Views: 222 Author: Amanda Publish Time: 2025-11-12 Origin: Site

Content Menu

>> Key Stages in Turning Lathe Operations

● The Role of Turning Lathes in Precision Manufacturing

>> Applications Across Industries

● What Makes a Turning Lathe Brand the Best?

● Top Turning Lathe Brands for High-Precision Parts

>> Hardinge

>> Makino

>> Trumpf

● Advanced Features of Modern Turning Lathes

>> Live Tooling

>> Hydrostatic Bearings and Vibration Damping

● The OEM Advantage: Precision and Scalability

● Expanded Turning Lathe Applications

>> Medical Device Manufacturing

>> Toolroom, Molds, and Furniture

>> High-Volume Precision Production

● Safety and Sustainability in Turning Lathe Operations

● Key Factors When Selecting a Turning Lathe Brand

● FAQ

>> 1. What is a turning lathe, and how does it work?

>> 2. Which industries require high-precision turning lathes?

>> 3. How do OEM turning lathe services benefit international buyers?

>> 4. What advanced features should I prioritize in a turning lathe?

>> 5. What are key factors for selecting the best turning lathe brand?

Turning lathes remain essential tools at the heart of modern manufacturing, providing unmatched precision, versatility, and efficiency for producing high-quality, high-tolerance parts. For international brand owners, wholesalers, and producers seeking OEM solutions, choosing the right turning lathe brand is critical to achieving superior results in industries ranging from aerospace and automotive to medical, electronics, and energy. This article offers a comprehensive guide to the world's best turning lathe brands, examines their advanced features, explores key industry applications, and explains how partnering with an experienced OEM enhances manufacturing success.[1][9][10][11]

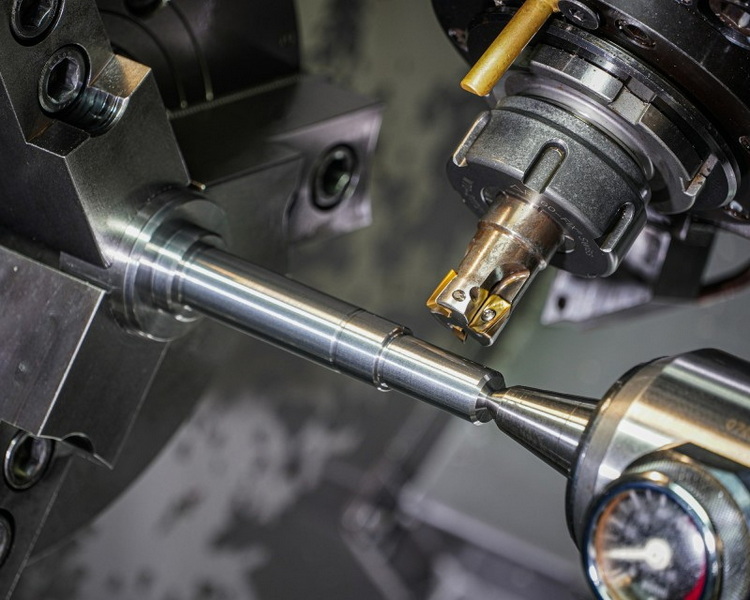

A turning lathe is a machine tool that rotates a workpiece against a stationary cutting tool, shaping it into precise, complex forms—most often cylinders, shafts, or other symmetrical parts. Turning lathe processes include external turning, facing, threading, boring, and grooving, all performed with high repeatability and exceptional surface finish. CNC (Computer Numerical Control) turning lathes further improve consistency and throughput by automating tool movement, material positioning, and quality controls.[12][13][14]

- Workpiece mounting with a chuck or centers

- Precision alignment and tool setup

- Controlled rotary motion and material removal

- In-process measurement and surface finishing

Modern turning lathes deliver the tight tolerances demanded by aerospace, automotive, electronics, medical, and robotics industries. High-precision parts, such as engine components, medical implants, connectors, and scientific instrument housings, require repeated accuracy and excellent surface quality that only advanced turning lathe systems can provide.[3][5][6][1]

- Aerospace: Machining turbine blades, fuel system parts, landing gear, and complex structures from superalloys like titanium and Inconel.[2][5][1]

- Medical: Shaping implants, orthopedic fasteners, surgical tools, and dental components with biocompatible materials.[2][3]

- Automotive: Production of engine shafts, pistons, bearings, and custom interior/exterior fittings.[8][1]

- Electronics/Precision Instruments: Creating housings, connectors, sensor mounts, and micro components for consumer and industrial devices.[6][2]

- Energy and Marine: Turning turbine rotors, valve stems, pump housings, and corrosion-resistant marine hardware.[1][2]

Selecting a top-tier turning lathe brand involves evaluating several criteria:

- Cutting-edge design: Integration of closed-loop controls, thermal compensation, and high-speed spindle technology

- High durability: Vibration-resistant construction, premium materials, and rugged frames

- Accuracy: Tolerances as fine as ±0.0001 inches for consistent part quality

- Advanced automation: Multi-axis configurations, live tooling, and robotic part handling

- Comprehensive support: Prompt service, spare part availability, and software upgrades

- Strict quality assurance: ISO certifications, traceability, and documented process control.[9][10][15][3]

Mazak's CNC turning lathes dominate high-tech sectors worldwide, renowned for reliability, speed, and precision. Aerospace and automotive manufacturers trust Mazak for critical parts built to strict certification standards.[5][9]

Brands such as Tsugami, Citizen, and Star excel at producing tiny, intricate parts with high length-to-diameter ratios. Their guide bushing architecture ensures excellent concentricity and minimal tool deflection, ideal for electronics, watchmaking, and minimally invasive medical devices.[15][16][3]

Hardinge specializes in manual and CNC toolroom lathes (like the HLV-H series) favored for ultra-fine adjustment capability. Laboratories and research centers choose Hardinge for prototyping and ultra-precision machining.[17]

As a North American leader, Haas delivers rugged, dependable CNC turning lathes with intuitive controls and robust after-sales support. Automotive workshops and OEM suppliers rely on Haas for efficient batch production and flexible part runs.[18][8]

Makino's advanced solutions cater to sectors where sub-micron accuracy and surface quality are essential, including medical and optical manufacturing. Their turning lathes incorporate state-of-the-art controls and smart tooling for reliable repeatability.[9]

Trumpf, iconic for its German engineering, produces heavy-duty multi-tasking turning lathes and turn-mill centers for industrial coupling, energy sector components, and robust mechanical assemblies.[9]

Based in the USA, D&E Machining provides aerospace-grade turning lathe services, tackling complex geometries, tight tolerances, and exotic materials for defense and aviation.[10]

Multi-axis turning lathes can machine several faces or complex cross-sections in a single setup, increasing throughput, reducing cycle times, and minimizing the risk of manual error.

Live tooling modules permit simultaneous milling, drilling, and tapping operations without removing the part, streamlining multi-step processes.

These advanced bearing systems absorb vibration, maintaining accuracy, extending tool life, and ensuring smooth surface finishes.

Bar feeders, robots, and automated part handling cells equip turning lathes for high-volume production, offering uninterrupted shifts and improved efficiency.[11][19][5]

Partnering with an OEM for turning lathe parts delivers:

- Flexible tooling for rapid prototyping and scalable batch runs

- Reduced capital investment, training, and operational overhead

- Consistent, documented quality with international certifications

- End-to-end service from design to finished component, including post-process inspection, packaging, and logistics

- Quick adaptation to design changes and accelerated time-to-market for new product launches.[20][21][22][2]

Turning lathes are indispensable for manufacturing engine housings, turbine blades, structural fasteners, and fuel-system components. CNC turning allows for complex geometries, controlled surface finishes, and complete traceability for certification.[5][1][2]

Ultra-smooth surfaces, minute tolerances, and biocompatible material handling are crucial for surgical instruments and implants. CNC lathes support efficient production of patient-specific components, meeting stringent hygiene and process validation standards.[3][2]

OEM suppliers use turning lathes to create precision shafts, bearings, engine components, and custom small-batch parts for vehicle assemblies. Automated setup and changeovers support high-mix, low-volume production runs.[8][1]

Tiny connectors, sensor housings, and precision mechanical elements benefit from high repeatability and surface finish. Lathe-based prototyping accelerates development and ensures robust assembly performance in microelectronics.[6][2]

Precision is paramount for turbine rotors, valve stems, and pump housings in energy and marine environments, where strong materials, corrosion resistance, and flawless fits ensure long-term reliability.[1][2]

Lathes provide the flexibility to produce tooling inserts, punches, dies, and core pins, expediting iterative testing for molds. In furniture and decorative arts, CNC lathes manufacture legs, spindles, and ornamental columns with consistent style and quality.[2][3]

CNC turning lathes excel in precision batch production. Automated tool changes, in-process probing, and programmed tolerances enable reliable part runs with minimal variability, supporting industrial equipment, automotive assemblies, and high-end consumer goods.[3][1][2]

Proper training, operator safety measures, and proactive maintenance are essential for preventing injury and maximizing value. Modern CNC turning lathes incorporate energy-efficient drives, coolant recycling, durable tooling, and optimized tool paths to support both environmental and economic sustainability.[4][2]

- Tolerance and repeatability requirements

- Compatibility with task-specific materials

- After-service, training, and upgrade offerings

- Automation and integration capability

- Price-to-performance balance[10][11][3][9]

Selecting the best turning lathe brand is a strategic decision—one that directly impacts product quality, efficiency, and long-term competitiveness. Leading manufacturers like Mazak, Hardinge, Haas, Tsugami, Makino, and Trumpf set industry standards with advanced precision, reliability, and innovation. Extensive applications across aerospace, medical, energy, automotive, and consumer sectors underscore the essential role of turning lathes. Collaborating with a professional OEM supplier enhances scalability, reduces costs, and increases quality assurance, positioning your enterprise for global success in high-precision markets.

A turning lathe spins the material against a stationary cutting tool, gradually removing outer layers to create parts of exact dimensions—commonly cylinders, rods, or rings. CNC features automate the process for consistent high-quality results.[13][14][12]

Aerospace, medical device manufacturing, automotive, electronics, energy, marine, defense, furniture, jewelry, and industrial tooling all rely on precision turning lathes for producing parts that meet strict tolerances and demanding functional requirements.[1][2][3]

OEM partners provide scalable production, rapid prototyping, strict quality controls, and seamless project management across custom and high-volume production—ensuring products match global standards and delivery timelines.[21][22][20][2]

Features to consider include multi-axis machining, live tooling, hydrostatic bearings, automation (robotic loaders, bar feeders), and software for documenting process controls and tolerances.[19][11][5]

Consider tolerance and repeatability, material compatibility, after-sales support, automation capacity, and overall cost effectiveness when choosing your supplier.[15][10][3][9]

[1](https://rwdtool.com/industrial-applications-of-a-cnc-lathe-machine/blog.html)

[2](https://www.sc-rapidmanufacturing.com/top-10-industrial-applications-of-turning-lathes.html)

[3](https://boruimc.com/applications-of-lathe-machines/)

[4](https://www.yashmachine.com/blog/applications-of-lathe-machines-in-workshop-environments/)

[5](https://machinetoolspecialties.com/blog/1036-leading-cnc-lathe-manufacturers-a-comparative-quality-overview)

[6](https://www.weerg.com/guides/lathe)

[7](https://www.wevolver.com/article/what-is-cnc-turning)

[8](https://www.chushing-tw.com/en-US/newsc10-top-5-industries-that-rely-on-conventional-lathes)

[9](https://www.tsinfa.com/cnc-lathes-manufacturer/)

[10](https://yijinsolution.com/news-blog/top-10-cnc-turning-parts-manufacturers-in-the-usa/)

[11](https://machinetoolspecialties.com/blog/1039-best-cnc-lathes-for-precision-machining)

[12](https://www.3erp.com/blog/turning/)

[13](https://de.meviy.misumi-ec.com/info/en/blog-en/manufacturing-en/26633/)

[14](https://www.xometry.com/resources/machining/what-is-turning-in-machining/)

[15](https://revelationmachinery.com/blog/cnc/most-popular-lathe-brands/)

[16](https://www.reddit.com/r/Machinists/comments/1heeqqd/whats_your_favorite_swiss_lathe/)

[17](https://www.practicalmachinist.com/forum/threads/new-manual-precision-lathe-recommendations.352461/)

[18](https://hy-proto.com/top-lathe-machine-manufacturer-compare)

[19](https://www.danobat.com/en-us/vertical-hard-turning-lathe/mikroturn-vertical)

[20](https://waycon.net/2025/05/15/what-is-oem-manufacturing/)

[21](https://www.castingcncmachining.com/blog/what-are-the-advantages-of-oem-machining-service-1463881.html)

[22](https://chemizol.com/blog/news-1/benefits-of-working-with-an-original-equipment-manufacturer-2)

content is empty!

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes

Best Practices from Leading Vacuum Mold Casting Companies Worldwide

Top Vacuum Mold Casting Providers for Custom Batch Production

How to Choose the Right Vacuum Mold Casting Service for Your Product