Views: 222 Author: Amanda Publish Time: 2026-01-17 Origin: Site

Content Menu

● Is CNC Machining Actually Profitable?

● Real-World Earning Potential

● Market Demand for CNC Machining

● How CNC Machining Businesses Make Money

● Key Profit Drivers in CNC Machining

● Best Niches to Make Money in CNC Machining

● Side Hustle vs Full-Time CNC Machining

● Risks and Challenges in CNC Machining

● Practical Ways to Increase Profit in CNC Machining

● Working with an OEM CNC Machining Partner

● FAQ

>> 1. How much money can a small CNC Machining shop make?

>> 2. Is CNC Machining a good side hustle?

>> 3. What profit margin is typical in CNC Machining?

>> 4. Which industries pay best for CNC Machining?

>> 5. What skills do I need to succeed in CNC Machining?

CNC Machining is one of the most flexible and scalable ways to earn money in modern manufacturing, from small side hustles to full‑scale industrial shops. With the right strategy, clear positioning, and disciplined cost control, it is absolutely possible to build a profitable CNC Machining business that serves local customers or global OEM brands.

CNC Machining is a manufacturing process in which computer‑controlled machines remove material from metal, plastic, or other workpieces to create precise components. Compared with manual machining, CNC Machining uses programmed toolpaths to achieve high accuracy, repeatability, and efficiency across large or small batches.

This process is fundamental in industries such as aerospace, automotive, medical, electronics, robotics, and industrial machinery. Because CNC Machining can produce complex geometries and tight tolerances, it is used throughout a product's lifecycle, from early prototypes to end‑use parts in mass production.

CNC Machining typically includes several main process types:

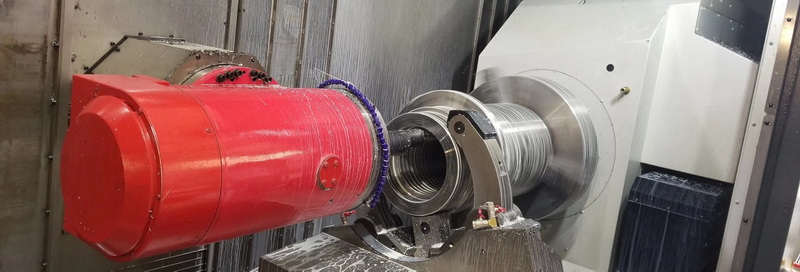

- CNC milling for creating prismatic or complex 3D shapes using rotating cutting tools.

- CNC turning (lathe) for producing shafts, bushings, and other rotational parts.

- Multi‑axis CNC Machining for advanced surfaces and intricate features in a single setup.

- Auxiliary processes like drilling, tapping, boring, and threading built into the same CNC Machining center.

CNC Machining can be highly profitable, but it is not automatically so. Profitability depends on machine utilization, pricing strategy, niche selection, and overall business management. Many small and mid‑sized shops operate with solid net margins once they understand their true costs and stop underpricing work.

Well‑run CNC Machining businesses often achieve low double‑digit net margins, with top performers going even higher in specialized markets. The key is to avoid being just another “cheap machine shop” and instead become a reliable, solution‑oriented CNC Machining partner. When a shop focuses on quality, delivery, and engineering support, customers are more willing to pay for value, not just machine time.

A typical small CNC Machining shop with one or two machines can reach annual revenues in the low to mid six‑figure range. As the business adds machines, automation, and skilled staff, total revenue and profit can scale significantly. In some cases, shops that specialize in high‑value CNC Machining work (such as aerospace, motorsport, or medical components) can generate very strong returns compared with more commodity‑style machining.

Income potential in CNC Machining spans a wide spectrum. At the low end, a hobbyist with a small machine in a garage may earn a few hundred or a few thousand dollars per year selling custom plates, signs, or small parts. At the high end, a focused CNC Machining company with multiple machines and stable B2B contracts can reach hundreds of thousands or even millions of dollars in annual revenue.

For example, consider the following typical profiles:

- Hobby user: Runs a desktop or benchtop CNC Machining setup on evenings and weekends, making custom products for local customers or online platforms. Earnings are modest, but the risk is low and skills grow over time.

- Side‑business operator: Owns a light industrial CNC Machining center, takes on contract jobs for local companies, and sells specialty products online. Income can reach five figures annually while still maintaining another job.

- Full‑time job shop: Operates several CNC Machining centers (mills, lathes, and possibly 5‑axis machines), employs programmers and operators, and serves industrial clients. This model can generate six‑figure revenues and solid profit margins.

The same hardware can deliver very different financial outcomes depending on how well the business is managed. A CNC Machining shop that carefully controls quoting, minimizes downtime, and builds strong repeat relationships will generally outperform one that accepts any job at any price.

Demand for CNC Machining continues to rise as industries push for greater precision, shorter product lifecycles, and faster turnaround times. As more products become customized and more companies rely on complex mechanical designs, the role of CNC Machining grows even more important.

Several trends support long‑term demand:

- Product complexity: Modern designs use intricate geometries, lightweight structures, and multi‑material assemblies that depend on precise CNC Machining.

- Shorter lead times: Brands and OEMs expect rapid prototypes and quick production ramps, all of which favor flexible CNC Machining capacity.

- Localization and diversification: Many companies now want diversified suppliers across regions, creating ongoing opportunities for CNC Machining partners in key manufacturing hubs.

In addition, specialized areas such as prototype CNC Machining, rapid tooling, and small‑batch precision production continue to expand. These segments value speed, engineering support, and reliability as much as cost, giving well‑organized CNC Machining providers a chance to earn higher margins.

CNC Machining businesses earn money by turning raw material into high‑precision parts and by offering related services that make life easier for customers. Revenue usually comes from a mix of one‑off jobs, repeat purchase orders, and long‑term supply agreements.

Typical income sources include:

- Custom component production: Producing machined parts from customer drawings or 3D models for various industries.

- OEM supply contracts: Acting as a long‑term CNC Machining partner for brands and manufacturers, delivering repeat batches of components that go into finished products.

- Prototyping and product development: Supporting engineering teams with fast CNC Machining prototypes, design‑for‑manufacturing feedback, and small trial runs.

- Tooling and fixtures: Providing CNC Machining services for jigs, fixtures, molds, and dies that support customers' own production lines.

Beyond the core machining work, value‑added services can significantly boost profitability:

- Post‑processing such as deburring, polishing, anodizing, heat treatment, or surface coating.

- Assembly and sub‑assembly work, combining multiple CNC Machining parts into finished modules.

- Quality documentation, measurement reports, and testing services for regulated industries.

The more problems a CNC Machining company solves for its customers, the easier it is to charge fair rates and maintain stable business.

Profit in CNC Machining does not just come from owning machines; it comes from how those machines are used, how jobs are chosen, and how work is organized. Several key factors determine whether a CNC Machining operation makes or loses money.

First, machine utilization is critical. Every minute a spindle is cutting material at a profitable rate contributes to earnings, while machine idle time is pure lost potential. Shops that standardize setups, apply quick‑change tooling, and schedule jobs intelligently can achieve much higher utilization than those that treat every job as a one‑off adventure.

Second, quoting and pricing strategy matter greatly. Many new CNC Machining businesses underprice jobs either because they miscalculate cycle times or because they fear losing the order. Over time, this leads to a high workload but low profit. A mature CNC Machining shop knows its cost per hour, includes setup, programming, and overhead in calculations, and sets minimum profitable rates.

Third, process efficiency and lean principles play a big role. Reducing material waste, optimizing toolpaths, organizing workstations, and minimizing unnecessary movement can shave significant time off each CNC Machining job. Over hundreds or thousands of parts, these small savings add up to a major competitive advantage.

Finally, customer relationships drive long‑term profitability. CNC Machining shops that communicate well, deliver on time, and maintain consistent quality often receive repeat orders and referrals. Reliable, long‑term customers reduce the constant pressure of hunting for the next job and provide predictable revenue streams.

Not all CNC Machining work is equal. Some niches offer higher prices, stronger long‑term demand, and better protection from low‑bid competitors. Positioning in the right niche can dramatically increase profitability.

High‑value CNC Machining niches include:

- Aerospace and defense: Components often require complex geometries, exotic materials, strict documentation, and rigorous quality standards. This complexity supports stronger pricing and long‑term contracts.

- Medical devices and instruments: Parts in this sector demand exceptional precision, fine surface finishes, and tight process control, making it a natural fit for high‑end CNC Machining.

- Motorsports and high‑performance automotive: Racing and performance applications need lightweight, high‑strength CNC Machining components where customers are willing to pay a premium for speed and reliability.

- Industrial machinery and robotics: Heavy‑duty components, frames, brackets, and housings are an ongoing need, and long product lifecycles encourage repeat CNC Machining orders.

- Electronics and enclosures: Precision housings, heat sinks, and small mechanical parts for electronics benefit from reliable CNC Machining with tight dimensional control.

Each niche has its own certification requirements, documentation standards, and quality expectations. A CNC Machining business that invests in the necessary skills and systems can build a strong brand and win long‑term customers.

CNC Machining is flexible enough to support several business models, from casual side projects to fully staffed factories. Which path makes sense depends on capital, risk tolerance, available time, and long‑term goals.

As a side hustle, CNC Machining usually focuses on:

- Custom products: Signs, panels, decorative pieces, small fixtures, or hobby components.

- Short‑run parts: Simple CNC Machining jobs for local businesses that need small quantities quickly.

- Online sales: Niche products sold on marketplaces or through personal websites.

This approach typically requires modest investment and can be run in a garage or small workshop. Income may be limited by available time, but it is a powerful way to build experience, test markets, and prepare for a more serious CNC Machining operation.

As a full‑time business, CNC Machining becomes more structured and capital intensive:

- Multiple machines (mills, lathes, and maybe multi‑axis equipment) working in parallel.

- Professional CAD/CAM software and robust production management systems.

- Dedicated staff for programming, operation, quality control, and customer support.

At this stage, the CNC Machining company can pursue larger contracts, serve OEM customers, and work with international clients. Revenue and profit potential are significantly higher, but so are responsibilities and financial risk.

Despite its potential, CNC Machining comes with real challenges that must be managed carefully. The most obvious is capital cost: industrial‑grade machines, tooling, measurement equipment, and software require substantial upfront investment. Financing these assets introduces ongoing repayment obligations that must be covered by consistent cash flow.

Competition is another major issue. Many regions have numerous CNC Machining shops, and some competitors may be willing to accept very low prices just to keep machines busy. Without a clear value proposition, a shop can get dragged into a race to the bottom on pricing, which quickly erodes margins.

Technical complexity also presents risk. Poorly chosen cutting parameters, incorrect fixturing, or programming mistakes can cause scrap, rework, and machine damage. Skilled CNC Machining operators and programmers are essential, but they can be difficult to hire and retain. Labor shortages, training needs, and turnover all affect productivity.

Operational risk includes quality problems, late deliveries, and equipment downtime. A single serious error can damage a relationship with a key customer. To manage this, a CNC Machining shop must implement quality systems, preventive maintenance, and clear production workflows.

Finally, business skills are just as important as technical skills. Many CNC Machining entrepreneurs are excellent machinists but less experienced in marketing, finance, and strategic planning. Without strong business management, even a technically capable shop can struggle to stay profitable.

Improving profitability in CNC Machining is not only about cutting costs; it is about designing a smarter business. Several practical strategies can deliver meaningful gains.

First, specialize. Instead of accepting every possible job, focus on a few areas where your CNC Machining equipment, skills, and processes give you an advantage. Specialization allows you to optimize fixtures, programs, and workflows for specific part families, reducing setup and machining time.

Second, invest in efficient tooling and fixturing. Quick‑change systems, modular fixtures, and standardized workholding can drastically reduce setup time between CNC Machining jobs. Over the course of a year, shaving even a few minutes off each setup can translate into many extra hours of productive spindle time.

Third, embrace process improvement. Regularly review toolpaths, cutting parameters, and job routings to remove waste. Use checklists to avoid errors, and organize the shop floor so that tools and materials are always where they are needed. Small, continuous improvements can compound into large productivity gains.

Fourth, enhance the service offering. By bundling CNC Machining with design assistance, DFM feedback, finishing, and assembly, you become more than just a part supplier. Customers are often willing to pay more for a turnkey solution that simplifies their supply chain and reduces their internal workload.

Finally, develop strong communication and reliability. Respond quickly to inquiries, provide clear quotations, and keep customers informed about order status. Consistent delivery and honest communication build trust, which often leads to repeat CNC Machining orders and long‑term partnerships.

For many overseas brands, wholesalers, and manufacturers, working with a specialized OEM CNC Machining factory is the most efficient way to obtain high‑quality parts at competitive cost. An experienced partner can provide end‑to‑end support, from early prototypes to precision mass production.

A capable OEM‑focused CNC Machining factory typically offers:

- Rapid prototyping with CNC Machining for metal and plastic components.

- CNC turning and multi‑axis machining for complex geometries.

- Sheet metal fabrication for enclosures, brackets, and structural parts.

- 3D printing for iterative design validation and low‑volume parts.

- Mold and tooling production to support injection molding or die casting.

By combining these capabilities, the factory can support the complete product lifecycle. International customers benefit from a single point of contact, consistent quality standards, and streamlined logistics. This is particularly attractive to companies that lack in‑house machining capacity but need reliable CNC Machining support for their products.

When selecting such a partner, buyers normally evaluate machining capabilities, available materials, quality control (including inspection reports and certifications), communication, lead times, and cost structure. A well‑organized CNC Machining supplier that offers OEM services can build long‑term relationships with brands and wholesalers who want stable, scalable production.

CNC Machining is a powerful pathway to earning money in the manufacturing world, but success depends on more than buying a machine and waiting for orders. Entrepreneurs and shop owners must understand their costs, choose profitable niches, and keep machines cutting as many productive hours as possible. When a CNC Machining business combines technical excellence with disciplined quoting, efficient workflows, and strong customer service, the result can be a highly profitable and sustainable operation.

Whether you start as a hobbyist, operate a part‑time side business, or run a full‑scale OEM‑oriented factory, CNC Machining offers a broad range of opportunities. Growing demand for precision parts, shorter product lifecycles, and the need for flexible manufacturing all continue to support this industry. With careful planning, continuous improvement, and a clear value proposition, it is entirely realistic to build a profitable future around CNC Machining.

A small CNC Machining shop with one or two industrial machines can often reach annual revenue in the low to mid six‑figure range once it has a steady customer base. Actual profit depends on overhead, pricing, and utilization, but many small shops achieve healthy net margins once they optimize their workflow and avoid underpricing.

For owners who manage operations effectively and keep machines busy with repeat work, this level of CNC Machining business can provide a solid full‑time income. As more machines and staff are added, revenue and profit can grow further, especially when the shop focuses on higher‑value markets.

CNC Machining can be an excellent side hustle for technically minded people who enjoy design and manufacturing. With a smaller machine and limited workspace, you can produce customized parts, signs, fixtures, or specialty items during evenings and weekends.

While side‑hustle income is usually modest at the beginning, it provides a low‑risk way to learn programming, setup, quoting, and customer communication. Over time, the experience and customer relationships built through a CNC Machining side business can form the foundation of a full‑time shop if desired.

Typical net profit margins for CNC Machining businesses often fall in the single‑digit to low double‑digit range, depending on how well costs are controlled and work is priced. Shops that treat machining as a commodity and compete on the lowest price may struggle to achieve healthy margins.

In contrast, CNC Machining operations that specialize in higher‑value parts, streamline their processes, and provide value‑added services often see significantly better profitability. By carefully tracking costs per hour, including labor and overhead, a shop can set target margins and adjust its quoting strategy to maintain them.

Industries that require high precision, reliability, and complex engineering typically pay the best for CNC Machining services. Aerospace, defense, medical devices, high‑performance automotive, motorsport, and advanced industrial machinery all fall into this category.

These sectors value consistent quality, documentation, and strong technical support, which gives well‑organized CNC Machining providers room to charge rates that reflect the complexity and risk of the work. Building capabilities tailored to one or more of these industries is often a smart strategy for long‑term growth.

Success in CNC Machining requires a combination of technical and business skills. On the technical side, key abilities include reading engineering drawings, using CAD/CAM software, selecting tools and cutting parameters, setting up fixtures, and understanding machining strategies for different materials.

On the business side, you need skills in quotation and pricing, basic accounting, customer communication, sales, and production planning. Many successful CNC Machining entrepreneurs grow into these roles over time, starting as machinists and gradually learning how to manage a profitable workshop.

1. https://financialmodelslab.com/blogs/how-much-makes/cnc-machining

2. https://www.elephant-cnc.com/blog/is-cnc-business-profitable/

3. https://www.equipmentcalculators.com/guides/cnc-business-profitable

4. https://www.reddit.com/r/hobbycnc/comments/192u3jm/did_you_make_money_with_your_cnc_machine_or_it_is/

5. https://startupfinancialprojection.com/blogs/profitability/cnc-machining

6. https://dataintelo.com/report/cnc-machining-services-market

7. https://www.onefinitycnc.com/post/how-to-make-money-with-a-cnc-machine

8. https://www.youtube.com/watch?v=hEYlFal4cqE

9. https://www.linkedin.com/pulse/cnc-machining-services-market-investment-landscape-isy5c

10. https://www.reddit.com/r/CNC/comments/1olhfp8/what_kind_of_money_is_there_in_machining/

11. https://www.facebook.com/groups/smallbusinessforsale/posts/3547275302193668/

12. https://www.fortunebusinessinsights.com/industry-reports/computer-numerical-controls-cnc-machine-tools-market-101707

13. https://www.youtube.com/watch?v=y7HSNmKysjI

14. https://www.cancam.ca/learning-centre/cnc-money-making-projects-to-boost-your-workshops-profitability/

15. https://www.intelmarketresearch.com/cnc-machining-service-for-prototypes-market-25901

content is empty!