Views: 222 Author: Amanda Publish Time: 2025-10-14 Origin: Site

Content Menu

● The Integral Role of 3D Print Prototypes in Modern Product Development

● Primary Advantages of Using 3D Print Prototypes

>> Accelerated Iteration Cycles

>> Design Complexity and Customization

>> Enhanced Communication and Decision-Making

● Integrating 3D Print Prototypes into Your Workflow

>> Design for Additive Manufacturing (DfAM)

>> Adopt Agile Development Methodologies

>> Combine Virtual and Physical Testing

● Real-World Success Stories Leveraging 3D Print Prototypes

● Future Trends in 3D Print Prototyping

● Frequently Asked Questions (FAQ)

>> 1. What is a 3D print prototype?

>> 2. How does 3D printing speed up product development?

>> 3. Can 3D printed prototypes be functional?

>> 4. Which industries benefit most from 3D printed prototypes?

>> 5. Is 3D printing cost-effective for prototyping?

In today's hypercompetitive global marketplace, reducing the time it takes to bring a new product from concept to market is a decisive factor in achieving commercial success. The technology of 3D print prototypes has emerged as a transformative force in product development cycles, enabling companies to innovate faster and launch earlier while maintaining high quality and minimizing costs. This article examines how 3D printing technology accelerates prototype creation, streamlines design iteration, and ultimately shortens time-to-market for new products across industries.

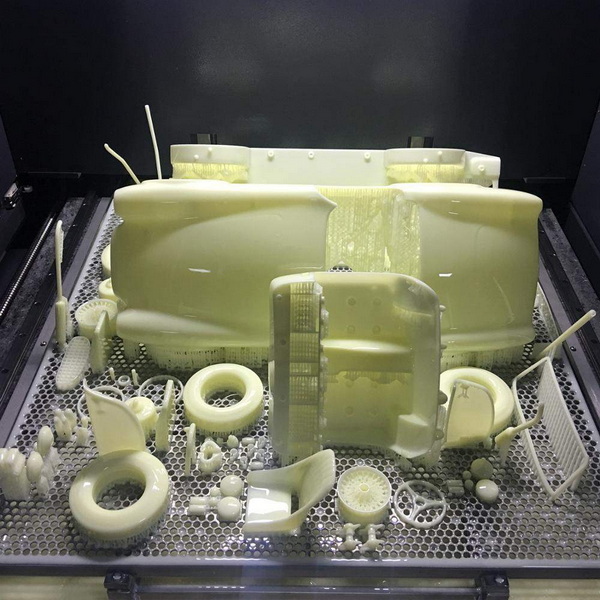

A product's journey typically follows stages of ideation, design, prototyping, testing, and manufacturing. Traditionally, prototyping could be a lengthy bottleneck requiring complex tooling or machining that extends timelines and increases costs. The advent of 3D print prototype technology revolutionizes this process by employing additive manufacturing — building up physical models layer by layer directly from digital CAD files.

This capability means that companies can rapidly convert digital concepts into tangible models for functional and aesthetic testing. Not only does this speed up production of prototype iterations, it empowers design teams to explore more ideas with fewer constraints related to tooling, complexity, or cost.

3D print prototype technology facilitates extremely fast design iterations. Designers generate a physical prototype typically within hours after finalizing a 3D CAD model. This speed enables:

- Immediate evaluation of critical product features

- Quick identification of design flaws or improvements

- Multiple prototype versions within a short timeframe to refine product details

Consequently, teams can incorporate user feedback rapidly, leading to a better-validated and refined product in record time.

Cost reduction is a major driver for adopting 3D printed prototypes. In traditional prototyping, creating molds, jigs, or CNC machining setups is expensive, especially for low-volume or custom parts. In contrast, additive manufacturing:

- Requires no expensive tooling or molds

- Uses materials more efficiently with near-zero scrap

- Favors short runs and one-off or batch prototypes economically

This affordability democratizes prototyping, enabling startups and small to medium enterprises (SMEs) to innovate aggressively without large upfront costs.

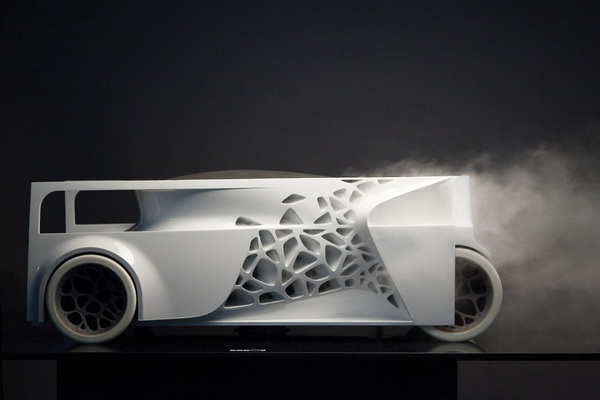

Additive manufacturing allows production of geometries and internal structures impossible or prohibitively expensive to make conventionally. 3D print prototypes permit:

- Complex lattice structures to minimize weight while maintaining strength

- Internal channels and features for functionality like fluid flow or heat transfer

- Customized parts tailored to individual customer needs or ergonomic requirements

Such freedom supports breakthrough innovation that distinguishes products in competitive marketplaces.

Physical prototypes greatly enhance stakeholder engagement and decision-making. Compared to purely digital renderings, tangible models:

- Help cross-functional teams visualize and experience the product firsthand

- Facilitate clearer communication of design intent between engineers, marketers, and clients

- Enable physical testing for ergonomics, aesthetics, and functional performance

This collaborative clarity reduces misunderstandings and expedites critical product development decisions.

The confluence of rapid iterations, cost-effective prototyping, complex design freedom, and improved collaboration directly contributes to significant reductions in time-to-market. Companies using 3D print prototypes benefit from:

- Shrinking development cycles from months to weeks or days

- Minimizing delays typically caused by tooling fabrication or design revisions

- Earlier product launches that seize competitive advantages and market opportunities

This speed is especially vital in dynamic sectors like consumer electronics, medical devices, automotive, and industrial equipment where timing can dictate success or failure.

To maximize benefits, products should be designed or adapted with 3D printing constraints and advantages in mind. Best practices include:

- Reducing support structures to save material and post-processing time

- Considering orientation and layer height to optimize strength and surface finish

- Utilizing lightweight infill and hollow structures where appropriate

Employing DfAM accelerates printing time and enhances prototype quality.

Agile development emphasizes short iterative cycles, continuous testing, and cross-disciplinary collaboration. Integrating 3D print prototypes into agile cycles allows teams to:

- Produce physical prototypes at each sprint for immediate validation

- Quickly pivot design directions based on real-world feedback

- Align development cycles closely with customer requirements

This agility reduces risks and shortens overall project lead times.

Before printing, leveraging virtual simulations such as Finite Element Analysis (FEA) or Computational Fluid Dynamics (CFD) can catch potential issues early. After creating the 3D print prototype, real-world performance testing complements virtual models to fine-tune designs effectively.

Adidas revolutionized its shoe production by using 3D printing to create midsoles customized for individual athlete needs. This rapid prototyping allowed accelerated testing and iteration, resulting in a high-performance shoe line launched faster than traditional methods could allow.

An automotive innovator, Local Motors, designed and printed the body and chassis of its Strati car using additive manufacturing. This approach slashed production time and costs while demonstrating the feasibility of 3D printing in full-scale vehicle manufacturing prototypes.

Looking ahead, integration of artificial intelligence with 3D printing is poised to enhance automation and precision further. Machine learning algorithms can optimize print paths, suggest design improvements, and predict structural weaknesses pre-print. Additionally, expanding materials technology—including composites and bio-compatible substances—will allow functional prototypes to mimic final production parts even more closely.

3D print prototypes have reshaped product development by providing unmatched speed, flexibility, and cost efficiency. Their use enables accelerated design cycles, enhanced innovation, and faster decision-making, leading to dramatic reductions in time-to-market. For manufacturers and OEMs aiming to thrive in a fast-paced, competitive environment, embracing 3D printing as a prototyping strategy is not just advantageous but essential. The technology empowers companies to experiment boldly, iterate rapidly, and bring captivating new products to customers sooner than ever before.

A 3D print prototype is a physical model created using additive manufacturing from a digital 3D design. It enables tangible testing and visualization of concepts before mass production.

3D printing reduces development time by producing physical prototypes quickly, enabling fast design modifications, and facilitating rapid validation and testing throughout the design process.

Yes, depending on the materials and technology used, 3D printed prototypes can be robust and functional enough for real-world testing of mechanics, fit, and usability.

Industries such as aerospace, automotive, consumer electronics, healthcare, and industrial equipment benefit greatly from 3D printing due to their need for innovation, precision, and speed.

Generally, yes. It eliminates expensive tooling costs, reduces waste, and supports small batch prototyping at a lower cost compared to traditional methods, benefiting projects with limited budgets or unique designs.

content is empty!