Views: 222 Author: Amanda Publish Time: 2025-09-25 Origin: Site

Content Menu

● Detailed Vacuum Casting Process

● Common Vacuum Casting Issues and Their Troubleshooting

>> Incomplete or Partial Fillings

>> Surface Defects and Sticky Parts

● Optimizing the Vacuum Casting Process

>> Control Temperature Precisely

>> Resin Handling Best Practices

>> Use Quality Materials and Mold Release Methods

>> Workflow and Quality Controls

● Frequently Asked Questions (FAQs)

>> 1. How can I detect leaks in my vacuum chamber?

>> 2. What is the ideal resin temperature before casting?

>> 3. How many parts can I produce per silicone mold?

>> 4. What causes air bubbles in cast parts?

>> 5. Can vacuum casting be used for mass production?

Vacuum casting is a widely used manufacturing technique for producing detailed, high-quality plastic parts with relatively low tooling costs and fast turnaround times. It is especially popular for rapid prototyping, custom part production, and short-run manufacturing in industries such as automotive, electronics, consumer goods, and more. While the process offers many advantages, it can also encounter various technical challenges that impact part quality and production efficiency.

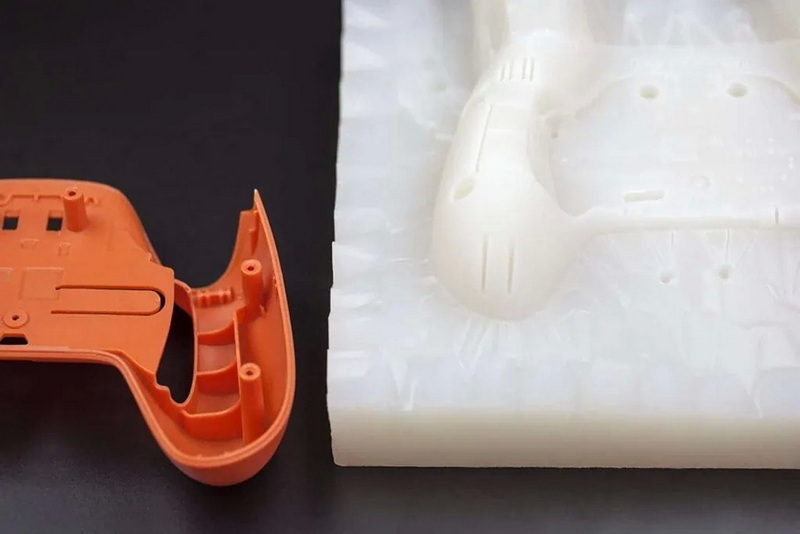

Vacuum casting is a process where liquid polyurethane or other casting resin is poured into a silicone mold under vacuum conditions. This vacuum environment eliminates trapped air, allowing the resin to fill intricate mold cavities and create a high-fidelity replica of the master model. The master model is typically created by CNC machining or 3D printing and then used to form a flexible silicone mold that can produce multiple copies with fine surface details.

The process is cost-effective for low to medium volume production, producing anywhere from 10 to 50 parts per mold before the silicone mold degrades. It is an ideal method for prototyping and producing parts with complex shapes, smooth finishes, and excellent dimensional accuracy.

The first critical step is creating a high-precision master model that will define the shape and detail of all subsequent parts. It can be made through CNC machining, 3D printing, or additive manufacturing. The master model's design should consider uniform wall thickness, draft angles, and proper venting features to facilitate smooth casting.

The master model is fixed inside a casting box, and liquid silicone rubber is poured around it under vacuum to prevent bubble entrapment. The silicone is then cured, typically at 40°C for 8–16 hours depending on size. After curing, the mold is cut open to remove the master and form a cavity for casting.

Polyurethane resin is prepared by heating to approximately 40°C and mixing with hardeners and pigments as needed. The resin is degassed under vacuum for about a minute to remove dissolved gases. Then it is gently poured into the mold placed inside a vacuum chamber. Vacuum removes air from the silicone mold cavity and the resin, eliminating bubbles and voids.

The resin-filled mold is cured in an oven—typically at 70°C—for about one hour, allowing the material to harden and take the mold's shape.

After curing, the cast is carefully removed from the mold and any excess material is trimmed. Additional finishing like sanding, painting, or polishing can be performed to meet surface quality requirements. This entire casting cycle can generally be repeated 20 to 50 times depending on mold durability.

Problem: Parts are not fully formed or have missing sections.

Causes and Solutions:

- Vacuum leaks or insufficient vacuum pressure: Inspect and maintain the vacuum chamber seals and hoses. Replace worn components and ensure the vacuum pump functions properly.

- Cold or thick resin: Preheat resin to recommended temperatures (~40°C) for optimal flow.

- Mold design flaws: Avoid overly thin sections or poor venting that impede resin flow. Re-design molds with consistent wall thickness and air vents.

- Pouring technique: Pour resin slowly to avoid trapping air or turbulence.

Problem: Visible or internal bubbles weaken parts and degrade surface finish.

Causes and Solutions:

- Incomplete degassing of resin mixture: Increase vacuum degassing time to fully remove trapped gases.

- Air trapped inside the silicone mold: Use vacuum casting techniques correctly, and apply mold release agents to improve resin flow.

- High pour speed: Pour resin carefully to reduce turbulence.

- Leaky vacuum system: Regularly check for leaks and maintain equipment.

Problem: Silicone molds deteriorate quickly, causing dimensional inaccuracies.

Causes and Solutions:

- Excessive heat or chemical exposure: Cure molds at proper temperatures and avoid harsh chemicals.

- Rough handling or improper storage: Handle molds gently and store in clean, controlled environments.

- Repeated casting cycles beyond expected lifespan: Plan mold replacement after 20-50 cycles depending on material and mold quality.

- Mold contamination: Clean molds routinely with mild solvents.

Problem: Parts show rough surfaces, stick to molds, or have release issues.

Causes and Solutions:

- Insufficient or uneven mold release application: Apply release agents evenly and allow proper drying time.

- Expired or poor-quality materials: Use fresh silicone and resin materials from reputable suppliers.

- Residual contamination: Clean molds and casting areas thoroughly before use.

- Incorrect curing cycles: Follow recommended times and temperatures strictly.

Routine inspection of vacuum chambers, hoses, and seals is critical. Employ vacuum gauges and soap tests to quickly detect and fix leaks. Reliable vacuum ensures bubble-free casting.

Temperature impacts resin viscosity and curing. Preheat resins and molds consistently to manufacturer-recommended setpoints—typically 40°C for resin and 40–70°C for mold curing. Avoid temperatures that degrade silicone molds.

Mix resin thoroughly but gently. Degas resin for 50–60 seconds or more to fully evacuate trapped air. Pour resin slowly in a laminar flow to minimize turbulence.

Invest in high-quality, durable silicone mold materials to extend mold life. Use effective mold release agents uniformly to ensure easy demolding and surface quality.

Design molds with uniform wall thickness, draft angles for release, and proper venting systems. Consult tooling experts to enhance mold fill and reduce defects. Avoid sharp corners or complex thin features.

Maintain detailed logs of vacuum pressures, temperatures, curing times, and resin batches. Train operators thoroughly and schedule regular equipment maintenance.

Vacuum casting is a versatile manufacturing technique that delivers high-quality parts efficiently for prototyping and short-run production. Common challenges like incomplete fills, bubbles, mold wear, and surface issues can be effectively managed through systematic troubleshooting and proper process controls.

By maintaining vacuum integrity, optimizing temperatures, carefully preparing resins, using quality materials, and designing molds thoughtfully, manufacturers can minimize defects and improve yield. Regular quality checks and preventive maintenance further support consistent, reliable vacuum casting outcomes.

With proper attention and expertise, vacuum casting becomes a powerful tool for producing detailed, dimensionally accurate parts with excellent surface finishes—meeting the demanding requirements of global industries.

Leaks can cause vacuum pressure drops affecting part quality. Use a vacuum gauge to monitor pressure stability, and apply soapy water around seals and hoses. Bubble formation indicates the presence of leaks that need repair.

Preheat polyurethane resin to approximately 40°C to reduce viscosity, helping it flow smoothly into molds. Follow resin manufacturer guidelines for precise temperature settings and heating duration.

Typically, molds can be used for 20 to 50 casting cycles before degradation affects accuracy. Mold life depends on materials used, maintenance, and casting conditions.

Air bubbles arise from incomplete resin degassing, trapped air in molds, fast resin pouring, or poor vacuum conditions. Increasing vacuum time and pouring resin slowly can reduce bubbles.

Vacuum casting is excellent for rapid prototyping and short to medium volume runs. For large-scale mass production, injection molding is generally more cost-effective due to mold durability and cycle time advantages.

[1](https://www.immould.com/vacuum-casting/)

[2](https://objectify.co.in/a-comprehensive-guide-to-vacuum-casting-everything-you-need-to-know/uncategorized/)

[3](https://an-prototype.com/ultimate-guide-to-vacuum-casting/)

[4](https://blog.isa.org/what-are-vacuum-casting-factories-a-comprehensive-guide-to-the-manufacturing-process)

[5](https://formlabs.com/blog/vacuum-casting-urethane-casting-polyurethane-casting/)

[6](https://leadrp.net/blog/overview-of-vacuum-casting/)

[7](https://www.rocheindustry.com/guide-to-vacuum-casting/)

[8](https://www.kemalmfg.com/complete-guide-to-vacuum-casting/)

[9](https://www.rapiddirect.com/blog/vacuum-casting-design-guide/)

[10](https://www.zintilon.com/blog/vacuum-casting/)

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal