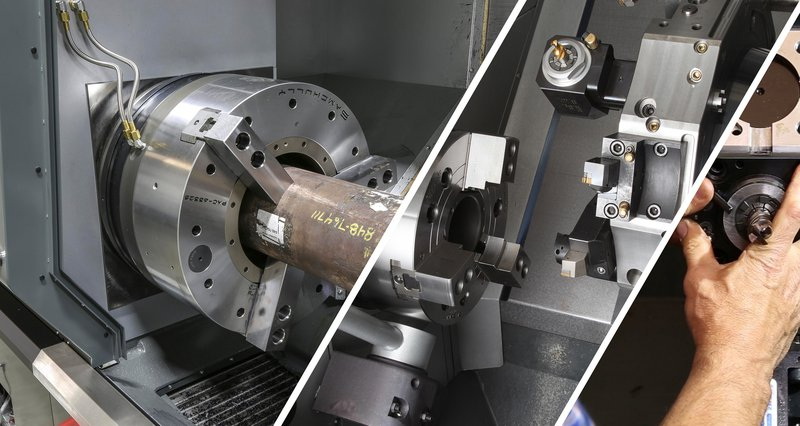

Traditional CNC lathes often work on two axes (X and Z), but multi-axis CNC lathes add Y-axis or additional rotary axes, allowing complex machining without re-fixturing.

- Effect on Production Time: Multi-axis machining reduces setups and indexing time. It enables simultaneous contouring on multiple faces, lowering overall processing time.

- Applications: Complex aerospace, automotive, and medical components benefit significantly from this technology.

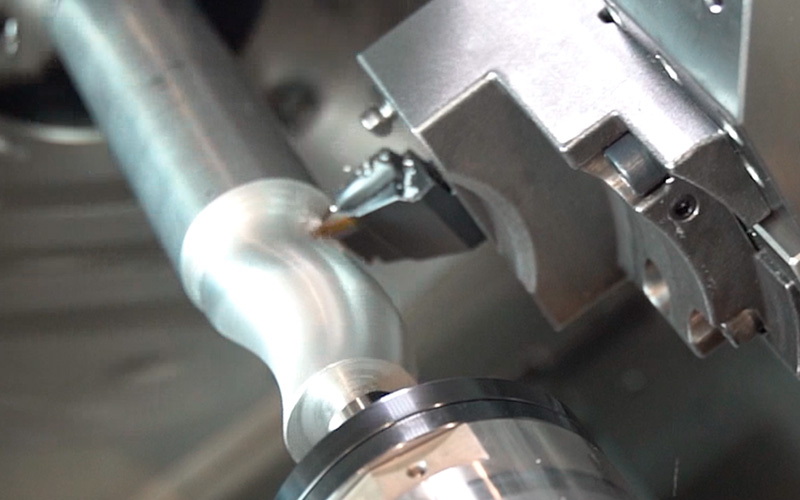

Live tooling equips CNC lathes with rotating tools driven independently of the spindle. The C-axis is a rotary control system that enables precise angular positioning of the spindle.

- Effect on Production Time: Live tooling and C-axis reduce the need to move a part between lathe and milling centers by performing milling, drilling, and tapping operations directly on the lathe.

- Outcome: This decreases handling time, potential errors, and improves throughput.

Computer-Aided Manufacturing (CAM) software algorithms optimize cutting tool paths to minimize rapid moves, reduce tool changes, and select efficient cutting strategies.

- Effect on Production Time: Optimized paths improve cycle time and extend tool life, reducing downtime for tool replacement.

- Example: Smooth arc moves replace linear, segmented moves to maintain tool engagement and avoid abrupt deceleration.

Advanced cutting tool materials, such as carbide and ceramic inserts, coupled with wear-resistant coatings (e.g., TiAlN, diamond-like carbon), increase cutting speeds and tool longevity.

- Effect on Production Time: Longer-lasting tools reduce tool change frequency and enable higher feed rates.

- Benefit: Lower tooling costs and more predictable production schedules.

Integrating automation systems like robotic part loaders and unloaders with CNC lathe turning centers significantly reduces idle time between jobs. Automated tool changers minimize manual handling, ensuring the machine keeps running for longer periods with minimal intervention.

- Impact on Production Time: Automation enables 24/7 production capability, drastically increasing throughput and meeting high-volume orders without sacrificing quality.

- Implementation: Shangchen uses state-of-the-art robotic arms interfaced directly with CNC lathes in our precision batch production lines to boost productivity.

Modern CNC lathe machines equipped with Internet of Things (IoT) sensors and connected via cloud platforms can continuously monitor their own operating conditions. This data helps predict tool wear, detect abnormal vibrations, overheating, or other potential failures before they cause unplanned downtime.

- Impact on Production Time: Reducing unexpected stoppages ensures consistent manufacturing flow and optimized machine availability.

- Benefit: Predictive maintenance saves both time and operational costs.

AI-driven CNC programming software is emerging as a powerful tool to optimize machining strategies automatically. By analyzing part geometry, material properties, and machine capabilities, AI algorithms generate the most efficient tool paths and cutting parameters.

- Effect on Production Time: This minimizes human error and programming time, resulting in faster setup and reduced cycle time.

- Future Outlook: As AI evolves, CNC operators will increasingly benefit from adaptive machining strategies that dynamically adjust during production runs.

Integration of sensors on cutting tools and machines enables real-time feedback on forces, vibrations, and temperatures. CNC systems can then adapt feed rates or spindle speeds dynamically to maintain optimal cutting conditions.

- Effect on Production Time: Optimized machining conditions reduce scrap rates and tool damage, which otherwise cause delays.

- Application: Especially beneficial when machining difficult alloys or geometries where cutting stability fluctuates.

The aerospace industry demands complex, high-precision components often made from tough metals like titanium and Inconel. Advanced CNC lathe turning with multi-axis capabilities and live tooling allows the production of turbine blades, engine parts, and structural elements in fewer setups, saving weeks of production time.

In automotive manufacturing, speed and volume are critical. High-speed CNC lathe turning enables fast batch production of engine components, shafts, and connectors with consistent quality, helping OEMs meet tight delivery deadlines without compromising durability.

Medical instruments and implants require precision and biocompatibility. CNC lathe turning with tool path optimization and advanced tooling allows the fabrication of implants with intricate shapes and smooth finishes quickly, fostering faster product launches.

At Shangchen, the integration of these advanced CNC lathe turning technologies has proven transformative in our OEM manufacturing operations.

- Cycle Time Reduction: Employing high-speed machining and live tooling on precision batch production lines has shortened part machining time by 35-50%.

- Single Setup Completion: Multi-axis lathes with C-axis control allow complex parts to be completed in one setup, improving throughput and accuracy.

- Customer Benefits: Our overseas clients report faster delivery times, high-quality finished parts, and cost-effective pricing due to optimized machining.

- Continuous Improvement: With real-time monitoring and predictive maintenance, machine uptime has increased by over 20%, further enhancing production schedules.

Advanced CNC lathe turning techniques usher in a new era of manufacturing efficiency. High-speed machining, multi-axis control, live tooling, tool path optimization, and advanced tooling materials synergize to reduce production time substantially. The integration of automation, IoT-enabled predictive maintenance, and AI-driven programming further accelerates manufacturing cycles and improves part quality.

For manufacturers and OEM service providers like Shangchen, embracing these technologies means faster turnaround, higher quality, and competitive pricing for international clients. Implementing such innovations not only streamlines manufacturing but also future-proofs operations in a fiercely competitive landscape. As technology evolves, CNC lathe turning will remain a backbone of rapid, precise, and cost-effective production, empowering industries worldwide.

CNC lathe turning uses computer numerical control to automate tool movements, increasing precision and repeatability compared to manual lathe turning, which relies heavily on operator skill.

Multi-axis lathes enable machining of complex parts without repositioning or multiple setups, reducing handling and setup times, thus speeding up production.

Live tooling allows additional operations like milling and drilling to be performed directly on the lathe, minimizing part transfers and combining production steps to save time.

While high-speed machining is effective on many metals, material properties like hardness can limit applicable speeds and feeds. Appropriate tooling and parameter adjustments are necessary.

CAM software calculates efficient tool paths that minimize non-cutting movements and balance cutting forces, leading to reduced cycle times and extended tool life.

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal