Views: 222 Author: Amanda Publish Time: 2026-01-17 Origin: Site

Content Menu

● Understanding Contouring Error in CNC Machining

● Classification of Contouring-error Reduction Methods

>> Interpolator-level Techniques

>> Cross-coupled Contouring Control

>> Real-time Contour Error Compensation

>> Pre-compensation and Off-line Optimization

>> Integrated Error Compensation for Nonlinear Trajectories

● Techniques for Contouring-error Estimation

>> Geometric Estimation in Task Space

>> Parametric Curve-based Estimation

>> Model-based and Data-driven Estimation

● Modern Control Strategies in Multi-axis CNC Machining

>> Cross-coupled and Orthogonal Control

>> Model Predictive Control and Intelligent Compensation

● Digital Twin-based Contouring-error Control

● Practical Implications for OEM-oriented CNC Machining

● Process Integration in a Modern CNC Machining Factory

● FAQ

>> 1. What is contouring error in CNC Machining?

>> 2. Why is contouring-error reduction critical for multi-axis CNC Machining?

>> 3. Which methods are commonly used for real-time contouring-error reduction in CNC Machining?

>> 4. How does digital twin technology help improve contouring accuracy in five-axis CNC Machining?

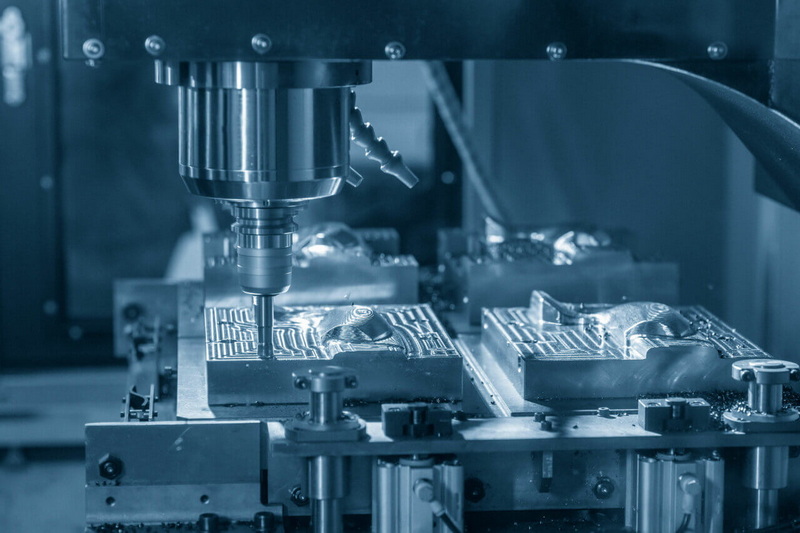

Multi-axis CNC Machining is the backbone of precision manufacturing for aerospace, automotive, medical and mold industries, where complex geometries and tight tolerances are standard rather than exception. In such applications, contouring-error reduction is one of the most critical challenges, because even a small deviation between the desired tool path and the actual path can lead to visible defects, dimensional inaccuracies, and costly scrap. For a factory like Shangchen that provides rapid prototyping, CNC Machining, turning, sheet metal manufacturing, 3D printing and mold production for overseas OEM customers, mastering contouring-error control directly impacts product quality, delivery time and international competitiveness.

In multi-axis CNC Machining, contouring error is defined as the shortest distance between the ideal reference contour programmed in the CAM system and the actual tool path generated by the machine tool. This error is typically measured in the normal direction of the path and differs from simple axis following error, which tracks deviation along each axis independently.

Several key factors generate contouring error in CNC Machining:

- Servo lag in feed drives, caused by limited bandwidth and inertia in linear and rotary axes.

- Interpolation error, especially when complex free-form curves are approximated by segmented linear or circular moves in multi-axis CNC Machining.

- Kinematic coupling in five-axis CNC Machining centers, where motion of rotary axes affects the effective position of the tool tip.

- Structural deformation, thermal drift and friction that become significant at high feed rates in high-speed CNC Machining.

For OEM-grade components, contouring errors can cause overcut or undercut of profiles, poor surface finish, and local form errors that disqualify parts from assembly or functional use.

Researchers and engineers have proposed multiple categories of contouring-error reduction techniques for multi-axis CNC Machining, each attacking the problem from a different level of the control hierarchy. These methods include interpolator-level optimization, cross-coupled control, real-time compensation, off-line pre-compensation, and integrated error-control strategies.

Interpolator-level methods modify how the controller generates reference trajectories before they are sent to servo drives in CNC Machining.

Key approaches include:

- Advanced interpolation combining 3D linear and circular segments to better approximate complex curves and surfaces in multi-axis CNC Machining.

- NURBS and spline interpolation that produces smooth trajectories with continuous velocity and acceleration, reducing excitation of machine vibration and servo lag in CNC Machining.

By generating smoother, more “machine-friendly” paths, these interpolators reduce contouring error even before feedback and compensation strategies are applied.

Traditional servo loops minimize position error independently for each axis, which is not optimal for contouring tasks in multi-axis CNC Machining. Cross-coupled control (CCC) addresses this by coordinating multiple axes to directly minimize contour error.

In CCC-based CNC Machining:

- A contour-error estimator computes the deviation normal to the reference path at each interpolation cycle.

- A cross-coupled controller then distributes corrective commands to all axes, ensuring the tool remains close to the programmed contour instead of only minimizing axis-wise errors.

This strategy has proven effective in 2D contouring and has been extended to multi-axis CNC Machining for complex parts such as impellers, blades and structural components.

Real-time compensation focuses on injecting corrective components into the command or feedback signals while CNC Machining is running. The idea is to react quickly to estimated contour or tracking errors and correct them within the same interpolation cycle.

Typical characteristics of real-time compensation in CNC Machining include:

- Real-time contour error calculation based on position feedback and reference trajectories.

- Computation of a correction vector, which is applied to the axis commands to reduce the normal error while respecting velocity and acceleration limits.

- Synergistic strategies that combine contour-error and tracking-error compensation to simultaneously improve path accuracy and servo performance in CNC Machining.

These methods are particularly useful in high-speed CNC Machining, where sharp corners and high curvature regions generate large dynamic errors if no compensation is applied.

Pre-compensation (or feedforward compensation) is executed before the actual CNC Machining operation takes place. Instead of relying solely on real-time adjustments, this approach uses models or data to “shape” the tool path and commands in advance.

Common strategies include:

- Model-based pre-compensation, using kinematic and dynamic models of the CNC Machining center to predict contour error along the programmed path and adjust commands to counteract it.

- Iterative learning control (ILC), where repeated CNC Machining of the same part allows the controller to learn systematic errors and refine the command profile each cycle.

- Data-driven methods using machine learning, which analyze historical CNC Machining data to predict where contour errors will occur and pre-compensate accordingly.

Pre-compensation methods are well suited for mass production or repeated OEM components, where the same paths are machined many times and there is enough data to justify offline optimization.

In complex five-axis CNC Machining, contour error interacts with other nonlinear trajectory errors such as tool orientation deviation and interpolation distortion. Integrated methods consider contour error, trajectory error and kinematic nonlinearity together.

These integrated compensation schemes:

- Use accurate computation of cutter-contact (CC) points and tool-center-point (TCP) trajectories for ball-end tools in five-axis CNC Machining.

- Calculate combined error metrics and apply coordinated corrections to all axes and tool orientation channels.

- Have been shown to significantly reduce both contour error and comprehensive nonlinear trajectory error in demanding multi-axis CNC Machining tasks.

Such methods are particularly valuable for high-end aerospace or medical OEM components, where the entire 3D shape must conform to strict design intent.

Reliable contour-error reduction in CNC Machining depends on accurate estimation of the actual contour deviation. Estimation techniques can be categorized into geometric, parametric and model-based approaches, each with different levels of complexity and accuracy.

Geometric methods treat the reference path as a curve in space and compute the shortest distance from the measured tool position to this curve.

In practice:

- For 2D CNC Machining, the reference contour is often line or arc segments, and contour error is obtained as the perpendicular distance from the actual point to the segment.

- For multi-axis CNC Machining, the tool-tip position is transformed into the workpiece coordinate system, and the distance to the 3D contour or surface is computed.

Geometric methods are conceptually straightforward but require precise kinematic modeling of the CNC Machining system, including rotary axes and tool length compensation.

Parametric estimation leverages the mathematical description of the path, such as spline or NURBS curves used in advanced CNC Machining.

Important aspects include:

- Using parametric equations of the contour and their derivatives to determine the closest point on the curve to the actual tool position.

- Exploiting curvature information to refine the error estimate, particularly in regions of tight curvature where contour error can accumulate.

- Integrating the error estimation routine directly into NURBS interpolators for high-speed multi-axis CNC Machining.

These methods are especially attractive in digital manufacturing workflows where the full parametric definition of the tool path is available from CAM systems.

Model-based estimation considers the physics of the CNC Machining process, combining kinematics, servo dynamics, friction and structural behavior to predict deviations.

Features of model-based estimation:

- Use of digital twins that replicate the real CNC Machining center in software, allowing virtual execution of tool paths to identify predicted contour errors.

- Inclusion of servo parameters, inertia, stiffness and damping, improving the fidelity of predicted contour error under different feed rates and cutting loads.

Data-driven estimation adds another layer:

- Learning contour error patterns from measured data, using techniques such as neural networks or hybrid models.

- Predicting error distributions under new CNC Machining conditions based on similarities to historical cases.

These methods are powerful for complex multi-axis CNC Machining cells where purely geometric or simple parametric estimations may not capture dynamic effects.

As manufacturing pushes toward higher speeds and tighter tolerances, control strategies for multi-axis CNC Machining have evolved to integrate advanced algorithms, optimization and intelligent features.

Cross-coupled control is extended in many variants to better address the multidimensional nature of contouring in CNC Machining.

Examples include:

- Orthogonal control that decomposes errors into tangential and normal components, focusing corrective action mainly on the normal component to preserve path smoothness in CNC Machining.

- Hybrid controllers that combine CCC with adaptive gain tuning, adjusting the cross-coupling strength according to local curvature and feed rate in CNC Machining.

These methods help maintain high contouring accuracy while avoiding excessive oscillations or instability at high speeds.

Model predictive control (MPC) has gained attention in the context of high-precision CNC Machining because it explicitly handles constraints and optimizes future control actions over a prediction horizon.

In multi-axis CNC Machining, MPC can:

- Predict axis behavior and contour error several interpolation steps ahead, then compute command sequences that minimize a cost function including contour error, jerk and actuator limits.

- Balance the trade-off between high feed rates and contour accuracy by respecting machine constraints while pursuing the best possible path-following performance.

Intelligent compensation methods, often leveraging machine learning, further enhance real-time control:

- Combining data-driven models with classical controllers to generate feedforward compensation in CNC Machining.

- Adjusting gains or compensation parameters on-the-fly, based on classification of motion segments (e.g., straight, gentle curve, sharp corner).

These strategies align well with Industry 4.0 initiatives and smart manufacturing practices in modern CNC Machining facilities.

Digital twin technology offers a powerful framework for integrating modeling, simulation and real-time feedback into CNC Machining operations. In contouring-error reduction, the digital twin can be used to design, test and refine control strategies before they are applied to the real machine.

A digital twin of a multi-axis CNC Machining center typically includes:

- Geometric and kinematic models describing machine structure, axes ranges and transformation chains.

- Dynamic models of servo drives, motors and mechanical transmission, capturing inertia, damping and stiffness.

- Interfaces to real-time data from the physical machine, such as encoder readings, drive currents and temperature sensors.

With this setup, engineers can:

- Run virtual CNC Machining of a tool path, measuring simulated contour errors and experimenting with different interpolation or compensation schemes.

- Implement model-based pre-compensation, where the tool path is slightly modified in simulation until predicted contour error is minimized, then apply the refined path on the shop floor.

- Combine digital twin output with on-line cross-coupled control or MPC to achieve layered contouring-error reduction in production CNC Machining.

This approach is particularly attractive for high-value OEM projects where risk and scrap must be minimized and process transparency is important.

For an OEM service provider like Shangchen, the theoretical methods described above have several concrete implications in daily CNC Machining practice.

Key benefits of adopting advanced contouring-error reduction include:

- Higher dimensional accuracy and better surface finish on complex free-form parts produced by multi-axis CNC Machining, improving acceptance rates in incoming inspections at customers.

- Capability to use higher cutting speeds and feeds while maintaining contour accuracy, thus shortening cycle times and increasing throughput in CNC Machining lines.

- Improved consistency in batch production, where repeated CNC Machining of the same part benefits from learning-based pre-compensation and optimized interpolation.

- Stronger technical credibility in front of overseas brand owners and industrial buyers, who often evaluate CNC Machining suppliers based on process capability, stability and documentation.

By integrating advanced interpolation, cross-coupled control, real-time compensation and digital twin concepts step by step, Shangchen can systematically upgrade its CNC Machining services to match international standards.

Implementing contouring-error reduction is not only a question of algorithms but also of process integration across the entire CNC Machining workflow.

Important integration points include:

- CAM to CNC: Ensure that NURBS or spline-based tool paths from CAM are preserved as much as possible, allowing advanced interpolation features in the CNC Machining controller to be fully utilized.

- Machine configuration: Calibrate kinematics of multi-axis CNC Machining centers, including pivot points and rotary offsets, so that contour-error estimation correctly represents real geometry.

- Measurement and feedback: Use probing, CMM inspection, or in-process sensors to validate contour accuracy on key features and feed this data back into compensation strategies.

- Continuous improvement: Treat contouring-error reduction as an ongoing project, periodically analyzing CNC Machining logs and inspection data to identify trends and refine parameters.

When these elements are aligned, a CNC Machining factory can steadily move from basic axis-level control to sophisticated contour-focused control that supports demanding OEM applications.

Multi-axis CNC Machining has evolved into a highly advanced manufacturing technology, but its full potential can only be realized when contouring errors are carefully controlled and reduced. Interpolator-level enhancements, cross-coupled control, real-time compensation, off-line pre-compensation, and integrated error control form a toolbox of methods that, when properly combined, can dramatically improve path accuracy and surface quality in CNC Machining. For OEM-oriented factories such as Shangchen, deploying these techniques in five-axis and multi-axis CNC Machining centers translates directly into fewer defects, higher throughput and greater customer trust in global markets. As digital twin and intelligent control technologies mature, contouring-error reduction will become even more predictive and adaptive, reinforcing CNC Machining as a core process for high-value industrial production.

Contouring error in CNC Machining is the normal-distance deviation between the actual tool path followed by the machine and the ideal reference contour programmed in the controller. It directly impacts surface finish, profile accuracy and the functional performance of parts produced by multi-axis CNC Machining.

In multi-axis CNC Machining, simultaneous motion of several linear and rotary axes makes the system highly sensitive to interpolation and dynamic errors. Reducing contouring error allows higher feed rates, smoother surfaces and more accurate geometries, which are essential for aerospace, automotive and medical components that rely on precise CNC Machining.

Common real-time methods in CNC Machining include cross-coupled control, which coordinates axes to minimize contour error, and real-time compensation strategies that modify commands based on instantaneous error estimates. More advanced systems may integrate model predictive control and synergistic tracking-plus-contouring compensation to optimize both axis following and path accuracy in high-speed CNC Machining.

Digital twin technology creates a virtual copy of a five-axis CNC Machining center that simulates kinematics, servo dynamics and even structural effects. Engineers can run tool paths inside this virtual environment to predict contour errors, apply model-based pre-compensation, and then transfer corrected paths to the physical machine, effectively improving contour accuracy before and during real CNC Machining.

A factory such as Shangchen can start by enabling advanced interpolation, calibrating kinematics, and applying cross-coupled control on key multi-axis CNC Machining centers. Over time, it can introduce real-time contour compensation, integrate feedback from measurement systems, and develop digital twin models for critical machines, thereby elevating the precision, reliability and competitiveness of its CNC Machining services for global OEM and brand customers.

content is empty!

Top On Demand 3D Printing Manufacturers and Suppliers in Germany

Top On Demand 3D Printing Manufacturers and Suppliers in Russia

Top On Demand 3D Printing Manufacturers and Suppliers in Portugal

Top On Demand 3D Printing Manufacturers and Suppliers in Spain

Top On Demand 3D Printing Manufacturers and Suppliers in France

Top CNC Turning Manufacturers and Suppliers in Czech Republic