Views: 222 Author: Amanda Publish Time: 2025-10-10 Origin: Site

Content Menu

● Introduction to 3D Print Prototypes and CNC Machining

● How 3D Print Prototypes Work

>> Popular 3D Printing Technologies

>> Advantages of 3D Print Prototypes

>> Limitations of 3D Print Prototypes

>> Advantages of CNC Machining

>> Limitations of CNC Machining

● Detailed Comparison: When to Choose Each Method

>> Project Speed and Flexibility

>> Design Complexity and Functionality

● Roles of 3D Print Prototypes in Modern Manufacturing

● CNC Machining in the Prototyping Lifecycle

● Integrating 3D Print Prototypes and CNC Machining

● Frequently Asked Questions (FAQ)

>> 1. What materials can I use with 3D print prototypes?

>> 2. Can CNC machining create hollow or complex internal structures?

>> 3. How long does it take to produce a 3D print prototype compared to CNC machining?

>> 4. Is post-processing necessary for 3D printed prototypes?

>> 5. Can I use 3D print prototypes for functional testing?

In the world of rapid prototyping and manufacturing, choosing the right method to bring your design to life is crucial. Two of the most popular options available today are 3D print prototypes and CNC machining. Each offers unique advantages depending on your project requirements, timeline, budget, and materials. This article delves deep into the differences between these methods, exploring their strengths and weaknesses to help you decide which is best for your project.

Rapid prototyping services have evolved significantly, making it easier than ever to transition from concept to physical product. Among the key technologies, 3D printing and CNC machining stand out:

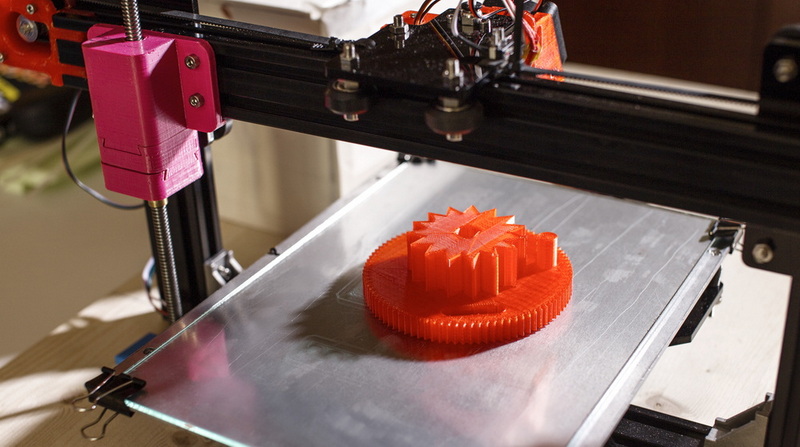

- 3D Print Prototype refers to creating a physical model through additive manufacturing, where materials are laid down layer by layer.

- CNC Machining is a subtractive manufacturing process that removes material from a solid block using computerized controls.

These technologies serve a broad spectrum of industries, including automotive, aerospace, consumer electronics, and medical devices, where accurate and timely prototypes are essential. Both methods support Original Equipment Manufacturer (OEM) services for brands, wholesalers, and producers globally.

3D printing creates prototypes by building objects layer by layer based on a digital 3D model. This additive approach contrasts sharply with traditional machining or molding techniques and offers remarkable advantages in flexibility and speed.

- Fused Deposition Modeling (FDM): Melts and extrudes thermoplastic filaments such as PLA or ABS to build the part. FDM is widely used for its affordability and speed.

- Stereolithography (SLA): Utilizes ultraviolet (UV) lasers to cure photopolymer resin, resulting in high resolution and smooth surface finishes.

- Selective Laser Sintering (SLS): Uses a laser to fuse powdered nylon or other materials into solid objects. SLS parts are noted for their strength and durability compared with other 3D printed materials.

- Speed: Many designs can be printed in a few hours, allowing for rapid iteration and faster product development cycles.

- Complexity: The additive process enables creation of geometries impossible or very difficult to achieve with traditional manufacturing, such as hollow structures, lattice frameworks, or internal channels.

- Cost: Low tooling costs and minimal setup make 3D printing ideal for prototyping and small batch production.

- Material Use: With less waste generated during production, 3D printing is an environmentally friendlier option for many projects.

- Customization: Design changes can be implemented quickly and prototypes reprinted without costly tooling adjustments.

- Material Strength: Most common 3D printed materials cannot match the mechanical properties of machined metals or some plastics.

- Surface Quality: Depending on the technology, surfaces may have visible layers, requiring additional finishing for cosmetic or functional needs.

- Size Constraints: The build size is limited by the printer's build volume, which may restrict the size of prototypes.

- Material Variety: While improving, the variety of usable materials in 3D printing is more limited than CNC machining options.

CNC machining transforms a solid raw material block into a finished prototype through a subtractive process, involving the precise removal of material using computer-controlled cutting tools. This technique remains a cornerstone for producing functional parts with tight tolerances.

- Milling: Uses rotary cutters to systematically remove material from a static block, maneuvering along multiple axes (commonly 3 to 5). Ideal for producing complex external shapes.

- Turning: Machines rotate the workpiece while a fixed cutting tool shapes the part, often employed in producing cylindrical or symmetrical components.

- Drilling: Precisely cuts holes of varying diameters and depths as part of the machining process.

- Material Versatility: Compatible with a wide array of materials—metals such as aluminum, stainless steel, titanium, as well as engineering-grade plastics like PEEK and Delrin.

- Precision and Repeatability: CNC machines achieve high dimensional accuracy, often within microns, critical for functional prototypes and tooling.

- Strength and Durability: Machined parts maintain the base material's strength, essential for load-bearing and functional testing.

- Surface Finish: Can produce smooth surfaces and sharp details often requiring minimal post-processing.

- Production Scale: Suitable for one-off prototypes as well as low to medium volume manufacturing runs.

- Cost: Higher startup costs and longer lead times, especially for complex geometries that necessitate multiple setups or custom tooling.

- Waste: Material is removed and discarded, increasing raw material costs and environmental impact.

- Design Constraints: Internal features or extremely complex shapes may be impossible or expensive to machine without assembly from multiple parts.

- Time: Longer production times for intricate designs compared to some 3D printing methods.

If your project timeline demands rapid iterations and swift turnaround, 3D print prototypes excel. Multiple versions can be produced quickly for form and fit testing, enabling agile product development. CNC machining generally requires more setup time and specialized programming.

When your design features complex internal cavities or lightweight lattice structures, 3D printing offers unmatched freedom. Conversely, if your prototype must endure high mechanical stress or thermal loads during functional testing, CNC machining's use of dense, high-grade materials offers superior performance.

For small quantities or one-off prototypes, 3D printing frequently reduces costs significantly by eliminating tooling fees. For batches or prototypes demanding metals or tougher plastics, CNC's higher per-part cost may be justified by the increased durability.

Your choice may be dictated by the available materials. While 3D printing materials continue to advance, CNC machining supports a broader spectrum including metals essential for many industrial applications.

3D printed prototypes have transformed product development by enabling:

- Concept Validation: Quickly materializing ideas to test ergonomics and usability.

- Fit Testing: Ensuring parts will assemble correctly before final production.

- Marketing Models: Producing visual prototypes for presentations or trade shows.

- Functional Simulation: Printing in advanced materials capable of short-term functional tests.

- Customization: Tailoring parts to individual or niche requirements on-demand.

Rapid prototyping accelerates innovation cycles and minimizes costly redesigns down the line. Partnering with experienced providers guarantees design optimization and material advice, ensuring the final prototype meets your exact needs.

Despite the rise of additive manufacturing, CNC machining retains a vital role where:

- Mechanical Performance is Key: Prototypes must withstand real-world conditions.

- Tolerances and Precision are Critical: Parts interfacing with others require exact dimensions.

- Material Properties Cannot Be Compromised: Metal or engineering plastic parts not achievable through 3D printing are essential.

- Pre-Production or Bridge Manufacturing: Small production volumes before transitioning to molding or mass production.

Experienced CNC shops help optimize designs for manufacturability and cost-efficiency, reducing iteration loops and facilitating smooth scale-up.

Many modern product development cycles combine both processes to balance cost, speed, and quality effectively:

1. Initial Concept Phase: Employ 3D print prototypes to validate design intent rapidly.

2. Prototype Refinement: Use 3D printed iterations to identify problem areas in fit or ergonomics.

3. Functional Testing Phase: Shift to CNC machined parts to evaluate end-use performance and mechanical strength.

4. Pre-Production: Refine CNC parts as production-intent prototypes.

5. Manufacturing Transition: Apply learnings to injection molding or mass manufacturing.

This hybrid approach maximizes each method's advantages and minimizes their drawbacks.

Choosing between a 3D print prototype and CNC machining depends largely on your project's specific needs. If speed, design complexity, and cost-efficiency guide your priorities, 3D printing is usually the best choice. However, if you require high strength, precise tolerances, or metal parts, CNC machining is the superior method.

By understanding the strengths and limitations of each technology, you can optimize your prototype production, reduce development time, and achieve better product outcomes. Selecting the right process early establishes a solid foundation for your product's success.

3D print prototypes are primarily made from various plastics and resins, including PLA, ABS, nylon, and photopolymer resins. Some advanced 3D printers can work with metal powders, but this is usually more costly and limited to specialized machines.

Due to the subtractive nature, CNC machining has limitations when it comes to hollow or highly complex internal geometries. Many internal features require multiple parts and assemblies or alternative manufacturing methods.

3D printed prototypes generally take less time, often from a few hours up to one or two days. CNC machining may require several days, particularly for intricate parts and secondary operations.

Yes, many 3D printed parts require post-processing such as sanding, polishing, or curing to improve surface finish and mechanical properties, especially when using SLA or resin prints.

Depending on the material and the printing technology, some 3D printed parts are suitable for limited functional tests, particularly in plastics. However, they usually don't match the strength or durability of CNC machined parts for high-stress applications.

content is empty!

Top 5 Axis CNC Machining Manufacturers and Suppliers in Norway

Top 5 Axis CNC Machining Manufacturers and Suppliers in Finland

Top 5 Axis CNC Machining Manufacturers and Suppliers in Greece

Top 5 Axis CNC Machining Manufacturers and Suppliers in Sweden

Top 5 Axis CNC Machining Manufacturers and Suppliers in Turkey

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes