Views: 222 Author: Amanda Publish Time: 2025-09-06 Origin: Site

Content Menu

● The Evolution and Importance of CNC Lathe Turning

● AI and Machine Learning: The Brain Behind Smarter CNC Lathe Turning

● Automation and Robotics: Efficient Production 24/7

● Multi-Axis CNC Lathe Turning: Unlocking Complex Geometries

● The Rise of Hybrid Manufacturing: Fusing Additive and Subtractive Processes

● Industry 4.0 and IoT: Creating Smart CNC Lathe Turning Ecosystems

● Advances in Tooling and Materials for Enhanced Performance

● Enhancing Operator Experience: Virtual and Augmented Reality

● Commitment to Sustainability Through CNC Lathe Turning Innovations

● Real-World Applications of Advanced CNC Lathe Turning

● FAQ

>> 1. What advantages does AI bring to CNC lathe turning?

>> 2. How does automation improve CNC lathe turning operations?

>> 3. What is the benefit of multi-axis CNC lathe turning machines?

>> 4. How do hybrid manufacturing systems impact CNC lathe turning?

>> 5. Why is Industry 4.0 significant for CNC lathe turning manufacturers?

CNC lathe turning is a cornerstone of precision manufacturing, indispensable in producing complex parts with high accuracy and repeatability. As the global manufacturing landscape rapidly evolves, 2025 promises a transformative era for CNC lathe turning, driven by emerging technologies that enhance every facet of production. From the infusion of artificial intelligence (AI) and machine learning to the rise of automation, Industry 4.0 integration, and hybrid manufacturing, CNC lathe turning is evolving into a smarter, more flexible, and efficient process. This article provides an in-depth exploration of these cutting-edge technologies and their implications for OEM manufacturers and brands worldwide.

CNC lathe turning has long been recognized for its ability to precisely machine cylindrical parts and complex geometries. Through computer numerical control, it achieves remarkable consistency and efficiency across industries such as aerospace, automotive, medical devices, electronics, and industrial machinery. However, the scope of CNC lathe turning is rapidly expanding, influenced by broader trends in digital manufacturing and the pressing demands for faster, more customized, and sustainable production.

Manufacturers are no longer satisfied with just repeatability; they seek adaptive systems capable of self-optimization, intelligent diagnostics, and integration into digitally connected ecosystems. As a result, CNC lathe turning machines are being fitted with advanced sensors, intelligent software, and multi-axis capabilities enabling the production of geometrically complex, high-precision parts with reduced human labor and waste.

Artificial intelligence and machine learning are revolutionizing how CNC lathe turning machines operate. These technologies empower machines to analyze vast amounts of real-time production data, identify patterns, and autonomously adjust cutting parameters for optimal performance.

- Real-time Optimization: AI algorithms monitor spindle speed, feed rate, and cutting forces during machining and dynamically adjust them to maximize efficiency and part quality.

- Predictive Maintenance: Machine learning models analyze sensor data to predict tool wear and machine part failures before they cause downtime.

- Quality Control: AI-driven vision systems detect dimensional deviations and surface anomalies, prompting immediate corrective actions.

By augmenting machines with these cognitive capabilities, manufacturers achieve significantly higher throughput, reduced scrap rates, and consistent best-in-class quality. For OEMs serving diverse global clients, such intelligent CNC lathe turning solutions translate into competitive advantages through shortened lead times and improved reliability.

Automation integration with CNC lathe turning is transforming factories into largely autonomous production hubs. Robotics systems, including automated loading/unloading and robotic tool changers, enable machines to operate continuously with minimal human oversight.

- Lights-Out Manufacturing: Machines run unattended during nights and weekends, drastically increasing uptime.

- Error Reduction: Automated material handling minimizes human errors in loading and part setup.

- Scalability: Production lines easily adapt to different part batches and specifications without extensive retooling.

By coupling CNC lathe turning with robotic arms and automated bar feeders, manufacturers realize significant cost savings and throughput improvements. This flexible automation is crucial for OEM providers catering to customized orders ranging from prototypes to precision batch production.

While traditional CNC lathe turning operates primarily on two axes (X and Z), multi-axis CNC turning machines (up to 9 axes) are becoming mainstream. This technological leap allows machining of parts with highly intricate shapes, undercuts, and complex contours with:

- Reduced Setup Times: Multi-axis machines complete complex machining in a single setup, eliminating multiple repositioning steps.

- Increased Machining Accuracy: Expanded axes provide more precise tool orientation for superior surface finish and tighter tolerances.

- Enhanced Design Freedom: Enables manufacturing of lightweight, multifunctional components demanded by aerospace, defense, and medical sectors.

OEM manufacturers can now offer advanced part geometries previously impossible or cost-prohibitive, thus broadening their market coverage and enhancing product innovation potential.

Hybrid manufacturing systems that combine CNC lathe turning with additive manufacturing capabilities bring a new paradigm to precision part production.

- Material Efficiency: Additive processes generate near-net-shape parts, while CNC turning finishes them for exact dimensions and surface qualities, minimizing raw material waste.

- Rapid Prototyping to Production: Designers iterate quickly with 3D printing and trust CNC turning for final high-quality finishes, accelerating development cycles.

- Complex Internal Features: Internal cooling channels or lattice structures can be 3D printed and then finished with CNC lathe turning, enhancing part performance.

This synergy opens new possibilities for manufacturing lightweight, high-performance parts essential for aerospace, medical implants, and customized OEM products.

Industry 4.0 integration leverages IoT connectivity, cloud computing, and big data analytics to elevate CNC lathe turning machines from standalone units to components of interconnected smart factories.

- Remote Monitoring: CNC machines equipped with IoT sensors transmit machine health and performance data accessible anywhere in real time.

- Data-Driven Optimization: Advanced analytics identify bottlenecks, optimize tool paths, and manage energy consumption, continuously improving factory performance.

- Collaborative Manufacturing: Interconnected machines communicate to synchronize production tasks, facilitating just-in-time manufacturing and reducing inventory costs.

For OEMs serving global markets, these intelligent systems ensure production agility, traceability, and responsiveness, meeting modern supply chain demands.

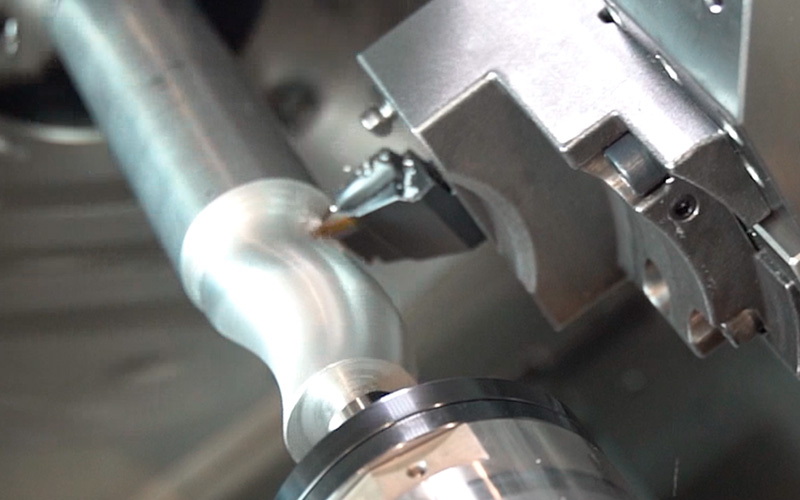

CNC lathe turning is also benefiting from breakthroughs in tooling and material sciences.

- Cutting Tools: New coatings (e.g., polycrystalline diamond, ceramic, and advanced carbides) increase tool life, enable higher cutting speeds, and support dry machining.

- Material Capability: Advanced alloys, composites, and biomaterials are machinable with precision, expanding CNC turning's application scope across industries.

- Ultra-Precision Machining: Submicron tolerances achieved with refined tooling elevate product quality for critical aerospace and medical applications.

These tooling and material innovations drive CNC lathe turning's evolution into ultra-precise, high-speed processes capable of meeting demanding OEM requirements.

Training and operational efficiency in CNC lathe turning are improving through VR and AR technologies.

- Immersive Training: Operators can practice complex machining setups in safe, simulated environments reducing learning curves and errors.

- Remote Support: AR headsets enable experts to guide on-site personnel through troubleshooting or machine setups in real time.

- Design Validation: Virtual visualization of machining operations helps identify and resolve potential issues before production.

These technologies increase safety, reduce setup times, and foster better knowledge transfer in CNC lathe turning facilities.

Manufacturers are increasingly focusing on reducing environmental impact while maintaining productivity.

- Energy Efficiency: Modern CNC turning machines incorporate low-power drives, regenerative braking, and optimized cycle times.

- Coolant Reduction: Dry machining and advanced minimum quantity lubrication (MQL) techniques reduce hazardous fluid use.

- Waste Minimization: High-precision machining and adaptive control reduce scrap parts, conserves materials, and optimize resources.

Sustainability initiatives in CNC lathe turning align manufacturers with global standards and evolving customer expectations for greener production.

Emerging CNC lathe turning technologies are crucial in several high-demand sectors:

- Aerospace: Complex turbine blades, landing gear components, and structural parts requiring intricate geometries and tight tolerances.

- Automotive: Engine shafts, transmission components, and customized parts benefiting from multi-axis and hybrid approaches.

- Medical: Biocompatible implants, surgical instruments, and prosthetics produced with ultra-fine finishes and precision.

- Electronics: Metal housings, heat sinks, and connectors manufactured with reliable repeatability and exacting specifications.

- Industrial Equipment: Shafts, bushings, gears, and fasteners made with high robustness tailored to demanding industrial environments.

OEMs leveraging the latest CNC lathe turning innovations can meet diverse, complex requirements across these industries with quality and speed.

The future of CNC lathe turning is being shaped by transformative technologies that infuse intelligence, automation, connectivity, and sustainability into traditional machining. AI-driven optimization and predictive maintenance, robotic automation for continuous production, multi-axis machining for complex designs, and hybrid additive-subtractive manufacturing are pushing the boundaries of what CNC lathe turning can achieve. Coupled with IoT-enabled smart factories and advances in tooling and materials, these innovations empower OEM manufacturers globally to deliver customized, high-quality components faster and more cost-effectively than ever before.

By embracing these emerging technologies, CNC lathe turning will continue to be a critical enabler of precision manufacturing in industries ranging from aerospace and automotive to medical and electronics. The manufacturers who adapt early will lead this new era of flexible, smart, and sustainable production—strengthening their competitive edge and meeting the ever-growing expectations of the global marketplace.

AI enhances CNC lathe turning by enabling real-time optimization of cutting parameters, predictive maintenance to prevent downtime, and quality control through vision systems, leading to higher productivity and consistent product quality.

Automation allows for continuous, lights-out manufacturing with robotic loading and unloading, reducing labor costs, minimizing human errors, and increasing throughput and flexibility in part production.

Multi-axis machines facilitate the machining of complex geometries in a single setup, reducing cycle times, improving dimensional accuracy, and enabling the manufacture of sophisticated parts previously difficult to produce.

Hybrid manufacturing combines additive 3D printing with subtractive CNC turning, reducing material waste, accelerating prototyping and production, and enabling complex internal structures in parts.

Industry 4.0 integration allows for smart, interconnected CNC machines capable of remote monitoring, data analytics, and collaborative production, improving operational efficiency, flexibility, and responsiveness to market demands.

[1](https://www.amitozmachinery.com/blog/2025-tech-revolution-advantages-of-cnc-turning-solutions/)

[2](https://www.ashishmachinery.com/blog/future-cnc-lathe-innovations-2025/)

[3](https://raysun.ae/emerging-trends-in-cnc-turning-machines-for-2025-and-beyond/)

[4](https://www.cncequipmentsales.com/blog/2025-cnc-turning-innovations-guide/)

[5](https://www.sansmachining.com/future-trends-in-cnc-turning-technology/)

[6](https://www.steckermachine.com/blog/cnc-machining-trends)

[7](https://schantzfab.com/new-cnc-machining-technology-trends-for-2025/)

[8](https://machinetools.bhavyamachinetools.com/cnc-lathe-market-in-2025-from-desktop-to-heavy-duty-machines-and-smart-controllers/)

[9](https://jayashapurabrass.com/blog-detail.php?blog=the-future-of-cnc-turning%3A-trends-and-technologies-to-watch)

[10](https://www.runsom.com/blog/metal-cnc-machines-the-2025-ultimate-guide/)

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal