Views: 222 Author: Amanda Publish Time: 2025-10-10 Origin: Site

Content Menu

● Introduction to 3D Print Prototype and Sheet Metal Fabrication

>> What is 3D Print Prototype?

>> What is Sheet Metal Fabrication?

● Advantages of 3D Print Prototype

>> Complex Geometry Capabilities

>> Cost-Effective for Low Volume

>> Material Variety for Prototyping

● Advantages of Sheet Metal Fabrication

>> Wide Range of Finishing Options

>> Established Standards and Compliance

>> Versatility in Post-Processing

● Challenges in 3D Print Prototype vs Sheet Metal Fabrication

>> Limitations of 3D Print Prototype

>> Limitations of Sheet Metal Fabrication

● Practical Applications of 3D Print Prototype

● Practical Applications of Sheet Metal Fabrication

● Synergies: Combining 3D Print Prototype and Sheet Metal Fabrication

● Environmental Considerations and Sustainability

● Industry Trends and Future Outlook

● FAQ

>> 2. Can 3D printed prototypes be used for functional testing?

>> 3. Is it possible to transition from a 3D Print Prototype to sheet metal production smoothly?

>> 4. How do costs compare between 3D printing and sheet metal fabrication?

>> 5. What post-processing is needed for 3D Print Prototypes?

In the fast-evolving world of manufacturing, choosing the right prototyping and production method is critical to achieving project success. Among the various techniques available, 3D print prototype and Sheet Metal Fabrication stand out as two of the most popular and versatile options. This article delves into their distinct advantages, challenges, and practical applications from the perspective of a manufacturing factory like Shangchen. Whether you are a brand owner, wholesaler, or producer, understanding these methods will help you make informed decisions tailored to your product needs.

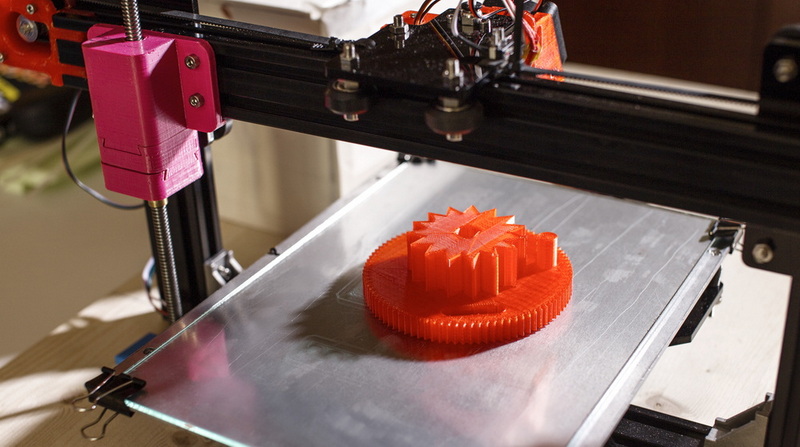

3D Print Prototype refers to the process of creating physical models directly from digital designs using additive manufacturing technology. Layers of material—typically plastics, resins, or metals—are deposited successively to build up the prototype. This technique is invaluable for quick concept testing, design validation, and iterative development. By using 3D printing, manufacturers can rapidly turn ideas into tangible objects, enabling faster product development cycles.

Sheet Metal Fabrication is a traditional subtractive and formative process where flat sheets of metal are cut, bent, and assembled to create components. This method allows for production of durable parts suitable for structural and functional applications, often mass-produced for industrial use. Processes such as laser cutting, stamping, bending, and welding are common in sheet metal fabrication, providing sturdy and long-lasting parts.

One of the most significant benefits of producing a 3D Print Prototype is the speed. Unlike traditional methods, additive manufacturing does not require expensive tooling or molds, enabling rapid turnaround times. This flexibility is perfect for quick design changes or multiple iterations during product development. Often, a 3D printed prototype can be ready within hours or days, dramatically shortening development timelines.

3D printing excels at producing complex geometries that are difficult or impossible with sheet metal. Intricate internal structures, lightweight lattices, organic shapes, and internal channels for fluid or air flow can be fabricated with precision without increasing cost significantly. This capability allows designers to experiment with innovative forms and optimize functionality without additional manufacturing complexity.

For a prototype or small batch of parts, 3D printing is cost-effective as it requires less setup and can leverage digital files directly. This reduces lead times and minimizes waste. Since there are no molds or dies to produce, costs do not escalate with each design change. Additive manufacturing can be particularly advantageous in low-to-mid volume production or highly customized parts.

Advancements in additive technologies support a variety of materials including engineering-grade plastics, metals like titanium, stainless steel, aluminum, and flexible resins. These materials help simulate the mechanical properties of final production parts to a certain extent, providing a better understanding of product behavior under real-world conditions.

3D printing introduces unparalleled design freedom compared to traditional manufacturing. Features like undercuts, hollow sections, and complex interlocking parts can be manufactured as a single piece without assembly. This freedom often enables reducing part counts in assemblies, leading to simpler, more efficient products.

Sheet metal parts usually have superior mechanical properties, making them suitable for applications demanding strength, impact resistance, or heat tolerance. Metals such as steel, aluminum, and copper alloys offer excellent durability, load-bearing capacity, and long-term stability under harsh conditions, which 3D printed parts sometimes cannot match.

While initially costlier due to tooling and setup expenses, sheet metal fabrication becomes economically advantageous for producing hundreds or thousands of parts. With established tooling and streamlined processes, the per-unit cost of sheet metal parts drops significantly compared to 3D printing, making it ideal for mass production.

Sheet metal components can be powder-coated, anodized, painted, or electroplated to enhance aesthetics, corrosion resistance, and durability. These finishing options make sheet metal parts suitable for consumer-facing products, industrial machinery, and outdoor applications where appearance and protection are critical.

Industries like automotive, aerospace, electronics, and medical devices require components to meet strict standards and regulations around safety, quality, and reliability. Sheet metal fabrication processes are mature and often certified to comply with these rigorous specifications, ensuring consistency and traceability.

Post-processing techniques such as welding, riveting, brazing, or adhesive bonding allow sheet metal parts to be assembled into complex structures. Additionally, secondary machining or punching operations can add holes, slots, or threads to enhance functionality.

Despite its benefits, 3D printing faces some challenges:

- Surface Finish and Accuracy: The layered nature of 3D printing can lead to rough surfaces, requiring sanding or polishing for a smooth finish comparable to sheet metal.

- Size Constraints: Large parts can be difficult or costly to print due to printer size limitations and long build times.

- Mechanical Properties: While materials have improved, many 3D printed parts still fall short of the strength and durability provided by fabricated metals.

- Material Costs: Specialty materials for metal 3D printing or high-performance resins may be expensive compared to bulk metal sheets.

- Design Complexity: Sheet metal fabrication is less suited for parts with highly complex or intricate geometries, particularly internal features.

- High Initial Costs: The requirement for tooling, dies, and setup increases upfront costs, making prototyping or small runs less affordable.

- Design Changes Impact Cost and Time: Any design revisions usually mean retooling and recalibration, which extend lead times and raise expenses.

- Weight and Material Waste: Traditional subtractive cutting processes can generate waste, and metal parts tend to be heavier than optimized 3D printed alternatives.

The advantages of 3D printing make it an essential technology for:

- Ergonomic and Aesthetic Prototypes: Creating handles, grips, or wearable devices with customized curves and shapes.

- Rapid Design Iteration: Testing multiple design versions rapidly without incurring costly tooling.

- Medical Models and Customized Implants: Producing patient-specific prosthetics and surgical guides.

- Functional Prototypes with Moving Parts: Building assemblies with integrated hinges or flexible joints.

- Low-Volume Production: Limited runs of specialized components such as aerospace or automotive replacement parts where quick turnaround is vital.

Sheet metal fabrication is ideal for:

- Structural Components: Chassis, brackets, frames, and enclosures requiring strength and rigidity.

- Mass-Produced Consumer Goods: Appliance panels, computer casings, and lighting fixtures.

- Automotive and Aerospace Parts: Durable, lightweight components built to standard specifications.

- Industrial Equipment: Machinery housings, HVAC systems, and electrical cabinets.

- Corrosion-Resistant and Finished Products: Outdoor and marine applications requiring coated or treated metal parts for longevity.

Many manufacturers, including Shangchen, successfully integrate both technologies to optimize product development. Typically, the process flows from:

1. Prototype Development with 3D Printing: Quickly verifying form, fit, and function using rapid prototypes.

2. Design Refinement: Adjusting designs based on prototype feedback.

3. Transition to Sheet Metal Fabrication: Engineering final parts for strength, manufacturability, and large-scale production.

4. Final Assembly and Finishing: Incorporating sheet metal parts with other components to build the final product.

This phased approach maximizes the advantages of both methods, reducing risk and cost while accelerating product launch.

Modern manufacturing increasingly considers environmental impact. 3D printing generally produces less waste material since it is additive rather than subtractive. However, energy consumption of some 3D printers and disposal of non-recyclable resins can be limiting factors.

Sheet metal fabrication, while often producing scrap, benefits from established recycling loops for metal waste. Selecting processes and materials with sustainability in mind helps brands meet green manufacturing goals.

- Advances in 3D Printing Materials: New metal powders, composites, and bio-compatible plastics are expanding application fields.

- Hybrid Manufacturing: Combining additive and subtractive methods in a single workflow is gaining momentum.

- Automation and AI Integration: Smart manufacturing technologies improve process control and quality assurance for both 3D printed and sheet metal parts.

- Customization at Scale: Rapid prototyping combined with scalable sheet metal production addresses growing market demand for personalized products.

Choosing between 3D Print Prototype and Sheet Metal Fabrication depends heavily on your product's design complexity, production volume, and functional requirements. 3D printing offers unparalleled flexibility and speed for early-stage prototypes and low-volume runs, while sheet metal fabrication excels in durability, scalability, and cost efficiency for mass production.

By leveraging the strengths of both processes, manufacturers can optimize product development, reduce time-to-market, and ensure high-quality end products. At Shangchen, we are committed to delivering comprehensive OEM services that incorporate these advanced manufacturing technologies to meet the diverse needs of international clients.

Consider your production volume, design complexity, material requirements, cost constraints, and the functional purpose of the prototype or part. 3D printing is ideal for rapid iteration and complex shapes, while sheet metal suits large-scale, durable parts.

Yes, depending on the material, many 3D printed prototypes can undergo functional testing, especially in plastics and some metals. However, their mechanical properties might differ from final sheet metal parts.

Yes. Initial prototypes can be designed with 3D printing to validate fits and functions, then re-engineered for sheet metal fabrication for final production.

3D printing has lower upfront costs and is cost-effective for low quantities but unit costs increase with volume. Sheet metal fabrication has higher setup costs but becomes cheaper as production scales up.

Post-processing often includes sanding, polishing, painting, or coating to improve surface finish, along with potential heat treatments to enhance material properties.

content is empty!

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes

Best Practices from Leading Vacuum Mold Casting Companies Worldwide

Top Vacuum Mold Casting Providers for Custom Batch Production

How to Choose the Right Vacuum Mold Casting Service for Your Product