Views: 222 Author: Amanda Publish Time: 2025-10-15 Origin: Site

Content Menu

● The Role of 3D Print Prototypes in Consumer Electronics

>> Key Advantages in Product Development

● How 3D Print Prototypes Transform Consumer Electronics Innovation

>> Creating Complex, Lightweight Components

>> Electronics Enclosures and Custom Accessories

>> Enhancing Connectivity and Thermal Management

● Integration of 3D Print Prototypes with Advanced Materials and Electronics

>> Multi-Material and Functional Prototyping

>> Embedded Sensors and Smart Prototypes

>> Sustainability and Eco-Friendly Manufacturing

● 3D Print Prototypes and OEM Rapid Manufacturing Services

>> Advantages of OEM Collaboration

● Future Directions of 3D Print Prototyping in Consumer Electronics

● FAQ

>> 1. What is a 3D print prototype in consumer electronics?

>> 2. How does 3D print prototyping reduce product development time?

>> 3. Can 3D print prototypes be used for final production parts?

>> 4. What are the benefits of working with an OEM for 3D print prototype services?

>> 5. How does 3D print prototyping support customization in consumer electronics?

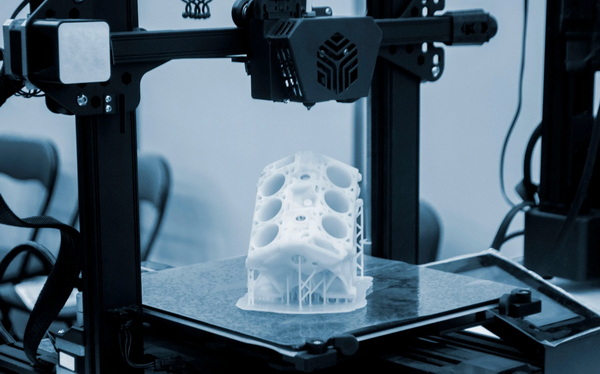

In today's fast-paced and highly competitive consumer electronics market, innovation speed and design flexibility are critical to success. One of the most transformative technologies powering this evolution is 3D print prototyping. By enabling rapid creation of accurate physical models, 3D print prototypes have revolutionized product development, allowing companies to test, refine, and launch new devices faster and at lower cost than ever before.

This article explores the vital role of 3D print prototypes in consumer electronics, highlighting key advantages, real-world applications, and future opportunities. It also outlines how working with expert OEM rapid manufacturing partners, like Shangchen, can accelerate innovation and production in this dynamic sector. Throughout, the focus remains on how 3D print prototypes enhance design, reduce risks, and speed time to market while supporting customization and sustainability.

3D print prototypes serve as essential tools in the ideation and development phases of consumer electronics. Traditionally, creating physical models involved slow, expensive processes, delaying critical feedback loops. In contrast, 3D print prototyping compresses these cycles, enabling multiple rapid iterations directly from digital CAD models. This capability improves design accuracy, accelerates functional testing, and helps assure the final product meets user expectations.

- Accelerated Product Cycles: Rapid prototyping reduces development time from months or years to weeks or days, critical in markets where product life spans have shrunk to months.

- Design Freedom: 3D printing supports complex geometries and lightweight structures impossible with conventional methods, enabling advanced features and improved performance.

- Cost Efficiency: Eliminating tooling costs and enabling quick adjustments lowers overall prototyping expenses, especially valuable for small batches and concept validation.

- Customization: Consumer electronics increasingly demand personalized features and accessories, which 3D print prototypes can rapidly develop and test.

- Risk Mitigation: Early detection of design faults through physical models avoids costly reworks or recalls post-production.

Leading brands such as Apple, Samsung, Huawei, and Xiaomi employ 3D print prototyping across wearables, smartphones, and smart home devices, underscoring its strategic importance.[1][2]

In consumer electronics, where usability, ergonomics, and aesthetics are paramount, 3D print prototypes allow designers and engineers to quickly produce and evaluate multiple design versions. For example, a smartphone hinge mechanism or smartwatch housing can be prototyped and stress-tested in days, not months. This increased velocity leads to better-optimized designs and faster introduction of innovative features.

3D printing facilitates fabrication of intricate shapes and lattice structures that reduce weight without sacrificing strength—a major advantage for portable devices like earbuds and fitness trackers. The technology also enables integration of internal sensor mounts and cable channels that improve assembly efficiency.

Enclosures protect delicate internal components while defining product aesthetics and often require rapid prototyping for fit, form, and finish validation. Additionally, 3D print prototypes support production of customized protective cases and aftermarket accessories, catering to growing consumer demands for personalization.

Innovations such as 3D printed antennas optimize signal strength and reduce interference for 5G devices and IoT sensors, often featuring complex geometries unachievable with traditional methods. Moreover, bio-inspired cooling structures printed with 3D technologies enhance thermal management in compact electronics like gaming consoles.[2]

As 3D print technology evolves, the incorporation of advanced materials and embedded electronics is pushing the boundaries of prototype capabilities and applications.

The ability to print with multiple materials simultaneously—including conductive, flexible, and rigid substances—enables prototypes that closely mimic final product functionality. This is particularly beneficial in consumer electronics for prototypes that integrate circuitry, sensors, or flexible parts, reducing the gap between design and functional testing.

3D printing now allows embedding sensors and electronic components directly within prototypes. This integration offers more realistic performance evaluation and supports the development of smart devices like fitness trackers, IoT hubs, and connected home appliances with functional prototypes.

The shift toward sustainability sees 3D printing as a key enabler by reducing material waste and energy consumption compared to traditional subtractive manufacturing. Using recyclable or biodegradable printing materials for prototypes aligns with consumer electronics brands' environmental goals and regulatory requirements, demonstrating responsible innovation.[3][4]

For consumer electronics brands, partnering with experienced OEM suppliers offering rapid prototyping and manufacturing services ensures smooth product development and high-quality output. Companies like Shangchen provide comprehensive capabilities, including:

- High-precision 3D printing for prototypes and functional parts

- CNC machining, sheet metal fabrication, and 3D printing integration

- Fast turnaround and scalability from prototype to batch production

- Expertise in materials suited to electronics such as durable polymers and metals

- Support for complex assemblies and finishing options

Such OEM collaborations enable brands to focus on innovation while leveraging supply chain efficiency, cost advantages, and technical expertise available in manufacturing hubs like China.[5][6][7]

Working with OEMs experienced in rapid manufacturing delivers benefits beyond technology, including:

- Access to advanced design-for-manufacture feedback early in development

- Consolidated services that shorten procurement and production timelines

- Quality control systems tuned for both prototypes and mass production

- Flexibility to scale production volumes rapidly as product demand grows

These synergies are pivotal in consumer electronics, where nimbleness and precision define market success.[8]

The coming years promise exciting advances, including:

- Embedded Electronics: Technologies fusing 3D printed circuits with mechanical parts will streamline manufacturing and reduce assembly complexity.

- Multi-material Printing: Simultaneous printing of metals, polymers, and conductive materials to produce fully functional, compact prototypes.

- Sustainability: 3D print prototypes reduce waste by minimizing raw material use and enabling recyclable or biodegradable materials.

- Repair and Aftermarket Parts: 3D printing facilitates economical small-batch production of replacement parts, supporting right-to-repair movements and enhancing customer satisfaction.[9][3]

These trends suggest that 3D print prototypes will become even more integral to how consumer electronics are designed, tested, and produced in coming years.

3D print prototypes stand at the heart of consumer electronics innovation, empowering brands to accelerate product development, improve design complexity, and deliver personalized solutions efficiently. By reducing costs and time-to-market, 3D print prototyping transforms traditional manufacturing boundaries. Collaborations with capable OEM partners ensure these advantages translate into market-ready products that delight consumers globally. As the technology evolves, 3D print prototypes will integrate more deeply with electronics manufacturing, fostering a smarter, faster, and more sustainable future for consumer devices.

A 3D print prototype is a physical model of a consumer electronic device or component created using 3D printing technology. It allows for testing design, fit, function, and aesthetics before mass production.[10][1]

By enabling fast iteration without the need for expensive tooling, 3D print prototypes shorten development cycles, allowing multiple design revisions and testing in days or weeks instead of months or years.[1][10]

Currently, 3D print prototypes are mainly for concept validation and small batch production. However, advances in materials and embedded electronics could soon allow direct 3D printing of end-use parts.[2][3]

OEMs provide comprehensive manufacturing expertise, fast turnaround, quality assurance, and scalability from prototypes to large-scale production, helping brands efficiently bring products to market.[6][8]

3D printing allows rapid creation of personalized parts and accessories, enabling brands to meet diverse consumer preferences and market demands quickly and cost-effectively.[1][2]

[1](https://www.3ds.com/make/solutions/industries/3d-printing-consumer-electronics)

[2](https://zone3dplus.com/how-3d-printing-is-powering-the-next-generation-of-consumer-electronics/)

[3](https://www.the-mtc.org/insights/three-dimensional-3d-printing-electronics-additive-manufacturing-components)

[4](https://www.leonhardtmfg.com/blog/top-5-benefits-of-3d-printing-in-manufacturing/)

[5](https://www.accio.com/supplier/rapid-prototyping-manufacturers-china)

[6](https://senyorapid.com/top-10-rapid-prototyping-manufacturers-in-china/)

[7](https://www.in3dtec.com)

[8](https://anebonmetal.com/danish/why-work-with-an-oem-for-3d-printed-products/)

[9](https://replique.io/en/2025/09/02/3d-printing-helps-oems-meet-right-to-repair-regulations-in-2025/)

[10](https://fathommfg.com/3d-printing-prototypes)

content is empty!

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes

Best Practices from Leading Vacuum Mold Casting Companies Worldwide

Top Vacuum Mold Casting Providers for Custom Batch Production

How to Choose the Right Vacuum Mold Casting Service for Your Product