Views: 222 Author: Amanda Publish Time: 2025-09-27 Origin: Site

Content Menu

● Introduction to 3D Printing Materials

● Common 3D Printing Materials

>> Thermoplastics: The Backbone of 3D Printing

>> Flexible and Specialty Filaments

● Industrial 3D Printing Materials

>> Metals for Strength and Precision

● Key Factors in Choosing the Right 3D Printing Material

● Applications Across Industries

>> Consumer Goods and Prototyping

● Enhancing Understanding Through Multimedia

● FAQs

>> 1. What material is best for beginners in 3D printing?

>> 2. Can metal be 3D printed for industrial parts?

>> 3. How important is thermal resistance when choosing a 3D printing material?

>> 4. Are flexible 3D printing materials durable enough for functional parts?

>> 5. Is 3D printing eco-friendly?

3D printing has revolutionized the manufacturing landscape, offering unparalleled customization, rapid prototyping, and streamlined production processes. With a variety of 3D printing materials available today, selecting the right one for your specific product can be a complex decision. This comprehensive guide explores the most popular 3D printing materials, their unique properties, common applications, and key factors to consider, enabling you to make the best choice to suit your product needs.

Additive manufacturing, commonly known as 3D printing, builds products layer by layer, allowing the creation of intricate designs and complex geometries that traditional manufacturing methods struggle to achieve. The choice of material impacts not only the product's strength and durability but also its functionality, aesthetic quality, and overall production costs. With ongoing advancements in 3D printing technology, materials now range from simple plastics to advanced composites and metals, each offering distinct advantages depending on the application.

3D printing offers an array of possibilities for industries from consumer goods and automotive to aerospace and healthcare. Understanding the properties and applications of different materials is essential for leveraging this technology successfully.

Thermoplastics are the most widely used materials in 3D printing due to their versatility, cost-effectiveness, and ease of use. These plastics melt when heated and harden upon cooling, allowing repeated reshaping without significant degradation.

- PLA (Polylactic Acid)

PLA is a biodegradable polymer derived from renewable plant materials such as corn starch or sugarcane. It is known for ease of use, low printing temperature, and minimal warping, making it perfect for educational models, concept prototypes, and decorative items. However, PLA tends to be brittle with low heat resistance, limiting its use in high-stress or elevated temperature environments.

- ABS (Acrylonitrile Butadiene Styrene)

ABS is a petroleum-based plastic renowned for its toughness, impact resistance, and moderate heat resistance. It is widely used for demanding applications like automotive parts, electronic housings, and functional prototypes. Printing ABS requires a heated print bed to avoid warping and emits fumes that need appropriate ventilation.

- PETG (Polyethylene Terephthalate Glycol)

PETG combines the printability and environmental friendliness of PLA with the durability and flexibility close to ABS. It offers excellent chemical and moisture resistance and is often used for food containers, mechanical parts, and transparent components.

- TPU (Thermoplastic Polyurethane)

TPU is a flexible, rubber-like filament that is highly elastic and abrasion-resistant. Ideal for applications like phone cases, gaskets, wearable parts, and other products requiring flexibility and impact resistance.

- Nylon

A strong, durable, and slightly flexible material, nylon offers superior wear and fatigue resistance, making it suitable for industrial parts, gears, hinges, and other functional components. Nylon can absorb moisture, so drying before printing is recommended to ensure quality.

Composite filaments combine base polymers with additives such as carbon fiber, glass fiber, or metal powders to enhance specific properties like stiffness, strength, or thermal resistance. Carbon fiber-infused nylon, for example, combines nylon's flexibility with improved rigidity and reduced weight, suited for aerospace and automotive applications.

Industries with rigorous performance demands often rely on advanced materials, including metals and resins, that can meet stringent structural, thermal, and aesthetic standards.

- Stainless Steel

Stainless steel is valued for its corrosion resistance, strength, and durability. It's widely used in tooling, medical implants, automotive parts, and aerospace components. Metal 3D printing technologies such as Direct Metal Laser Sintering (DMLS) allow production of complex geometries with excellent mechanical properties.

- Titanium

Known for an excellent strength-to-weight ratio, corrosion resistance, and biocompatibility, titanium is frequently used in aerospace, medical implants, and high-performance engineering parts. Its high cost is balanced by superior performance attributes.

- Aluminum

Aluminum's lightweight nature and excellent thermal conductivity make it ideal for automotive and aerospace parts. Metal 3D printing with aluminum powders enables rapid production of lightweight and complex components.

Used primarily in SLA (Stereolithography) and DLP (Digital Light Processing) printers, resins provide superior surface finish and high detail resolution.

- Standard Resins

These resins are excellent for creating visually appealing prototypes and models with smooth surfaces but tend to be brittle and unsuitable for functional parts.

- Tough and Durable Resins

Engineered for higher impact strength and flexibility, these resins suit functional parts and end-use applications where durability is critical.

- Biocompatible and Dental Resins

Specialized resins certified for medical and dental use facilitate the production of surgical guides, prosthetics, and orthodontic devices with safe, body-friendly properties.

Understanding these factors can simplify the process of material selection and ensure your product performs as expected:

- Mechanical Requirements

Assess tensile strength, impact resistance, flexibility, fatigue life, and hardness. Functional parts requiring endurance typically call for robust materials like ABS, Nylon, or metals.

- Thermal Resistance

Products exposed to high temperatures benefit from materials with high glass transition temperatures or melting points, such as ABS or metal alloys.

- Surface Finish and Aesthetic Needs

If visual appearance or fine detail is a priority, resins or post-processed materials provide smooth finishes while certain plastics may require sanding or coating.

- Printability and Equipment Compatibility

Some materials demand specific printers or environments (e.g., heated beds, enclosed chambers, inert atmospheres). For newcomers, PLA and PETG offer ease of use; advanced users may prefer high-performance filaments or metal powders.

- Cost and Availability

Budget considerations may limit choices. While PLA and ABS are affordable, specialty filaments, composites, and metal powders tend to be more expensive.

- Environmental Impact

Sustainability concerns have encouraged the use of biodegradable PLA and recyclable materials. Some industrial materials require recycling and responsible disposal protocols.

PLA and PETG are popular in producing consumer products, household items, and colorful prototypes thanks to their ease of printing and decent performance.

Manufacturers in automotive and aerospace industries rely heavily on ABS, Nylon, carbon fiber composites, aluminum, and titanium for producing a wide range of components, from fixtures to critical structural parts that demand high strength and temperature resistance.

Titanium and biocompatible resins have transformed medical device manufacturing. 3D printing allows for personalized implants, prosthetics, surgical models, and dental aligners tailored precisely to patient anatomy.

Educational institutions widely use PLA and ABS to teach design, engineering, and manufacturing principles, often coupled with open-source 3D printers.

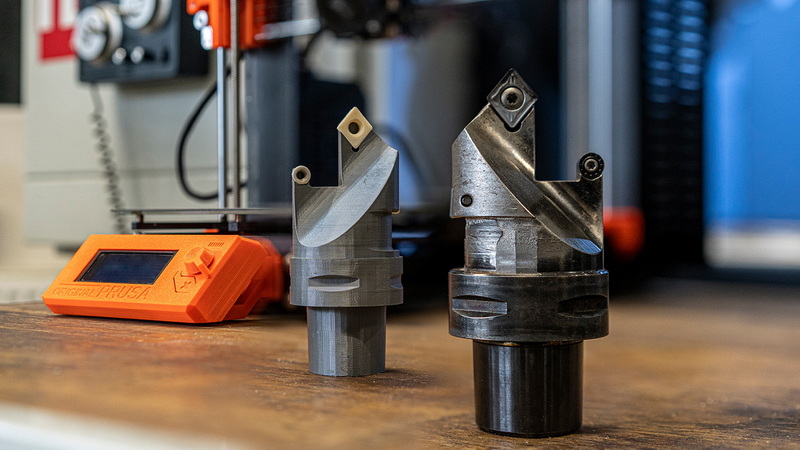

Visual aids such as videos of printing processes for specific materials can demonstrate their behavior during printing, surface finish, and possible post-processing techniques. For instance, a video showcasing the flexibility of TPU or the layer-by-layer metal sintering process illustrates real-world applications vividly. Photo comparisons of prints made from PLA, ABS, and composite filaments help users discern differences in texture and detail achievable with each material.

Selecting the right 3D printing material is pivotal to the success of your product. The choice depends on the part's mechanical, thermal, and aesthetic requirements, along with cost, printer capability, and environmental considerations. Whether you prioritize rapid prototyping with easy-to-use PLA, durable parts with Nylon and composites, or high-strength metal components for aerospace, understanding each material's properties ensures optimized performance and satisfaction. As 3D printing technology continues to advance, material innovation will broaden your possibilities, enabling customized production solutions tailored exactly to your needs.

PLA is the best option for beginners due to its low printing temperature, minimal warping, and ease of use, making it ideal for educational purposes and simple prototypes.

Yes, metals such as stainless steel, titanium, and aluminum are extensively used in industrial 3D printing for manufacturing durable, complex, and high-performance components using technologies like DMLS and SLM.

Thermal resistance is crucial if the component will be exposed to high temperatures, such as engine parts or appliances. Materials like ABS, Nylon, or metals perform better in such environments compared to PLA.

Flexible materials like TPU offer good elasticity and impact resistance, making them suitable for applications requiring flexibility, such as gaskets, phone cases, or wearable devices. However, they may not match the strength of rigid plastics or metals for load-bearing parts.

3D printing can be eco-friendly, especially when using biodegradable materials such as PLA or recycling plastic waste. However, some resins and metals require proper recycling and responsible disposal to minimize environmental impact.

content is empty!

What Are The Benefits of Rapid Prototyping to The Manufacturer?

What Are The Advantages of Using Pytorch for Rapid Prototyping?

What Are The Advantages and Disadvantages of Rapid Prototyping?

Top On Demand 3D Printing Manufacturers and Suppliers in Netherlands

Top On Demand 3D Printing Manufacturers and Suppliers in Norway

Top On Demand 3D Printing Manufacturers and Suppliers in Turkey

Top On Demand 3D Printing Manufacturers and Suppliers in Poland

Top On Demand 3D Printing Manufacturers and Suppliers in Vietnam