Views: 222 Author: Amanda Publish Time: 2025-10-11 Origin: Site

Content Menu

● The Rising Importance of 3D Print Prototypes in Precision Manufacturing

● Overview of 3D Printing Technologies for Prototype Services

● Materials Used in 3D Printing Prototypes

● Designing Effective 3D Print Prototypes

● Applications Across Industries

● Quality Assurance and Certification

● FAQ

>> 1. What is the main advantage of using 3D print prototypes in manufacturing?

>> 2. Which 3D printing technology is best for high-detail prototypes?

>> 3. Can 3D print prototypes be used for functional testing?

>> 4. What materials are commonly used for 3D printed prototypes?

>> 5. How quickly can 3D print prototypes be produced?

In the rapidly evolving world of product development and manufacturing, 3D print prototypes have become indispensable tools for businesses and engineers aiming for precision, efficiency, and innovation. The use of 3D printing technology revolutionizes how prototypes are created, allowing for fast iteration, customization, and high accuracy, which traditional manufacturing methods often struggle to achieve. For brands, wholesalers, and manufacturers looking for OEM services, leveraging premium 3D print prototype services can drastically shorten development cycles and improve product quality. As a leading factory specializing in rapid prototyping, CNC machining, precision batch production, lathe turning, sheet metal fabrication, 3D printing, and mold production, Shangchen has positioned itself to serve international clients with top-notch OEM capabilities.

Prototyping is a cornerstone of successful product development. It enables the verification of design concepts, functionality, and ergonomics before committing to mass production. 3D print prototypes elevate this process by allowing highly complex and precise models to be fabricated rapidly. These prototypes help reduce costly design changes and accelerate time to market. Using advanced additive manufacturing technologies, materials, and high-detail precision printing, manufacturers can now create prototypes with intricate geometries, tight tolerances, and superior surface finishes essential in precision manufacturing fields such as aerospace, automotive, and medical device industries.

The adoption of 3D print prototypes also facilitates better collaboration among engineering teams, designers, and stakeholders by providing tangible models that communicate design intent clearly. This collaboration fosters innovation and helps identify potential design flaws earlier, saving both time and resources.

Several 3D printing technologies are employed in producing high-quality prototypes tailored to clients' specific requirements:

- Selective Laser Sintering (SLS): This technology fuses powdered materials like nylon, creating durable and functional prototypes with excellent mechanical properties and complex shapes. It is ideal for strong, end-use parts and engineering prototypes.

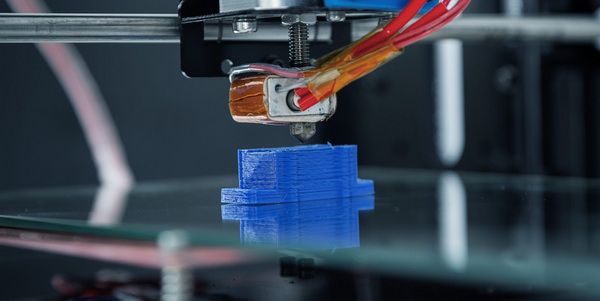

- Fused Deposition Modeling (FDM): Widely used for rapid prototyping, FDM extrudes thermoplastics layer by layer to build detailed, robust prototypes suitable for functional testing. It's one of the most accessible and economical 3D printing methods.

- Stereolithography (SLA): SLA uses UV light to cure resin, producing prototypes with extremely smooth surfaces and high accuracy, ideal for visual models and fine detailing. SLA prototypes are especially useful for parts that require a polished finish.

- PolyJet Printing: This multi-material technique builds prototypes by jetting layers of photopolymer and curing them with UV light, allowing color and texture variation in single prints. It is perfect for prototypes that require multi-material and multi-color properties.

- Direct Metal Laser Sintering (DMLS): For metal prototypes, DMLS provides the ability to create high-strength, complex metal parts without the need for tooling. This is crucial for industries demanding metal prototypes with structural integrity.

- HP Multi Jet Fusion (MJF): MJF combines speed and detail, providing prototypes with excellent surface finish and mechanical performance, suitable for functional and production-grade parts.

Each technology is selected based on the prototype's intended application, required material properties, and the precision necessary for the manufacturing process.

Materials are a critical factor in 3D printed prototypes, influencing functionality, durability, and appearance:

- Thermoplastics: ABS, PLA, Nylon, PETG, and ULTEM are common choices, ranging from cost-effective to high-performance materials for elasticity, heat resistance, or structural integrity. Thermoplastics are often used for parts requiring toughness and impact resistance.

- Resins: Standard, engineering, and flexible resins offer varying degrees of strength, detail, and elasticity for prototypes that require smooth finishes or rubber-like properties. Engineering resins provide enhanced mechanical performance for functional testing.

- Metals: Stainless steel, aluminum, titanium, and other alloys serve in applications needing high strength, corrosion resistance, or biocompatibility. Metal prototypes created using processes like DMLS enable direct functional testing of parts under real-world conditions.

- Composite Materials: Carbon fiber and fiberglass enhance strength-to-weight ratios, ideal for structural prototypes in automotive and aerospace sectors. These composites improve mechanical properties while maintaining lightweight characteristics.

Shangchen's expertise allows offering a wide range of these materials optimized for diverse manufacturing demands, ensuring clients receive prototypes that closely simulate the final products.

The success of a prototype depends heavily on its design and preparation for 3D printing. Key considerations include:

- Designing with self-supporting geometries to minimize waste and reduce the need for support structures during printing.

- Ensuring proper wall thickness and structural strength to prevent deformation and maintain integrity, especially for functional testing.

- Allowing for precise tolerances and fitting parts, critical when prototypes involve assembly or interfacing with existing components.

- Incorporating design features for modularity and ease of assembly, enabling flexible iteration and testing of individual parts.

- Accounting for necessary test points and integration for future electronics or sensors, especially in prototypes that simulate smart devices.

Proper file preparation, including converting CAD models to STL or other suitable formats, and optimizing for printing orientation, layer height, and resolution, is essential for achieving desired results.

Shangchen's design collaboration ensures prototypes are optimized for both form and function with expert consultation on material selection, printing technology, and finishing processes.

3D print prototypes accelerate product development by enabling quicker design iterations at lower costs compared to traditional methods. This results in:

- Faster validation of design concepts, allowing businesses to launch products in shorter timelines.

- Reduced tooling costs and wastage, as prototypes are built additively with minimal materials.

- Ability to create complex geometries otherwise unfeasible or prohibitively expensive with conventional manufacturing.

- Enhanced communication through physical models, improving understanding across teams and with clients.

- Lower waste due to additive manufacturing's efficiency, supporting sustainable production practices.

Additionally, rapid prototyping through 3D printing supports customization and personalization, meeting unique client demands swiftly.

3D print prototypes find extensive use in sectors requiring precision and customization, such as:

- Automotive: Creating lightweight structural parts, engine components, and interior design elements that undergo functional testing and validation before production.

- Aerospace: Manufacturing components with complex geometries and stringent performance specifications, vital for safety-critical applications.

- Healthcare: Designing custom prosthetics, surgical guides, anatomical models, and implants tailored to individual patients for improved outcomes.

- Consumer Goods: Producing ergonomic product models and functional testing prototypes that align with market trends and user preferences.

- Electronics: Fabricating functional housings, circuit board prototypes, and integrated components to accelerate development cycles.

Each of these industries benefits from the precision and flexibility offered by 3D print prototype services.

Shangchen factory maintains stringent quality control standards aligned with internationally recognized certifications such as ISO 9001:2015, IATF 16949:2016 for automotive, and AS9100D for aerospace industries. These certifications ensure that every prototype meets demanding precision, dimensional accuracy, and performance criteria necessary for high-stakes applications. Continuous monitoring, inspection using CMM (Coordinate Measuring Machines), and in-process testing support defect-free prototype production.

3D print prototype services have become vital assets in precision manufacturing, enabling companies to innovate faster, reduce costs, and improve product quality through advanced additive manufacturing technologies and materials. Factories like Shangchen combine rapid prototyping, CNC machining, and mold production to provide bespoke OEM solutions tailored for international brands and manufacturers requiring exacting standards. The future of manufacturing heavily depends on integrating 3D printing prototyping services to stay competitive and agile in a global market.

3D print prototypes allow rapid iteration, precise detail, and cost savings by eliminating expensive tooling in early design stages.

Stereolithography (SLA) is ideal for high-resolution prototypes with fine details and smooth surface finishes.

Yes, technologies like SLS, FDM, and metal printing produce durable prototypes suitable for functional and mechanical testing.

Common materials include thermoplastics (ABS, Nylon), resins (standard and engineering), metals (steel, aluminum), and composites.

Depending on size and complexity, prototypes can often be produced within 24 to 72 hours, enabling fast design cycles.

content is empty!

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes

Best Practices from Leading Vacuum Mold Casting Companies Worldwide

Top Vacuum Mold Casting Providers for Custom Batch Production

How to Choose the Right Vacuum Mold Casting Service for Your Product