Views: 222 Author: Amanda Publish Time: 2026-01-17 Origin: Site

Content Menu

● Are All Mass Produced Parts CNC Machining?

● Where CNC Machining Fits in Mass Production

>> CNC Machining in Rapid Prototyping

>> CNC Machining in Low‑to‑Medium Volume Production

>> CNC Machining in High‑Volume Mass Production

● Mass Production Processes vs CNC Machining

● Why CNC Machining Is Popular for Production

>> Precision and Repeatability

● Not All Parts Need CNC Machining

● How Shangchen Uses CNC Machining for OEM Mass Production

>> CNC Machining for Prototypes and Validation

>> CNC Machining for Batch and Serial Production

>> Hybrid CNC Machining Solutions

● When Is CNC Machining the Best Choice?

● Integrating CNC Machining with Other Processes

>> CNC Machining and Sheet Metal Fabrication

>> CNC Machining and 3D Printing

>> CNC Machining and Tooling Manufacture

● Additional Considerations for OEM Buyers

● FAQ

>> 1. Is CNC machining suitable for mass production?

>> 2. Why not use CNC machining for every mass‑produced part?

>> 3. What industries rely most on CNC machining?

>> 4. How does CNC machining compare to 3D printing in production?

>> 5. How can Shangchen help with OEM CNC machining projects?

Not all mass‑produced parts are made by CNC machining, but CNC Machining has become one of the most important technologies for both rapid prototyping and precision mass production in modern manufacturing. Many products combine CNC machining with processes such as die casting, stamping, injection molding, and 3D printing to achieve the best balance of cost, speed, and quality.

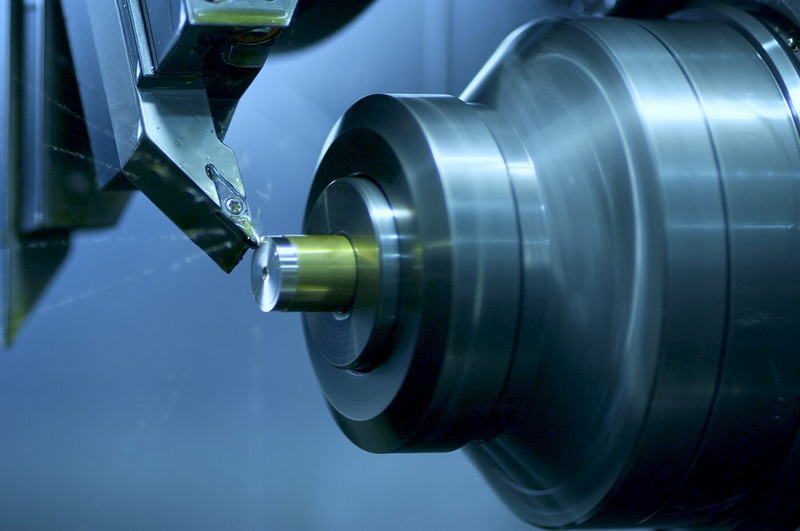

CNC machining (Computer Numerical Control machining) is a subtractive manufacturing process where computer‑controlled machines remove material from a solid workpiece to create precise parts. The machine follows programmed toolpaths based on CAD/CAM data to achieve tight tolerances and complex geometries with consistent repeatability.

- CNC machining controls milling, turning, drilling, tapping, pocketing, and contouring operations automatically with minimal manual intervention.

- It is widely used for metals, plastics, composites, and even some ceramics in industries such as aerospace, automotive, medical, energy, robotics, and electronics.

- CNC machining delivers excellent dimensional accuracy, surface finish, and part‑to‑part consistency in both prototype and production environments.

In a typical CNC machining workflow, engineers create a 3D model, program toolpaths in CAM software, set up workholding and tools on the machine, run trial parts, validate dimensions, and then start continuous production runs once everything is confirmed.

Mass production is the large‑scale manufacturing of standardized products in high volumes using repeatable processes, standard tooling, and optimized workflows. Once the process is set up, the same part is produced thousands or even millions of times with minimal variation.

- Typical goals of mass production include lower unit cost, higher throughput, and consistent quality across all parts.

- Mass production lines often use specialized machines, automation, conveyors, robots, and inline quality‑control systems.

- Standardization of parts, materials, and processes allows factories to streamline purchasing, logistics, and assembly.

Common examples of mass‑produced items include consumer electronics, automotive components, household appliances, medical devices, and industrial hardware. Many of these products leverage CNC machining at one or more stages, even if the final parts are not fully machined from solid stock.

The direct answer is no: many mass‑produced parts do not rely solely on CNC machining, even though CNC machining is a core technology in modern factories. The choice of process depends on material, geometry, volume, tolerance, cosmetic requirements, and cost targets.

- CNC machining is ideal for high‑precision parts, medium‑to‑high volumes, and components that need tight tolerances or complex shapes.

- Processes like die casting, metal stamping, injection molding, extrusion, forging, and additive manufacturing are often preferred for very high volumes, extremely low unit cost, or special shapes that CNC machining alone cannot economically achieve.

- In many projects, CNC machining is used together with other processes, for example to post‑machine cast, molded, or forged blanks to their final precision.

For this reason, it is more accurate to say that CNC machining is a central pillar of mass production rather than the only method. It supports both the visible end parts and the hidden infrastructure such as molds, dies, and fixtures.

CNC machining plays several critical roles across the product life cycle from concept to mass production. As a result, it appears in almost every successful industrial project in one form or another.

In the early design stages, CNC machining is one of the fastest ways to turn a digital model into a functional part made from real engineering materials.

- Engineers use CNC machining to create prototypes for fit‑and‑function tests, assembly trials, and performance validation.

- CNC machining prototypes can match production materials such as aluminum alloys, stainless steel, brass, or engineering plastics, providing realistic mechanical behavior.

- Compared to building a mold or die, CNC machining prototypes require lower upfront cost and are ideal when the design will still change.

For quantities ranging from a few dozen to a few tens of thousands, CNC machining often becomes the main production process.

- The same CNC machining programs used for prototypes can be refined for efficient production, using optimized feeds, speeds, and toolpaths.

- Modular fixtures and multi‑part setups allow multiple pieces to be machined in a single cycle, improving productivity.

- CNC turning centers and machining centers can be automated with bar feeders, pallet changers, and robotic loading for continuous operation.

Even in high‑volume environments, CNC machining continues to play essential roles.

- CNC machining is used to finish critical dimensions on castings, forgings, and molded parts, such as bearing bores, sealing faces, and threaded features.

- High‑value or safety‑critical components in automotive, aerospace, and medical sectors often depend on CNC machining to guarantee consistent precision.

- CNC machining supports engineering changes and model upgrades by adapting programs and fixtures more easily than replacing entire tooling sets.

Below is a conceptual comparison of CNC machining with several common mass production processes in a typical OEM supply chain.

- CNC machining: Flexible, precise, and suitable for a wide range of volumes; especially strong for complex geometries and tight tolerances.

- Metal stamping: Best for thin sheet metal parts like brackets, covers, and enclosures, especially at high volume.

- Die casting with secondary machining: Efficient for complex metal shapes where the casting forms the bulk geometry and CNC machining finishes critical areas.

- Injection molding: Ideal for high‑volume plastic components and housings where tooling cost is justified by very low per‑piece cost.

- 3D printing (additive manufacturing): Powerful for highly complex internal geometries, lightweight structures, and fast iteration, usually at low‑to‑medium volumes.

Rather than competing directly, these processes frequently complement each other. CNC machining works alongside them to create tooling, refine dimensional accuracy, and offer flexible production where hard tooling is not economical.

Even though not every mass‑produced part uses CNC machining, CNC machining remains one of the most versatile and powerful production methods available. Several advantages explain why OEM brands and wholesalers often specify CNC machining in technical drawings.

CNC machining delivers very tight tolerances and excellent repeatability, even in long production runs.

- Computer control ensures that each toolpath is executed the same way every time.

- Thermal compensation, in‑process probing, and advanced control systems help maintain accuracy over long shifts.

- Precision CNC machining reduces scrap rates, rework, and assembly problems, lowering overall project cost.

Modern multi‑axis CNC machining centers can run around the clock with automation and minimal human intervention.

- Tool magazines, automatic tool changers, and pallet systems keep machines cutting rather than waiting.

- Multi‑tasking machines that combine milling and turning can complete complex parts in a single setup.

- Well‑planned CNC machining cells support just‑in‑time production, reducing inventory and lead times.

Changing a CNC machining program is much faster and cheaper than re‑designing a mold or stamping die.

- Engineers can update CAD models, regenerate CAM toolpaths, and upload new programs without physical tooling changes.

- This flexibility is especially valuable for startup products, customized versions, engineering upgrades, and small‑batch variants.

- CNC machining enables quick response to customer feedback and market requirements.

CNC machining supports a very broad range of materials.

- Common metals include aluminum, steel, stainless steel, tool steel, brass, copper, bronze, and titanium.

- Plastics such as ABS, PC, POM, PA, PEEK, and acrylic are routinely machined for functional components.

- Specialty alloys and composite materials can also be processed with the right tooling and parameters.

Because one CNC machining center can switch between materials and projects with a change of tools and fixtures, it offers unmatched versatility compared with many dedicated production machines.

Some high‑volume parts are produced without any CNC machining on the final component because of simple geometry and low functional tolerance requirements.

- Simple sheet metal components can be stamped in progressive dies, formed, punched, and assembled without CNC machining.

- Plastic items like caps, closures, and simple covers are usually injection molded in multi‑cavity tools, again without machining on the final item.

- Certain fasteners and small hardware are cold‑headed or roll‑formed on dedicated equipment with extremely high cycle rates.

Even in these situations, however, CNC machining is often used in the background.

- CNC machining produces the dies and molds for stamping, forging, and molding operations.

- CNC machining is used to manufacture jigs, fixtures, and gauge blocks that allow high‑speed production and reliable inspection.

- When tools wear or need modification, CNC machining updates and repairs them to extend their service life.

So while the final part may not be a “CNC machined part” in the strict sense, CNC machining still supports the mass production ecosystem.

Shangchen is a Chinese factory focused on rapid prototyping, CNC machining services, precision batch production, lathe turning, sheet metal fabrication, 3D printing, and mold manufacture for global OEM brands, wholesalers, and manufacturers. CNC machining is central to nearly every project handled in the facility.

For OEM customers, speed and accuracy during early development are critical.

- Shangchen uses high‑speed CNC machining centers to create functional prototypes from aluminum, steel, stainless steel, brass, and engineering plastics.

- These CNC machining prototypes support mechanical testing, assembly verification, and pilot builds before investing in full tooling.

- Customers can iterate on design quickly by modifying CAD files and receiving updated CNC machining samples in short lead times.

Once the design is stable, Shangchen transitions smoothly into production.

- CNC machining production lines handle low‑to‑medium volumes and also repeat orders for spare parts and aftermarket components.

- CNC turning and CNC milling operations are combined to produce complex cylindrical and prismatic parts in a single coordinated process.

- Quality control includes dimensional inspection, surface roughness checks, hardness tests, and functional fit tests to ensure each CNC machining batch meets specification.

Many OEM projects benefit from a hybrid strategy.

- Shangchen can produce early batches completely by CNC machining while tooling for die casting, forging, or molding is being built.

- After tooling is ready, raw forms are produced by casting or molding and then moved to CNC machining centers for final precision machining.

- This approach combines the speed and flexibility of CNC machining with the cost advantage of high‑volume processes.

By offering CNC machining, sheet metal fabrication, 3D printing, and toolmaking under one roof, Shangchen provides OEM customers with a single point of contact and an integrated supply chain.

CNC machining is not the only tool, but it is often the best solution under specific technical and commercial conditions.

- Tight tolerances: When drawings require tight dimensional or geometric tolerances, CNC machining is usually essential on at least the critical surfaces.

- Medium volumes: For quantities from dozens to tens of thousands, CNC machining can be more economical than investing in complex tooling.

- Complex features: Deep pockets, multi‑axis contours, threads, splines, and precision bores are often most efficiently produced through CNC machining.

- Frequent design changes: When the product is evolving or needs customized variants, CNC machining allows fast changes at low incremental cost.

- High‑value components: Parts that are safety‑critical or central to performance benefit from the precision and reliability of CNC machining.

For OEM decision‑makers, a common approach is to use CNC machining early in the product life cycle and then evaluate whether a transition to other processes is justified as volumes increase.

OEM success increasingly depends on combining CNC machining with complementary technologies rather than relying on any single method.

Castings and forgings provide the basic shape, while CNC machining delivers final accuracy.

- Rough shapes are produced by die casting, sand casting, investment casting, or forging.

- CNC machining then mills reference faces, bores holes, cuts threads, and finishes sealing surfaces.

- This combination is common in engine parts, pump bodies, valve components, and structural brackets.

Sheet metal processes are efficient for thin parts, but CNC machining refines key features.

- Laser cutting, stamping, and bending create brackets, frames, and housings.

- CNC machining adds precision bosses, slots, counterbores, and machined edges where accuracy or flatness is critical.

- Inserts and machined blocks can be welded or fastened into sheet assemblies to create hybrid structures.

3D printing and CNC machining work together to unlock advanced designs.

- Additive manufacturing builds complex internal channels, lattice structures, or conformal cooling paths.

- CNC machining then finishes external surfaces, interfaces, and precision mounting points.

- This combination is used for advanced heat exchangers, lightweight aerospace parts, and high‑performance tooling.

CNC machining is essential for making molds, dies, and fixtures.

- Mold cavities and cores for injection molding and die casting are CNC machined from tool steel or hardened alloys.

- Progressive dies for stamping and forming rely on CNC machining for cutting profiles and precision pockets.

- Workholding fixtures and inspection gauges are machined to ensure reliable production and repeatable quality.

Because of this, CNC machining not only produces end parts but also enables the entire mass production infrastructure.

OEM brands, wholesalers, and manufacturers choosing a CNC machining partner should evaluate several factors.

- Engineering support: Strong design‑for‑manufacturing feedback helps optimize parts for CNC machining, cost, and performance.

- Process range: Access to CNC machining, turning, sheet metal, 3D printing, and tooling offers more flexible solutions.

- Quality systems: Robust inspection, documentation, and traceability are essential for demanding industries.

- Lead time and logistics: Reliable delivery, professional packaging, and export experience reduce risk for overseas customers.

- Communication: Clear technical communication in drawings, models, and reports ensures that CNC machining output matches expectations.

A partner like Shangchen, with integrated CNC machining and complementary processes, can guide customers through these decisions and manage projects from prototype to mass production.

Not all mass‑produced parts are CNC machining parts, but CNC machining is one of the most important technologies enabling precision mass production in modern industry. Many products rely on multiple processes, yet CNC machining is used at least for prototyping, tooling manufacture, or final finishing of critical features. For OEM brands, wholesalers, and manufacturers, partnering with an experienced factory such as Shangchen that integrates CNC machining with sheet metal fabrication, 3D printing, and tooling production provides the flexibility to choose the most suitable and cost‑effective route from concept to mass production.

Yes, CNC machining is widely used for mass production, especially when parts require tight tolerances, complex geometries, or high‑value materials. With automation, multi‑axis machines, and standardized setups, CNC machining can produce thousands of identical parts with consistent quality and competitive costs in many applications.

Some very high‑volume parts with simple geometries are cheaper to make using dedicated processes such as stamping, injection molding, or cold heading. These processes have higher tooling costs but very low per‑part costs at large volumes. CNC machining is therefore reserved for precise, complex, or flexible parts where its accuracy and adaptability provide real technical and commercial advantages.

Industries that require precision and reliability rely heavily on CNC machining, including aerospace, automotive, medical devices, robotics, electronics, energy, and industrial equipment. In these sectors, CNC machining is used for both prototypes and production components, from engine parts and medical implants to precision housings, gear components, and custom fixtures.

CNC machining is generally faster and more cost‑effective than 3D printing for medium‑to‑high volume production of parts made from standard metals and plastics. 3D printing excels in low‑volume, highly complex designs that benefit from internal channels or lattice structures. CNC machining offers superior surface finish, tighter tolerances, and lower unit cost when volumes increase, making it the preferred choice for many production parts.

Shangchen supports OEM customers from rapid CNC machining prototypes through to precision batch production and hybrid mass production solutions. With CNC machining centers, turning equipment, sheet metal lines, 3D printing capability, and in‑house tooling manufacture, Shangchen can recommend the most efficient mix of processes for each project. The team can manage the entire supply chain, from engineering support and sampling to full‑scale production and global shipment, to ensure stable quality and reliable delivery.

1. https://www.hlhprototypes.com/cnc-machining-versatile-solutions-for-mass-production-in-various-industries/

2. https://www.fictiv.com/articles/cnc-machining-for-production

3. https://eurometalsolutions.com/blog/complete-guide-to-cnc-machining-everything-you-need-to-know/

4. https://jlccnc.com/blog/cnc-machine-overview

5. https://bimetall.cat/en/blog/que-es-la-produccio-en-serie/

6. https://precisioncncmachining.com/custom-cnc-machining-vs-mass-production/

7. https://sinoindustry.com/services/cnc-machining-china/

8. https://cnc-cn.de/en/cnc-technology-in-transition-from-mass-production-to-customized-manufacturing/

9. https://www.vulcanus-stahl.de/en/blog/cnc-machining-vs-manual-machining

10. https://www.china-machining.com/services/cnc-machining/

11. https://www.lsrpf.com/blog/how-does-cnc-machining-work

12. https://www.kirmell.co.uk/cnc-machining-vs-traditional-machining-which-is-right-for-your-project/

13. https://jlccnc.com

14. https://www.rapiddirect.com/blog/cnc-production-machining/

15. https://www.timaycnc.com/blog/difference-cnc-vs-traditional-manufacturing/

content is empty!

Top On Demand 3D Printing Manufacturers and Suppliers in Russia

Top On Demand 3D Printing Manufacturers and Suppliers in Portugal

Top On Demand 3D Printing Manufacturers and Suppliers in Spain

Top On Demand 3D Printing Manufacturers and Suppliers in France

Top CNC Turning Manufacturers and Suppliers in Czech Republic