Views: 222 Author: Amanda Publish Time: 2025-10-28 Origin: Site

Content Menu

● CNC Milling Services: A Foundation of Precision

● Key Metals for CNC Milling Services

>> Aluminum: Lightweight, Versatile, and Cost-Effective

>> Stainless Steel: Durability and Corrosion Protection

>> Brass: Machinability and Conductivity

>> Titanium: Strength with Light Weight

>> Carbon & Alloy Steels: High Strength, Cost-Effective Solutions

>> Copper: Superior Thermal and Electrical Performance

>> Other Metals: Magnesium, Bronze, Nickel, Tungsten

● Engineering Plastics in CNC Milling Services

>> ABS: Affordable and Easily Machined

>> Nylon: Durable, Wear-Resistant, and Flexible

>> Delrin (Acetal/POM): Precision and Consistent Quality

>> PEEK: Extreme Performance Under Stress

>> Other Plastics: PVC, Polycarbonate, PET, HDPE

● Composites and Specialty Materials

● Selecting the Right Material: Criteria for CNC Milling Services

● Advanced Applications for CNC Milling Services

● Future Trends in CNC Milling Service Materials

● FAQ

>> 1. What are the most commonly used metals in CNC Milling Services?

>> 2. Which engineering plastics are suitable for CNC Milling Services?

>> 3. How do I decide which material is best for my CNC project?

>> 4. Can CNC-milled materials be certified for critical industries?

>> 5. Why is professional support crucial in material selection for CNC Milling Services?

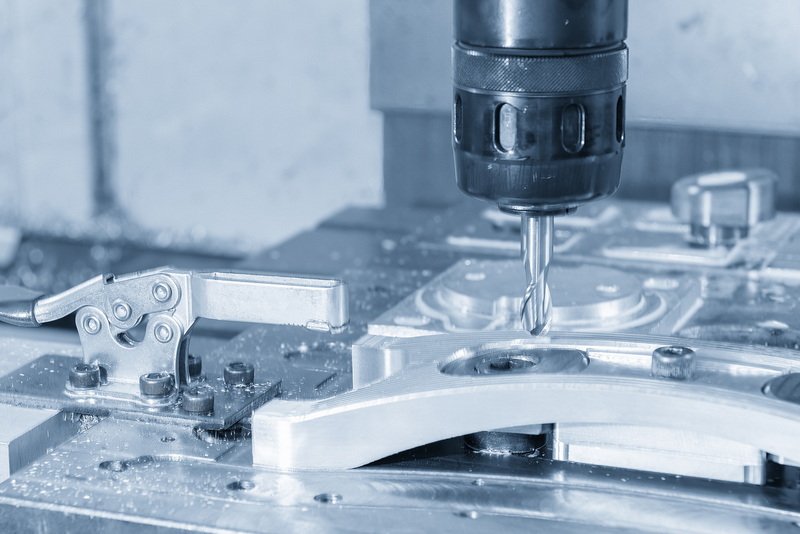

CNC Milling Services are at the core of modern manufacturing, providing precise machining solutions for industries ranging from aerospace and automotive to medical devices and consumer electronics. The effectiveness, durability, and quality of CNC-milled products depend largely on material selection—a critical step that impacts every aspect of the machining process, from the speed and efficiency of production to the cost and longevity of components.[2][5][6]

Identifying the best materials for CNC Milling Services requires a thorough understanding of metal alloys, engineering plastics, composites, and their unique properties. This article will explore popular options, application scenarios, and key criteria for material selection, offering an in-depth resource for buyers, engineers, and OEM partners.

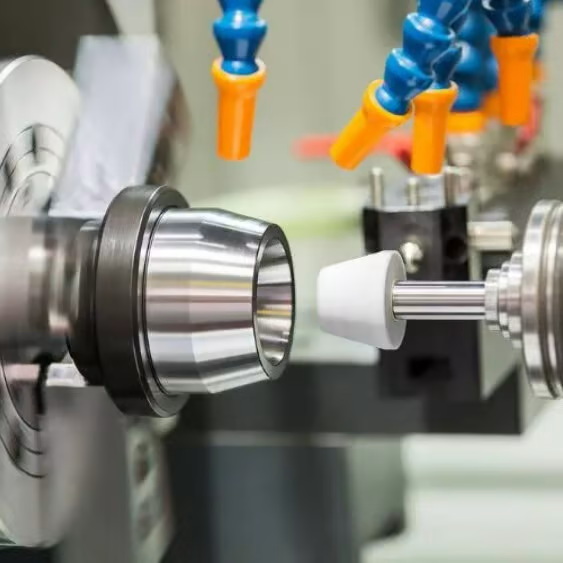

CNC (Computer Numerical Control) milling is an automated subtractive process that produces parts with exceptional accuracy and repeatability. Whether for custom prototypes or large-scale OEM production, CNC milling excels at crafting parts from both metals and plastics with micron-level tolerances.[9]

Modern CNC milling equipment is compatible with hundreds of materials, each optimized for specific industry challenges and performance demands. Factory partners like Shangchen, equipped with advanced machinery and strict quality standards, provide flexibility in material choice and production scale to suit global needs.

Aluminum stands out due to its light weight, machinability, corrosion resistance, and attractive price. Multiple alloys such as 6061 and 7075 are routinely selected—6061 offers a great balance of strength and machinability, while 7075 is preferred when maximum strength is crucial. Aluminum is favored in aerospace, automotive, consumer electronics, and medical industries, supporting applications like aircraft accessories, vehicle components, and heat sinks.[6][2]

Properties:

- Lightweight and corrosion-resistant

- High strength-to-weight ratio

- Good thermal and electrical conductivity

Stainless steel's reputation for strength, durability, and corrosion resistance makes it essential in medical, marine, food processing, and structural applications. Common grades include 304, 316, and 303—each chosen for particular balance of corrosion resistance and machinability. While stainless steel generally requires longer machining times than aluminum, it yields high-performance components with excellent longevity.[5][2][6]

Properties:

- High tensile strength

- Outstanding resistance to chemicals and moisture

- Suitable for harsh environmental exposure

Brass provides easy machining, pleasing aesthetics, and strong resistance to corrosion. It is often used in electrical components, decorative parts, plumbing fixtures, bushings, and valve seats. Different series of brass alloys—like leaded C360—are selected for improved machinability or corrosion resistance as needed.[2][6]

Properties:

- Smooth surface finish

- Good electrical and thermal conductivity

- Excellent machinability

Titanium is exceptional when a high strength-to-weight ratio, biocompatibility, and corrosion resistance are required—such as aircraft frames, sporting equipment, and medical implants. Titanium is more expensive and challenging to machine, but its unique properties are indispensable for critical aerospace and healthcare parts.[6][2]

Properties:

- Remarkable corrosion resistance

- Very high strength

- Biocompatibility (suitable for implants and surgical devices)

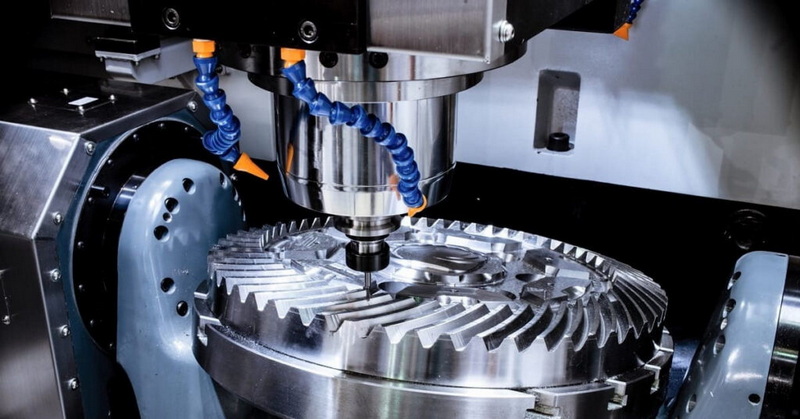

Carbon steels like C1018 and C1045, as well as alloy steels such as 4140 and 4340, offer excellent strength and reasonable costs. They are used in gears, shafts, machinery frames, and industrial components where durability and wear resistance are crucial. Alloying elements like chromium or molybdenum modify hardness, toughness, and heat resistance for custom engineering needs.[2]

Properties:

- High mechanical strength

- Heat-treatable for improved properties

- Cost-effective for high-volume production

Copper's ability to conduct heat and electricity is unmatched, making it the number one choice for electrical contacts, heat exchangers, and complex conductive components. The material is relatively soft and requires clean machining for top surface finishes.[5][2]

Properties:

- Best-in-class electrical and thermal conduction

- Corrosion-resistant

- Good machinability with sharp tooling

Advanced applications may call for magnesium for ultra-lightweight designs, bronze for wear-resistant bushings, nickel and tungsten for parts exposed to extreme temperature or stress. Each metal presents unique machining challenges, from flammability (magnesium) to tool wear (tungsten), that must be factored into process planning.[2]

ABS (Acrylonitrile Butadiene Styrene) is a durable, well-machinable thermoplastic used in prototype development, consumer products, and pipes. Strong impact resistance and flexibility suit ABS for mass production and electronic housings.[5][2]

Properties:

- High impact and temperature resistance

- Good machinability and surface finish

Nylon's low friction coefficient, resilience, and moderate machining difficulty make it ideal for gears, bushings, and connectors in automotive and industrial fields. Grades like Nylon 6, Nylon 66, and Nylon 510 deliver tailored properties for load bearing and wear resistance.[5][2]

Properties:

- Highly wear-resistant

- Mechanically tough

- Available in multiple grades for application-specific needs

Delrin, or Polyoxymethylene (POM), delivers stability, wear resistance, and a low friction coefficient. It's preferred for high-precision applications needing minimal dimensional change and a consistently smooth finish.[2]

Properties:

- Outstanding dimensional stability

- Easy to cut, drill, and shape

- Excellent fatigue resistance

PEEK (Polyether Ether Ketone) offers high mechanical strength and stability at temperatures up to 250°C, ideal for demanding aerospace, medical, and high-temperature equipment components. Though expensive, PEEK can replace metals in applications needing chemical resistance and lightweight construction.[2]

Properties:

- High temperature and chemical resistance

- Lightweight yet strong

- Ideal for parts with continuous stress exposure

PVC delivers affordability, durability, and chemical resistance for pipes, insulators, and medical devices. Polycarbonate combines machinability with transparency, useful for domes and fixtures. PET maintains properties under moisture loads, while HDPE (High-Density Polyethylene) is tough and widely used for mechanical stress applications.[2]

CNC Milling Services can also handle composites such as carbon fiber- and glass fiber-reinforced polymers, offering strength-to-weight advantages for specialized parts in aerospace and defense. Modern factories equipped for precision machining may even process advanced ceramics, ultra-high-molecular-weight polymers, and custom alloy blends for one-off or mass production needs.[9][5]

Successful material selection depends on:

- Mechanical Properties: Assessing tensile strength, hardness, elasticity, and fatigue resistance to suit the application.

- Machinability: Evaluating cutting ease, tool wear, and achievable surface finish, which affects production speed and efficiency.

- Cost and Availability: Balancing premium performance against raw material and machining costs, especially for high-volume orders.

- Corrosion and Temperature Resistance: Choosing materials based on environmental exposure—marine, chemical, extreme temperature, or sterile conditions.

- Industry Requirements: Matching standards and certifications for medical, aerospace, automotive, and electronics markets.

Consulting with CNC factories experienced in diverse material processing, such as Shangchen, helps OEM partners optimize projects for strength, quality, pricing, and long-term reliability.

CNC Milling Services extend beyond prototyping to mass production of functional, structurally critical components for global industries. In aerospace, milled titanium or aluminum parts satisfy both weight reduction and critical safety. For automotive, steel and advanced plastics serve as gears, connectors, and sensor housings. Medical devices rely on stainless steel, titanium, Delrin, and PEEK for biocompatibility and strength.[3][6]

Each industry leverages the diversity of CNC Milling Services to achieve highly tailored results, whether for niche applications or broad-scale international supply.

Innovations in metallurgy and polymer science continually expand the options available for CNC milling. Expect to see:

- Increased use of hybrid materials and multi-layer composites for ultra-high-performance applications.

- Smarter alloys engineered for reduced tool wear and faster machining cycles.

- Sustainable bioplastics and recycled metal alloys for green manufacturing initiatives.

- Nano-engineered surfaces for electronics and medical micro-components.

Partnering with progressive CNC milling providers ensures access to the latest materials and processes for state-of-the-art production.

Selecting the best materials for CNC Milling Services is a vital part of product development and manufacturing success. Understanding the performance profiles—ranging from aluminum's versatility and stainless steel's strength to PEEK's high-end engineering—guarantees optimal efficiency, cost savings, and product durability. Work with expert CNC factories like Shangchen for tailored solutions and professional support to meet the demands of the global market.

Aluminum, stainless steel, brass, titanium, and various alloy steels represent the most frequently used metals due to their outstanding machinability and well-balanced properties.[6][2]

PEEK, Delrin, nylon, ABS, PVC, and polycarbonate are popular plastics, each offering distinct advantages for price, machinability, and environmental resistance.[5][2]

Consider the part's function, mechanical stress, required precision, exposure to chemicals or moisture, and cost constraints; consult specialist CNC suppliers for expert recommendations.[5][2]

Yes, reputable CNC factories offer full traceability, certifications (ISO, ASTM), and compliance to regulatory standards essential for aerospace, medical, and automotive applications.[3][9]

Expert CNC partners help balance design goals, production costs, and industry requirements, minimizing risk and ensuring the best outcome for each project.[6][2]

[1](https://jlccnc.com/blog/cnc-machining-materials-guide)

[2](https://www.solutionsmfg.net/blog/cnc-milling-material-selection-guide/)

[3](https://www.facturee.de/en/material-for-cnc-machining-a-comprehensive-guide/)

[4](https://www.cnccookbook.com/a-comprehensive-guide-to-cnc-milling-tools-and-their-uses/)

[5](https://www.makerverse.com/resources/cnc-machining-guides/cnc-milling-everything-you-need-to-know/)

[6](https://www.norck.com/blogs/news/top-10-cnc-milling-materials-for-precision-manufacturing-an-ultimate-guide-2025)

[7](https://www.americanmicroinc.com/resources/cnc-machining-material-guide/)

[8](https://www.protolabs.com/resources/design-tips/cnc-machining-materials/)

[9](https://www.wevolver.com/article/cnc-milling-a-comprehensive-guide-to-understanding-and-mastering-the-technology)

[10](https://www.cadrex.com/cnc-machining-starter-guide)

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal