Views: 222 Author: Amanda Publish Time: 2025-11-16 Origin: Site

Content Menu

● Why Precision Lathe Turning Matters

● Essential Principles of Turning Lathe Operations

>> Key Turning Lathe Functions

● Material Selection and Preparation

● Design for Manufacturability (DFM)

>> DFM Guidelines for Turning Lathe Projects

● In-Process Monitoring and Process Control

● Advanced Machining Strategies

>> Swiss-Type Lathes for Ultra-Fine Work

>> Thermal and Process Stability

>> Deburring, Part-Off, and Cleanliness

● Troubleshooting Common Turning Lathe Issues

● Maximizing Lathe Longevity and Performance

● Quality Control and Inspection Techniques

● Evolving Technologies in Turning Lathe Operations

● Application Examples in Industry

● FAQ

>> 1. How do you choose the right material for high-tolerance turning lathe parts?

>> 2. What are the most important setup steps for precision turning lathe projects?

>> 3. How can operators maintain tight tolerances during mass production?

>> 4. What features should be avoided when designing for turning lathe production?

>> 5. Why is thermal stability crucial for high-precision lathe work?

Precision turning lathe operations are essential for industries where every micron counts, such as aerospace, automotive, electronics, and medical device manufacturing. High-tolerance projects require not only advanced machinery but also meticulous planning, robust process control, and a deep understanding of both material and design nuances. This guide blends expert knowledge and proven strategies for precision turning on lathes, ensuring consistent results for demanding applications.[1][3][11]

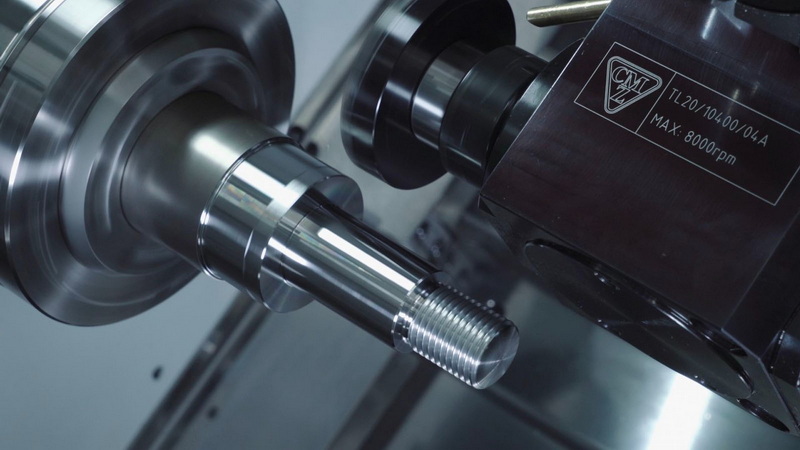

Precision turning lathes can achieve exceptional tolerances, often less than ±0.01 mm, and deliver high repeatability for both prototyping and mass production. These capabilities are indispensable for producing critical components where fit and function are non-negotiable. The modern turning lathe, especially in the context of CNC technology, combines speed, efficiency, and unparalleled precision for cylindrical parts.[4][12][13][14]

- High throughput and shorter lead times for complex, high-precision parts.[14]

- Broad material adaptability, from aluminum to titanium to specialty polymers.[12][4]

- Automation capabilities that reduce human error and increase scalability.[6][11]

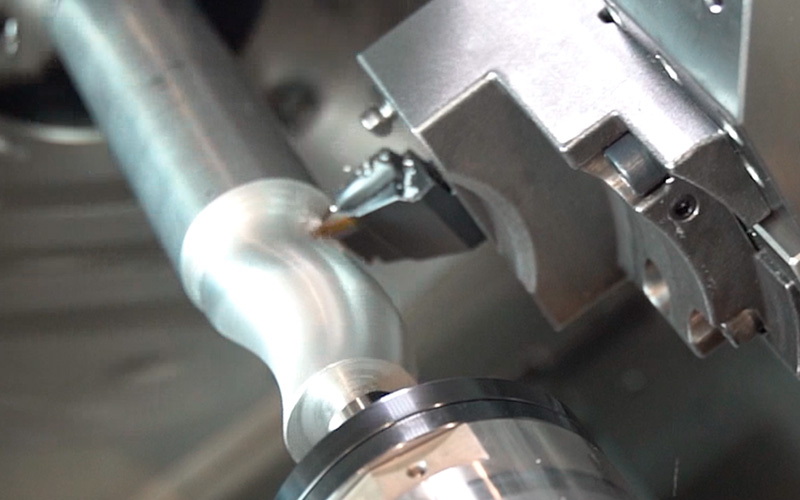

Precision turning relies on securing a workpiece within a chuck or collet and rotating it at high speeds while a cutting tool removes material. The process can produce a variety of geometries, including tapers, grooves, threads, and intricate forms, using manual or CNC lathes.[4][14]

- Straight Turning: Reducing a diameter to specification.

- Taper Turning: Producing conical profiles.

- Threading: Creating internal or external threaded features.

- Knurling: Adding grip enhancements for functionality.

- Grooving and Parting: Forming slots or separating finished parts from stock.[15][4]

Material choice critically influences outcomes in high-tolerance projects. Each material offers distinct challenges in machinability, heat resistance, and tool life.[16][12][4]

- Aluminum: Highly machinable but sensitive to surface defects; use sharp tools and avoid over-clamping.[12]

- Stainless Steel/Titanium: Demanding due to toughness; require rigid setups and constant coolant flow.[4][12]

- Plastics: Prone to warping from heat; select sharp tools and lower speeds, and consider air or minimal liquid cooling.[12]

Tip: Select standard sizes and shapes where possible to minimize waste and lower costs.[4]

Design plays a pivotal role in the efficiency and accuracy of turning. Poorly considered part geometry can lead to increased costs, longer cycles, or even impossible-to-manufacture designs.

- Use shapes that rotate concentrically for easy machining.

- Simplify features to minimize setups and tool changes.

- Specify only the tolerances that are required for function.

- Design with standard bar stock and tool accessibility in mind.

- Avoid unnecessary sharp internal corners; use fillets or radii where permissible.[4]

- Consider post-process steps such as heat treatment or surface finishing in your design planning.

Length-to-diameter guidance: For shafts and bores, ratios above 4:1 often require special attention to minimize deflection and maximize accuracy.[3]

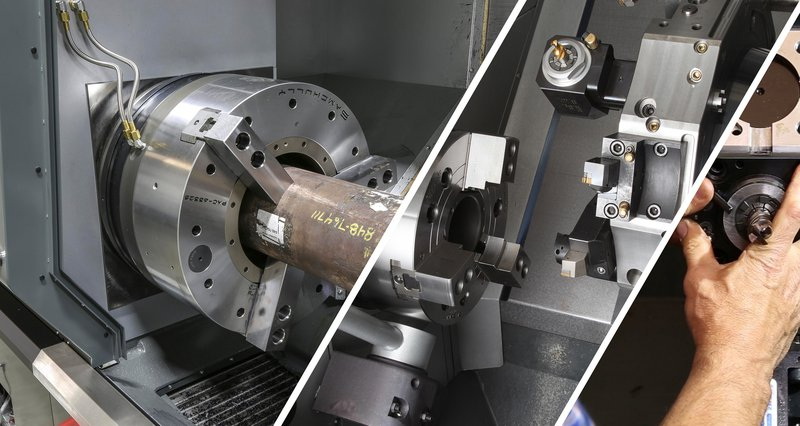

Rigorous setup is the backbone of precision lathe turning.

- Workpiece Verification: Inspect materials for defects and ensure correct dimensions.

- Machine Calibration: Check all axis movements, spindle alignment, and tool offsets using micrometers or CMMs.

- Tool Setup: Install fresh or appropriately maintained carbide, ceramic, or CBN inserts. Set accurate offsets and verify cutting edge alignment.[6]

Tip: Lock down the compound slide and tailstock to ensure no unwanted movement during critical cuts.[7]

Ensuring consistent results requires constant vigilance during production.

- In-Process Probing: Enables real-time checks without removing parts, ensuring accuracy at every stage.

- Tool Wear Monitoring: Measure and offset for tool wear using sensors or periodic inspections to prevent out-of-tolerance parts.

- SPC (Statistical Process Control): Collect sample measurements and plot control charts to spot trends or deviations before they lead to defects.[17][18]

Swiss turning lathes are optimal for small, slender parts with high length-to-diameter ratios. The use of guide bushings close to the work zone virtually eliminates deflection, greatly enhancing precision in critical applications such as medical or aerospace components.[5][19]

High-precision work over extended runs requires:

- Thermally stable machines and work environments.

- Coolant systems that manage heat at both the spindle and tool tip.

- Regular warm-up cycles and in-process temperature monitoring to avoid part drift due to expansion.[5]

- Integrate in-machine deburring to eliminate a secondary operation, safeguarding tight tolerances.[5]

- Use precise part-off strategies to maintain accuracy and prevent part damage upon separation.

- Fine coolant filtration systems are critical for both tool longevity and surface finish, especially for sliding headstock machines or fine-fitting parts.[5]

Precision projects are prone to several common pitfalls. Solutions involve a blend of process, hardware, and environmental adjustments.

| Problem | Cause & Solution |

|---|---|

| Out-of-Tolerance Parts | Check axial alignment, recalibrate tools, adjust tool offsets |

| Chatter/Vibration | Reduce length-to-diameter ratio, add supports, optimize speeds |

| Poor Surface Finish | Use sharper inserts, adjust feeds/speeds, check coolant application |

| Tool Breakage | Monitor tool wear, reduce feeds, select more appropriate tool |

| Thermal Distortion | Upgrade coolant flow, regulate shop temperature, use compensation sensors |

- Regularly schedule preventive maintenance checks, including spindle, slide, and turret inspections.

- Clean chip conveyors, coolant tanks, and machine covers to avoid contamination build-up.

- Continually update operator training for both machine skills and process knowledge.

Precision turning demands equally rigorous quality control.

- Use calibrated micrometers, calipers, and CMMs for dimensional checks.

- Apply surface roughness testers to ensure finishes meet specifications.

- Document first-article inspection results and track process data via SPC charts.

- Adoption of advanced sensors and AI-driven analytics for predictive maintenance and real-time accuracy corrections.[20]

- Hybrid lathes with live tooling allow for milling, drilling, and turning in a single setup, minimizing handling and errors.[4]

- Digital twins and simulation software optimize setup, reduce cycle time, and assess risk before physical production begins.

- Medical Devices: Micro shafts and custom fasteners with tolerances down to ±0.005 mm.

- Aerospace: High-strength, lightweight alloys shaped with flawless surface integrity for safety-critical assemblies.

- Automotive: Precision valve bodies and gear blanks produced in batches with total interchangeability.

Turning lathe operations form the bedrock of modern high-precision manufacturing. By making thoughtful decisions in material selection, design for manufacturability, and upfront setup, organizations ensure their lathe operations produce consistently high-tolerance components. Integrating robust process controls, quality assurance, and up-to-date CNC technology maximizes productivity and reduces variability, regardless of project complexity. Both traditional and advanced strategies—ranging from Swiss lathes to AI-powered analytics—position shops to meet the most demanding industrial requirements. Successful precision turning is not just a matter of equipment, but a holistic process blending skilled programming, careful setup, diligent monitoring, and ongoing training for continuous improvement in every turning lathe operation.[13][21][17][6][12][5][4]

Choose materials considering strength, thermal stability, and machinability. Favor standard, readily available stock to minimize cost and ensure predictable outcomes.[12][4]

Verify the calibration of the lathe, check tool offsets, inspect the spindle, and secure the workpiece properly, using appropriate workholding for the part geometry.[20][6]

Apply in-process probing, implement tool wear monitoring, and utilize SPC techniques to catch deviations quickly. Automation and real-time feedback systems help maintain consistency.[17][5]

Avoid sharp internal corners, deep holes at odd angles, asymmetrical designs, and unnecessary geometric complexity. Use chamfers and radii to improve machinability and durability.[4]

Uncontrolled temperature changes can cause both machine and workpiece distortion, leading to dimensional drift out of tolerance. Use actively cooled machines, run warm-up cycles, and monitor shop climate for best results.[22][5]

[1](https://www.makerverse.com/resources/cnc-machining-guides/best-practices-designing-for-cnc-turning/)

[2](https://thedatascientist.com/a-practical-guide-for-cnc-lathe-service-selection-for-precision-manufacturing/)

[3](https://www.focusedonmachining.com/blog/6-dfm-tips-for-cnc-turned-parts)

[4](https://www.symachining.com/precision-turning-parts/)

[5](https://nomura-ds.com/blog/high-volume-tight-tolerance-things-to-consider-for-your-swiss-lathe)

[6](https://cncwmt.com/qa/cnc-turning-machine-operation-best-practices-and-tips/)

[7](https://www.practicalmachinist.com/forum/threads/need-advice-taking-off-precise-amount-on-lathe.92269/)

[8](https://www.youtube.com/watch?v=H0AyVUfl8-k)

[9](https://www.hobby-machinist.com/threads/heres-how-to-get-0-0001-precision-on-your-ancient-hobby-lathe.28127/)

[10](https://www.youtube.com/watch?v=2-z_UdZMn8o)

[11](https://shamrockprecision.com/precision-machining-guide-cnc-turning-to-milling/)

[12](https://www.longshengmfg.com/how-to-achieve-%C2%B10-01mm-tolerance-consistently-a-guide-to-high-precision-cnc-lathes/)

[13](https://www.3erp.com/blog/cnc-machining-tolerances/)

[14](https://www.xometry.com/resources/machining/what-is-turning-in-machining/)

[15](https://turntechprecision.com/clueless-machinist/2020/8/25/10-machining-operations-performed-on-a-lathe)

[16](https://gmicorp.com/3-tips-for-tight-tolerances-in-precision-parts/)

[17](https://tonzamaking.com/blog/why-quality-control-matters-in-high-precision-cnc-turning/)

[18](https://www.bakerindustriesinc.com/blog/best-practices-for-quality-control-in-cnc-machining/)

[19](https://www.youtube.com/watch?v=Jz4AMGgn5Vs)

[20](https://cncwmt.com/qa/cnc-lathe-precision-inspection-and-error-analysis/)

[21](https://www.youtube.com/watch?v=1ucIlVctnVo)

[22](https://www.reddit.com/r/Machinists/comments/131z5m6/lights_out_cnc_turning_what_sort_of_automatic/)

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal