Views: 222 Author: Amanda Publish Time: 2025-10-16 Origin: Site

Content Menu

● Understanding AI's Role in 3D Print Prototyping

>> Generative Design and Optimization

>> Predictive Maintenance and Quality Assurance

>> Accessibility and Automation

● The Advantages of AI in Next-Generation 3D Print Prototyping

>> Cost Efficiency and Material Savings

>> Enhanced Product Performance

● Industry Applications Transforming with AI-Driven 3D Print Prototyping

>> Aerospace and Automotive Sectors

>> Healthcare and Biomedical Engineering

>> Consumer Goods and Electronics

● Additional Advancements Accelerated by AI in 3D Print Prototyping

>> Real-Time Adaptive Printing

>> Integration with IoT and Digital Twins

>> AI-Enhanced Materials Discovery

>> Collaborative AI and Human Creativity

● Challenges and Future Outlook

● Frequently Asked Questions (FAQs)

>> 1) How does AI improve the design process of 3D print prototypes?

>> 2) Can AI predict and prevent 3D printer failures?

>> 3) Does AI make 3D printing more accessible to beginners?

>> 4) What industries benefit most from AI-enhanced 3D print prototyping?

>> 5) How does AI contribute to sustainability in 3D printing?

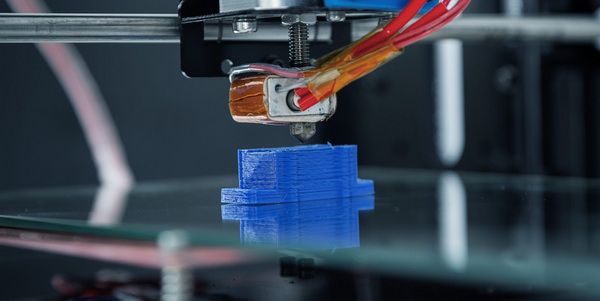

The fusion of artificial intelligence (AI) with 3D printing technology has ushered in a new era for prototyping and manufacturing. As industries ranging from aerospace to healthcare seek faster, more precise, and cost-effective production methods, AI-driven enhancements in 3D print prototyping are revolutionizing how products are designed, tested, and refined. This article explores how AI is shaping next-generation 3D print prototypes, unlocking capabilities that streamline workflows, maximize material efficiency, and accelerate innovation at an unprecedented scale.

The term "3D Print Prototype" has become central to modern manufacturing, representing the forefront of rapid, flexible product development. With AI integration, the potential for this technology grows exponentially, allowing businesses and engineers to solve complex design challenges and improve production outcomes.

Artificial intelligence significantly elevates 3D print prototyping by automating and optimizing multiple stages of the product development cycle. Instead of relying on manual design tweaks and trial-and-error approaches, AI algorithms analyze vast datasets to generate, evaluate, and enhance prototype designs efficiently.

One of the most transformative applications of AI in 3D print prototyping is generative design. This technology utilizes AI-driven software that can automatically create hundreds or thousands of optimized design variants by considering factors like weight, material strength, and manufacturing constraints. This capability enables the production of lightweight yet highly resilient 3D print prototypes tailored precisely for their intended function.

- AI systems reduce design iteration cycles drastically, making the prototype development faster.

- Material usage is minimized while maintaining structural integrity, reducing costs and waste.

- Complex geometries, once impossible with conventional methods, become achievable, pushing the boundaries of innovation.

Generative design, powered by AI, essentially acts as a virtual engineer, exploring design possibilities that human designers may not conceive. For example, it can create skeletal or lattice structures that deliver strength where needed while removing unnecessary material, resulting in ultra-light, performance-optimized prototypes essential for industries like aviation and automotive.

AI integration extends beyond design into production reliability. Machine learning models continuously monitor printer conditions through sensor data, predicting equipment failures before they happen, thus preventing costly downtime and delays.

At the same time, AI-powered quality control analyzes print outputs in real-time, detecting defects such as layer inconsistencies or material deformations. This proactive error correction ensures that 3D print prototypes meet stringent quality standards on the first try, reducing waste and time. Predictive analytics also enables adaptive modifications during printing, adjusting parameters dynamically to ensure continuous quality improvement.

Traditionally, 3D printing required expert knowledge for slicing models and setting print parameters. AI is democratizing this process by automating complex parameter selection, enabling less technical users to produce high-quality prototypes with ease. AI software also improves user experience by suggesting optimal print orientation and layering strategies, which enhance the strength and surface finish of 3D print prototypes.

Automation powered by AI means repetitive tasks like file preparation, error detection, and printer calibration are minimized, freeing human resources for higher-value innovation work. This accessibility broadens the use of 3D printing technologies across sectors, turning rapid prototyping into a standard part of product development lifecycles.

AI streamlines workflows from conceptualization to production, enabling companies to create functional 3D print prototypes in a fraction of the time compared to traditional methods. This speed is critical for industries where rapid response to market changes or innovation cycles is essential. Faster prototyping accelerates product validation, allowing companies to gain competitive advantages through quicker iterations and product launches.

By optimizing designs through AI-driven analysis, manufacturers avoid over-engineering parts and reduce material waste. AI's continuous process monitoring reduces failed prints by identifying and correcting issues early, lowering scrap rates and overall production costs. These savings are especially important when working with expensive or specialty materials where minimizing waste is critical.

AI optimizes parts to meet specific performance requirements—be it strength, flexibility, or thermal resistance—ensuring prototypes reflect real-world application conditions more accurately. This leads to better product validation and fewer redesign cycles. For example, AI can simulate stress tests on different designs virtually, selecting the best prototype for actual production, improving reliability.

By reducing material usage and energy consumption through precise control and fewer print failures, AI-assisted 3D print prototyping supports more sustainable manufacturing practices. Automated resource optimization aligns with global trends toward eco-friendly production. Environmentally conscious enterprises benefit by reducing carbon footprints while maintaining productivity.

AI-enhanced 3D print prototypes are transforming aerospace and automotive manufacturing by enabling the production of lightweight yet robust parts. Reducing the weight of parts directly improves fuel efficiency and performance, critical for these high-demand sectors. Additionally, AI predictive maintenance ensures uninterrupted additive manufacturing, which is essential for meeting stringent delivery schedules.

- Aerospace companies use AI to generate complex turbine components that balance durability and weight.

- Automotive manufacturers rapidly prototype specialized parts with internal geometries optimized for strength.

Healthcare is one of the most profoundly impacted sectors by AI-driven 3D print prototyping. AI enables rapid prototyping of personalized medical devices such as implants and prosthetics with anatomical optimization beyond human design capabilities. This patient-specific customization accelerates treatment preparation, improves outcomes, and reduces costs.

- Customized surgical tools and implants are prototype-produced faster, tailored precisely to patient scans.

- Bio-compatible materials combined with AI-based design are pushing innovations in 3D bioprinting.

In consumer goods, AI allows mass customization, enabling designers to produce personalized products with optimized features quickly. Electronics manufacturing benefits from faster iteration on components requiring miniaturization and precise tolerances, improving product reliability.

- AI enhances prototype testing by simulating real-world usage scenarios.

- Rapid design-change implementation supports agile product development.

Emerging AI models enable printers to adjust parameters like temperature, speed, and layer thickness dynamically during printing, responding to material behavior and environmental conditions. This real-time adaptation minimizes defects and improves surface finishes on 3D print prototypes, especially for complex or high-performance materials.

AI-driven 3D print prototyping increasingly integrates with Internet of Things (IoT) sensors and digital twin technology, creating virtual replicas of printers and parts. These digital twins simulate printing processes, predict outcomes, and optimize workflows before physical prototyping, reducing trial and error.

AI supports the discovery and use of new materials by analyzing molecular structures and predicting printability and properties. This capability expands the palette of 3D print prototypes beyond traditional plastics and metals into composites, ceramics, and bio-materials, unlocking novel applications.

Rather than replacing human designers, AI acts as a collaborative tool that enhances creativity by suggesting innovative solutions and automating routine tasks. This synergy boosts innovation velocity in 3D print prototype development, allowing human ingenuity to focus on vision and functionality.

Despite the many advancements, integrating AI-driven systems into 3D print prototyping requires significant investments in technology, skilled labor, and data management infrastructure. Companies also face challenges around data privacy, algorithm transparency, and meeting stringent regulatory requirements in sensitive sectors like healthcare and aerospace.

Looking forward, the synergy between AI and 3D print prototyping promises continued innovation. Emerging AI techniques such as reinforcement learning and quantum computing-enhanced algorithms hold the potential to radically improve adaptive printing and materials science. Factories may soon operate autonomously with AI managing entire production lines, ushering in an era of on-demand, smart manufacturing.

The impact of AI on next-generation 3D print prototyping is profound and multifaceted. By automating design, boosting efficiency, and enhancing product quality, AI transforms how prototypes are created—from concept to reality. This transformation accelerates innovation cycles, reduces costs, and expands possibilities for manufacture across diverse industries. As AI technologies evolve, their integration with 3D printing will continue to be a crucial driver for competitive advantage in the global marketplace.

AI employs generative design algorithms to create optimized and complex structures quickly, reducing manual design time and minimizing material use while enhancing strength and performance.

Yes, AI uses sensor data and machine learning to predict equipment wear or malfunction, allowing for proactive maintenance that reduces downtime and increases productivity.

Absolutely, AI automates many technical settings such as slicing and print orientation, enabling users with little technical background to produce high-quality 3D print prototypes.

Industries such as aerospace, automotive, healthcare, consumer electronics, and biomedical engineering benefit significantly due to faster, cost-effective, and personalized prototyping solutions.

By optimizing material usage and reducing print errors, AI lowers waste and energy consumption, promoting more sustainable and eco-friendly manufacturing processes.

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal