Views: 222 Author: Amanda Publish Time: 2025-10-15 Origin: Site

Content Menu

● What is 3D Printing and 3D Print Prototyping?

● Advantages of 3D Print Prototypes in Automotive Manufacturing

● Common Applications of 3D Print Prototypes for Automotive Parts

● Materials Used in 3D Print Prototypes for Automotive Parts

● The 3D Printing Process for Automotive Prototypes

● How 3D Print Prototypes Accelerate Product Development

● Cost Benefits and Efficiency Gains with 3D Printed Prototypes

● Examples of Leading Automotive Manufacturers Using 3D Print Prototypes

● Emerging Trends: From Prototypes to End-Use Parts

● Challenges and Considerations in 3D Printing Automotive Prototypes

● FAQ

>> 1. What is a 3D print prototype in automotive manufacturing?

>> 2. How does 3D printing speed up prototype development?

>> 3. What materials are commonly used for 3D printed automotive prototypes?

>> 4. Can 3D printed prototypes be used for functional testing?

>> 5. Are 3D printed automotive parts used in production or only for prototyping?

3D print prototype technology has revolutionized the automotive industry by offering faster, cost-effective, and highly versatile solutions for developing automotive parts. Manufacturers worldwide increasingly rely on 3D printed prototypes to accelerate product development, reduce costs, and test complex designs. This article explores what manufacturers need to know about 3D print prototypes for automotive parts, highlighting applications, benefits, materials, processes, and emerging industry trends to help optimize production workflows efficiently.

3D printing, also known as additive manufacturing, is a process of creating objects layer by layer from a digital model. Unlike traditional subtractive methods that remove material, 3D printing adds material only where needed, enabling the creation of complex geometries impossible or costly with conventional manufacturing techniques.

A 3D print prototype is a physical, often functional, model of a part produced through 3D printing technology. These prototypes serve to validate designs, test fit and function, and allow rapid iteration before committing resources to full-scale production.

This innovative approach enables automotive manufacturers to bring ideas from concept to reality rapidly while reducing the typical barriers of conventional prototyping methods.

3D print prototypes provide numerous advantages to automotive manufacturers:

- Rapid Iteration: Multiple design versions can be produced quickly, accelerating the development cycle and allowing engineers to test and modify designs in real time.

- Cost Efficiency: Eliminates expensive tooling and molds, significantly reducing initial costs for product validation and minimizing financial risks.

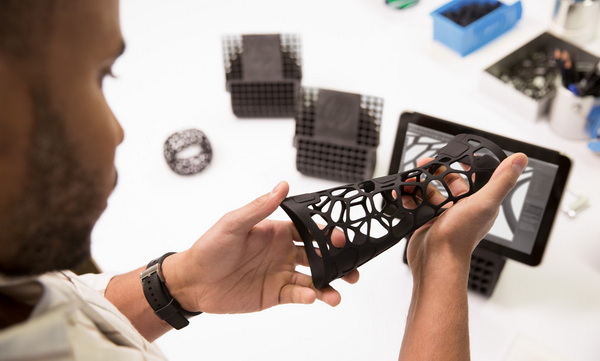

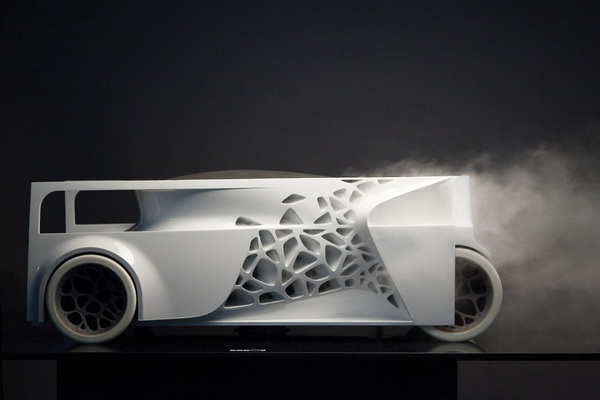

- Complex Geometries: Enables manufacturing of intricate parts with internal channels, lattice structures, and organic shapes that are difficult or impossible with traditional manufacturing.

- Customization: Supports bespoke parts tailored to specific customer or project needs, ideal for limited-edition models or prototype testing.

- Reduced Waste: Adds material only where needed, making the process environmentally friendly by minimizing excess material and supporting sustainable manufacturing practices.

- On-Demand Production: Prototypes and low-volume parts can be produced exactly when needed, reducing inventory costs and enhancing supply chain flexibility.

These advantages provide manufacturers with a competitive edge in automotive design, enabling faster time-to-market and enhanced product quality.

Manufacturers use 3D print prototypes across various development stages and automotive components, such as:

- Rapid Functional Prototyping: 3D printed engine covers, aerodynamic components, custom interior fittings, and dashboard panels allow designers to physically assess usability and fit.

- Tooling and Manufacturing Aids: Prototyping functional jigs, fixtures, and molds to assist in assembly processes and manufacturing accuracy.

- Spare Parts Production: On-demand printing of rare or discontinued parts supports legacy vehicles and reduces downtime.

- Design Validation: Physical testing of fit, form, and performance before committing to expensive tooling and mass production.

- Low-Volume & Customized Parts: Ideal for specialty parts in limited production runs or tailored customer specifications, promoting flexibility in manufacturing.

The use of 3D print prototypes thus spans concept validation, tooling, spare parts, and final product customization, making it integral to modern automotive production.

Choosing the right material for a 3D print prototype depends on the functional requirements and the testing environment:

- Polymers and Plastics: Materials such as ABS (Acrylonitrile Butadiene Styrene), polycarbonate, nylon, and polyurethane provide durability, flexibility, and impact resistance suitable for various prototype applications including interior components and non-structural parts.

- Metal Alloys: Stainless steel, aluminum, titanium, and other metal powders allow for prototypes that require high strength, heat resistance, and durability, such as engine parts, brackets, and structural components.

- Composite Materials: Carbon fiber or glass-filled polymers combine enhanced mechanical strength with lightweight properties, ideal for load-bearing prototypes and aerodynamic parts.

Material advancements continue to expand the functional capabilities of 3D print prototypes, allowing close simulation of final part behaviors under real operating conditions.

The typical 3D print prototyping process involves several critical steps:

1. CAD Design: Engineers create or refine a detailed 3D model using computer-aided design (CAD) software, ensuring the design meets precise specifications.

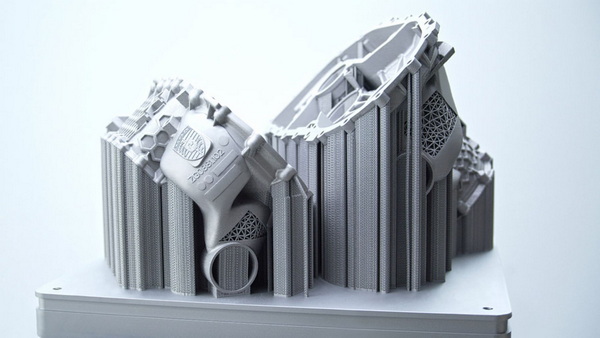

2. Preparation: The CAD file is converted into a format readable by a 3D printer (typically STL) and then sliced into thin layers by specialized software to guide the printer.

3. Printing: The 3D printer builds the prototype by depositing material layer by layer, using techniques such as Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), or Stereolithography (SLA).

4. Post-Processing: After printing, the prototype usually undergoes finishing steps like cleaning, curing, sanding, or painting to meet aesthetic and functional requirements.

5. Testing & Iteration: The prototype is subjected to fit, form, and function testing and feedback is incorporated into design improvements for subsequent iterations.

This process enables iterative design improvements with turnaround times reduced from traditional weeks or months to days or even hours.

3D print prototypes impact automotive product development by:

- Speeding Up the Design Cycle: Physical models allowing immediate feedback enable engineers to fine-tune designs continuously without waiting for long tool production lead times.

- Reducing Risks: Early identification of design flaws during prototyping prevents costly mistakes in mass production, ensuring product quality.

- Enhancing Collaboration: Tangible prototypes improve communication across design, engineering, and manufacturing teams, streamlining decision-making and approval processes.

- Supporting Innovation: Complex shapes, lightweight structures, and functional integration made possible by 3D printing push the boundaries of automotive design and performance.

Such acceleration fundamentally changes how manufacturers innovate, shortening development times and raising design standards.

3D print prototypes offer substantial cost benefits:

- Lower Initial Investment: By avoiding costly tooling and molds especially in the early stages, 3D printing significantly reduces upfront expenses.

- Material Savings: Additive processes use only the material needed, minimizing waste compared to subtractive methods like machining.

- Labor Reduction: Automation in 3D printing reduces manual labor involved in prototype creation and finishing.

- Inventory Optimization: On-demand printing eliminates the need for large physical stock, reducing storage costs and risks of obsolescence.

- Faster Time-to-Market: By speeding prototype production and validation, products reach the market sooner, generating revenue faster.

These efficiency gains contribute profoundly to lean manufacturing principles and improved financial performance.

Prominent automotive companies have embraced 3D printed prototypes to stay competitive and innovate rapidly:

- Ford: Utilizes 3D printing extensively for engine covers, aerodynamic enhancements, and interior prototype components, benefiting from rapid design validation and cost control.

- BMW: A pioneer using 3D printing since the 1990s, BMW prints both concept car parts and functional prototype components, supporting advanced designs in limited editions and special models.

- Porsche: Leverages 3D printing to produce spare parts for classic and vintage cars, preserving automotive heritage and reducing lead times for hard-to-find components.

- General Motors (GM): Employs 3D printing for lightweight, complex parts focused on fuel efficiency and improving vehicle performance, also using it for rapid tooling.

These industry leaders demonstrate how integrating 3D print prototypes sustains innovation while managing costs and quality.

The role of 3D printing in automotive manufacturing is evolving beyond prototyping toward production-scale applications, including:

- Final Part Production: Manufacturing low-volume, highly complex, or customized parts directly with 3D printing technologies.

- Lightweight Structures: Utilizing lattice and honeycomb designs enabled by additive manufacturing to reduce vehicle weight and improve fuel efficiency.

- Integrated Functionality: Combining multiple components into single, efficient printed parts that reduce assembly complexity.

- Just-in-Time Manufacturing: Printing parts on demand to streamline supply chains and reduce lead times.

- Sustainability Efforts: Recycling materials and reducing waste through additive processes support greener automotive manufacturing.

As technology advances in printer speed, build volume, and material diversity, 3D printing will become a cornerstone of automotive production strategies.

Despite its many benefits, 3D printing does present challenges:

- Material Limitations: Some automotive-grade materials are difficult to print or require specialized processes not universally available.

- Surface Finish and Tolerances: Printed parts often require post-processing to meet exact dimensional and aesthetic specifications, adding time and cost.

- Large Part Constraints: Size limitations of most printers may necessitate assembly or hybrid manufacturing approaches for bigger components.

- Cost at High Volume: For mass-produced parts, traditional manufacturing methods may still be more economical per unit.

- Intellectual Property Security: Digital models carry risks of unauthorized access or duplication, requiring secure data handling.

Manufacturers must thoughtfully integrate 3D prototypes by balancing benefits against these practical considerations.

3D print prototypes have become an indispensable tool for automotive manufacturers, enabling rapid, cost-effective innovation and refinement of parts with complex designs. From initial design validation to low-volume production, 3D printing accelerates product development and helps companies maintain competitive advantages. While challenges remain, ongoing advances in materials and technology promise to further expand the role of 3D printing in automotive manufacturing, making it a foundational technology for current and future vehicle development.

A 3D print prototype is a physical, often functional, model of an automotive part created through 3D printing for design validation, testing, and iteration before full-scale production.

3D printing rapidly produces parts layer-by-layer without the need for tooling or molds, allowing multiple quick iterations and shortening the product development lifecycle.

Polymers like ABS, polycarbonate, and nylon are common, along with metal alloys such as stainless steel and aluminum, selected based on prototype functionality and testing requirements.

Yes, prototypes can be made from materials that simulate end-use properties, allowing rigorous testing of fit, form, and function under real-world conditions.

Initially for prototyping, 3D printing is increasingly used for low-volume, customized, or complex end-use automotive parts as technology and materials advance.

content is empty!

Vacuum Mold Casting Solutions for Automotive Component Manufacturing

How Vacuum Mold Casting Benefits Aerospace and Defense Industries

Vacuum Mold Casting in Medical Device Prototyping: Precision and Reliability

Custom Vacuum Mold Casting for Electronics and Consumer Products

Vacuum Mold Casting for Industrial Equipment: Durability Meets Precision

How Vacuum Mold Casting Reduces Production Costs Without Sacrificing Quality

Comparing Lead Times: Vacuum Mold Casting vs. Other Prototyping Methods

Increasing Operational Efficiency with Vacuum Mold Casting Technologies

How Automation Enhances Vacuum Mold Casting Production Speed

Cost-Effective Vacuum Mold Casting for Small to Medium Batch Runs