Views: 222 Author: Amanda Publish Time: 2025-08-08 Origin: Site

Content Menu

>> How 5-Axis Differs from Traditional Machining

● Applications of 5-Axis Machining in Precision Manufacturing

>> Medical Device Manufacturing

● Key Features of the Best 5-Axis Machining Services

>> Flexible Materials Processing

● Choosing the Right 5-Axis Machining Partner

>> Assess Experience and Track Record

● How 5-Axis Machining Streamlines Prototyping and Batch Production

>> Advanced Techniques in 5-Axis Machining

>>> Simultaneous vs. Indexed Machining

>>> High-Speed Machining (HSM)

>>> Automated Tooling and In-Process Measurement

>>> Digital Twin and CAM Integration

● Why Choose Us for 5-Axis Machining?

● The Future of 5-Axis Machining Services

● FAQ

>> 1. What is the difference between 3-Axis and 5-Axis Machining?

>> 2. Which materials can be used in 5-Axis Machining?

>> 3. How accurate is 5-Axis Machining?

>> 4. Can 5-Axis Machining handle both prototypes and large production runs?

>> 5. What factors should I consider when selecting a 5-Axis Machining provider?

In today's demanding manufacturing environment, precision, efficiency, and complexity are not just desirable—they're essential. Enter 5-Axis Machining: the cutting-edge solution revolutionizing industries from aerospace to medical device manufacturing. Whether you're an OEM, a product developer, or a production manager, understanding and leveraging the advantages of true 5-Axis Machining services can give your business a vital competitive edge.

This article explores everything you need to know about 5-Axis Machining, why it's a game-changer for precision manufacturing, how to select the best service partners, and the latest trends in this ever-evolving technology.

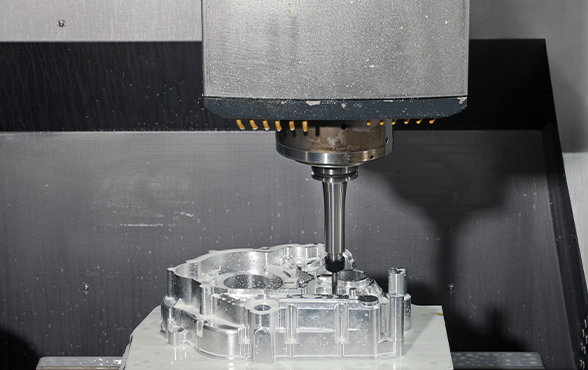

5-Axis Machining refers to a modern computer numerical control (CNC) process that utilizes three linear axes (X, Y, and Z) and two additional rotary axes, allowing the cutting tool to approach the material from any direction. This results in the ability to machine complex shapes in a single setup, providing unmatched quality and versatility.

- 3-Axis Machining: The cutting tool moves up/down, left/right, and forward/backward.

- 5-Axis Machining: Adds tilting and rotating movements, enhancing accessibility and precision for intricate components.

- Reduced setups: Achieve complex geometries in one go.

- Superior accuracy: Multi-angle approach minimizes human error.

- Improved surface finish: Smoother, more uniform results.

- Shorter lead times: Accelerated production, fewer steps.

- Enhanced innovation: New design possibilities, previously impossible to manufacture.

5-Axis Machining is indispensable for aerospace manufacturing, enabling rapid production of turbine blades, impellers, housings, and structural components with intricate curvatures and tight tolerances. The complexity of aerospace components demands machining processes that can maintain superior precision while handling tough materials such as titanium and superalloys. This technology reduces the need for multiple setups, decreasing risk of misalignment and ensuring consistent parts that meet exacting standards.

In the automotive sector, 5-Axis Machining facilitates precise manufacture of engine blocks, transmission cases, gearboxes, and custom automotive parts. Its ability to produce components with complex curves and detailed internal features improves performance, reduces weight, and speeds up product development cycles. This machining approach supports both prototyping and mass production needs, enabling rapid iteration and cost-effective manufacturing.

Medical devices, implants, surgical tools, and prosthetics require ultra-fine accuracy and biocompatible materials. 5-Axis Machining excels in producing these parts with exacting tolerances, smooth finishes, and complex geometries. The technology enables manufacturers to create customized implants that perfectly match patient anatomy, which is critical in orthopedic and dental applications. Additionally, the ability to machine intricate channels and surface textures benefits surgical instrument performance.

The electronics and robotics industries benefit from the precision and versatility of 5-Axis Machining in fabricating enclosures, housings, and intricate mechanical components. Complex features such as multi-faceted faces, internal cavities, and thin-walled structures can be efficiently produced, enhancing device performance and reliability. 5-Axis processes also simplify assembly by producing components that fit with minimal post-processing.

Top-tier service providers invest in state-of-the-art 5-Axis CNC machines capable of ultra-high-speed, high-precision operations. These machines are equipped with advanced control systems, multi-axis controllers, and vibration damping technologies that ensure stability and accuracy even during complex operations. Modern 5-Axis centers often integrate robotic arms and automated loading systems to boost efficiency and consistency.

Experienced engineers and machinists play a pivotal role in programming, toolpath optimization, and final inspections. Their expertise enables the efficient use of multi-axis CNC technology, selecting optimal tooling and cutting parameters to minimize wear and maximize quality. Continuous training and certification ensure they remain updated with the latest software and machining strategies.

The best services employ rigorous inspection protocols, utilizing coordinate measuring machines (CMMs), laser scanners, surface roughness testers, and in-process verification systems. This multi-level approach guarantees the highest consistency and adherence to specifications, reducing waste and rework. Automated inspection reduces human errors and accelerates quality feedback during production runs.

From aluminum and stainless steel to titanium, copper, plastics, and composites, leading providers offer a diverse array of material capabilities. Specialized tooling and machine configurations accommodate the specific challenges posed by each material, such as heat generation, chip removal, and surface finish requirements. This flexibility allows manufacturers to innovate with new materials and designs.

End-to-end project support includes design-for-manufacturability (DFM) reviews, rapid prototyping, secondary processing such as surface finishing and anodizing, and assembly services. This all-in-one approach facilitates smoother transitions from concept to production while maintaining quality and timelines. Vendors who understand various industry standards and certifications (ISO, AS9100, etc.) provide added assurance.

When selecting a 5-Axis Machining service, inquire about the make and model of their CNC machines, the software platforms they use for CAM programming, and the extent to which their workflow integrates digital solutions such as CAD/CAM, ERP, and cloud communication. Advanced digital workflows reduce errors and improve responsiveness.

Review company portfolios, case studies, and client testimonials to get insight into their expertise in your industry and with your material types. Partners with diverse experience can better handle complex projects or unexpected challenges.

Choose partners who demonstrate flexibility in production scale, from single-piece prototypes to high-volume manufacturing, and who offer tailored solutions such as custom tooling, fixtures, or hybrid machining approaches integrating additive manufacturing.

A clear, itemized quote with detailed timelines, terms, and pricing helps avoid misunderstandings and facilitates budget planning. Look for service providers willing to discuss project specifics and provide suggestions for optimization.

Effective and timely communication is critical in collaborative manufacturing projects. Select partners who maintain proactive contact, provide frequent progress updates, and swiftly resolve technical or logistical issues.

5-Axis Machining dramatically accelerates the product development cycle. Complex prototypes that once required multiple setups, special fixtures, and human intervention can now be created quickly and with fewer errors. OEMs benefit from rapid design iteration and flexibility across batch sizes, from single pieces to extended production runs.

By reducing the number of setups, 5-Axis machining minimizes repositioning labor and cumulative errors, allowing prototyping phases to proceed rapidly and smoothly. This agility is particularly important for startups and fast-moving industries where time-to-market is critical.

In batch production, 5-Axis capabilities ensure repeatability and quality, even when handling geometrically complex parts. This reduces the need for secondary finishing and inspection, lowering overall costs and downtime.

- Simultaneous 5-Axis: All five axes move simultaneously during cutting, enabling the production of sculpted surfaces, complex cavities, and multi-curved components with high precision. This method is ideal for industries demanding surface finish and accuracy such as aerospace and medical.

- Indexed 5-Axis: The rotary axes reposition the part to a fixed angle, and machining occurs on that indexed face. This approach is more cost-effective for simpler geometries and increases throughput in certain applications.

High-speed machining leverages rapid spindle speeds, faster feed rates, and optimized toolpaths to reduce cycle times dramatically. Combined with 5-Axis control, HSM enables simultaneous multi-directional cutting without sacrificing accuracy. This technique is particularly beneficial with lightweight metals like aluminum, accelerating production while maintaining surface quality.

Modern 5-Axis centers incorporate automated tool changers that allow multiple tools to be loaded and switched without manual intervention, minimizing downtime. Touch probes and in-process inspection systems measure parts during machining, enabling real-time corrections and quality assurance, which reduces scrap rates.

Digital twin technology creates a virtual replica of the machining process, allowing simulation and optimization of toolpaths before actual production. This leads to fewer errors, better surface finishes, and longer tool life. Integration with advanced CAM software enables precise toolpath generation and feeds directly into CNC controls for streamlined production.

As a seasoned provider with years of expertise, our company delivers:

- Precision Tolerances: Down to ±0.005mm in metals and plastics.

- Fast Turnarounds: Prototyping in as little as 24–72 hours.

- Diverse Applications: From single prototypes to large-scale production.

- Global OEM Partnerships: Trusted by international brands and suppliers.

- Complete Service Portfolio: Including rapid prototyping, CNC milling, lathe turning, sheet metal, and advanced mold fabrication.

- Advanced Material Handling: Capable of machining diverse materials like titanium, stainless steel, aluminum, copper, plastics, and composites.

- Comprehensive Support: DFM consultations, secondary processing options, and assembly services ensuring smooth project execution.

Ongoing advances in automation, AI-aided process planning, IoT-connected devices, and smart factories continue to elevate 5-Axis Machining's impact on precision manufacturing. AI-assisted programming software is already reducing the time needed to generate complex toolpaths, while smart sensors embedded in machines provide continuous feedback on tool wear and machine conditions. This connectivity enables predictive maintenance, reducing downtime and extending machine lifespan.

Future developments aim towards fully autonomous machining centers capable of adjusting parameters on the fly to optimize efficiency and quality. Integration with broader Industry 4.0 systems will enable seamless supply chain connections, adaptive manufacturing, and more sustainable operation by minimizing waste and energy consumption.

Manufacturers leveraging these technologies will consistently deliver higher-quality products faster and at lower costs, maintaining competitiveness in rapidly evolving markets.

5-Axis Machining stands at the forefront of modern manufacturing, supporting innovation across industries that demand complexity, speed, and ultra-high precision. For OEM partners, wholesale buyers, and product developers, leveraging the best 5-Axis Machining service is not just a smart choice—it's a strategic imperative for driving growth, quality, and innovation.

If you're ready to accelerate your next project with advanced 5-Axis Machining, reaching out to a strong manufacturing partner could be your most valuable move.

3-Axis Machining allows movement along three linear axes, while 5-Axis Machining adds two rotary axes. This means the tool can approach the part from virtually any angle, giving far greater flexibility in design and manufacturing complexity.

A wide range of materials are suitable, including aluminum, stainless steel, titanium, brass, plastics, and even composites. Specialized tooling and techniques allow efficient handling of each material.

Top 5-Axis Machining centers can achieve tolerances as tight as ±0.005mm, making them ideal for high-precision industries such as aerospace, medical, and optical manufacturing.

Yes. Modern 5-Axis services are highly flexible, supporting both single-piece prototypes and mass production with consistent quality and repeatability.

Consider factors like available equipment, technician expertise, quality assurance systems, material capabilities, transparent pricing, and responsive communication.

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal